Attachments

The Game Changer

GMM 50 / GMM 35 multi-tine grab

The perfect attachment for every application

Liebherr develops and manufactures innovative attachments and quick coupler systems to the highest quality standards. The line-up ranges from quick coupler systems to digging tools and grabs for a wide variety of applications. The choice of the right tool has a significant influence on the success of a project. For this reason, Liebherr has developed numerous attachments which, in terms of their shape, quality and technical specification, are tailored to the respective applications and the size of the respective machines. Real-world experience and continuous advanced development ensure that Liebherr attachments are always state of the art.

Clamshells

Clamshells with their large range of shell shapes and sizes are ideally tailored to the most diverse construction applications as well as the handling of bulk materials.

Various grab shells made of solid, high-strength material are available for excavation work, deep shafts or exposing existing construction elements on building sites as well as for the handling of solidified goods. Bulk shells with a large capacity ensure economical loading and unloading of trucks, wagons or ship holds containing all kinds of fine and coarse-grained bulk materials. Large, flow-optimised oil ducts and powerful rotary actuators ensure fast work cycles – the sealed rotary drive and solid construction ensure a long service life. The extensive options are not only available for special applications, they also help to ensure that each grab is perfect for its specific application.

Multi-tine grabs

Multi-tine grabs are developed and designed for the toughest and most challenging operating conditions in the field of recycling and scrap handling. The use of the highest quality materials guarantees extreme stability, robustness and durability. A variety of tine shapes and designs and a wide range of options give you the flexibility to handle diverse materials efficiently and economically. The shape of the tines has been optimised to ensure perfect penetration and retention of bulky yet loose material.

Sorting grabs

Sorting and demolition grabs are designed for both recycling and demolition work. They also optimise excavator versaitlity on any construction site. They enable effective loading and feeding of sorting, shredding and treatment systems as well as careful and precise separation of materials. They are equipped with an endless turning device and impress with their extremely robust design and high clamping force. There are four different sizes, each with three shell variations, depending on the machine type, job and material.

Stone tongs, an extended design of the sorting grab, enable safe and efficient placement and loading of stones and boulders thanks to their special shell shape and serration.

Wood grabs

Customised wood grabs ensure fast and safe transport or handling of logs in timber yards, sawmills, the woodworking industry or in ports. Depending on the application and requirements, the ideal grab can be configured from a wide range of pincer shapes. The wood grapples have a large opening width and are designed to transport both logs en masse or individually. Timber tractors, log handlers and material handling machines can be equipped with Liebherr wood grapples.

Parallel grab

The parallel grab ensures efficient and safe installation of utility poles during track construction for railway electrification. Pre-installed poles can be lifted directly with the grab and positioned precisely in the prepared foundation - without the need for additional labour. Its easy handling, high productivity, and uncompromising safety make the grab an outstanding solution for demanding rail projects.

Backhoe buckets

Liebherr backhoe buckets have many uses, ranging from traditional civil engineering, gardening and landscaping to mining. Whether on the construction site or in the quarry, backhoe buckets convince with their innovative geometry, optimum dead weight and deep lateral cutting edges which give perfect penetration and low digging resistance, resulting in high productivity and fuel efficiency. The shape and the long bottom also enable excellent filling and emptying behaviour as well as easy pick-up and movement of bulky items, such as pieces of concrete and asphalt. Depending on the job and ground conditions, a choice can be made between a cutting edge, different teeth and other features.

2-in-1 buckets

Liebherr 2-in-1 buckets combine a backhoe bucket and face shovel in a single attachment. In combination with a SWA 33 or SWA 48 quick coupler, these buckets can be changed quickly and easily from the cab without any conversion work. The perfect kinematics for operation in face-shovel or backhoe guarantees precise, accurate and powerful work. In addition to the classic work of a backhoe bucket, the Liebherr 2-in-1 also enables efficient work in shoring, uncovering – or precise sanding of – lines and pipes as well as backfilling foundations.

Grading bucket

The grading bucket has been specially developed for use with a tiltrotator which enables complex applications to be mastered with ease. The bucket with its bevelled shape and the long, flat bottom, can be angled perfectly to work on house walls or other obstacles as well as demanding levelling and modelling tasks. Its conical design and proven stiffening elements ensure optimum filling and emptying which, along with its low tare weight, provide a highly efficient digging solution. The use of high-quality steel also ensures high resistance and a long service life. For abrasive materials, an optional HD reinforcement set and bolt-on cutting edge are also available.

Ditch-cleaning-buckets

With their large cutting width, ditch-cleaning-buckets are ideal for pulling and modelling earth banks, digging trenches with an appropriate profile, grading work as well as for various slope angles. Depending on the application and task, there is a wide range to choose from. The protected built-in tilt cylinder generates a tilt angle of up to 2 x 50°, depending on the bucket type. The shape of the ditch-cleaning-bucket enables particularly precise levelling work and optimum emptying behaviour.

