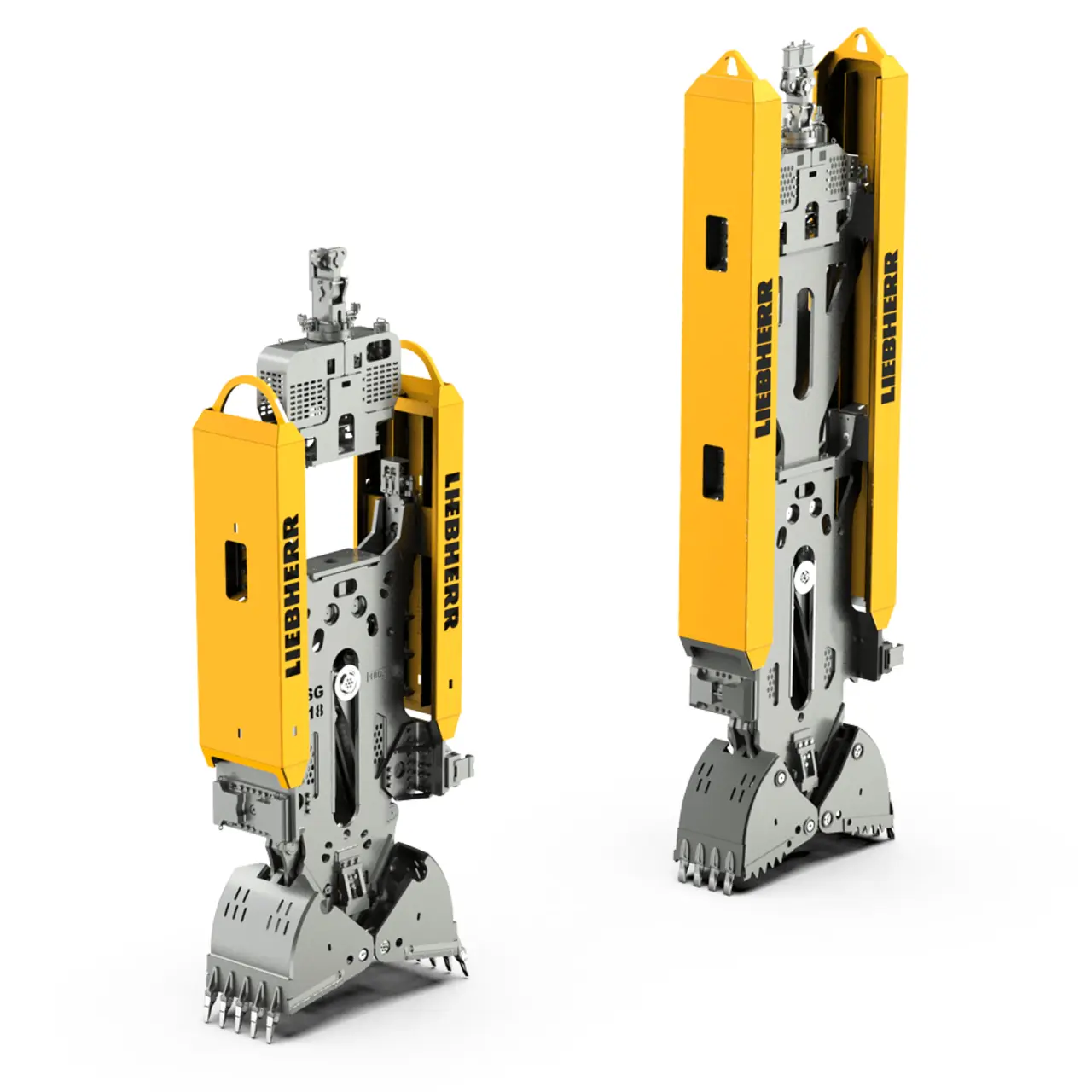

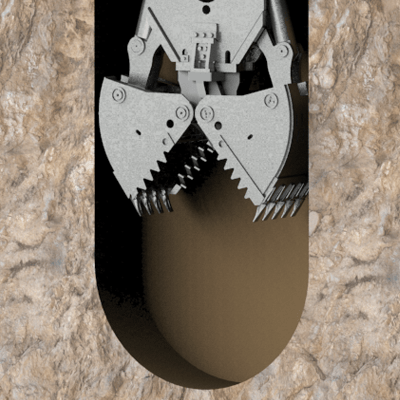

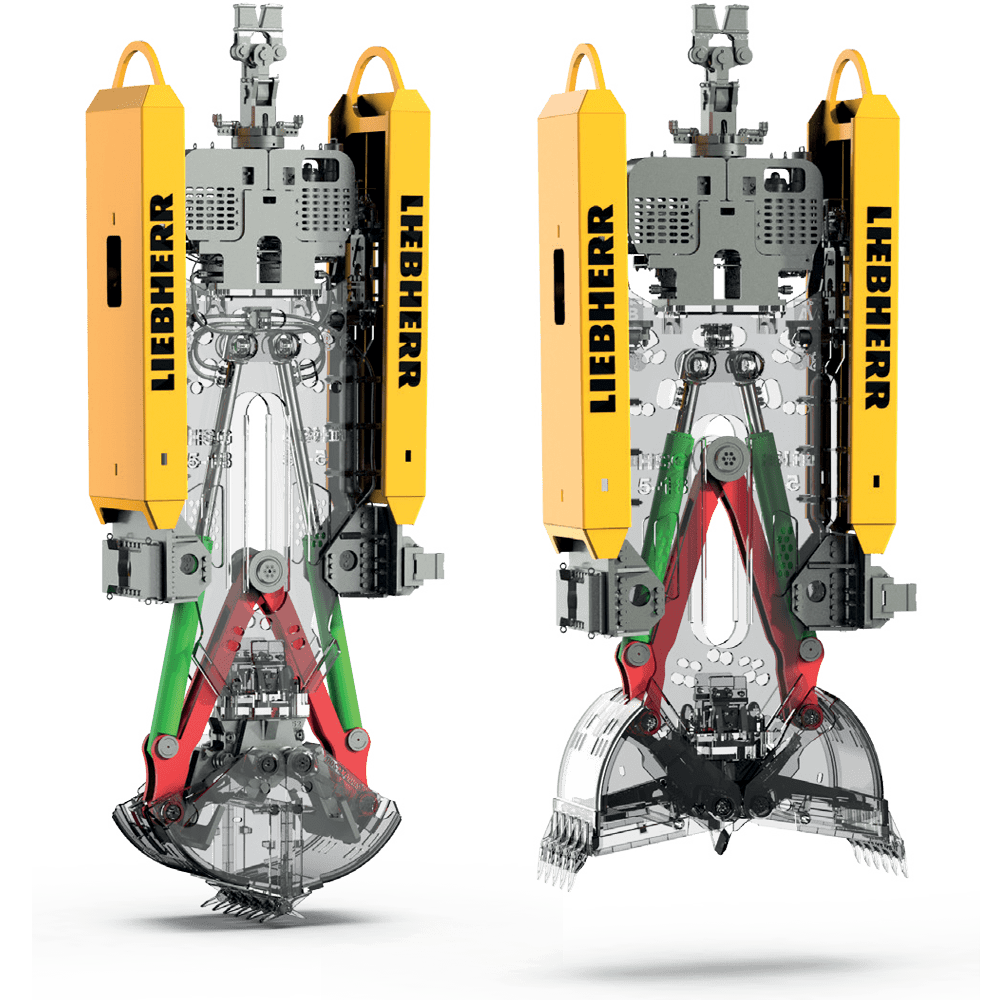

HSG 5-18 C/L

Slurry wall grab

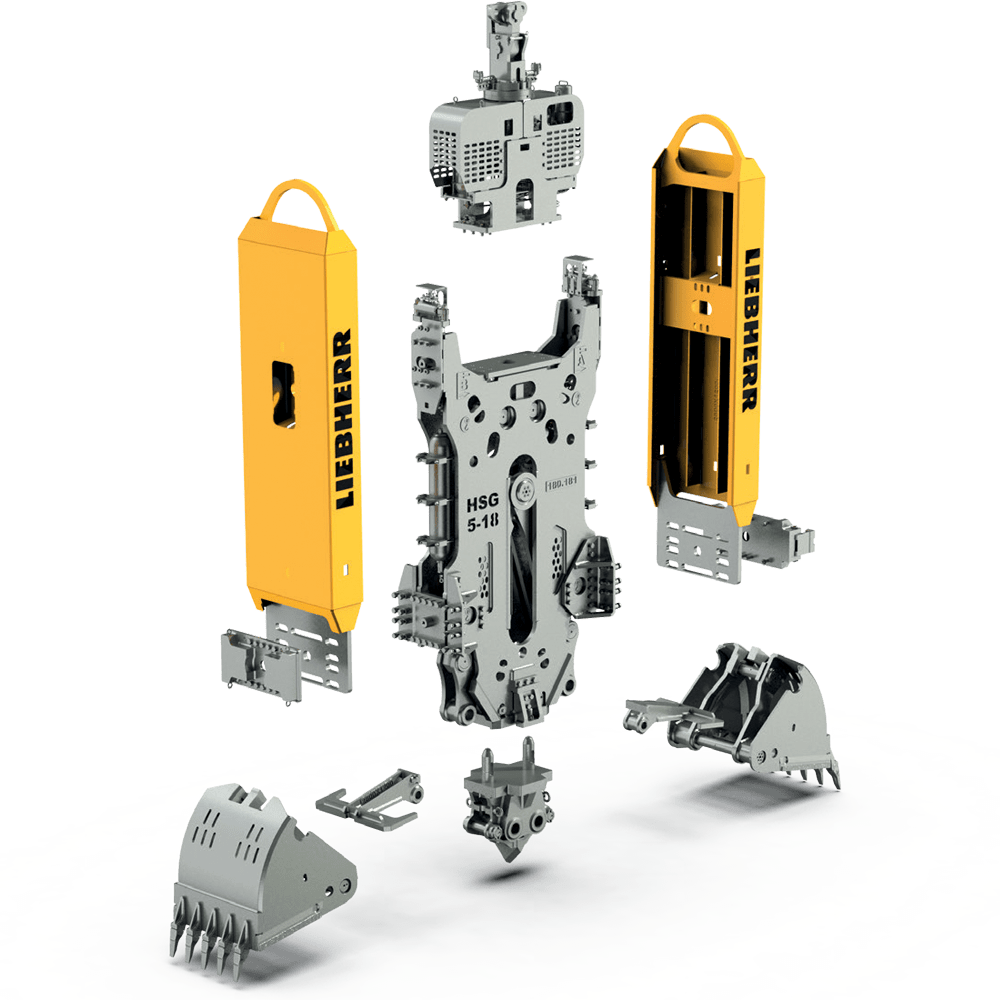

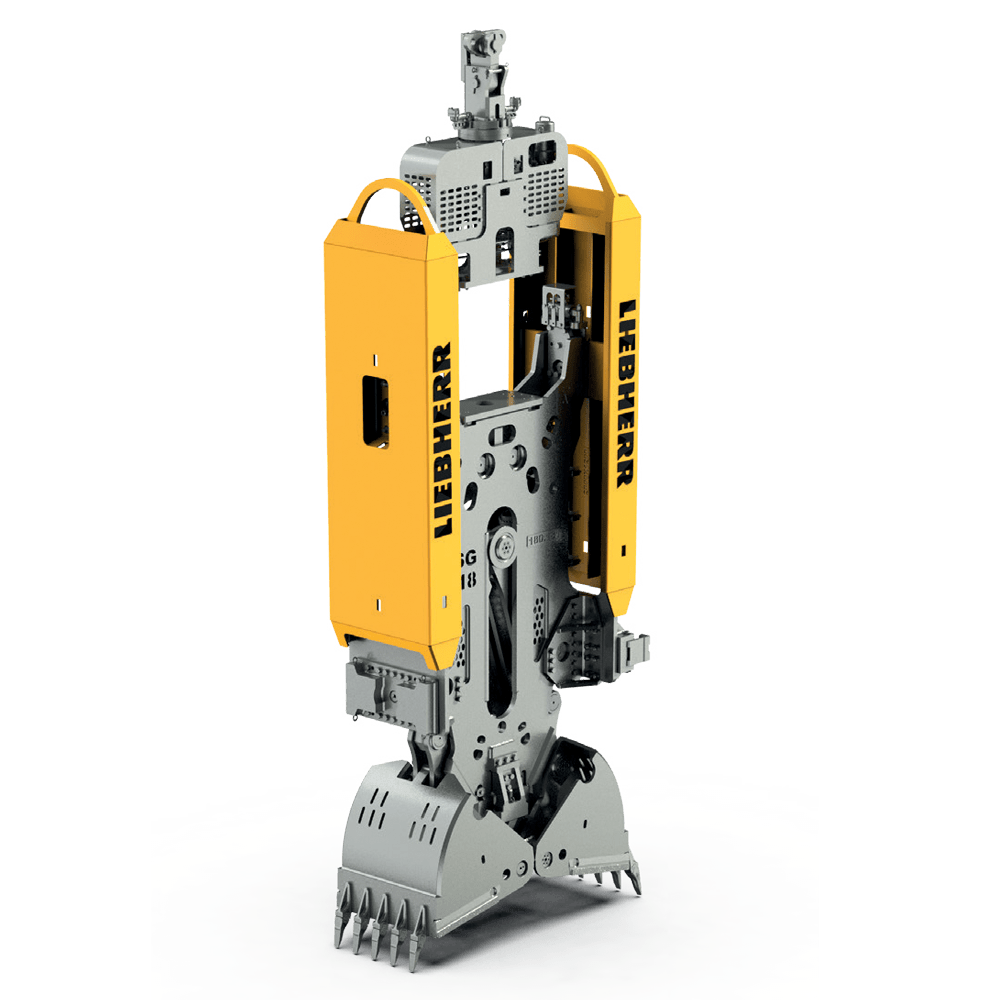

