Hydraulic cylinders from Liebherr – innovation, performance, durability and top quality

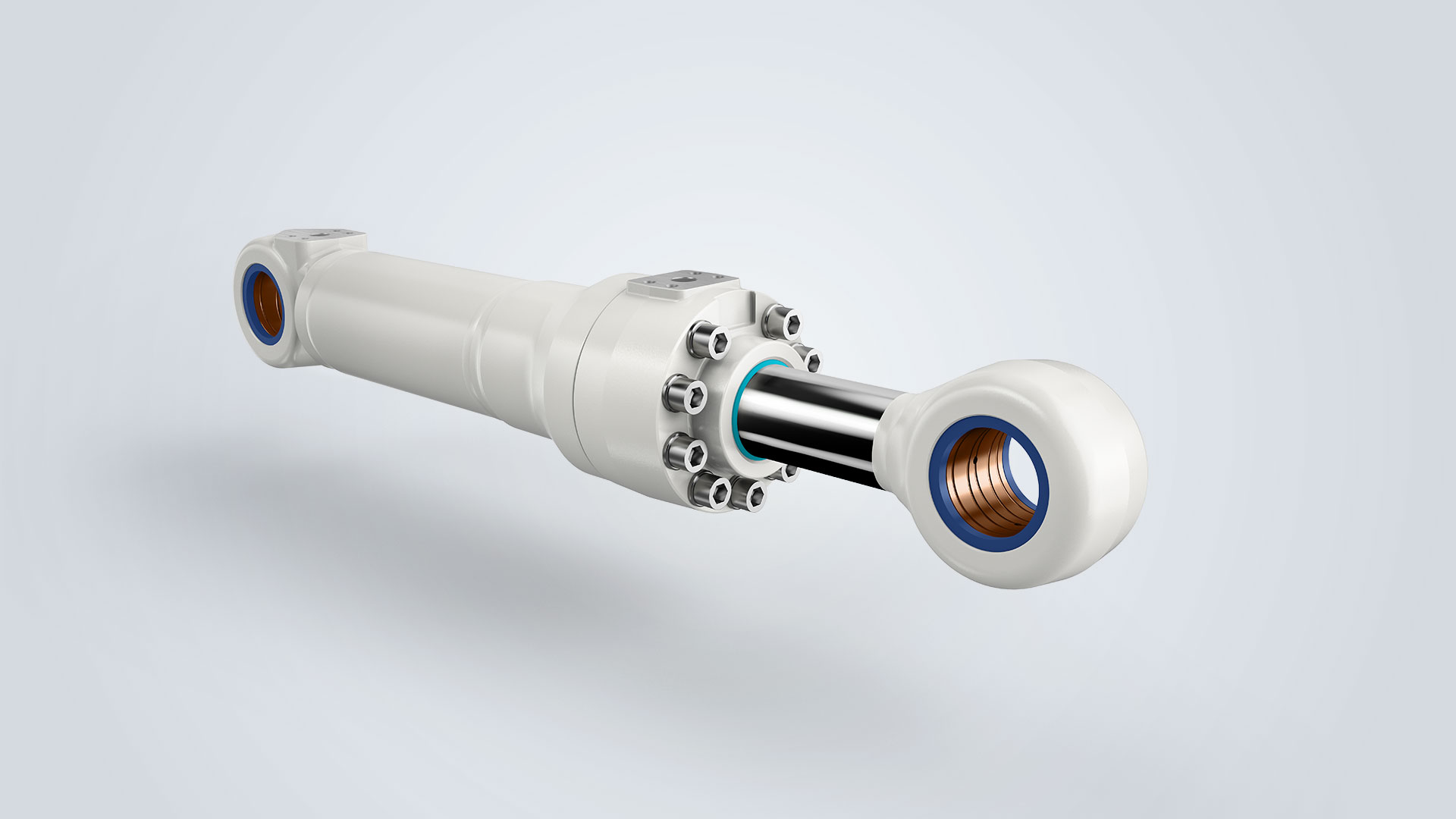

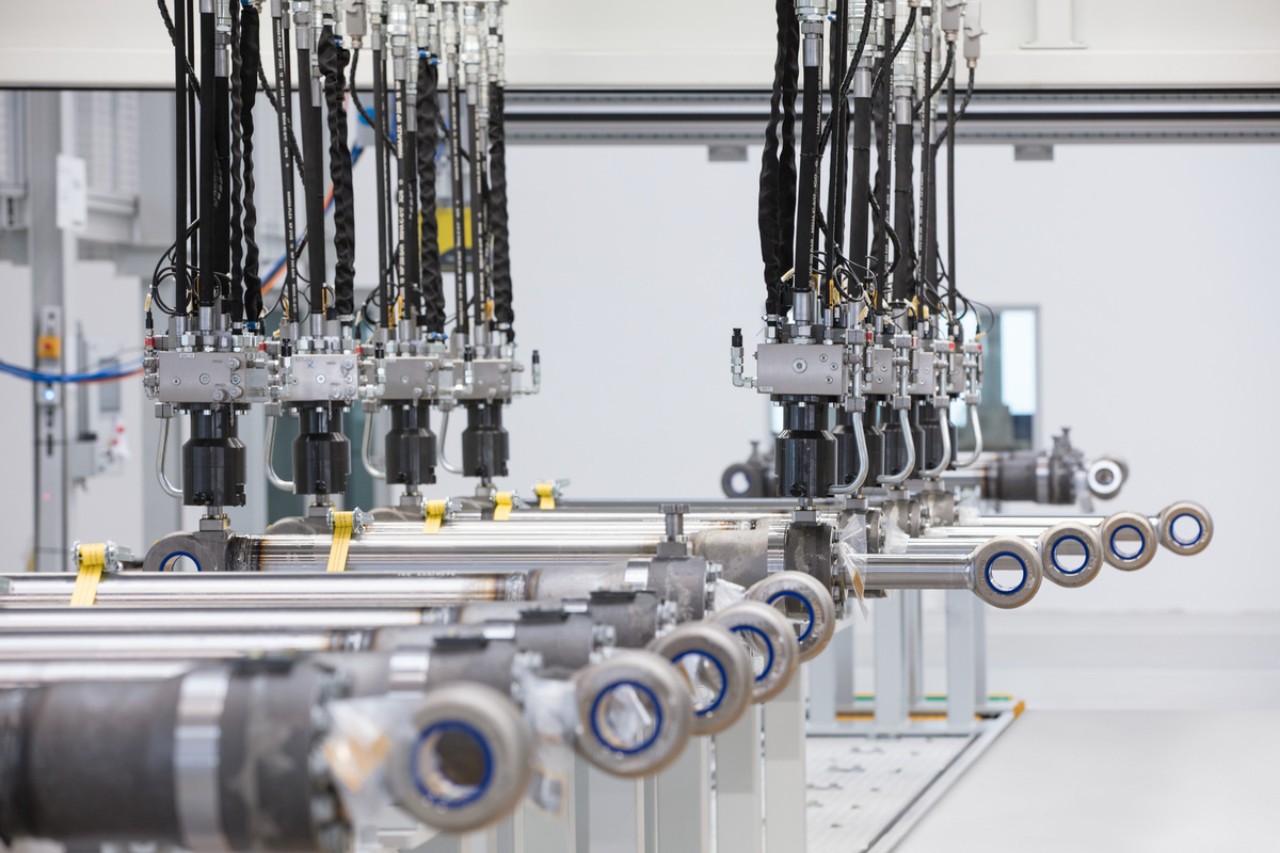

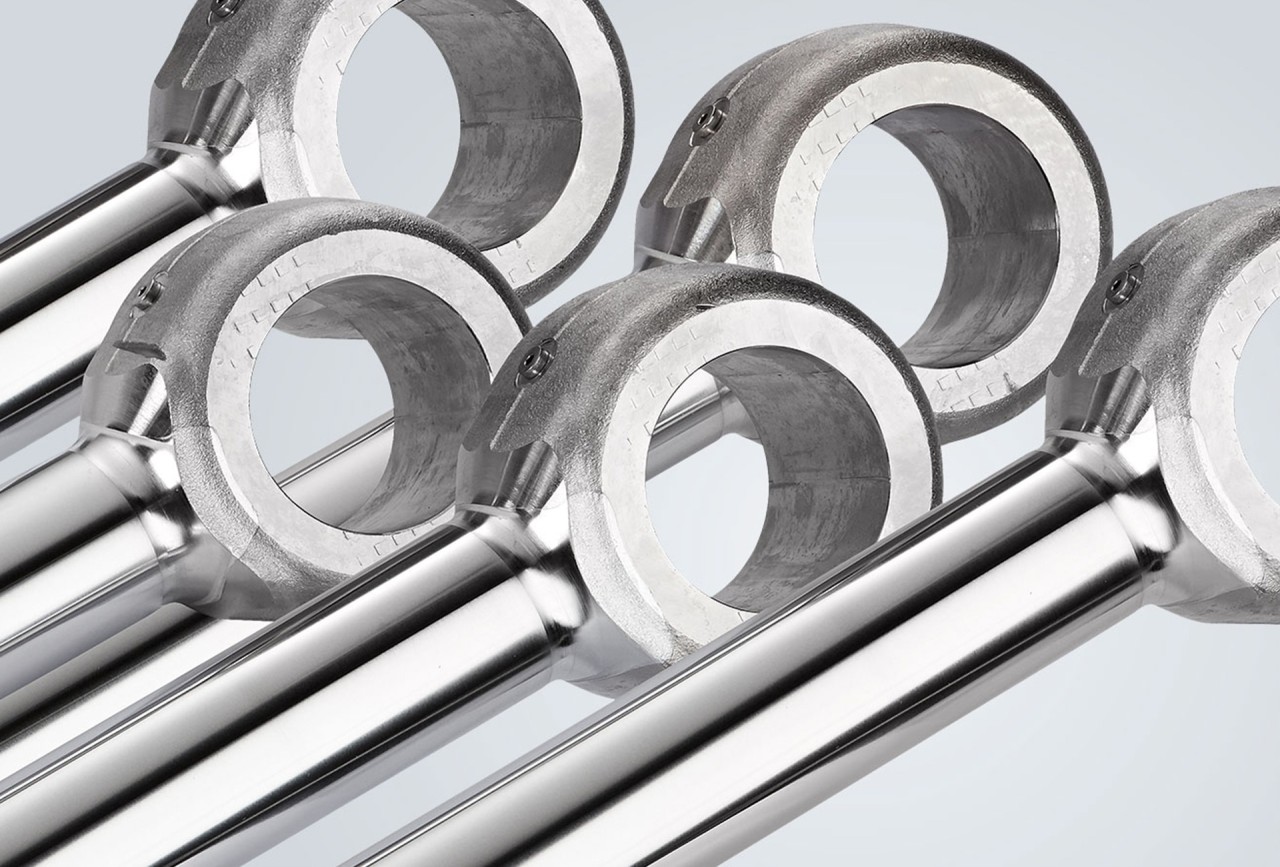

Liebherr develops and manufactures high‑quality hydraulic cylinders for demanding applications across a wide range of industries. The portfolio includes standard cylinders, large cylinders, piston accumulators, shock absorbers, as well as lightweight and customised solutions – all engineered for maximum load capacity and long service life.

With state‑of‑the‑art manufacturing technology and deep engineering expertise, we produce hydraulic cylinders that deliver outstanding precision, reliability and genuine Liebherr quality for continuous, long‑term operation.

