Betomix and Mobilmix series

Betomix and Mobilmix series

LiPerformance highlights

Reach your goal faster with modules

Energy and resource efficiency

Increase in output capacity of up to 20 % possible

Reduction in mixing time of up to 30 % possible

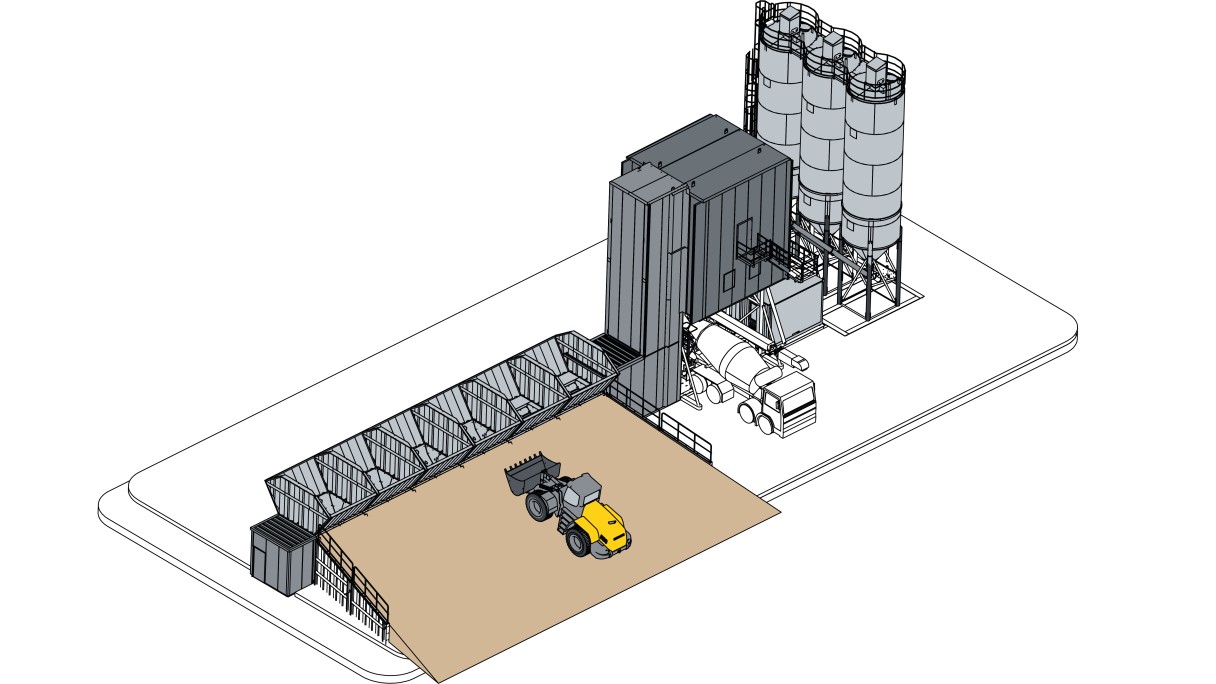

The new Betomix and Mobilmix series

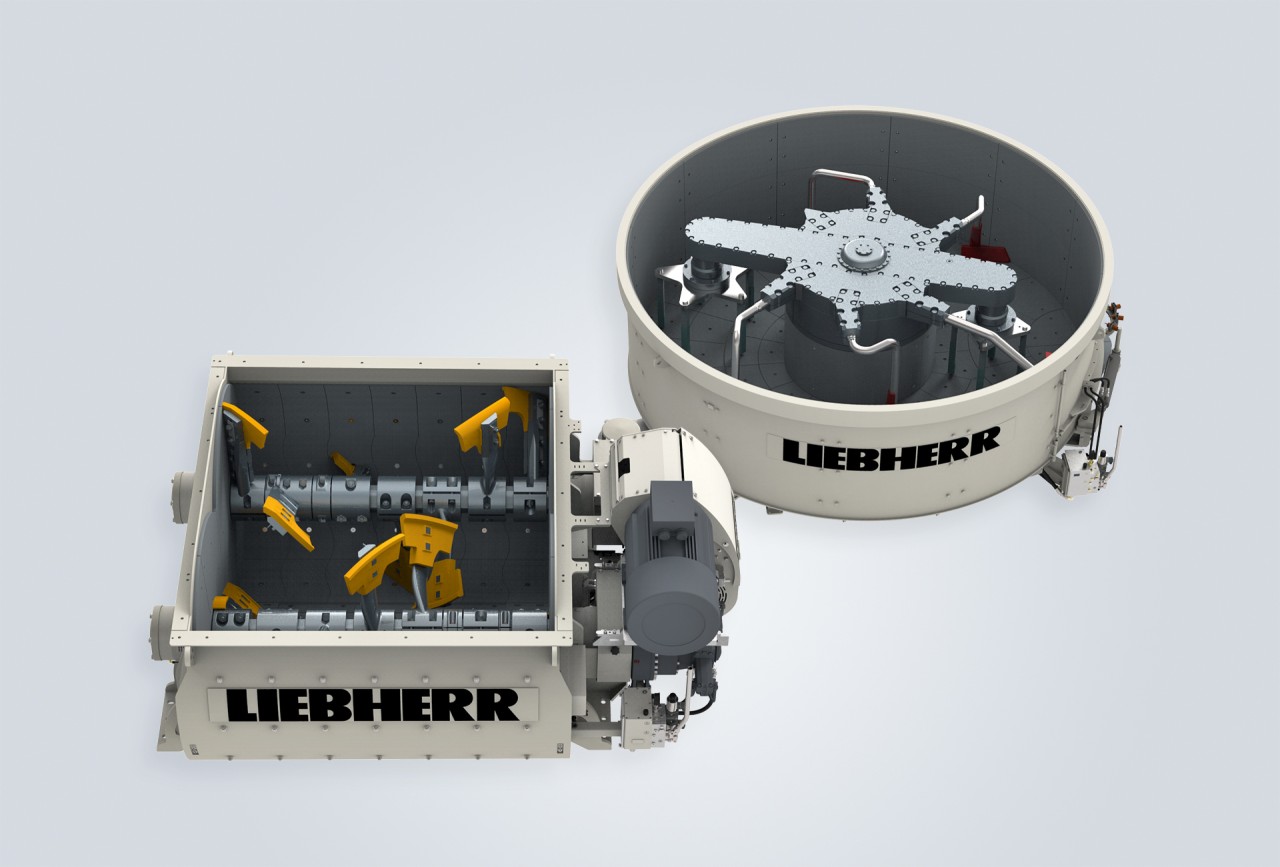

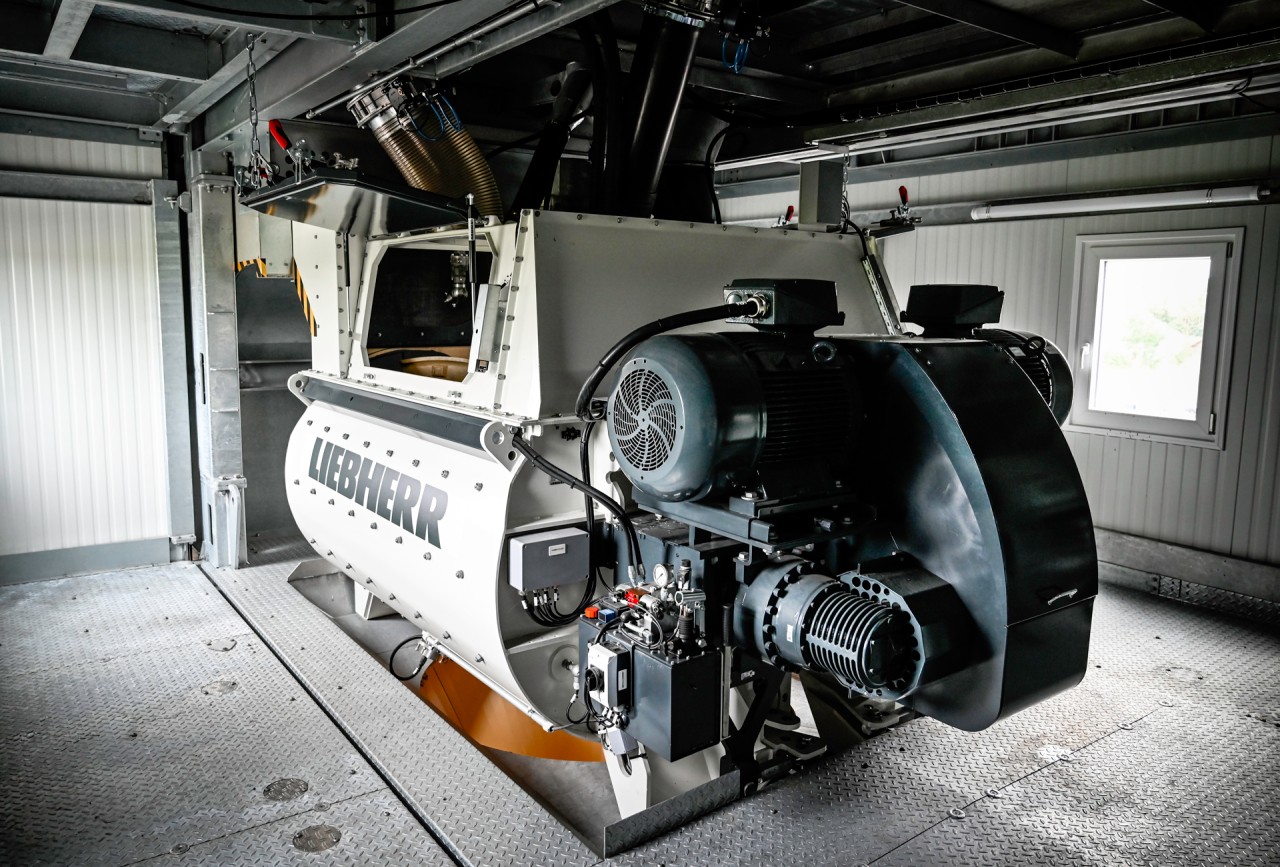

The new generation of concrete mixing plants from Liebherr revolutionize the production of concrete by enabling economical production. The modular design of our Betomix and Mobilmix series offers a wide range of options that can be flexibly adapted to the customer's needs. This flexibility enables the quick and uncomplicated realization of both stationary and mobile concrete mixing plants.

