LRT 1090-2.1

Rough terrain crane

LRT 1090-2.1 - The safe choice!

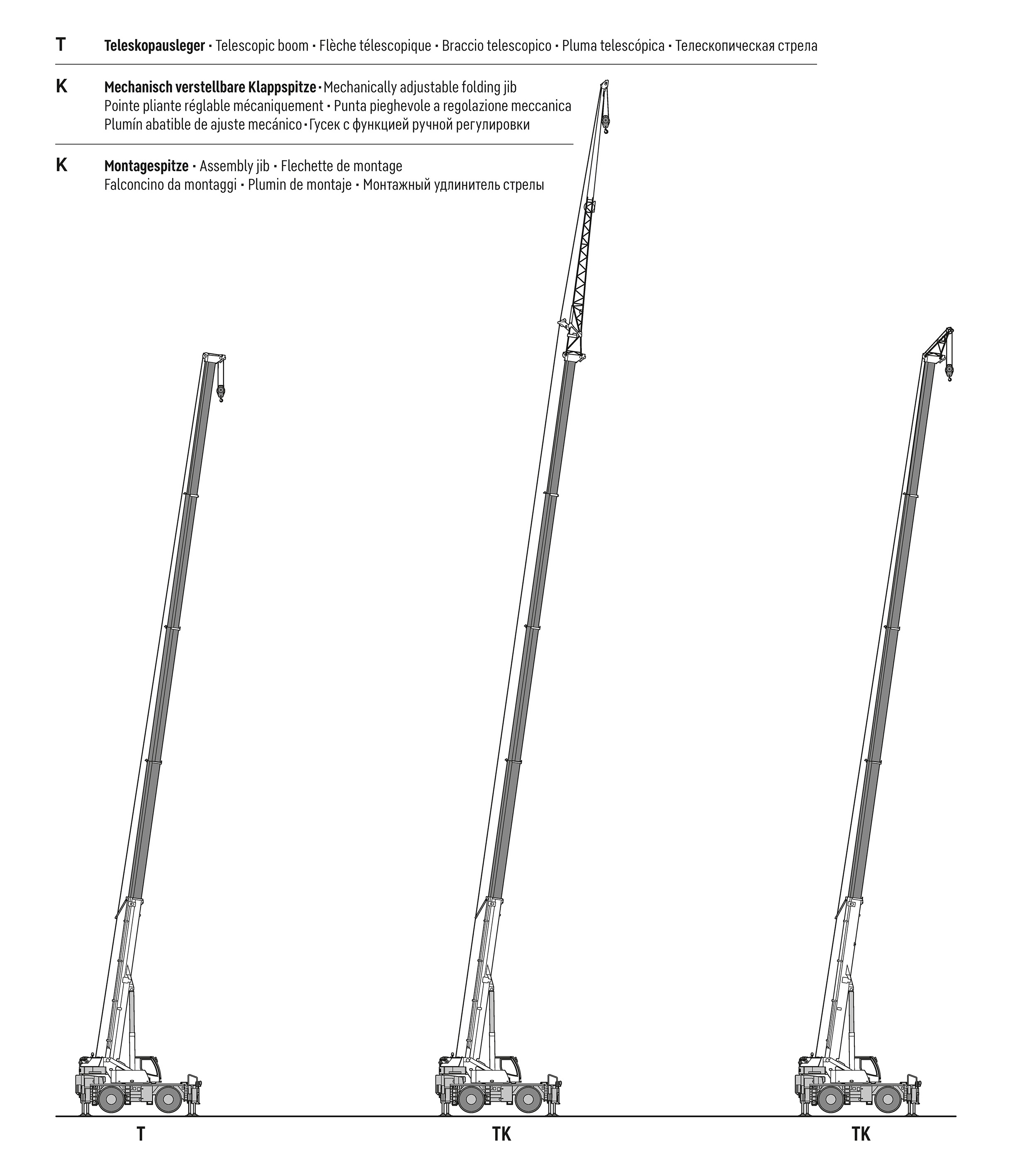

Our LRT 1090-2.1 rough-terrain crane was designed primarily to deliver a high safety level. It is fitted as standard with an outrigger monitor, which automatically detects the support status and includes it in the crane control system. You want even more safety? Then it is delivered as standard by the VarioBase® variable support base. It enhances flexibility on site and also increases the crane’s lifting capacity. The telescopic boom on the rough terrain crane features time-tested rope pull technology. This telescoping technology enables the boom to be extended quickly to any length using a two-stage hydraulic cylinder with a rope extension mechanism. The system is very easy to operate – it enables you to set the perfect lifting capacities using two different telescoping paths, for either power or length.

Max. load capacity - 90 t

90 t

Telescopic boom - 47 m

47 m

Max. hoist height - 66 m

66 m

Max. radius - 50 m

50 m

Number of axles - 2

2

What's inside

Wide and safe as standard:

Safe and variable in practice:

Everything under control:

Time-tested technology:

Worldwide safety standard:

Photo gallery

Technical data

| Max. load capacity | 90 t |

| at radius | 2.50 m |

| Telescopic boom from | 12.00 m |

| Telescopic boom up to | 47.00 m |

| Lattice jib from | 2.00 m |

| Lattice jib up to | 19.00 m |

| Drive engine/make | Cummins |

| Drive engine | 6-Zylinder-Diesel |

| Drive engine/power | 188 kW |

| Number of axles | 2 |

| Drive/Steering standard | 4 x 4 x 4 |

| Driving speed | 25.00 km/h |

| Total ballast | 13.00 t |

Downloads

Videos

Rough Terrain Crane

Rough Terrain Crane - Walkaround

LRT 1090-2.1 - Swabian power for Heligoland

Boom/jib combinations

Boom/jib combinations

Technology

ECOmode

VarioBase®

SafetyChart