Hydraulic solutions for your application

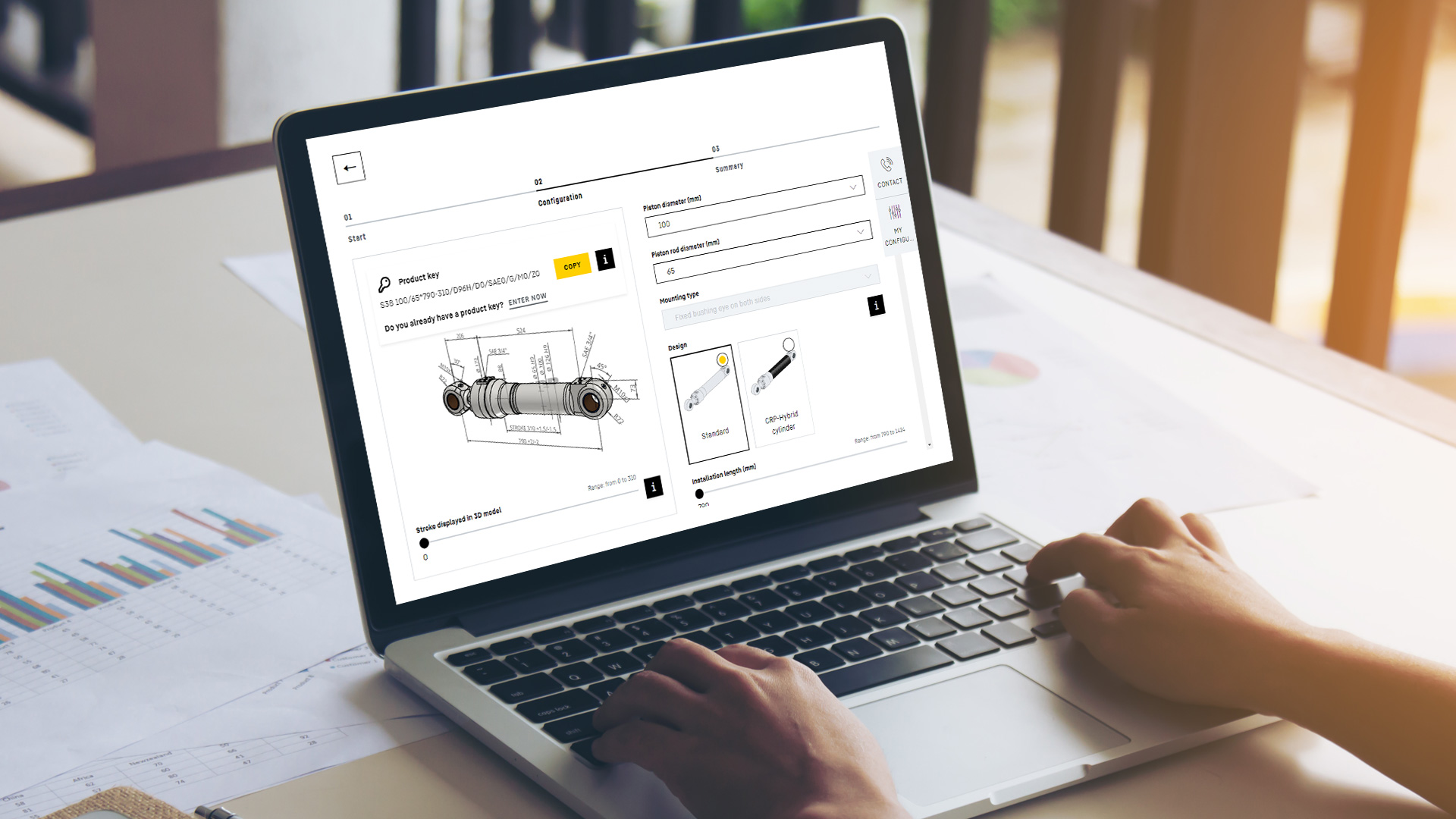

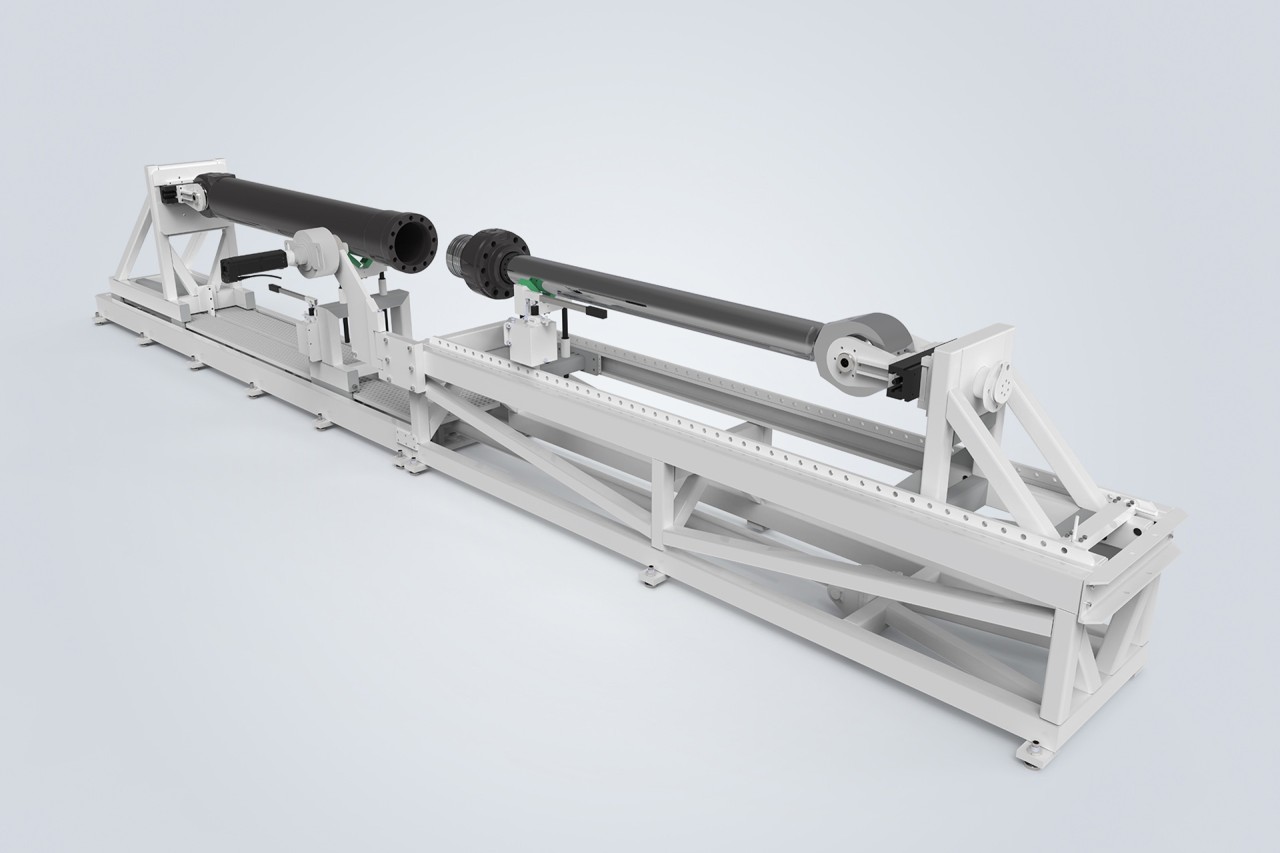

In close cooperation with our customers, we create innovative solutions for hydraulic cylinders and shock absorbers in addition to our standard series. With standard piston diameters up to 500 mm and stroke lengths up to 8 m, our optimised product portfolio impresses with its great variety.