Tilt buckets

The ideal ratio between cutting width and contents makes the tilt buckets a true all-rounder. In terms of the cutting width and capacity it lies between the backhoe bucket and the ditch-cleaning-bucket. The protected built-in tilt cylinder allows a tilt angle of 2 x 50°, while the bucket shape offers high flexibility and optimum emptying behaviour during excavation work. The bucket is ideal for excavation, loading and grading work, as well as for pulling and modelling slopes and earth banks with a wide range of slope angles. The wear-resistant material also ensures a long service life.

Universal buckets

The universal bucket, like the tilt bucket, lies between the backhoe bucket and ditch-cleaning-bucket in terms of its cutting width and contents. As a result, this bucket shape offers a high degree of flexibility and, in keeping with its name, can be used as an all-rounder for a wide variety of jobs. The universal bucket is an ideal match for the tiltrotator or the LiTiU tilt unit. In this combination, the bucket is perfect for creating different slope angles or modelling embankments and earth walls.

Tiltrotators

With the Liebherr tiltrotator, attachments can be rotated endlessly and tilted to both sides with an angle of 2 x 50°. This expands the range of applications enormously, increases flexibility and turns the hydraulic excavator into a multifunctional machine. By eliminating manoeuvring work and unproductive repositioning of the hydraulic excavator, economic efficiency is significantly increased and the ground is protected at the same time. The protected, horizontally mounted swivel cylinder has no protruding parts that could be damaged when working in confined areas, even at the maximum tilt angle. The tiltrotator not only enables work to be carried out in the shortest possible time, but also with high precision and accuracy.

Tilt units LiTiU

The LiTiU is a tilt unit designed as a sandwich attachment variant, which makes it possible to increase the tilt angle for mechanical and hydraulic attachments without changing tools. This widens the range of possible applications and thus significantly increases flexibility and productivity. By eliminating manoeuvring work and unproductive repositioning of the excavator, economic efficiency is increased enormously and the ground is protected at the same time.

The externally routed hydraulic lines ensure a constant and even oil flow. This makes the LiTiU the ideal supplement for attachments with their own rotatory drive, such as sorting grabs, or also for attachments that require a high oil quantity with minimal pressure loss, such as hammers, plate vibrators, millers and mulchers.

