LTM 1650-8.1

Mobile crane

LTM 1650-8.1 - The maximum on eight axles.

Children with famous parents often have a hard life – they are under great pressure from birth and are expected to be successful. The same can be said of the LTM 1650-8.1, which we unveiled at the Bauma 2019 event, the successor to the legendary LTM 1500-8.1, the best-selling large crane ever. Of course, this heavy duty crane has the same genetic concept as its predecessor – ultimate performance on eight axles. The result is that the 8-axle crane can complete hoisting work in the 700-tonne class or even higher with ease. It therefore has a nominal lifting capacity of 700 tonnes. In a lifting capacity comparison, the LTM 1650-8.1 exceeds its predecessor’s capacity by between 15 and 50 percent, depending on its equipment package.

Max. load capacity - 700 t

700 t

Telescopic boom - 80 m

80 m

Max. hoist height - 152 m

152 m

Max. radius - 112 m

112 m

Number of axles - 8

8

What's inside

Maximum lifting capacity: 700 t / 770 US t

Flexible: 54 or 80 m / 177 or 263 ft

Global mobility:

Economical and flexible: VarioBallast®

Green: ECOdrive

Photo gallery

Technical data

| Max. load capacity | 700 t |

| at radius | 3.00 m |

| Telescopic boom from | 16.70 m |

| Telescopic boom up to | 80.00 m |

| Lattice jib from | 6.00 m |

| Lattice jib up to | 91.00 m |

| Drive engine/make | Liebherr |

| Drive engine | 8-Zylinder-Diesel |

| Drive engine/power | 505 kW |

| Number of axles | 8 |

| Drive/Steering standard | 16 x 8 x 16 |

| Driving speed | 85.00 km/h |

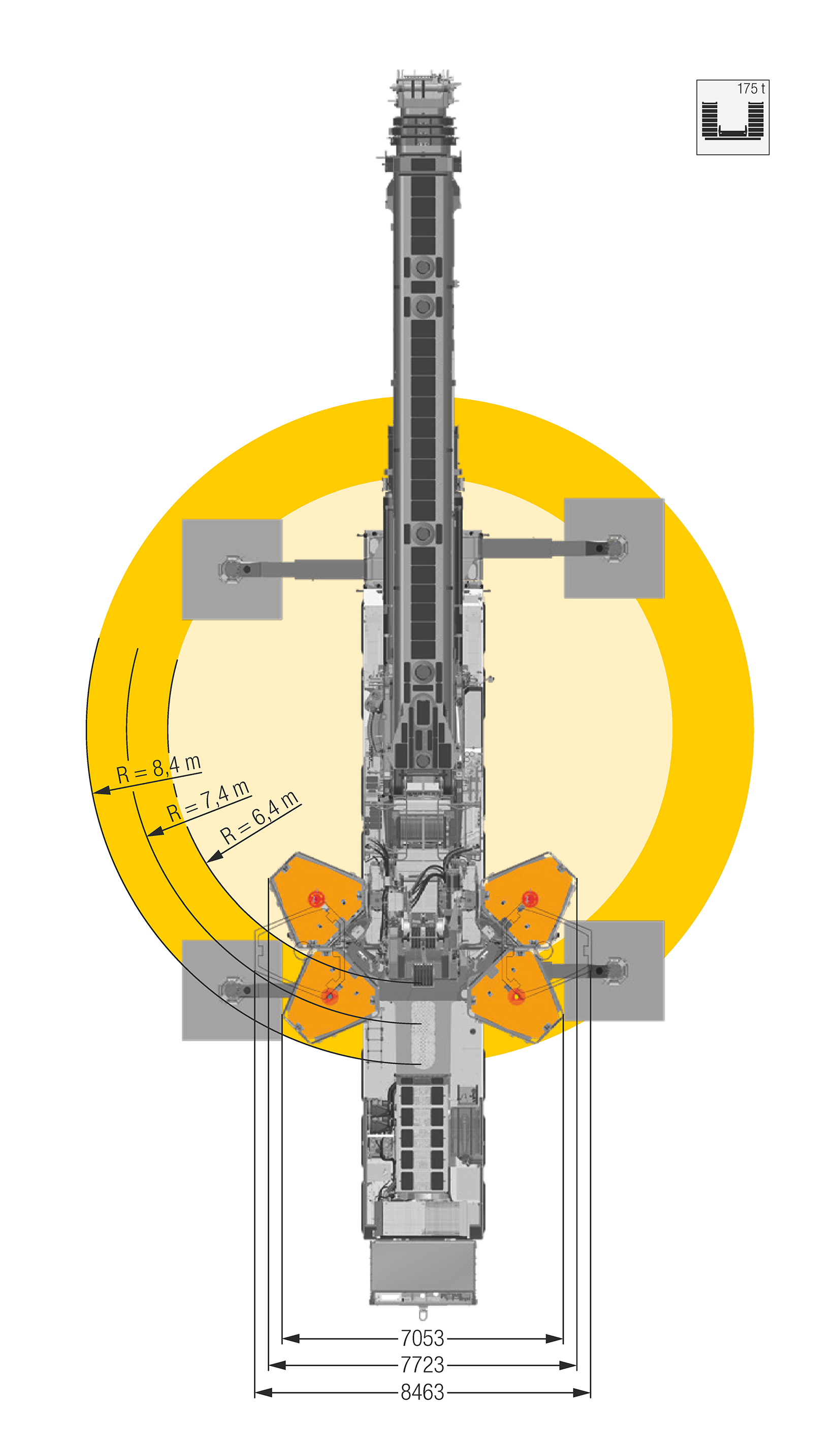

| Total ballast | 175.00 t |

Downloads

Videos