Our product portfolio includes standard cylinders, single and double-acting cylinders and even large cylinders and shock absorbers. We also offer a piston accumulator series and lightweight fibre composite solutions. With our customer-oriented mindset, we strive to adapt to your needs. We have the right hydraulic component for your every application.

Hydraulic cylinder series-production range

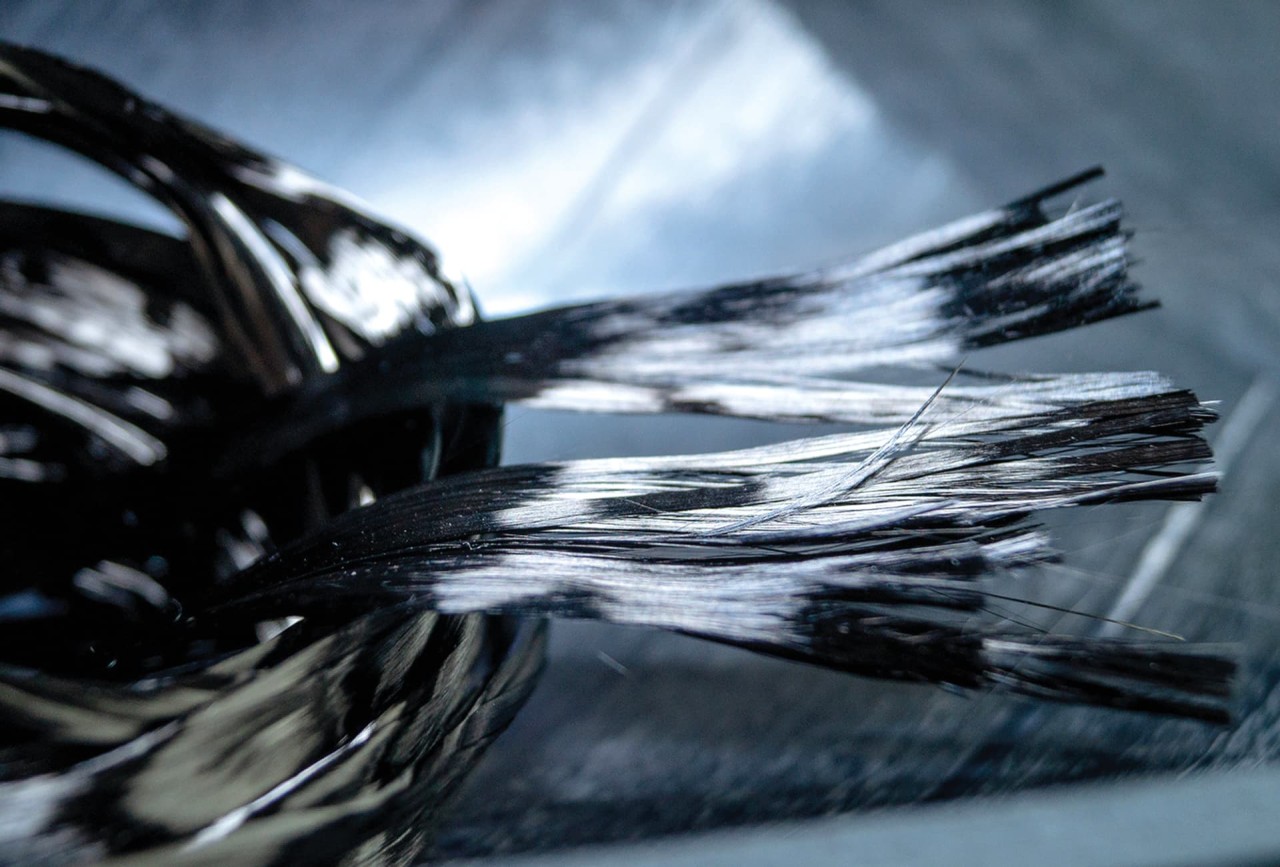

Lightweight solutions made of carbon fibre-reinforced plastic

Robustness and longevity in components do not have to be in contradiction with weight optimisation and cost-effectiveness. This is precisely the challenge that Liebherr has set itself with its solutions using carbon fibre reinforced plastic.

