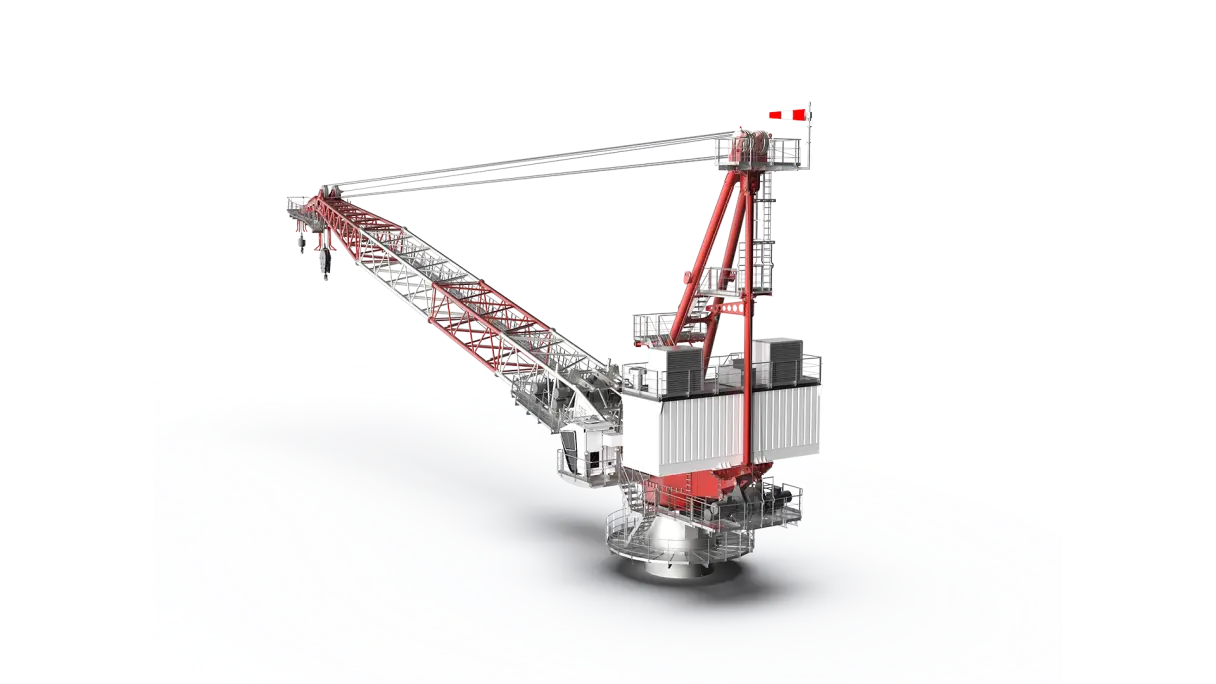

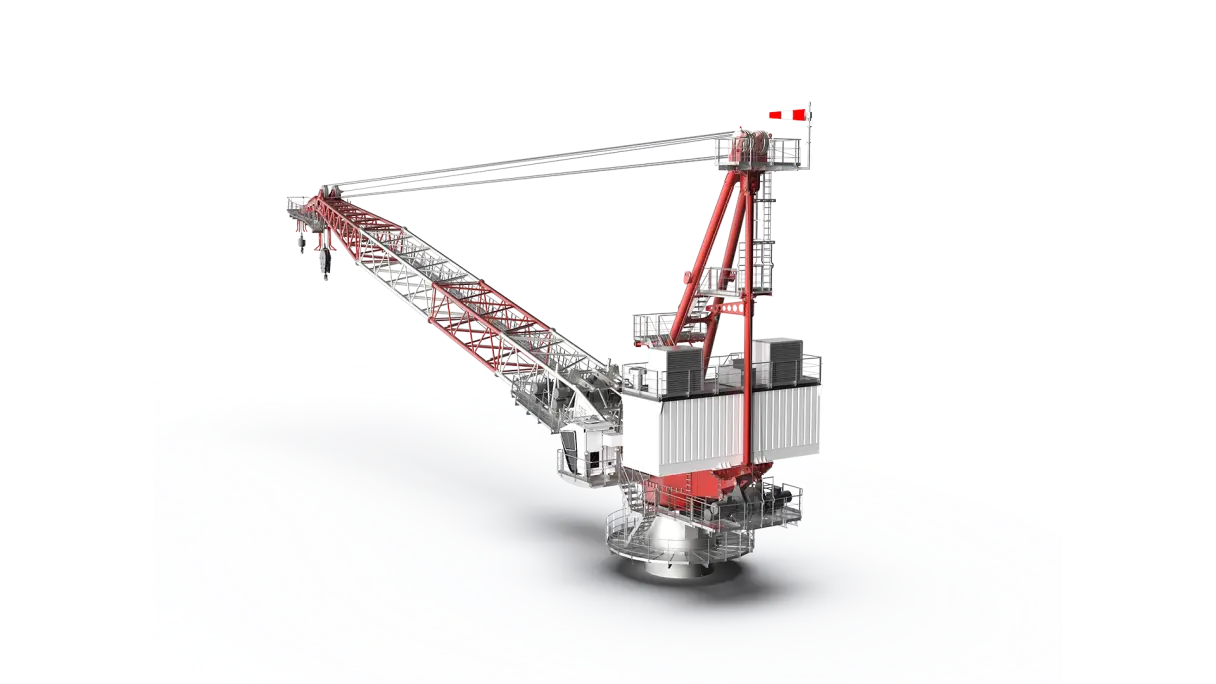

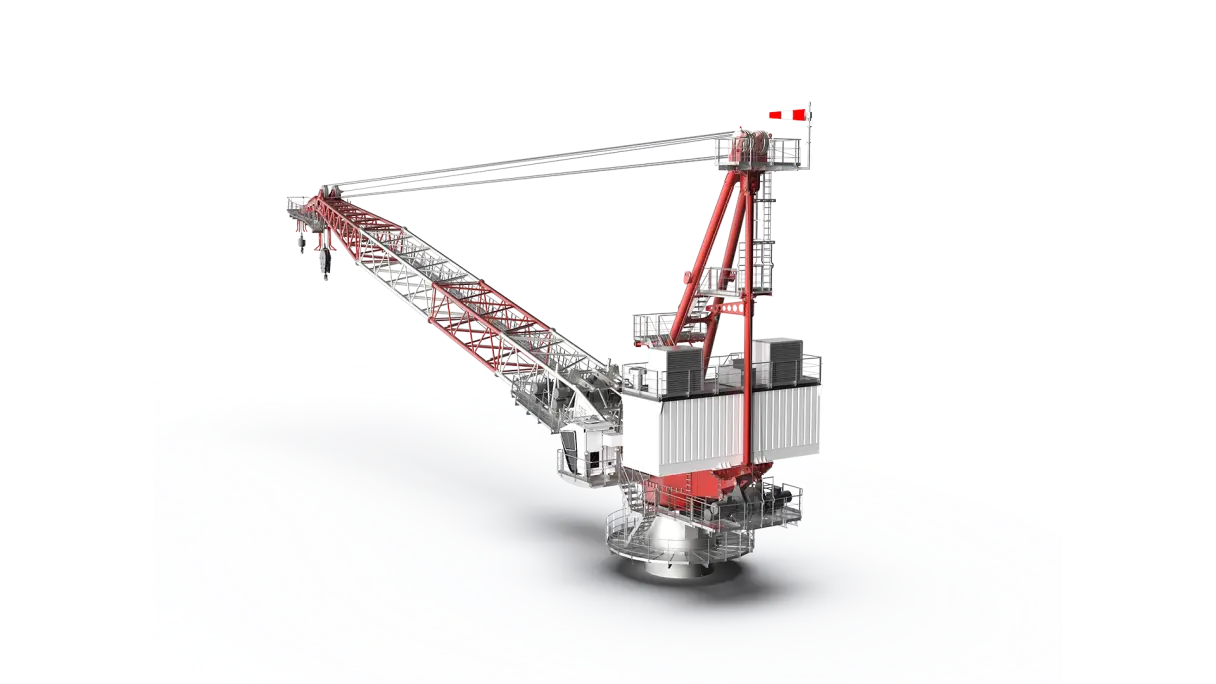

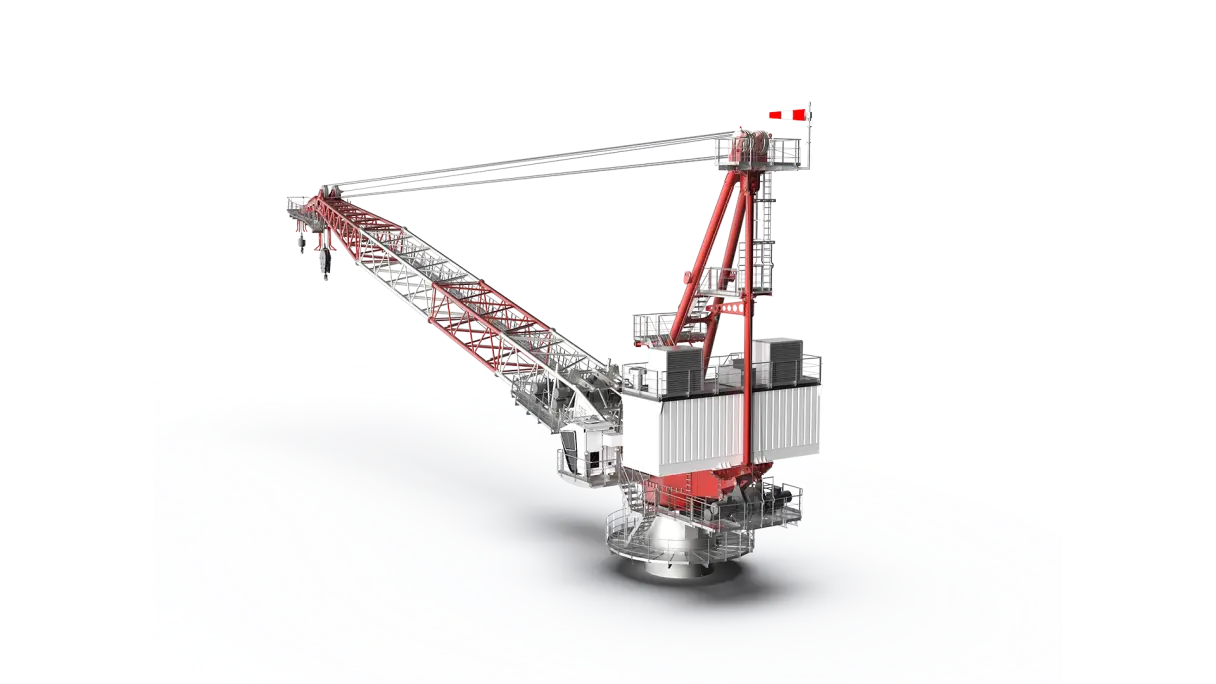

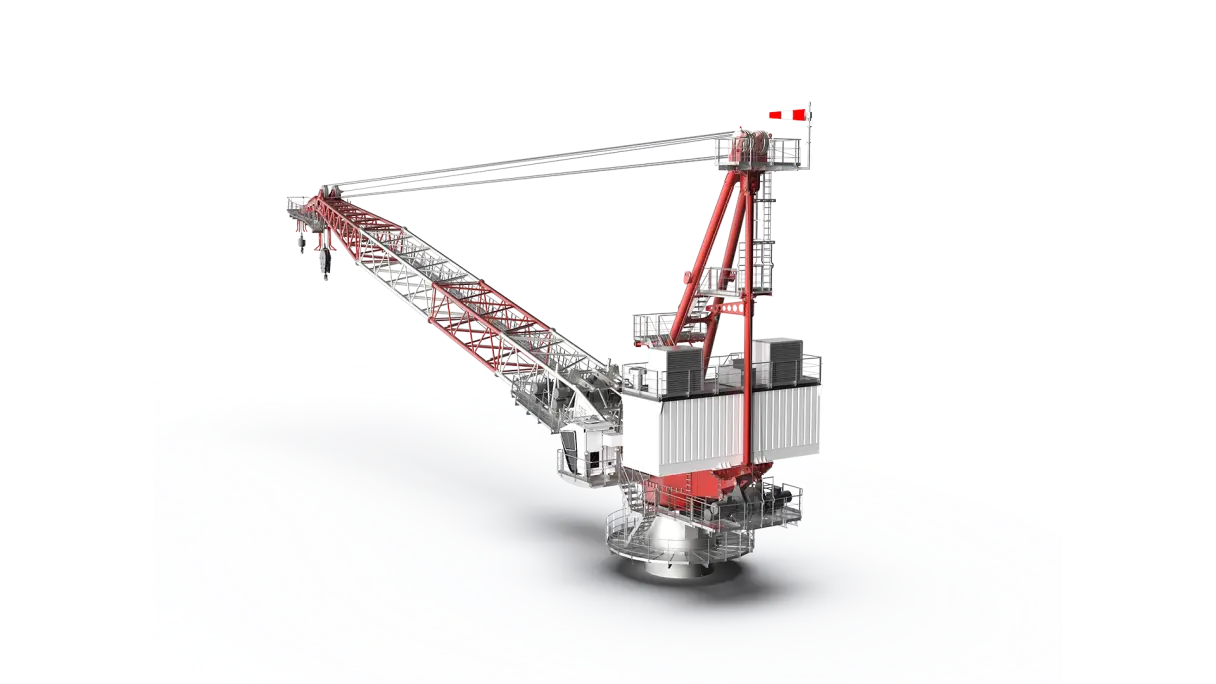

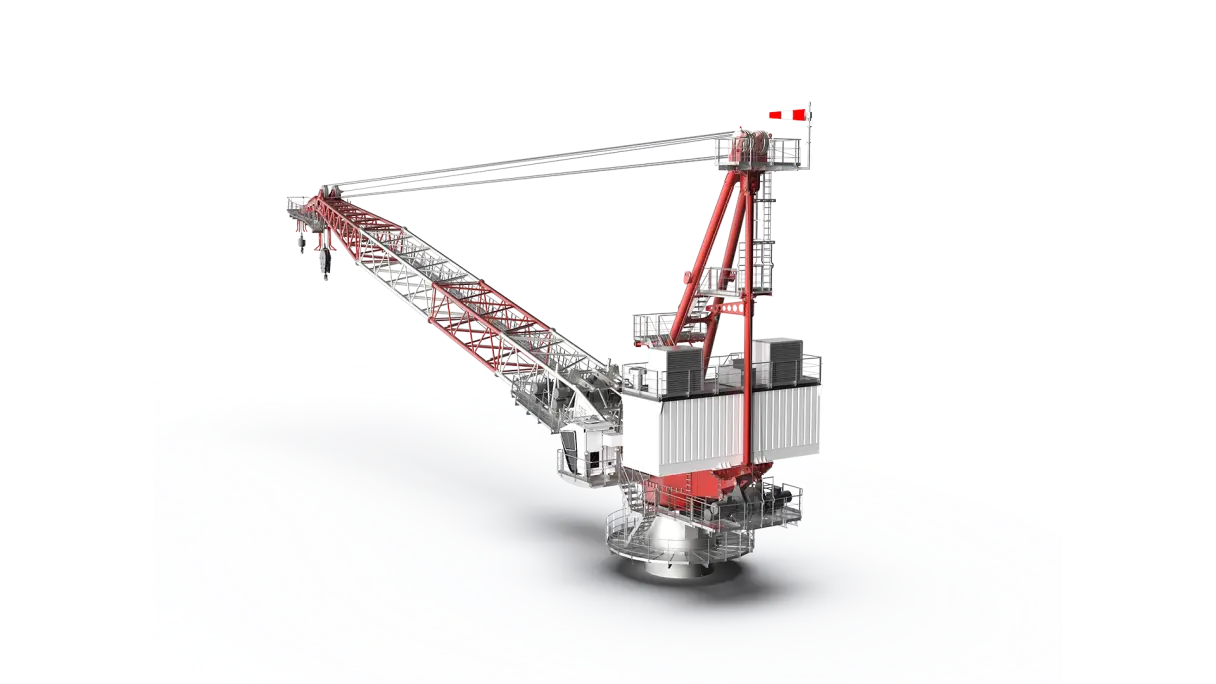

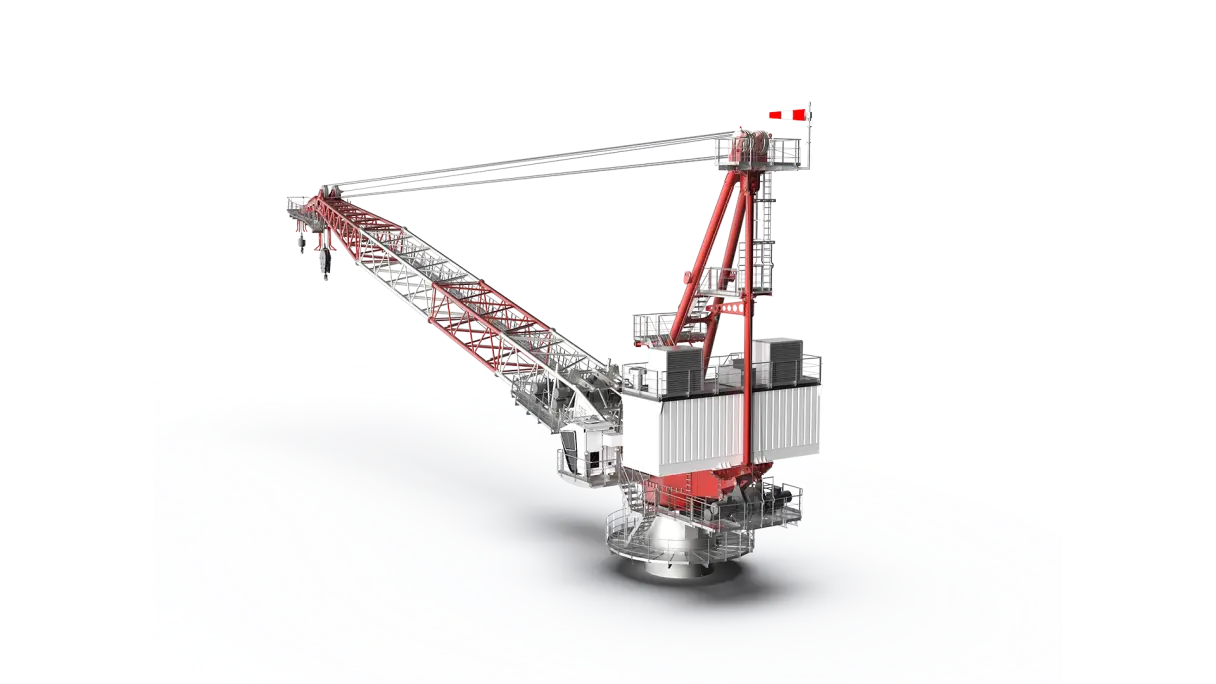

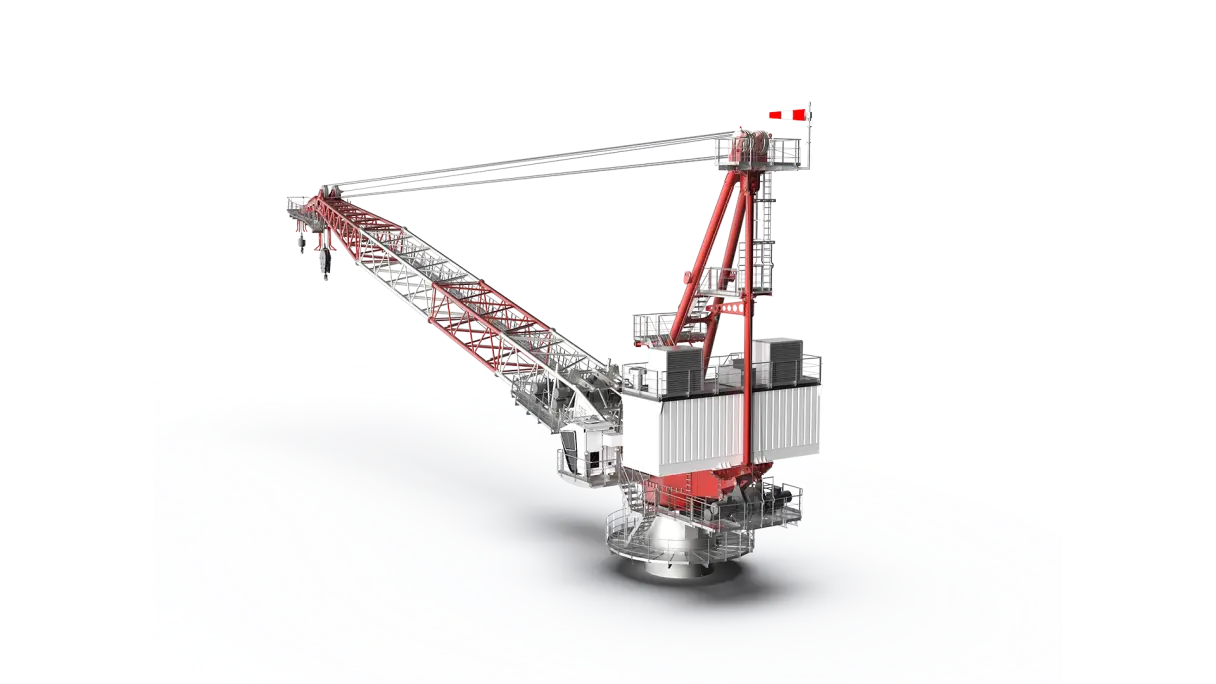

