The production range at a glance

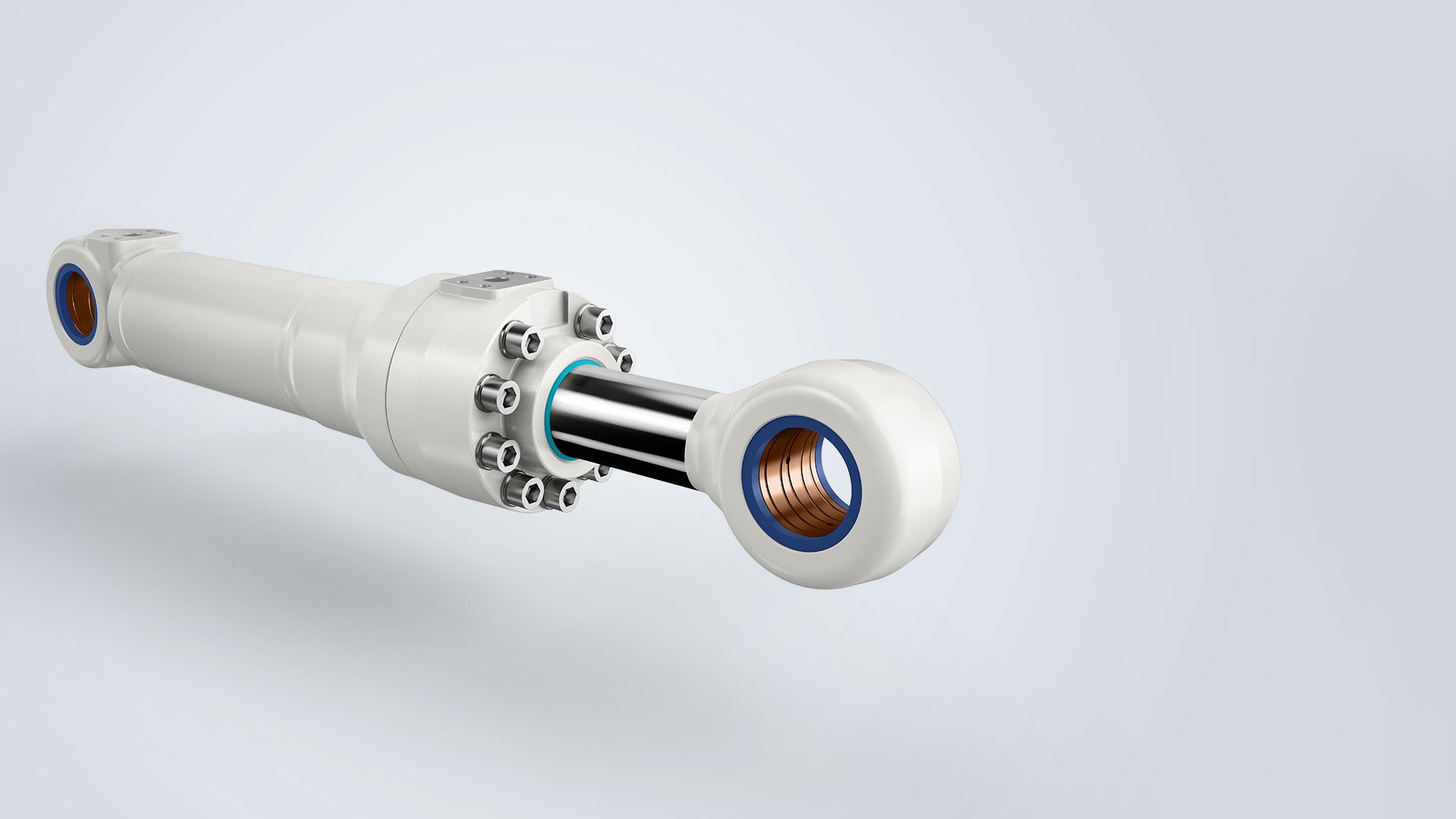

The hydraulic cylinders for pressures up to 380 bar offer customers a flexible range of available cylinder variants. The use of standardised components means that new cylinders and spare parts are available quickly with maximum flexibility.