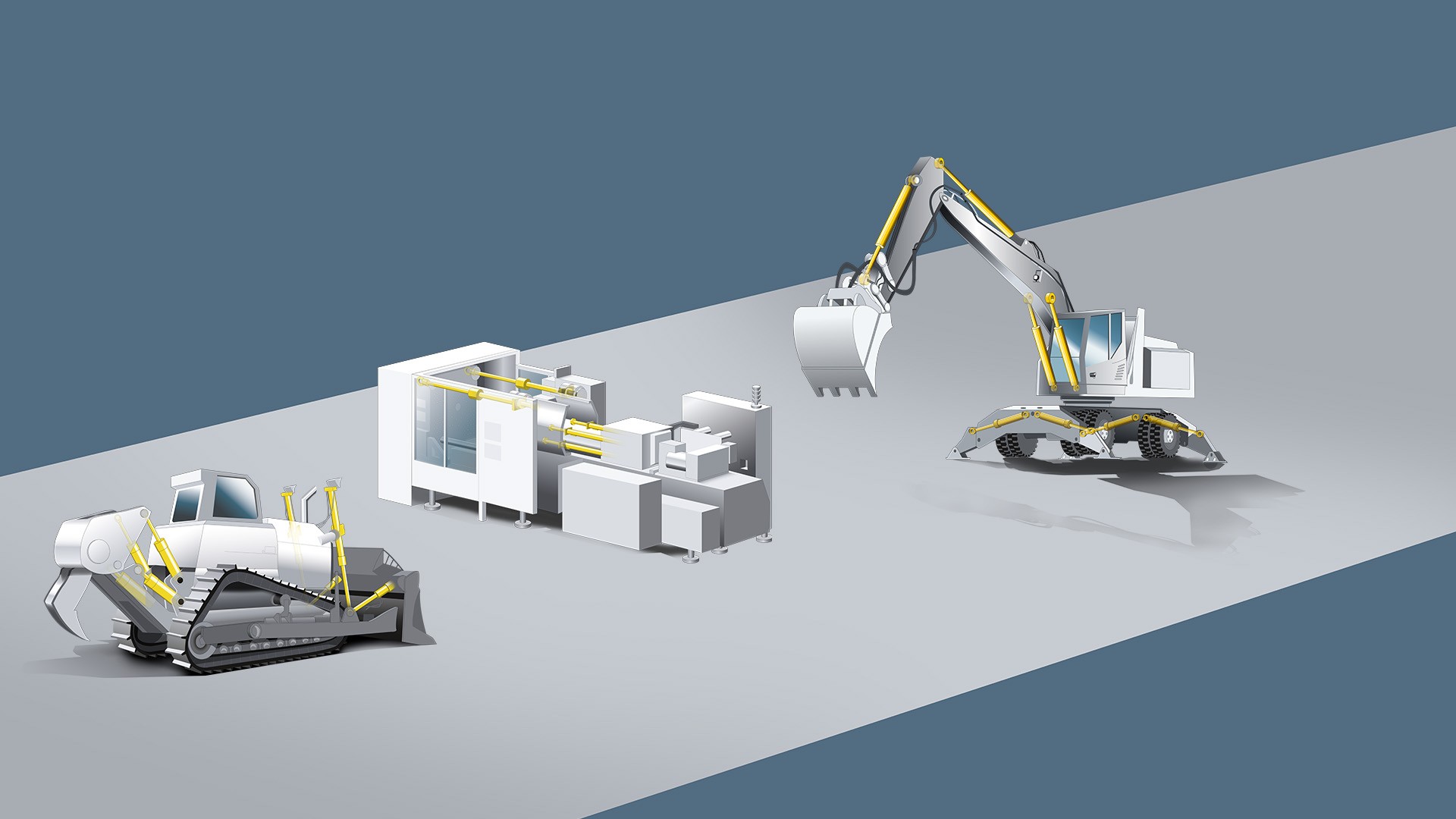

Applications

Your partner for hydraulic solutions

Liebherr-Components Kirchdorf GmbH, located in Kirchdorf an der Iller, is an independent company that develops and produces a large product portfolio of hydraulic solutions. Some 75,000 hydraulic cylinders leave the factory every year.

We made it!

Winner of the Lean Base Award 2024

Liebherr-Components Kirchdorf GmbH was honoured with the Lean Base Award 2024! As one of the largest Lean Awards in the German-speaking world, organised by Lean Knowledge Base, it recognises outstanding Lean concepts and achievements in companies.

