The RL series – compact and versatile

On both fixed and floating offshore installations, especially in the wind power industry and in the oil and gas sector, RL cranes are mainly used for maintenance and supply work.

The particularly weight-optimized and compact design is the characteristic feature of the RL series. The small tail radius as well as the low construction height make the ram luffing crane an ideal application for small and unmanned platforms or vessels. Depending on the model, lifting capacities of up to 100 tonnes are possible.

Excursion on the RL 2600

On our test stand at our Rostock plant, our expert will take you on a tour of the RL 2600. Let yourself be inspired by our most compact crane solution from Liebherr's offshore portfolio!

30 t max capacity

30 m outreach

30 t max capacity

36 m outreach

50 t max capacity

42 m outreach

75 t max capacity

48 m outreach

100 t max capacity

55 m outreach

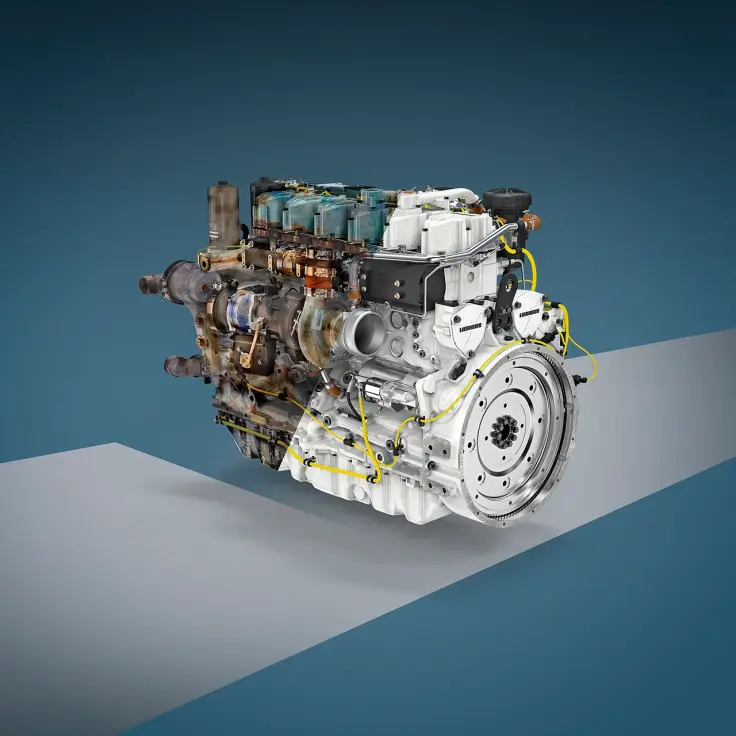

Drive systems

Electric drive

Diesel-hydraulic drive

Special features of the RL series

Winches relocated to the boom

Easier and safer handling of the crane due to no adjusting of rope lengths during luffing needed

High comfort cabin

Improved ergonomics and new air conditioning ensures low-fatigue work even in difficult offshore conditions

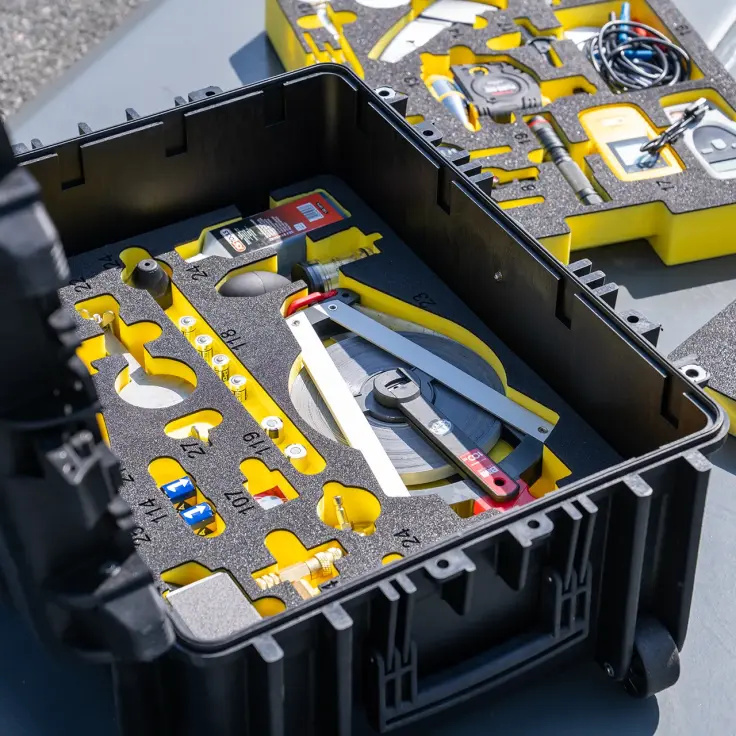

A new age of maintenance

LiMain, modularity of main components and additional platforms ease all maintenance processes to a minimum

Compact design

Machine house included in slewing column resulting in a small tail radius

Talk to our specialists

Customer voice

"For platform operators, weight and space requirements for equipment are key cost elements. Any reduction ensures savings, which is why Liebherr's RL crane is the number one choice. It is lightweight, reliable and flexible in terms of positioning. In addition, our crane operators are delighted with the ease of maintenance and sensitive crane control."

Steve Haro, Head of Operations, Navtech Marine Services

The RL series in a nutshell

Assistance systems and digital solutions for ram luffing cranes

EXpressure

A special feature of the new RL crane series is the innovative cabinet inside the slewing column. The technology behind this innovation is called "EXpressure", the world's first explosion-proof Ex d cabinet that safely releases explosion pressure. It has been developed by our partner R. Stahl AG.