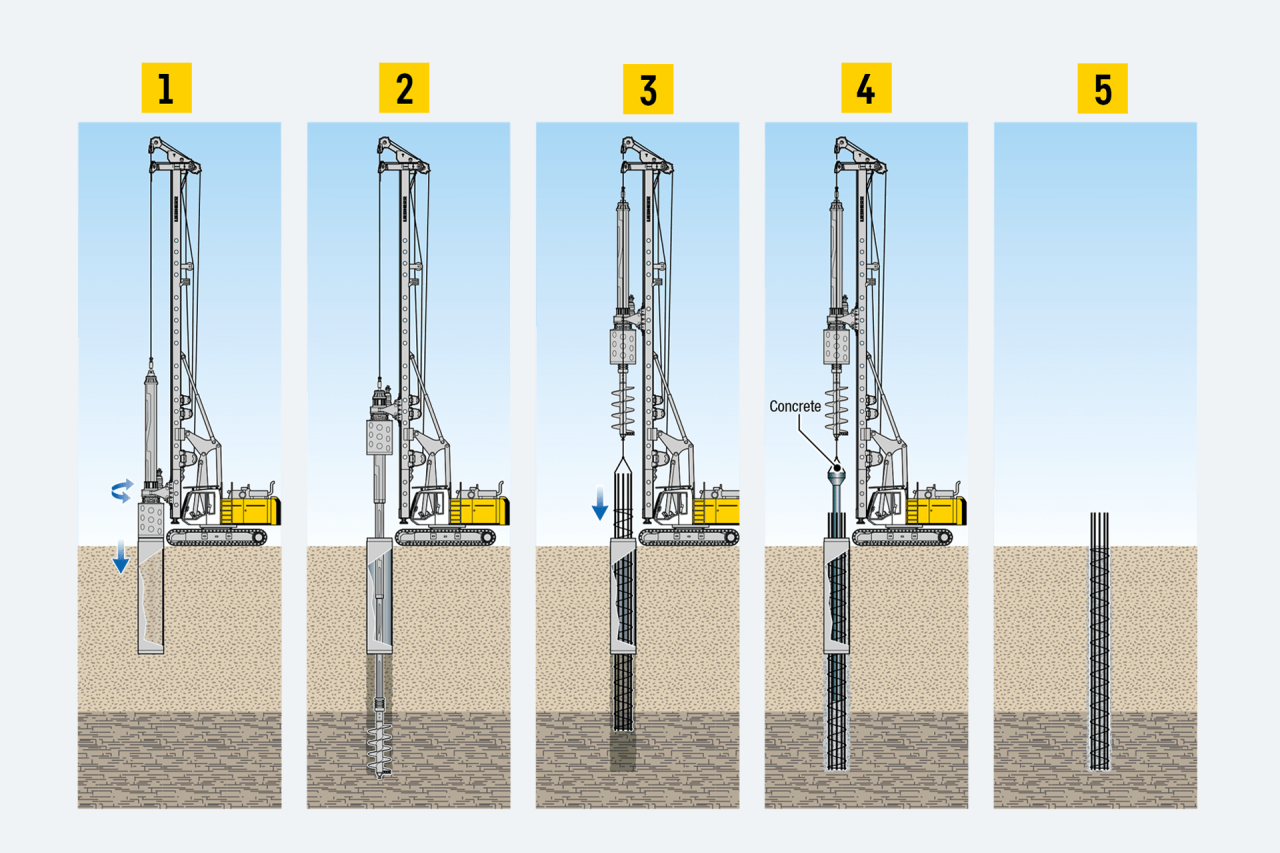

Kelly drilling belongs to the most common dry rotary drilling methods and is used for the production of bored piles with a large diameter (from a size of approx. 500 mm). The process is suitable for nearly all types of soil and rock. The soil is conveyed with relatively short rotary drilling tools, such as augers, core barrels, buckets and special drilling tools. A typical element of this drilling method is the drill rod, the so-called Kelly bar, which is telescopic and facilitates large drilling depths.

Video Kelly drilling

The video shows Liebherr drilling rigs in different Kelly drilling applications.

01/08

Machines

Results 1-6 of 11

1

2

01/06

It was close!

Spectacular performance of LB 36