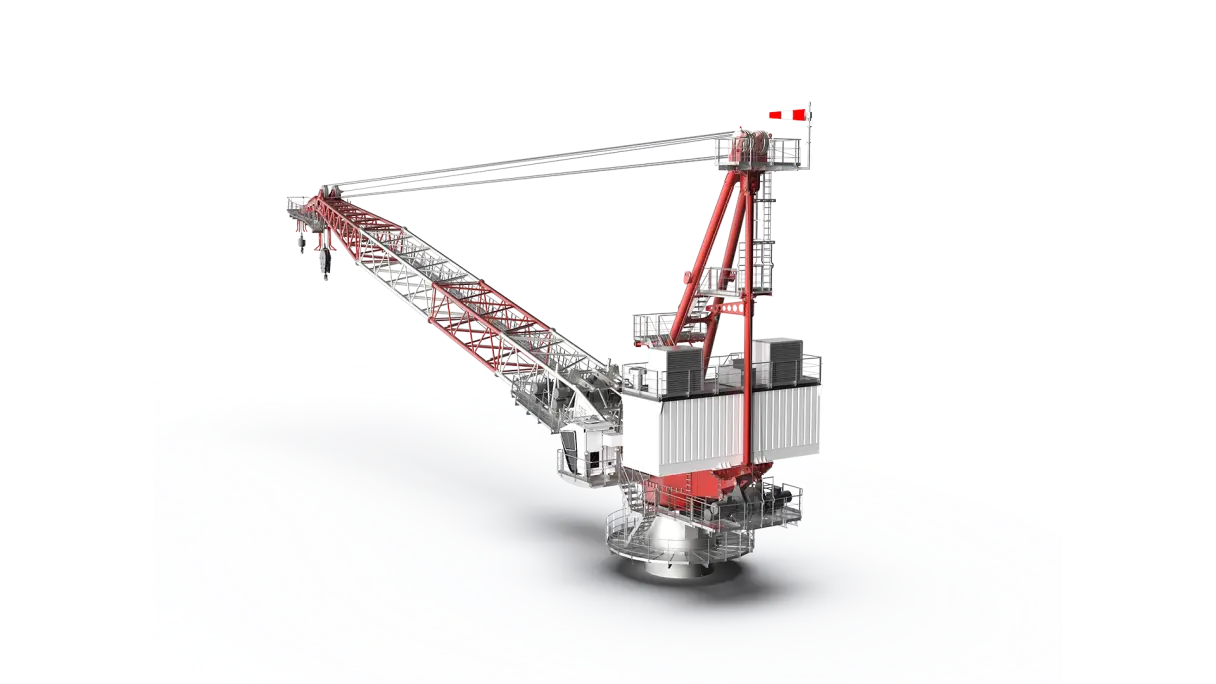

The BOS series – Unmatched quality in offshore cranes

Our Liebherr BOS offshore crane series stands out for its exceptional quality, flexible deployment, and compact, function-oriented design. Featuring Liebherr’s in-house Litronic crane control system, the BOS is a top choice