Components

ComponentsLitronic-FMS planar sensor P78-HR

The Liebherr P78-HR sensor in conjunction with the Liebherr Litronic-FMS 3K / CCS type coating thickness and basis weight determination system has become indispensable for many industrial processes.

The areas of use include the coating of paper, box, film, non-woven and textile webs.

The sensor installations take place, for example, before and after the squeegee for the exact determination of the coating or the humidity

The Litronic-FMS III evaluation and transfer unit, which is a mandatory part of the system, is used to record, process and prepare the values measured by the sensors.

The integrated software is used for convenient parametrisation and calibration. Thanks to the various interfaces, signal transmission to the higher-level control is feasible.

Measurement by the Liebherr sensor system is based on the physical principle of capacitance determination in the high-frequency stray field.

In addition to their high precision and robustness, the measuring devices from Bad Schussenried are characterised by their reproducibility.

Once the sensor has been calibrated, further measuring points can be set up or devices renewed on this basis at any time without great effort. The plant thus always remains reliable, regardless of its previous term and age.

| Physical principle | Capacity determination in the high frequency stray field |

| Frequency | 20 MHz |

| Measurement location | 1.) paper, cardboard, foil, fleece, textile webs 2.) Production, finishing and processing plants or comparable |

| Measuring range | 1) 0 - 100 % moisture content (measuring window adjustable) Basis weight determination 5... 25.000 ...50.000 g/m², solution 0.5 g/m²1.) Coating thickness measurement 5 µm ... 25 mm ... 50 mm, solution 0.5 µm1 2) 0 - 100 % moisture content (measuring window adjustable) |

| Update cycle | 32.64 ms |

| Measurement value transfer | digital: RS-485, streaming |

| Max. number of sensors on the bus | 16/4 |

| Maximum bus length | 1200 m |

| Power supply | 8 - 30V, 0.4 VA |

| Material temperature | max. 80 °C |

| Temperature measurement measuring range | -10 – 80 °C |

| Measuring accuracy temperature measurement | +/- 0.5 °C |

| Operating ambient temperature | 5 – 72 °C |

| Working temperature - electronics | -20 – 80 °C |

| Storage temperature | -25 – 80 °C |

| Wearing protection | Al2O3 (ZrO2) fine-grain stabilized aluminium oxide |

| Protection class | IP68 |

| Connection line length/type | LAPP UNITRONIC® ROBUST C 7x0.14 shielded/6 m |

| Housing/flange material | 1.4404 |

| Dimensions: Ø/Height | 78 mm / 53 mm / 73 mm |

| Weight without cable | 0.960 kg |

| Clamping flange weight | 0.300 kg |

| 1) (depending on material) |

Characteristics

• Pure capacitive measuring method

• Non-contact measurement possible

• Temperature compensation

• Direct digital measurement value determination

• Digital measured value transmission

• Up to 4 sensors per evaluation module (FMS 3K) (Up to 16 sensors per evaluation module (FMS II))

• High quality stainless steel housing

- Indirect measuring method: Capacity determination in the high frequency stray field. This method uses the different dielectric constant (permittivity) of water and different materials.

- Fully reproducible sensors: If the plant is subsequently extended with sensors or if sensors are replaced, no recalibration is necessary thanks to the built-in microprocessor.

- Waterproof and dustproof: The sensor is also suitable for the harshest environments thanks to its IP68 protection class.

- Very hard wearing protection: The sensor surface consists of a 2 mm thin zirconium oxide ceramic.

- Process control and regulation: Thanks to extensive interfaces, the coating thickness and area weight measurement can be integrated into process control systems and controls.

- Cost saving: Time-consuming and costly laboratory analyses are no longer necessary or can be reduced.

- Limit values: Maximum or minimum limits can be set using the software. Light or sound signals can be triggered if required.

- Mean value calculator: The sensor passes on already averaged values to the FMS evaluation and transfer module.

- Contactless: With a constant material web, it is possible to achieve good measured values at the smallest distance.

- Colour-insensitive: Thanks to the measuring principle, the paint of the material to be measured does not matter.

- Increased temperature ranges: For use at increased material temperatures, we offer our P78-SCT sensor, which is designed for max. 90 °C material temperature.