Industries that rely on us

Liebherr hydraulic cylinders are used worldwide in a wide variety of industries – from the harsh conditions in mining to the highest precision in marine technology. Our claim: maximum robustness, reliability and durability in every application. At the same time, we continuously invest in research and advance development in order to actively shape technological trends. This results in solutions that not only meet today's requirements, but also support key future issues such as emission reduction and digital transformation.

Your one-stop shop for high-precision CFRP solutions

– from material to finished solution

At Liebherr’s Oberopfingen site, we combine decades of process expertise in carbon fibre reinforced plastics (CFRP). With our one-stop shop approach, we deliver comprehensive CFRP solutions – from design and production through to system integration. Our focus is on CFRP hybrid cylinders and other high-performance lightweight structures that achieve maximum weight savings while ensuring outstanding strength and stiffness. Thanks to our expertise in composite process engineering, new design freedoms are unlocked: lightweight, sustainable, robust, and future-oriented.

Our expertise at one location

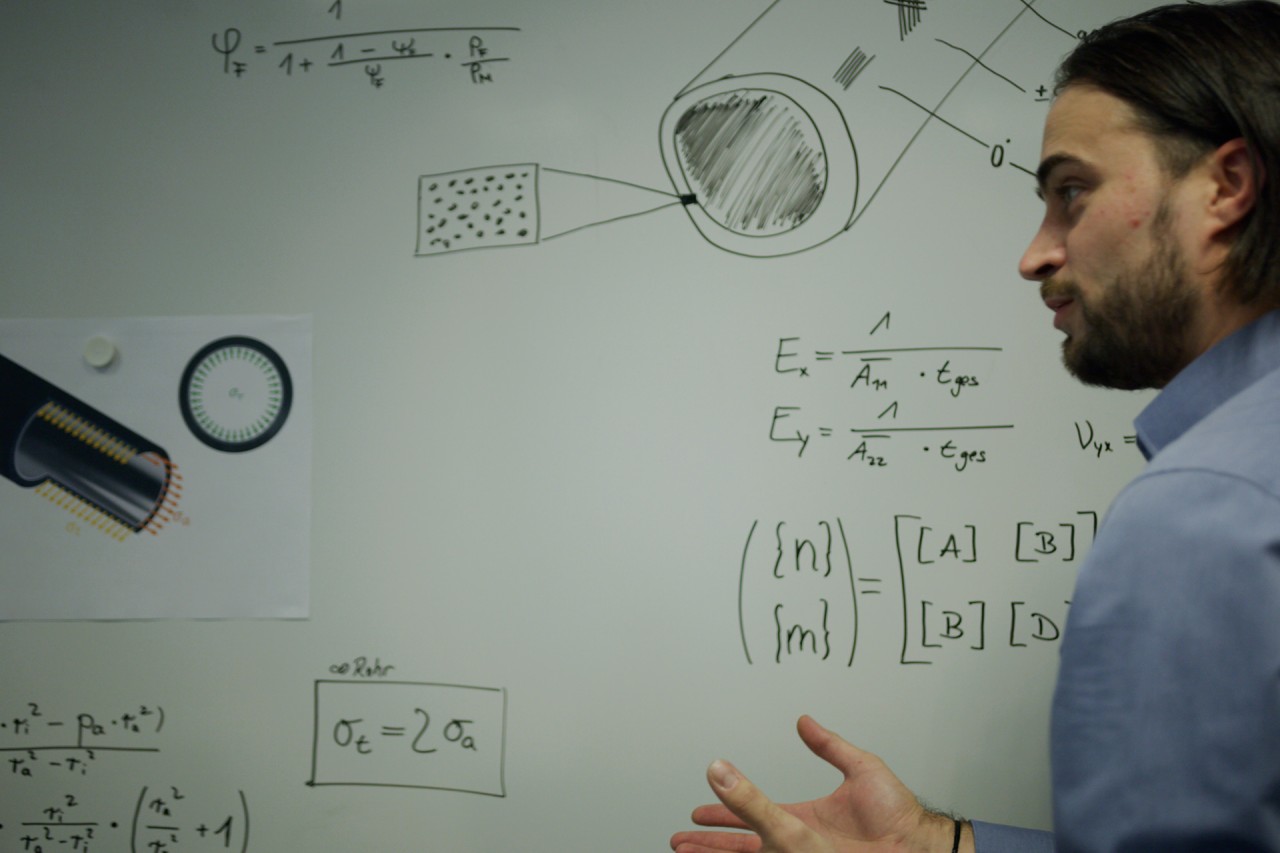

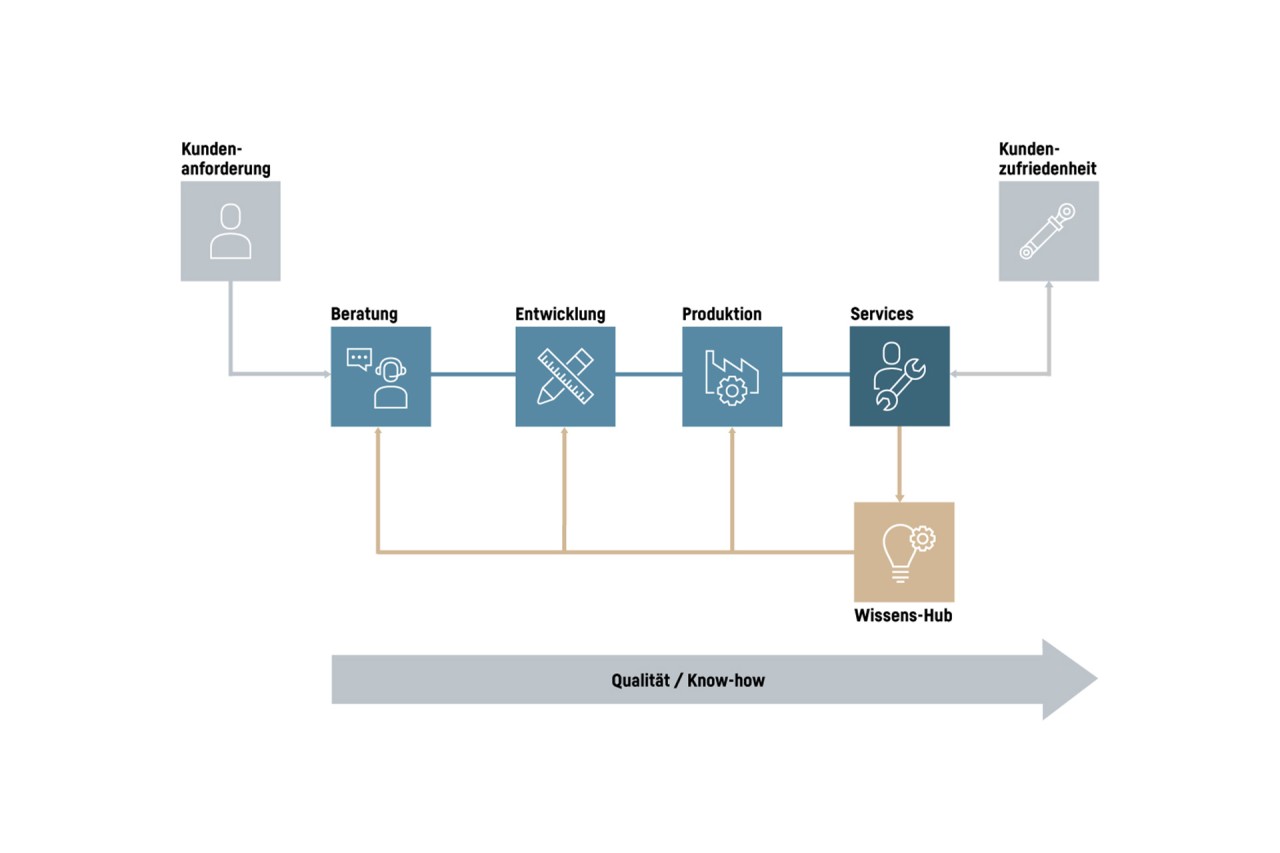

Quality - the basis for hydraulic cylinders that set standards