among operators and a global leader in the offshore crane market. This state-of-the-art slewing bearing crane with a wire luffing mechanism offers a versatile drive train, available in all-electric, electro-hydraulic, or diesel-hydraulic configurations.

The BOS 2600 in a nutshell

Designed for applications requiring high lifting capacities at medium or long outreach, the BOS is the ideal choice. Take a look at the BOS 2600 together with our colleague on the test stand in Rostock.

Various crane sizes depending on customer needs

| Crane type | BOS 2600 | BOS 4600 | BOS 4600 E | BOS 7500 | BOS 14000 | BOS 35000 | BOS 45000 |

| Max. lifting capacity | 75 t | 140 t | 100 t | 300 t | 600 t | 1,250 t | 1,400 t |

| Boom length | 57 m | 69 m | 69 m | 84 m | 102 m | 102 m | 102 m |

| Slewing radius | 360° unlimited | 360° unlimited | 360° unlimited | 360° unlimited | 360° unlimited | 360° unlimited | 360° unlimited |

| Overturning moment | 2,600 tm | 4,600 tm | 4,600 tm | 7,500 tm | 14,000 tm | 35,000 tm | 45,000 tm |

Key elements of the BOS

A-frame

Find out more

Comfort offshore cabin

Find out more

Hoisting winches

Find out more

Slewing platform

Find out more

Machinery house

Find out more

Lattice boom

Find out more

Main/auxiliary hoists

Find out more

Boom walkway

Find out more

Get in touch

Offshore crane performance put to the test

Before our cranes are put into action, they go to the ultimate test: a full-scale performance check. Project manager Raik Wichmann gives a behind-the scenes look at the cranes’ key features, while the team puts them through their paces with precision and power.

