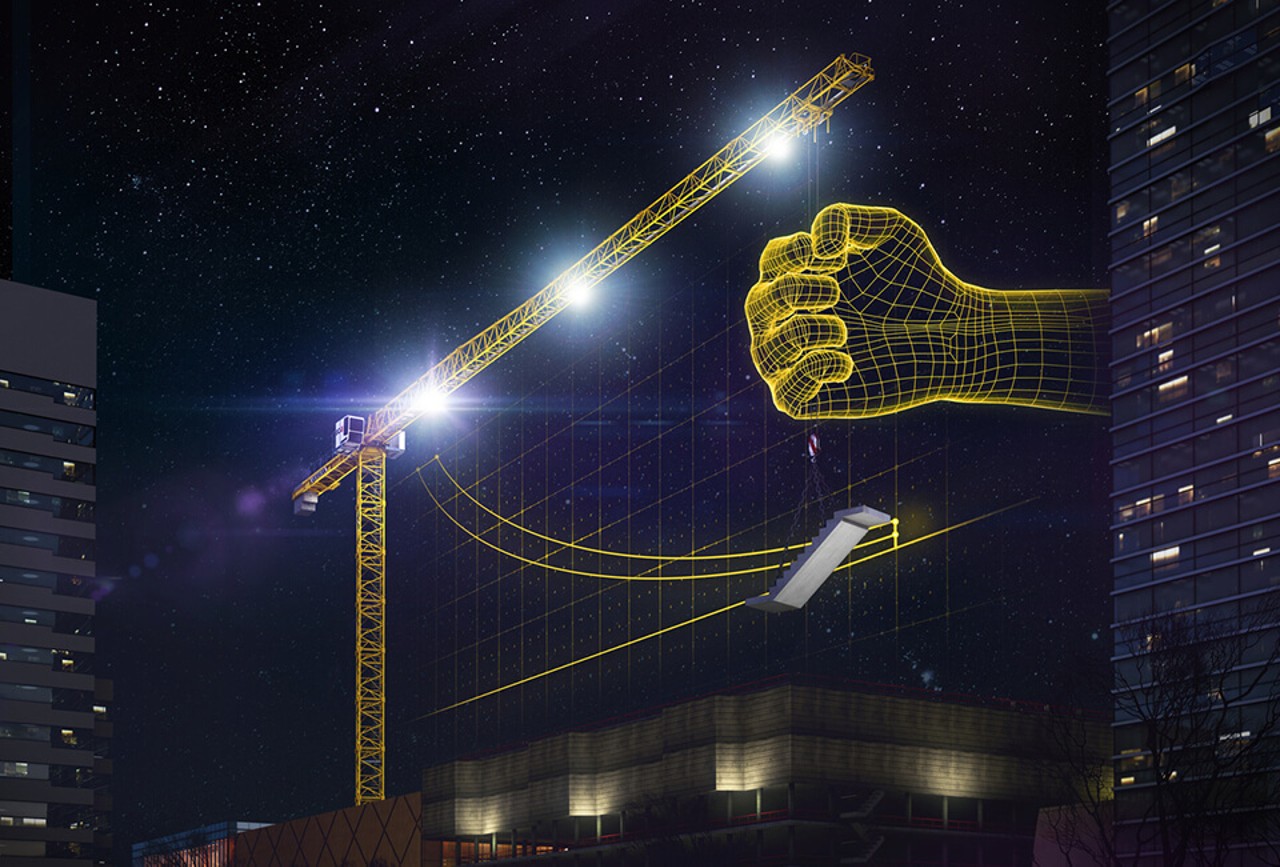

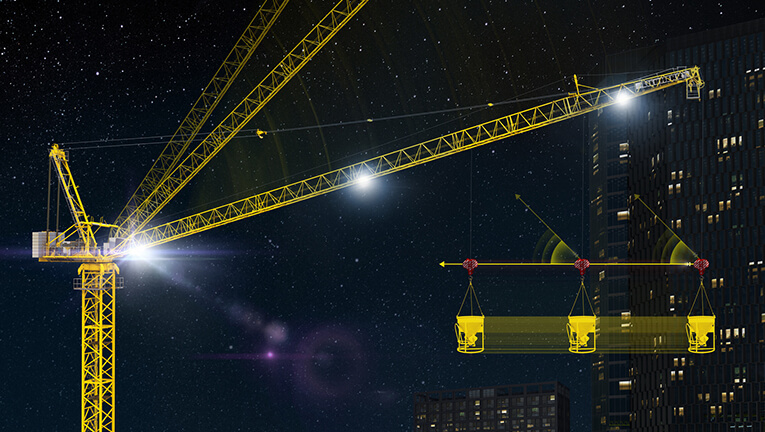

LEVEL LUFFING

Moves loads in a straight line.

Precise movement of loads is indispensable for efficiency and safety on the construction site. Filigree prefabricated building elements, the use of glass or light alloy components, concreting work under time pressure and the ever smaller construction sites are challenges that need to be mastered by crane operators.

The level luffing function makes the crane operator’s work easier, as he does not have to readjust the height of the load manually. This allows him to concentrate on positioning the load. That makes work on the construction site more efficient and enhances safety for everyone involved.

If the assistant is activated when moving the jib, the control system automatically readjusts the hoist gear. The exact calculation means the load can be moved along a horizontal line. Such precise work is possible with concreting work in particular.

The level luffing can be used flexibly. Depending on the type of hoisting, the crane operator can decide whether to use the assistant or not. The level luffing can also be activated or deactivated during hoisting.

SAFETY AND COMFORT

FULL CONTROL LEVER DISTANCE AVAILABLE AT ALL TIMES

The Litronic control system means the full control lever distance is always available, irrespective of the potential speed.

PRECISION IN THE WIND

The control sensor registers the movements of the jib using high resolution sensors and counteracts the movements caused by the wind.

KEEP YOUR LOAD UNDER CONTROL

The integral oscillations-damping system compensates for fast slewing and braking manoeuvres.

SLEW HOWEVER YOU WISH

A short familiarisation time as every crane operator can decide on one of three slewing gear modes and tailor it to suit his preferences.

THE HUMAN-MACHINE INTERFACE

Electronic monitoring system (EMS)

The best control system also includes a clear and unambiguous operation. The EMS 4 with the TC-OS user interface is optimised for an intuitive operation. A menu navigation geared towards the different user roles, clear control elements and an intuitive presentation make work with our assistance systems child's play.

The right view

Eliminating distractions and displaying exactly what is needed. You can display different operating pictures depending on requirements, site situation and personal preference and complete them with additional information. The camera can also be shown on the display.

Targeted relocation

The EMS display is a useful aid when positioning loads. Besides indicating the trolley position, reference points can also be set. This means that the crane can return to a specific handling point again and again.

During servicing

The display also helps to prevent downtimes. It shows warnings and error messages in plain text. This allows you to respond right away and avoid potential interruptions in advance.

CONTROL STAND

ERGONOMIC CONTROL STAND

The control stand in the Liebherr cabin sets new ergonomic standards.

CONTROL LEVERS

The control levers provide access to all the essential functions of the crane, including the special Micromove and Load Plus functions.

RADIO CONTROL

Besides controlling the crane from the cabin, we also provide radio controls for all crane models.

HOOK CAMERA

You can keep the load in view at all times on the screen in the cabin using autofocus and zoom.

CONTACT

Want to master working with the Tower Crane Litronic?

The training centre at Liebherr-Werk Biberach GmbH provides a range of training courses covering all aspects of controlling and working with cranes.

More information at

www.liebherr.com/tc/training