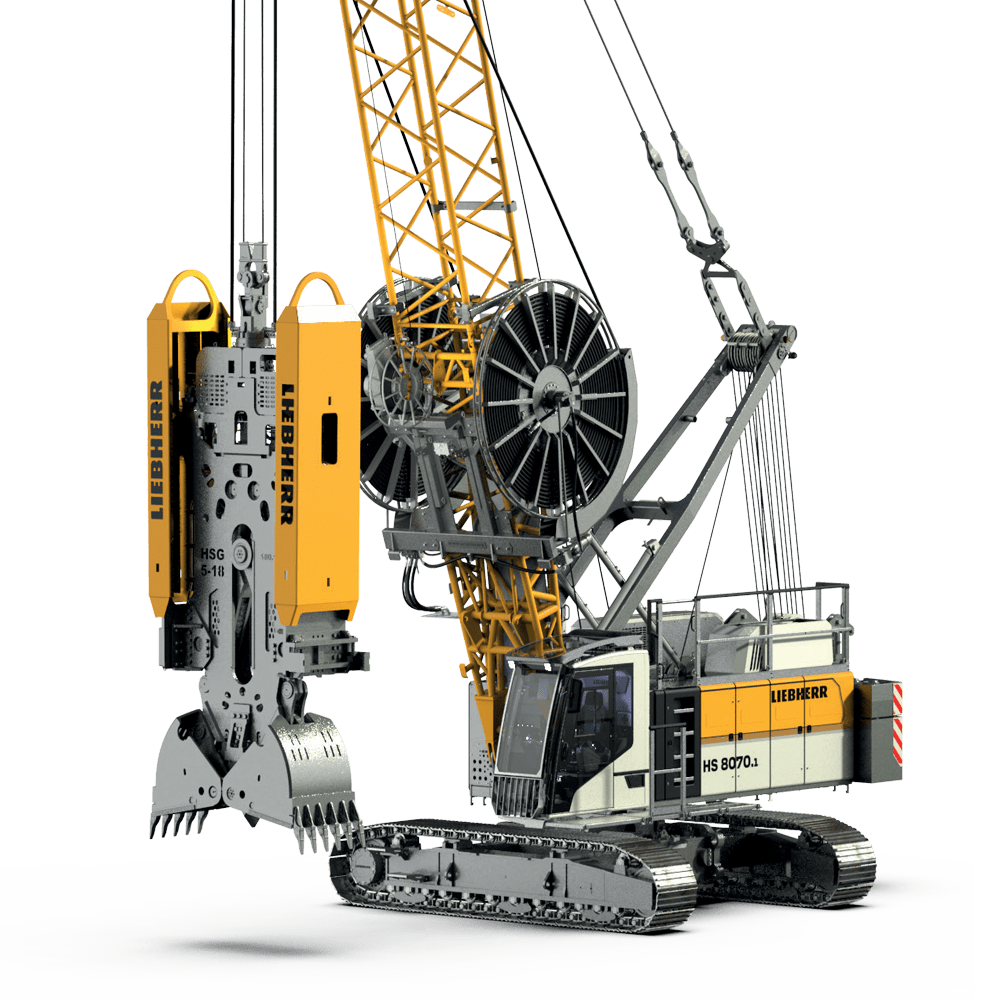

The hydraulic slurry wall grab is modularly designed and has an extremely robust base body. As the names of the grabs imply, HSG 5-18, slurry walls with thicknesses between 500 and 1800 mm can be installed, depending on the composition. The base body of the “L” (large) version is 2.5 m longer. The resulting total height of the grab at 9.5 m, as well as the high weight with low centre of gravity provide for even better vertical positioning and are especially advantageous when installing larger dimensioned slurry walls. When working in difficult ground conditions, the dead weight of the grab can...

Wall thickness - 500 - 1,800 mm

500 - 1,800 mm

Jaw opening width - 2,500 - 3,600 mm

2,500 - 3,600 mm

Max. closing force at teeth - 594 kN

594 kN