Battery-powered and emissionfree

Electromobility is not only omnipresent in the automotive industry. In line with our claim to shape long-term industry trends, we are also driving forward the electrification of our construction machine portfolio. Many municipalities and cities are increasingly demanding minimal CO2 emissions and a significant reduction in noise pollution for construction projects. With the Liebherr unplugged series, we are responding to these challenges.

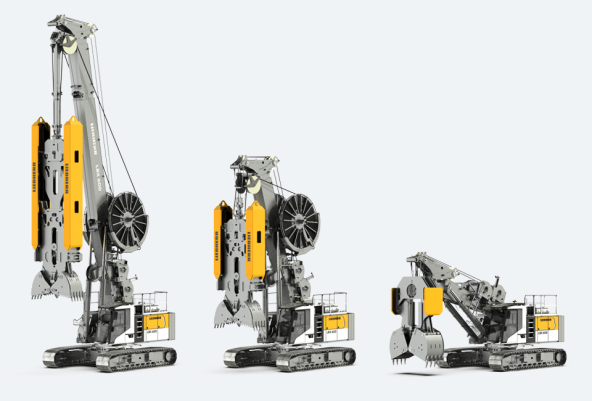

Featured products

History unplugged

2019. How it all began.

The idea of electrifying a construction machine of this size definitely showed foresight and the result proved the engineers right. The LB 16 unplugged, the world's first battery-powered drilling rig was definitely a milestone.

2019. First mission.

The first practical application on one of the largest road construction sites in western Austria has already shown: with such electrically driven machines, emission-free deep foundation is feasible.

2020. Evolution.

This was followed by the world's first battery-powered crawler cranes at the end of 2020. With both unplugged cranes, there is no loss of performance or usability compared to the conventional version. The LR 1200.1 and LR 1250.1 unplugged have maximum lifting capacities of 200 and 250 tonnes respectively.

2022. Hole-in-one.

The announcement of new models.

What's new in 2022.

Es ist angerichtet. Die neuen Modelle haben ihre Batterien aufgeladen und elektrifizieren mit Null-Emission