Fast assembly and availability

Sustainable and economical concrete production

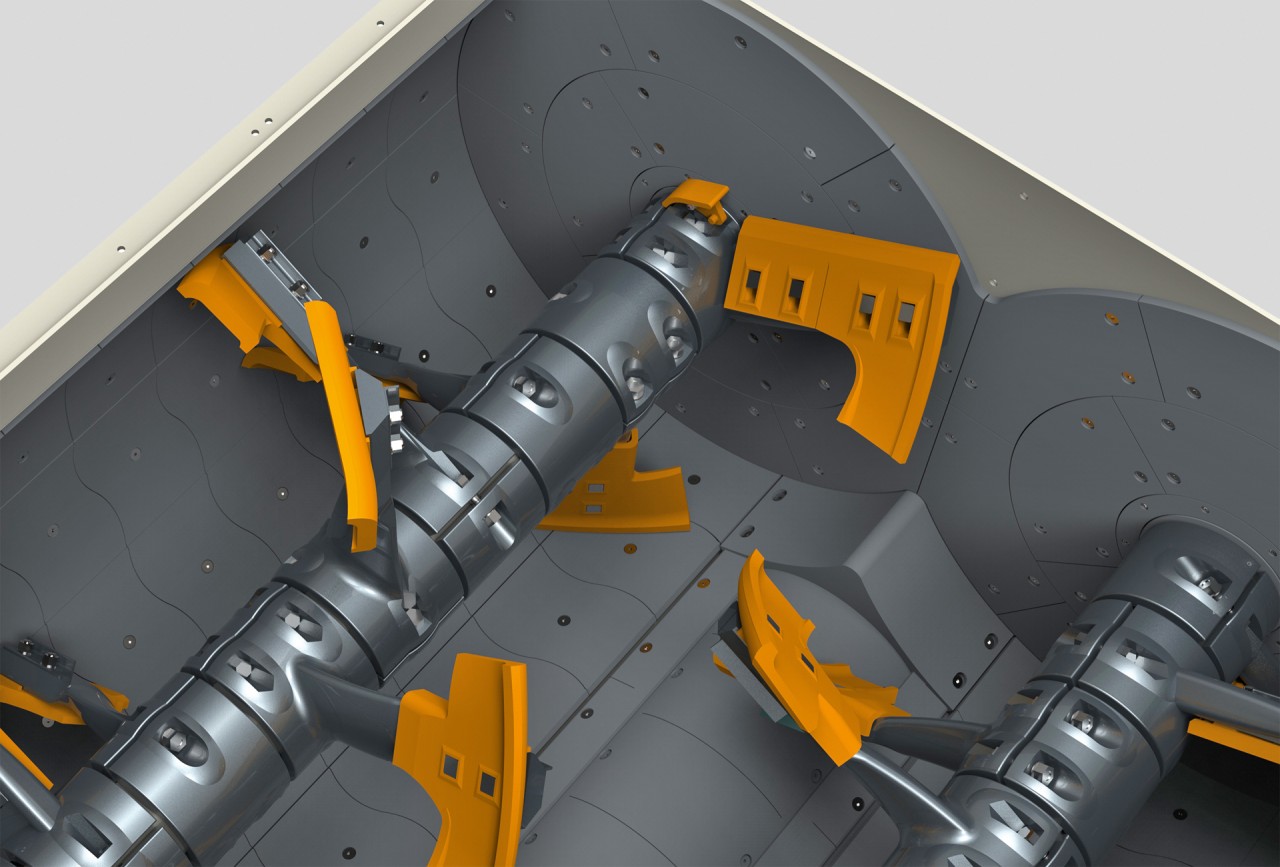

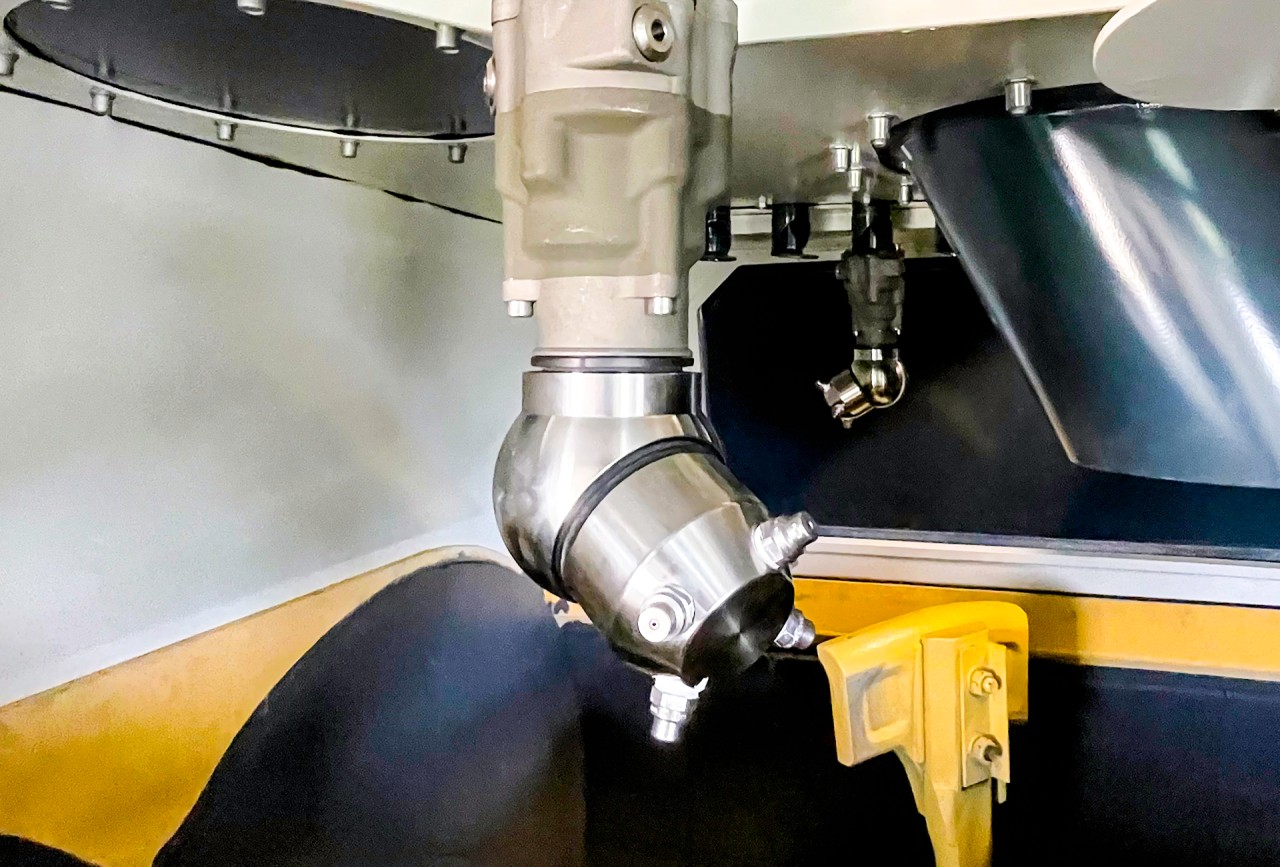

High-performance mixing systems

User friendliness

Product details

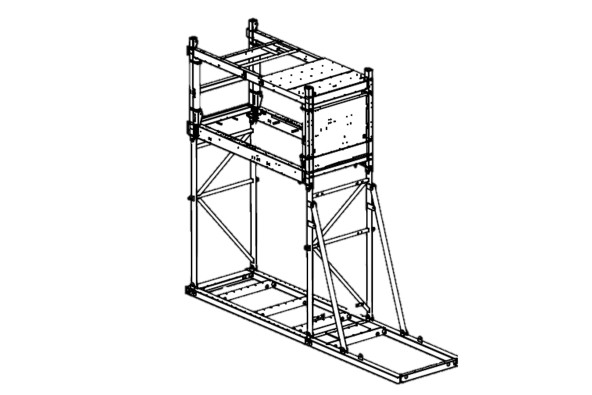

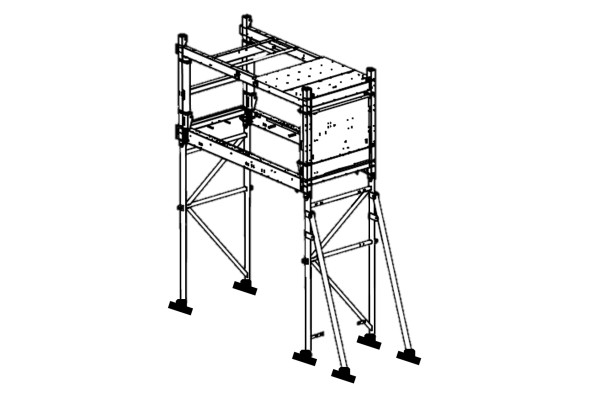

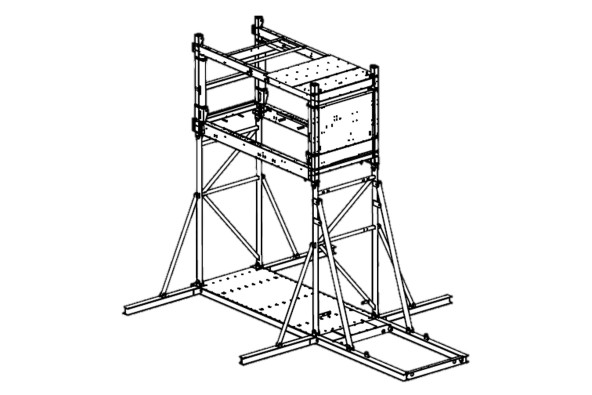

Maximum mobility, minimum assembly time

When developing the new Mobilmix, the focus was on fast assembly, high flexibility and sustainable concrete production. The innovative folding concept, combined with pre-cabling ex works, enables concrete production under the appropriate conditions after 9 days. No concrete work is required thanks to the design with steel foundation, lateral supports and tear plate cover. A simple, even, compacted soil is sufficient.