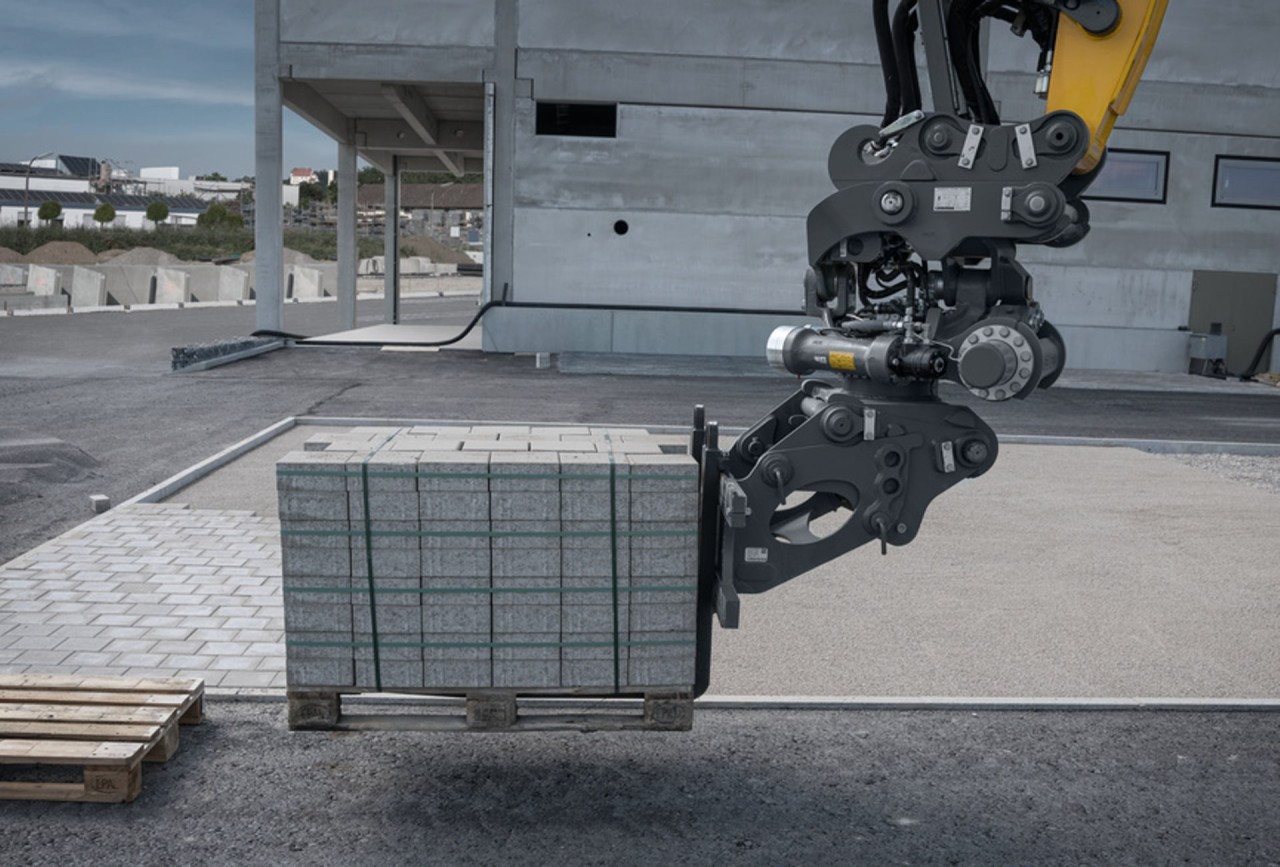

Pallet forks

The Liebherr pallet fork for hydraulic excavators ensures quick, safe and easy material transport on the construction site. In combination with the tiltrotator, the pallet fork enables the hydraulic excavator to perfectly position and align the cargo. With a Liebherr quick coupler system, it is also possible to quickly switch from an attached attachment to the pallet fork in order to efficiently carry out any transport or lifting work that arises. The pallet fork extends the range of applications for the excavators and significantly increases their flexibility on construction sites.

Stick extensions

The stick extension transforms a handling machine or hydraulic excavator into a multifunctional working machine. It can be attached without major effort or conversion work. It increases flexibility and reach and enables additional applications, such as creating smaller slopes, using mower rakes, performing clearing work and tree care as well as grading work. The stick extension with tilt kinematics is available in two different sizes and various lengths.

For material handling machines, a stick extension for suspended attachments is also available.

Grading beam

The grading beam is specially designed for use with a tiltrotator and enables fast and precise grading work on large, horizontal surfaces. It increases flexibility, expands the application possibilities of wheeled and crawler excavators and at the same time saves additional machine costs. The grading beam can also be used to transport the tiltrotator, grading bucket and pallet fork thanks to the optional dismount device, allowing the entire attachment package to be transported easily and safely.

Quick coupler systems

Liebherr’s quick coupler systems, which have been tried and tested for decades and are constantly being further developed, guarantee maximum safety and efficiency as well as maximum flexibility. Almost any hydraulic or mechanical attachment can be changed conveniently, quickly and easily. Depending on the machine and application, the fully automatic Solidlink quick coupler system is available in addition to hydraulic or mechanical quick coupler systems.

Quick coupler systems for tilt kinematics

For mobile and crawler excavators as well as handling machines with tilt kinematics, the fully automatic Solidlink quick coupler system is available in addition to hydraulic or mechanical quick coupler systems in various sizes. Liebherr’s quick coupler system not only guarantees simple and fast attachment changes, but also maximum safety thanks to numerous safety features. It enables maximum flexibility in daily use on the construction site and increases machine utilisation to up to 90% thanks to an extended range of applications.

Fully automatic quick coupler systems for suspended attachments

Liebherr developed the fully automatic MH 40C Solidlink and MH 110B Solidlink quick coupler systems to enable hanging attachments to be changed in seconds without having to leave the cab. During the coupling process, all hydraulic and electrical lines are connected or disconnected at the touch of a button. The machine-side upper part is equipped with an integrated rotatory drive and can be used for any number of attachments with lower part (without rotatory drive). This means that the suspension and the rotatory drive can be saved for each additional attachment.

Solidlink quick coupler system for wheel loaders

Developed by Liebherr for wheel loaders, the fully automatic Solidlink quick coupler system consists of an automatic hydraulic coupling block and a robust quick coupling adapter. Numerous hydraulic and mechanical attachments can be changed safely and automatically at the push of a button – directly from the cab. The Solidlink quick coupler system enables high utilisation of the wheel loader and thus increased operating efficiency.

Contact us

If you have any more questions, please contact our local sales of service team.

Services for attachments

Only a complete package of high-performance machines, attachments and services will lead to success. Our service solutions are designed to provide you with the best possible support in your everyday work.

Tooth systems

The economic efficiency of Liebherr machines can be optimised by specifically adapting the tooth shape to suit the respective applications. Liebherr provides comprehensive tooth programmes with a wide range of tooth shapes for every task to help make your machines more economical.

Half-shell replacement on the SWA Generation HD quick coupler

Maintenance of construction machinery can often be time-consuming and costly. However, Liebherr has developed an SWA quick coupler that makes the replacement of wear parts on the construction site quick and easy.

Range of refurbished Liebherr multi-tine grabs

Liebherr has developed and defined a new repair programme for the multi-tine grabs GM 64/65, GM 69/70, GMM 50 and GMM 80. This programme makes the maintenance and repair of these grabs more efficient and faster, which increases the availability and reliability of the respective machines.

Preparation of attachments

To reduce wear on attachments with worn-out bores, they can be effectively retrofitted with steel bushings. For this purpose, the existing locating holes are precisely prepared with a special drilling fixture and suitable drilling equipment.

Everything on board – Solidlink emergency case

We offer emergency cases that are tailored to the requirements for quick couplers. They contain the most important spare parts as well as tools and instructions for quick replacements on site.