Newsletter Maritime Cranes

Issue 2/2019

Liebherr TCC 78000

Assembly Almost Completed

The assembly work for Liebherrs new heavy duty portal crane TCC 78000 at the port of Rostock is almost completed.

With the support of two LHM 800, the boom was fixed at a height of 61 metres. The Liebherr TCC 78000 is one of the world's most powerful land-based heavy duty portal cranes with a maximum lifting capacity of 1,600 tonnes on our factory site in the port of Rostock, Germany.

LPS 420 E

Delivery to Novorossiysk

NCSP Group, the largest Russian port operator in terms of cargo turnover, is the first customer of the new purely electric Liebherr portal crane, the Liebherr LPS 420 E.

The objective of this new investment and the expectation into the brand new machine is to increase productivity while at the same time becoming an emission-free port. NCSP thus develops into an environmentally conscious role model in the industry.

LRS Log Handler

Efficient Timber Handling

The main field of application of a log handler is the fast, maneuverable and, in particular, mobile transport of logs within industrial plant premises and timber handling terminals.

Especially in wood-processing companies such as sawmills, paper or pulp mills, but also for transhipment in ports and inland ports, the Liebherr Log Handler is considered to be a robust, reliable and powerful machine.

Details Log Handler:

- Lifting capacity: 30 t

- Grapple capacity: 8.2 m²

- Pactronic hybrid system: +100 kW

LiSIM Simulator for Port Nelson

Realistic Virtual Training Solution

The simulator is actually two in one allowing for training on more aspects of real port operations, with both a generic ship crane simulator and the LiSIM version of the LHM 550 mobile harbour crane, both utilising much of the same hardware.

Port Nelson’s General Manager Operations, Matt McDonald sees the simulator purchase as a “step-up in safety” for the port. "We can simulate situations that you hope never to see in real life and train people on how to react to them, the same as the aviation industry has done for years.”

Liebherr Container Cranes

Productivity when it matters

King Abdullah Port, Saudi Arabia - One of the world’s fastest growing ports and home to 10 Liebherr STS cranes and 48 Liebherr RTGs. Since its launch Liebherr have worked with the port to help deliver exceptional productivity and continued growth.

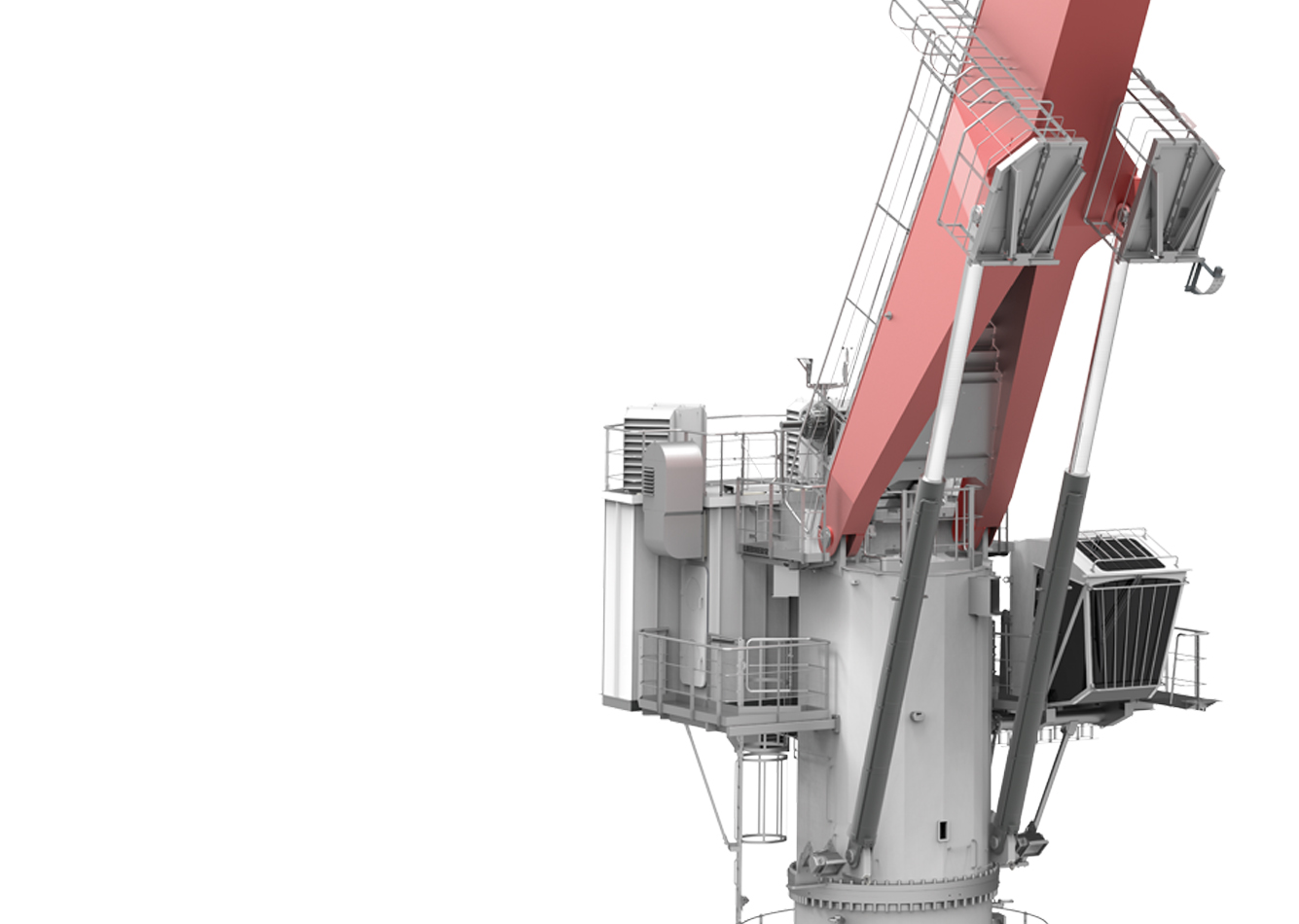

Combining Design and Power

First RL 2650 with 75 t SWL

Liebherr-MCCtec Rostock GmbH signed a contract to deliver a ram luffing crane, type RL 2650 to Navtech Marine Services based in the United Arabian Emirates. The crane will be used for lifting heavy parts on existing oil platforms in the Arabian Gulf Region and execute maintenance tasks.