Wide variety of variants

Applications

Worldwide service network

Product range at a glance

| Type | Differential cylinders |

|---|---|

| Stroke lengths | Up to 2,300 mm |

| Piston diameter | 100 - 220 mm |

| Piston rod diameter | 65 - 150 mm |

For use anywhere

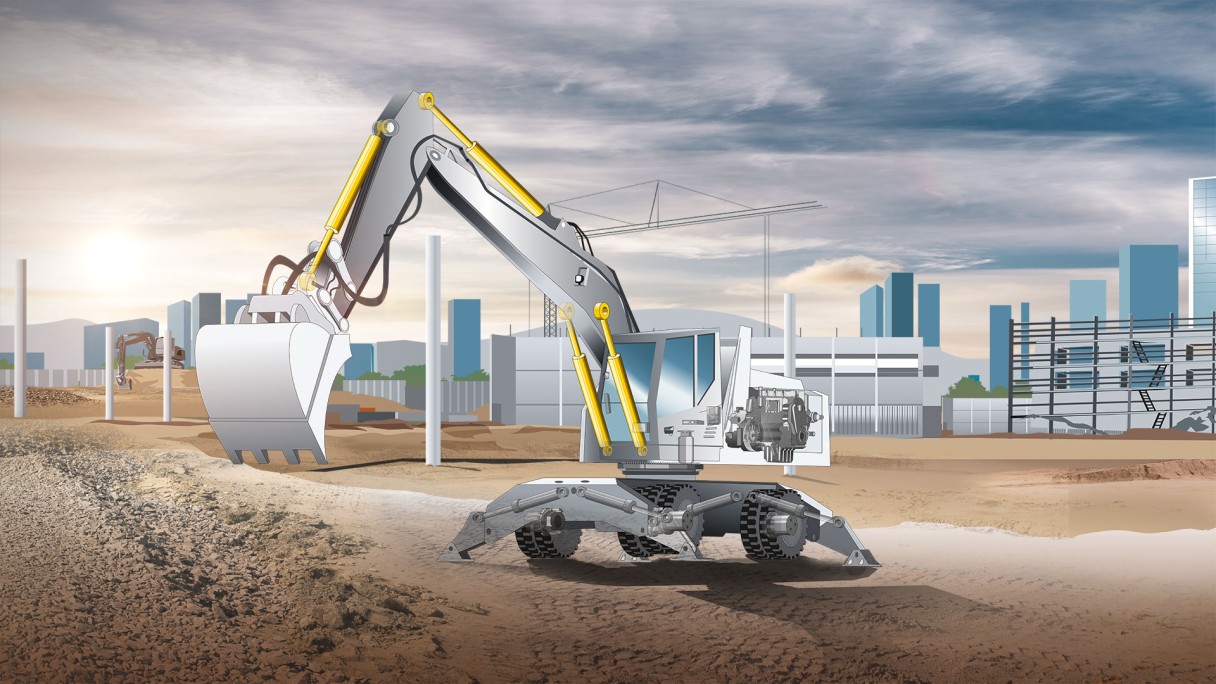

The hydraulic cylinders of the 380 bar series-production range come in handy in mobile applications. They are used wherever durable and robust products are required in highly dynamic applications. For example, they are perfect in mobile machinery in mobile and crawler excavators as hoist, stick and bucket cylinders.

For mobile excavators, all hydraulic cylinders in the series-production range can be envisioned. See for yourself.

Technical designs to fit your needs

- Coating

- Cushioning

- Seals

High-quality chrome and nickel-chrome coatings are standard. Depending on the application, a coating with normal or increased resistance is possible. Seawater coating is also available.

High-quality chrome and nickel-chrome coatings are standard. Depending on the application, a coating with normal or increased resistance is possible. Seawater coating is also available.

Find out more about our series-production range

Configurator

Unique on demand: Your custom series-production hydraulic cylinder is just a few clicks away.