LTM 1650-8.1 - The maximum on 8 axles

Handover first LTM 1650-8.1

LTM 1650-8.1 - First job dismantling a bridge

LTM 1650-8.1 - On the edge of space

Two are better than one

LTM 1650-8.1 in explosive use

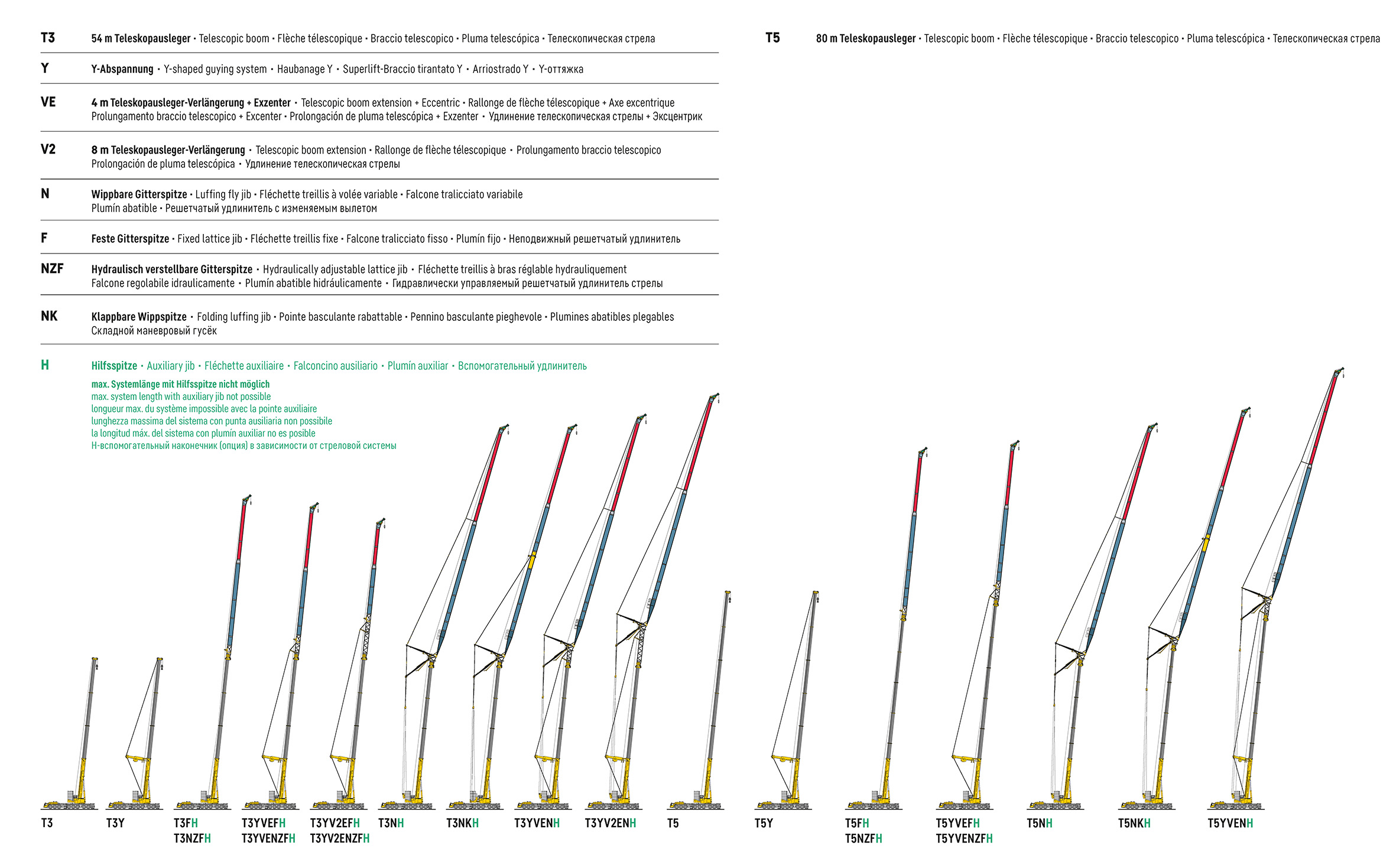

Boom/jib combinations

Boom/jib combinations

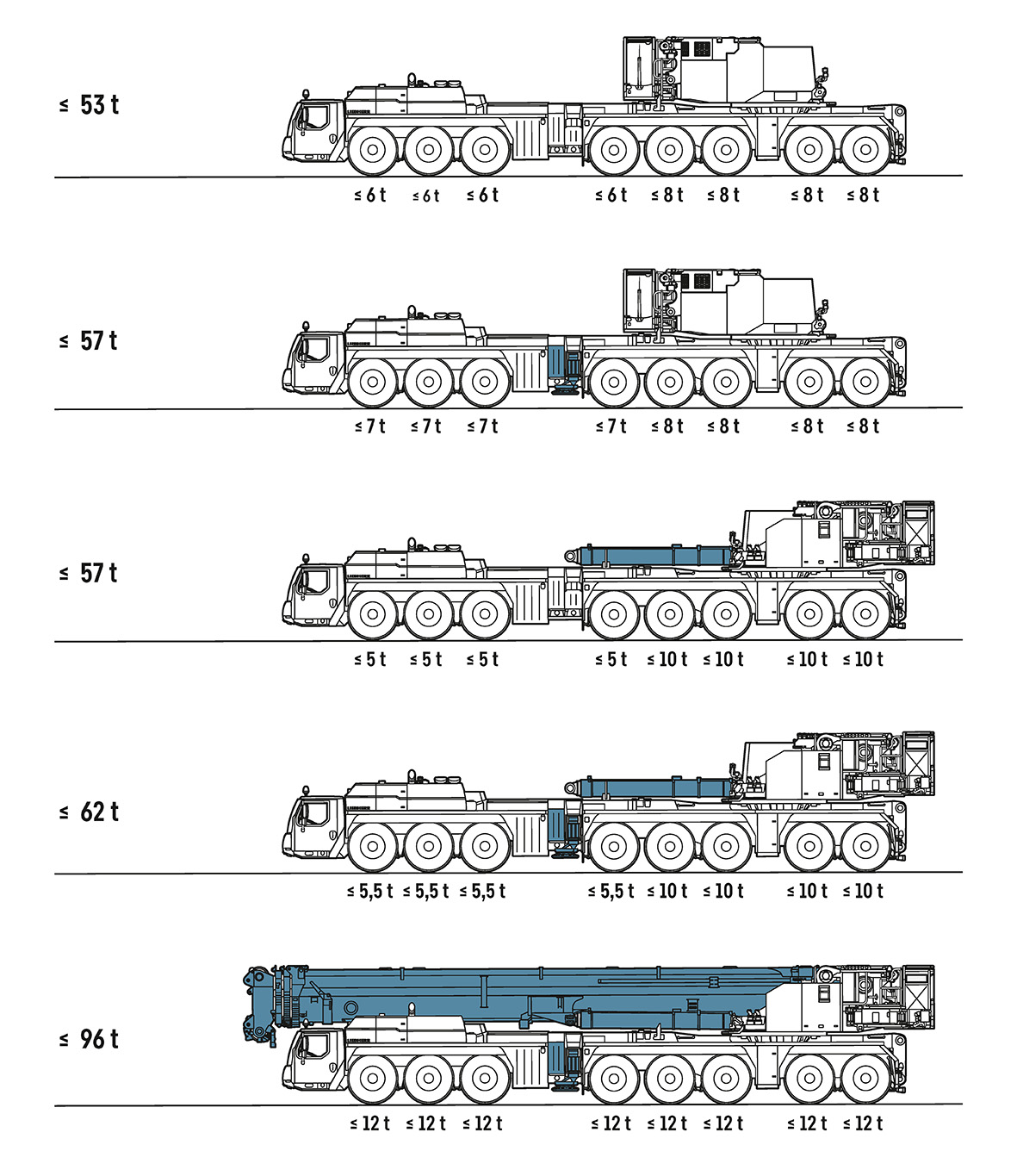

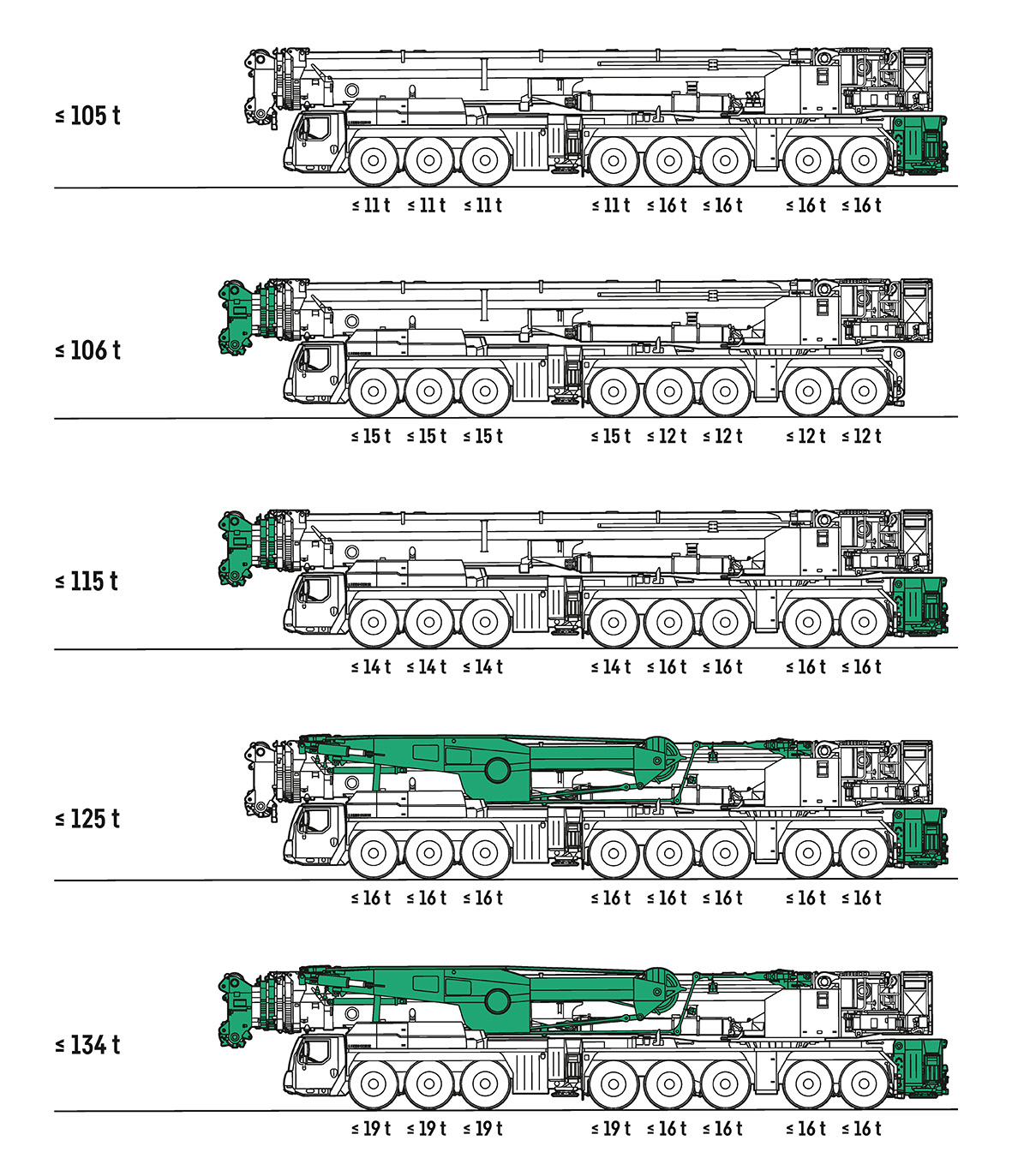

Driving conditions

On-road driving