Details of the project:

- Pedestal diameter of less than 3 m

- Maximum lifting capacity of up to 75 t

- Delivery is planned in 2020

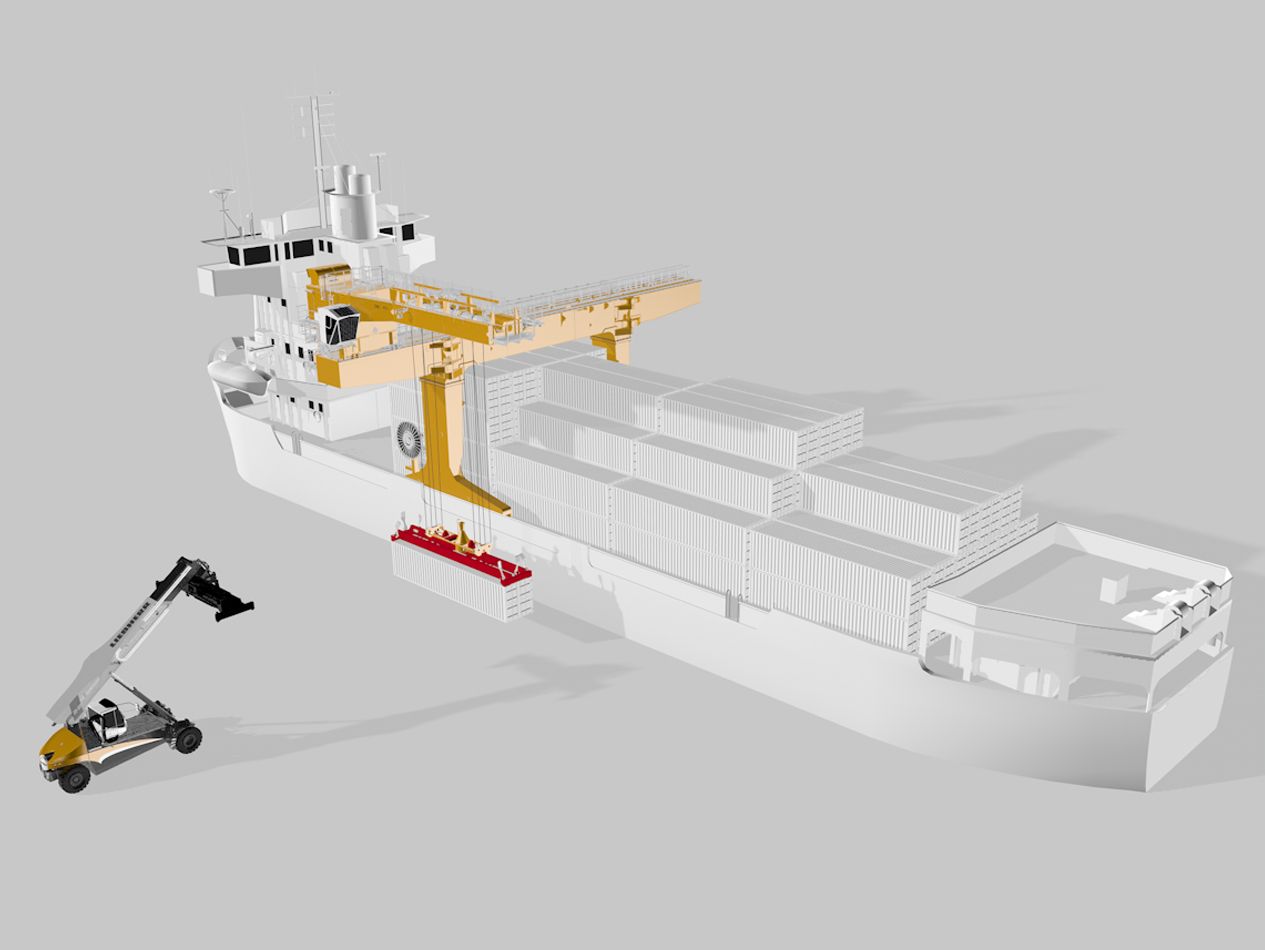

Special Design Ship Crane

Liebherr CCB

Speed and precision are decisive success factors in effective container handling. The C-design developed by Liebherr reduces the self-weight and is more compact than a usual gantry solution.

Two parallel independent hydraulic power packs for hoisting, trolley travelling and gantry travelling systems optimize the power consumption and offer maximum operational safety.

Maritime Cranes

Exhibitions & Events

TOC Europe

18.-20.06.2019

Rotterdam

The Netherlands

Coaltrans Asia

23.-25.06.2019

Bali

Indonesia

Offshore Europe

03.-06.09.2019

Aberdeen

UK

Offshore Europe

03.-06.09.2019

Aberdeen

UK

NEVA

17.-20.09.2019

St. Petersburg

Russia

TOC Europe

18.-20.06.2019

Rotterdam

The Netherlands

Kormarine

22.-25.10.2019

Busan

South Korea

Breakbulk Americas

08.-10.10.2019

Houston,TX

USA