The Liebherr Group

For more than 75 years, Liebherr has stood for a large, continually developing range of sophisticated products and services. Exceptionally practical, seasoned and proven engineering as well as a consistent high quality level ensure customer benefit in all product areas.

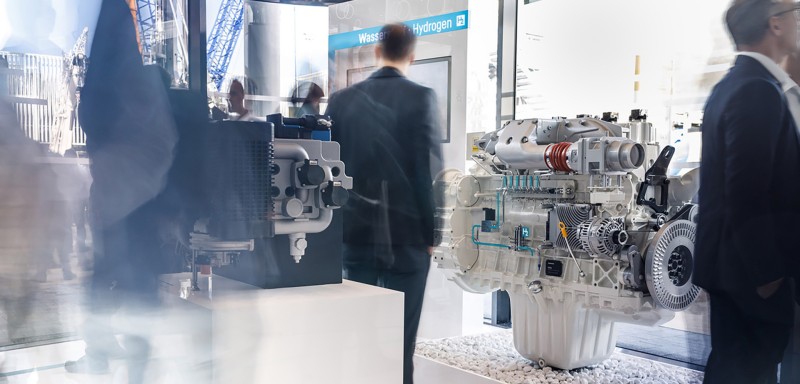

Highlights from the Liebherr world

About Liebherr

More than 50,000 employees help to shape technological progress in many industries. The Group is managed to this day by the Liebherr family.

01/03

Other topics

- Used Equipment Marketplace

- Merchandising shop

- Sales and service