At Liebherr, quality begins in the development phase. From technical consultation to the careful selection and support of our suppliers, right through to production, we ensure that the highest standards are consistently maintained. During the entire production process, permanent operational quality assurance monitors every step and rectifies any deviations immediately.

All measures are anchored in a comprehensive quality management system – from intensive supplier qualification and seamless process control to the continuous improvement of our processes. In this way, each individual process step contributes to the sustainable overall quality of our hydraulic cylinders.

Our hydraulic cylinder exhibit at Bauma 2025

Under the motto “Hands on the Future”, Liebherr showcased how it is actively shaping tomorrow by addressing future challenges today – because construction machinery must operate with the highest efficiency while conserving resources and protecting the environment. Liebherr’s modular hydraulic cylinders are the key to sustainable and high-performance heavy-duty applications.

Winner of the Lean Base Award 2024

Liebherr-Components Kirchdorf GmbH was honoured with the Lean Base Award 2024! As one of the largest Lean Awards in the German-speaking world, organised by Lean Knowledge Base, it recognises outstanding Lean concepts and achievements in companies.

Your partner for hydraulic solutions

Liebherr-Components Kirchdorf GmbH, located in Kirchdorf an der Iller, is an independent company that develops and produces a large product portfolio of hydraulic solutions. Some 75,000 hydraulic cylinders leave the factory every year.