Mobilmix

- Foldable for quick installation with steel foundations

- The advantages are quick installation, pre-cabling ex works and no need for concrete work

- Compacted soil with 300 kN/m² is sufficient as a foundation

| Type | 2.5 | 3.0 | 3.5 | 4.0 |

| Theoretical output in compacted fresh concrete1 | 105 m³/h (137 yd³/h) | 120 m³/h 157 yd³/h) | 135*/139**m³/h (176*/181**yd³/h) | 150*/154**m³/h (196*/201**yd³/h) |

| Theoretical output in compacted fresh concrete with LiPerformance*** | 115 m³/h (150 yd³/h) | 132 m³/h (172 yd³/h) | 148*/152**m³/ (193*/198**yd³/h) | 165*/170**m³/h (215*/222**yd³/h) |

| Mixer size | 2.5 m³ (3.3 yd³) | 3.0 m³ (4.0 yd³) | 3.5 m³ (4.5 yd³) | 4.0 m³ (5.2 yd³) |

| Ring-pan mixer | ✓ | – | – | – |

| Twin-shaft mixer | ✓ | ✓ | ✓ | ✓ |

| Max. Storage volume aggregates in-line silo2 | 140-500 m³ (183-654 yd³) | 140-500 m³ (183-654 yd³) | 140-500 m³ (183-654 yd³) | 140-500 m³ (183-654 yd³) |

| Max. Storage volume of aggregates tower silo3 | 400-600 m³ (523-785 yd³) | 400-600 m³ (523-785 yd³) | 400-600 m³ (523-785 yd³) | 400-600 m³ (523-785 yd³) |

| Max. Number of cement silos | 6 | 6 | 6 | 6 |

| Vertical feeder elevator | ✓ | ✓ | ✓ | – |

| Steel foundations | ✓ | ✓ | ✓ | ✓ |

| Litronic-MPS 3 control system | ✓ | ✓ | ✓ | ✓ |

1 Mixing time 30 seconds 2 4-6 chambers 3 4-8 chambers | * Truck mixer filling ** Truck filling *** 10-20 % higher output depending on plant configuration only possible with Liebherr Litronic-MPS 3 control system | |||