Journey to Tema

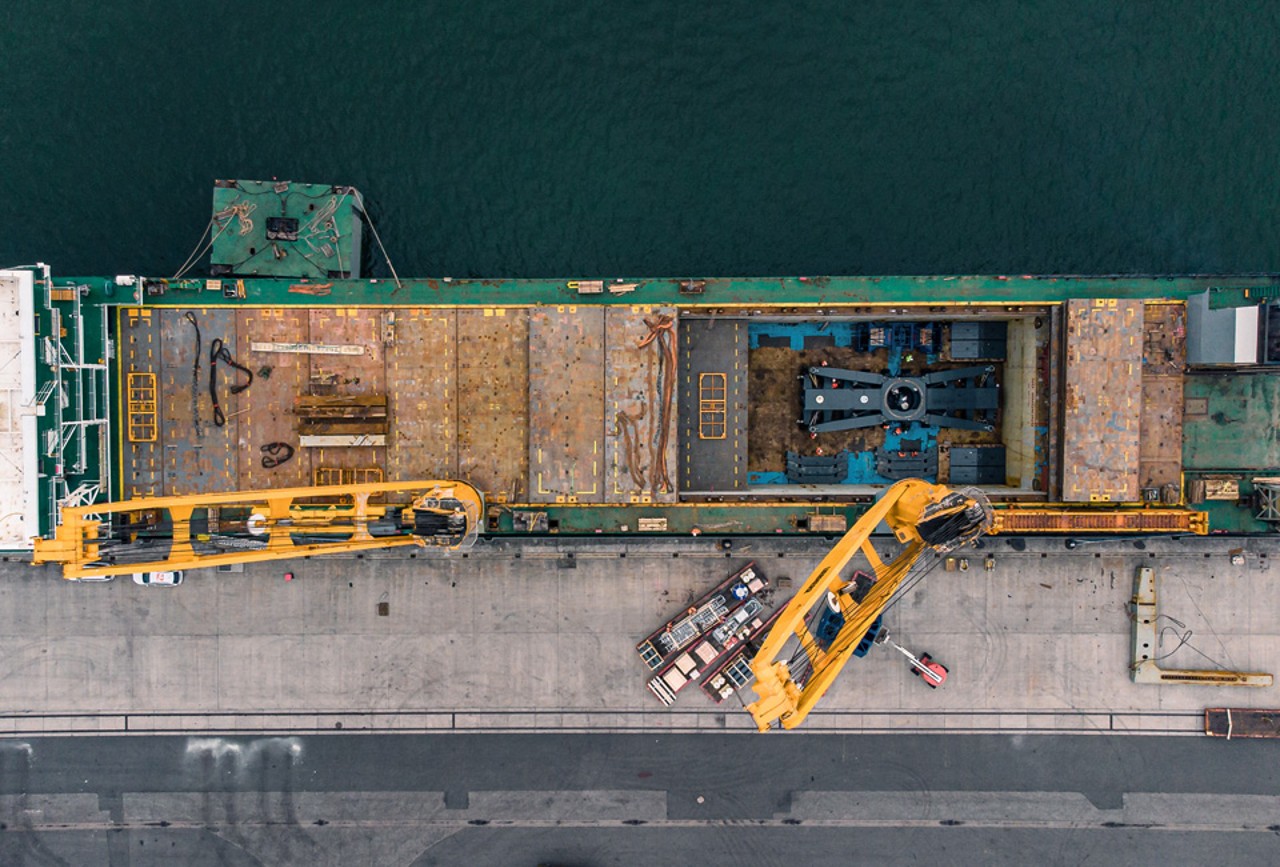

Two Liebherr mobile harbour cranes, weighing 454 tons each, were lifted onto the weather deck of the multi-purpose heavy-lift vessel BBC Russia in just two days, including lashing for a safe ocean voyage. The cranes, two CBB 3800-250, have a maximum lifting capacity of 250 tons each. The carrying vessel has a deadweight of 12,400 mt, its two Liebherr ship cranes used in the operation have a combined lifting capacity of 500 mt.

Big businesses need big data

The focus of the LiDAT smartApp is on making processes faster, more environmentally friendly and more cost-efficient. The web application offers the possibility of detailed analysis and shows starting points for improving the efficiency of handling processes. This gives you the opportunity to realise huge competitive advantages. Since its launch in 2018, the software has evolved significantly and established itself as a digital bestseller in the maritime sector. Benefit from the power of big data analytics.

Sign up now!

Stay up to date with our latest product highlights, innovative technologies and exciting jobsites.