Jobsite driving

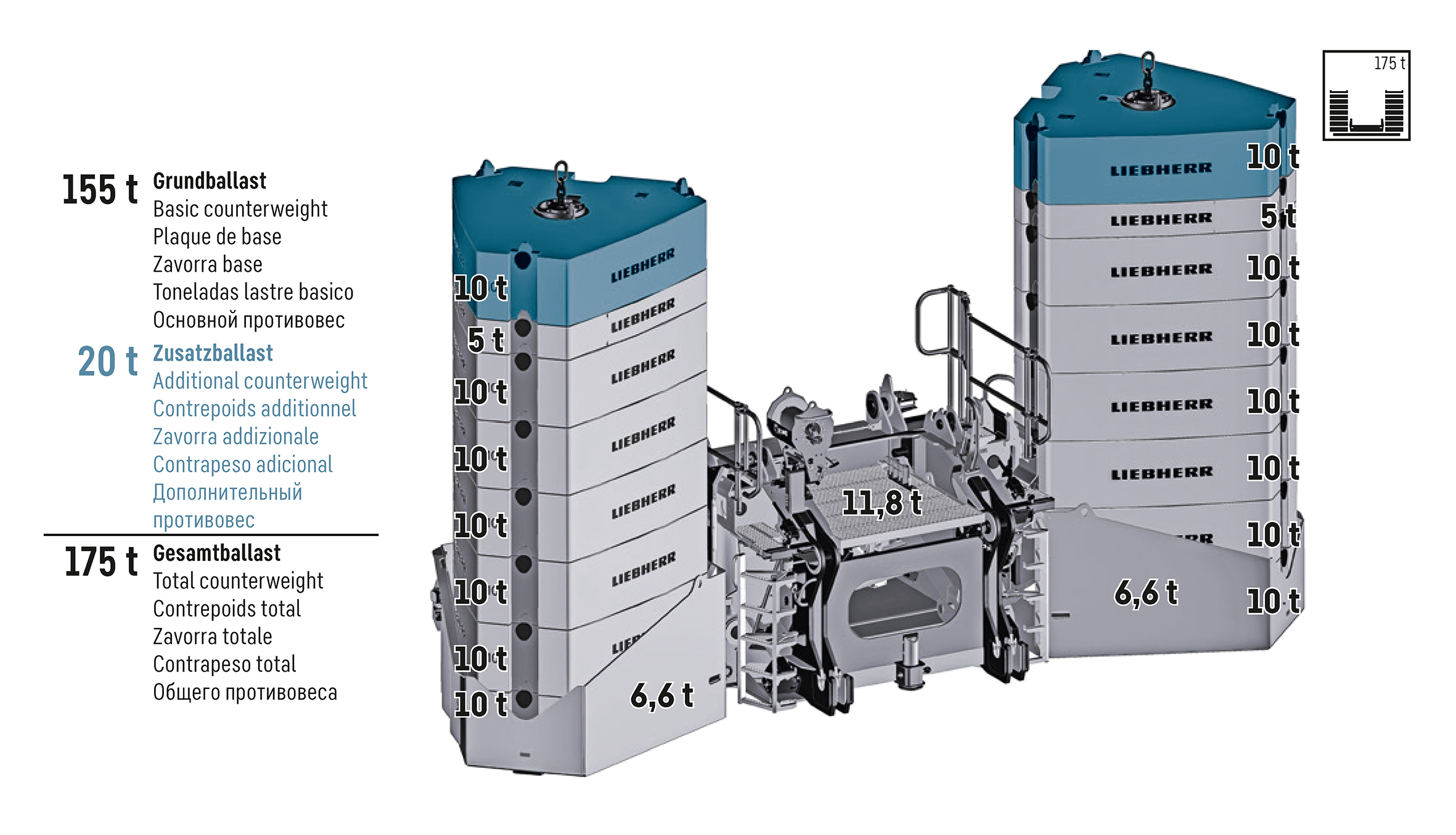

Ballast systems

Counterweight

VarioBallast: Counterweight radius

Technology

ECOmode

ECOdrive

Single-engine concept

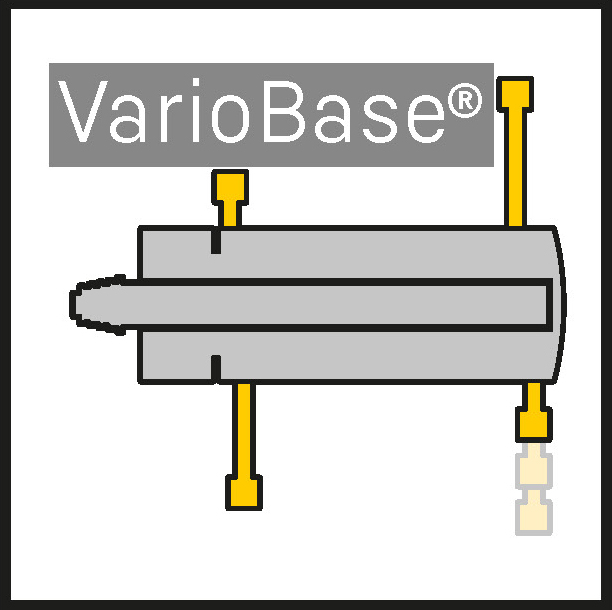

VarioBase®

VarioBallast® (hydraulic)

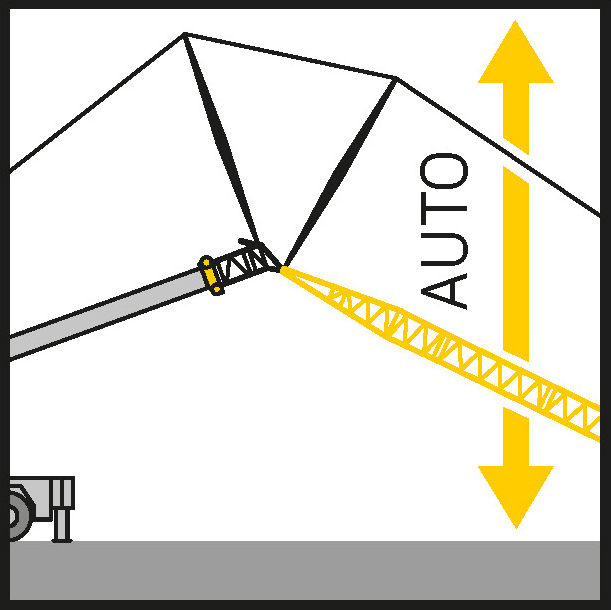

Automatic erection of the luffing jib

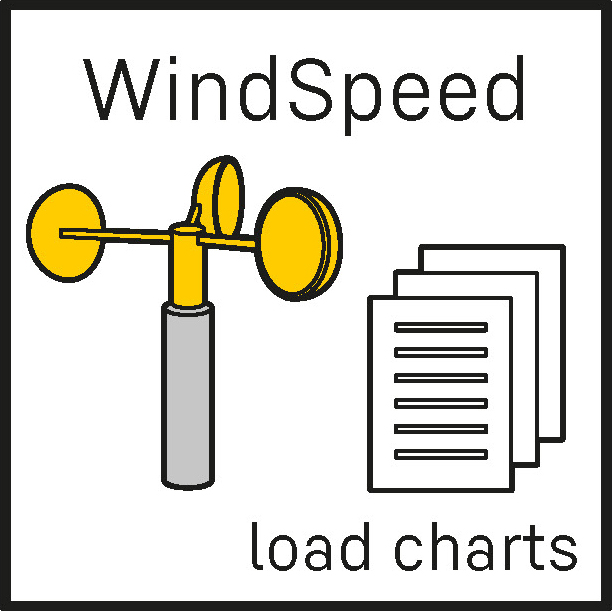

WindSpeed load charts