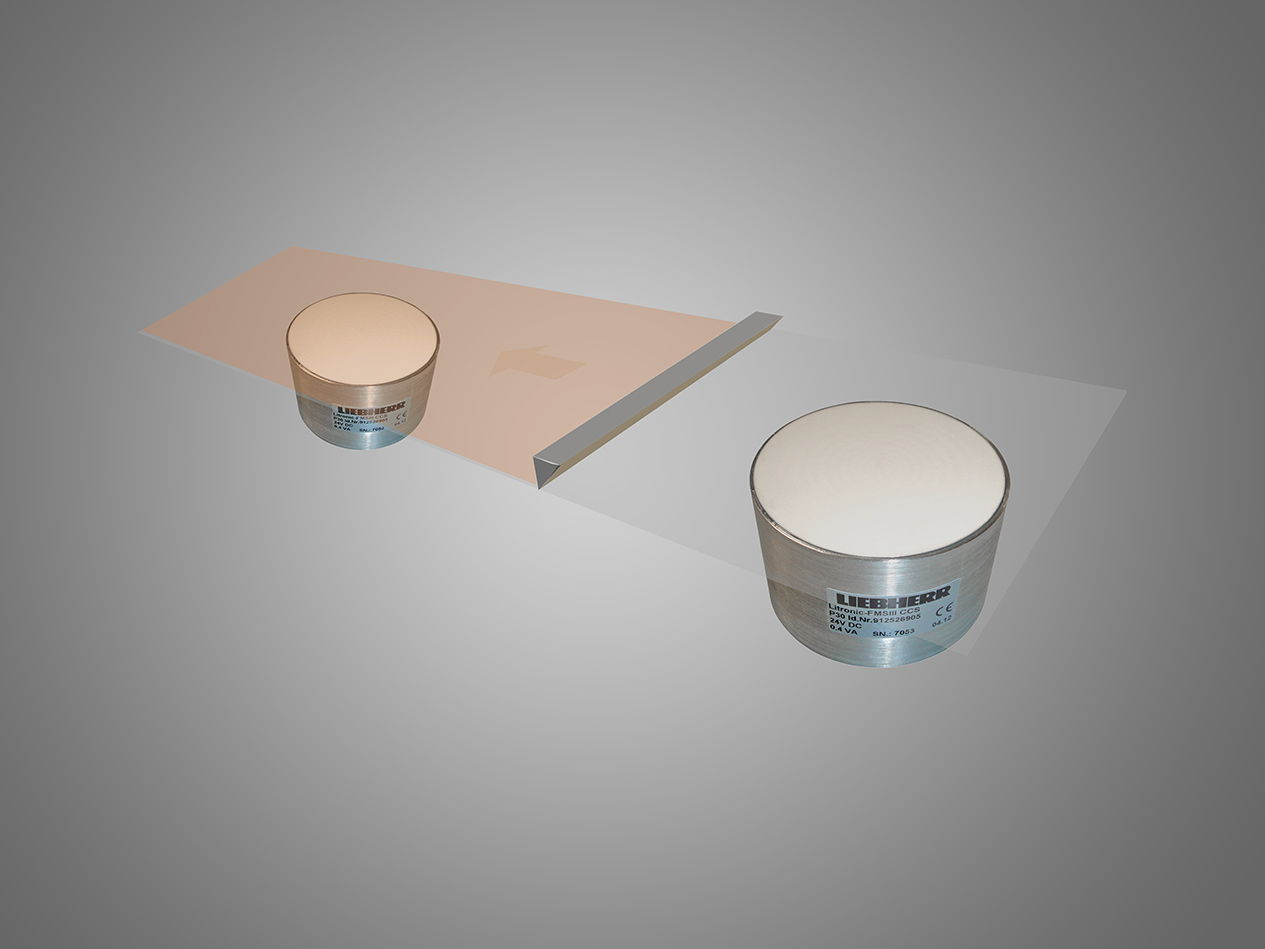

- “The Little One”: The P30-SC also fulfils the same requirements as its large role model, only it has this one advantage of being preferred in tighter installation conditions.