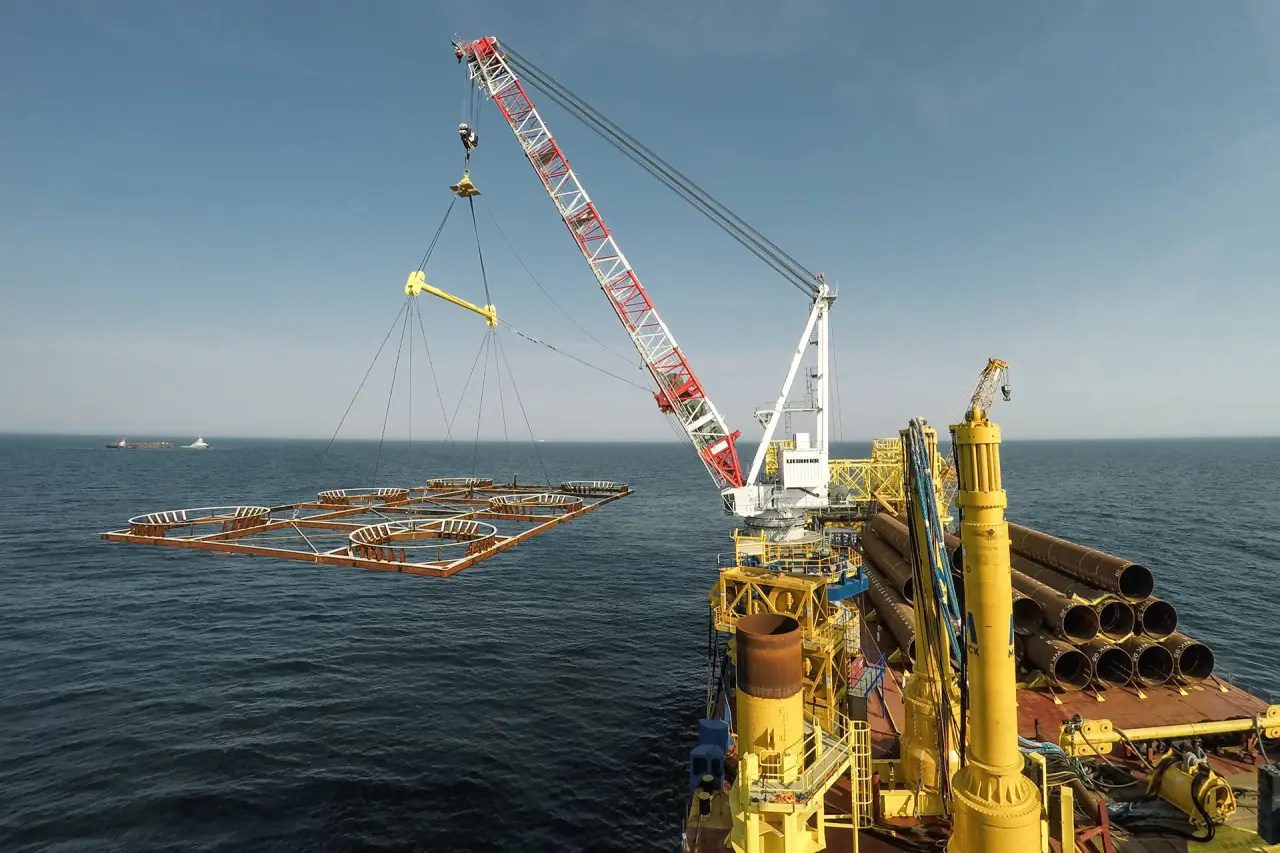

Our BOS giants

Meet our BOS giants, the BOS 35000 and BOS 45000, engineered to tackle the most demanding heavy-duty applications. With their impressive lifting capacities and exceptional outreach, these cranes are perfect for large-scale offshore projects, ensuring efficiency, reliability, and flexibility. Whether you're installing offshore wind parks or handling massive components for oil and gas platforms, our BOS giants are ready to elevate your operations to new heights.