Lightweight construction in hydraulics – weight-optimized hydraulic cylinders

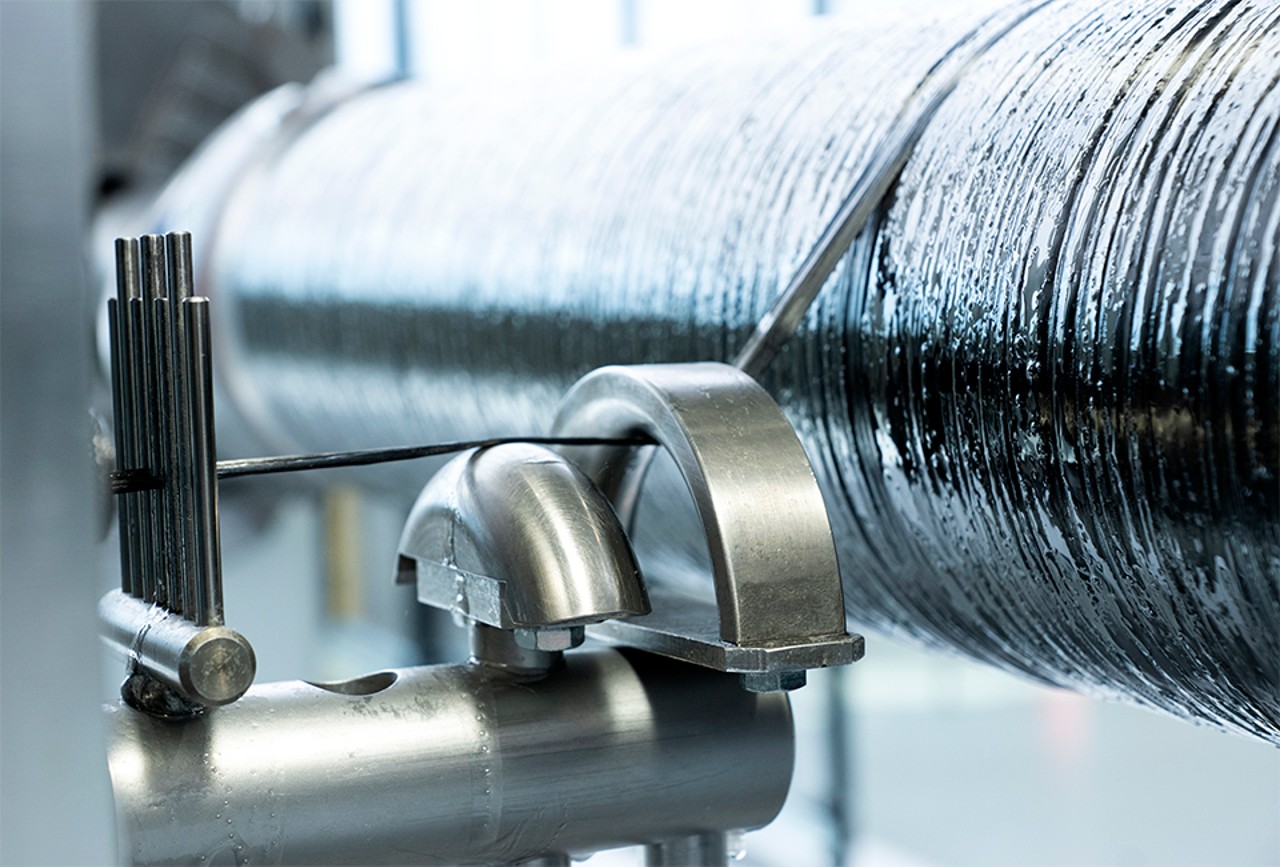

Hydraulic cylinders are indispensable in many areas of application because they enable high power transmission in a small space. The high requirements for strength and rigidity make the use of fiber composite materials attractive.

The combination of experience in cylinder development and expertise in the field of fiber composites creates optimal conditions for innovative solutions. Hybrid cylinders with CFRP winding offer a weight reduction while maintaining the same installation situation, which enables easy replacement without changing the device design.

A wide range of applications

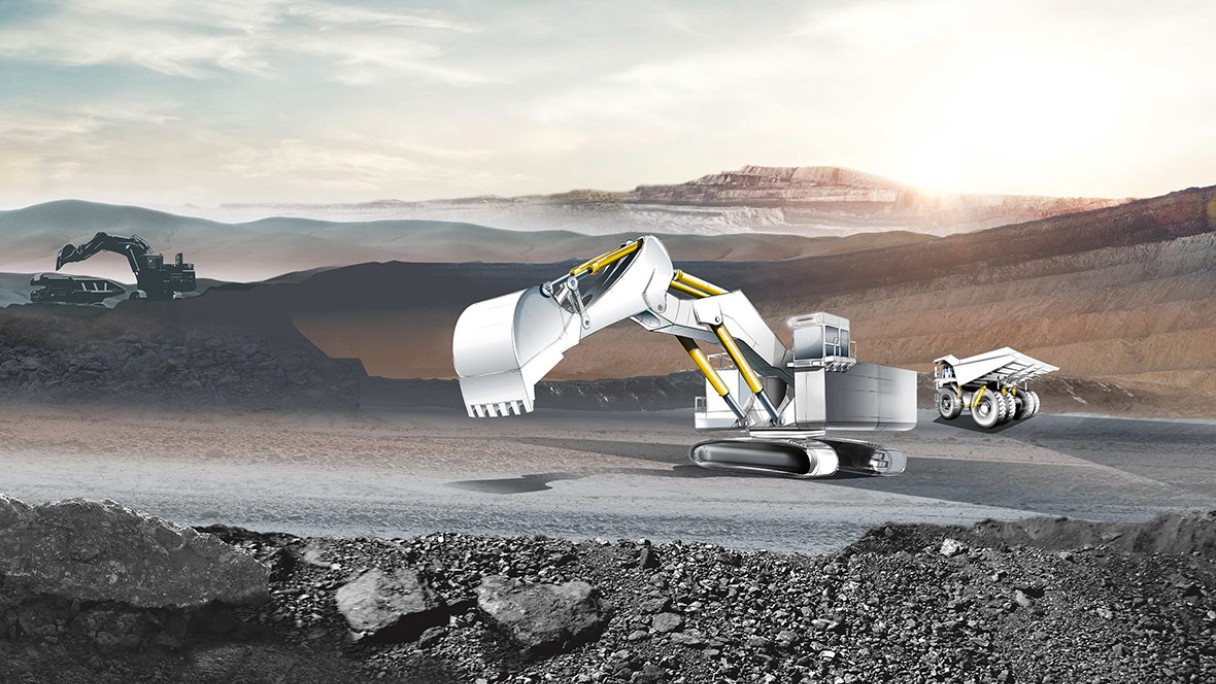

Earthmoving and mining

Material handling technology