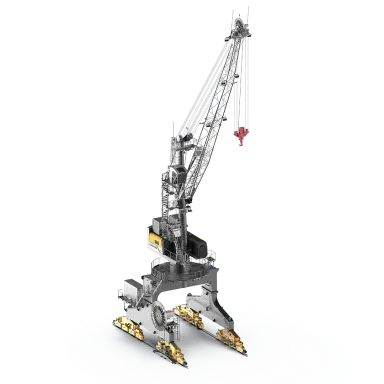

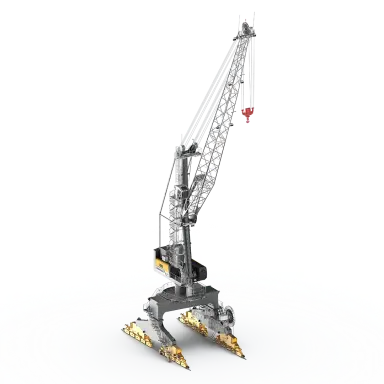

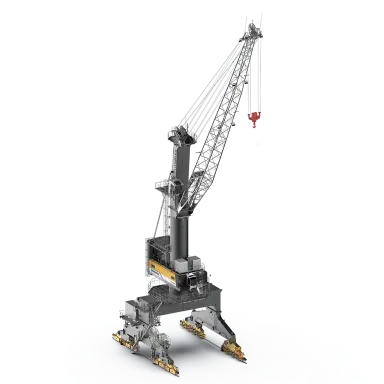

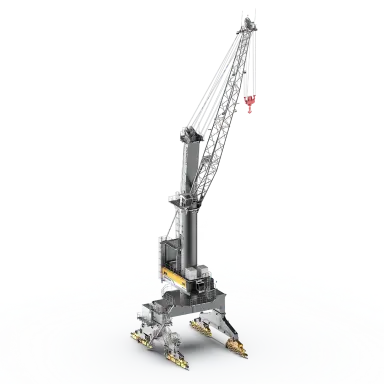

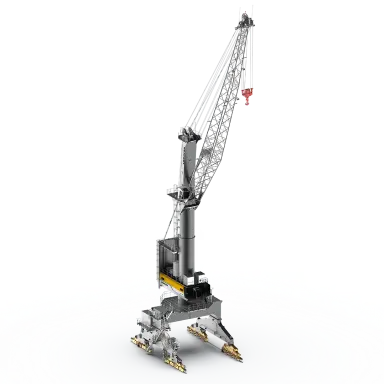

Individual portal solutions on rails

Compare Liebherr portal slewing cranes

| LPS 180 | LPS 280 | LPS 420 | LPS 550 + High Rise | LPS 600 + High Rise | LPS 800 + High Rise | |

| Max. lifting capacity | 64 tonnes | 84 tonnes | 124 tonnes | 154 tonnes | 208 tonnes | 308 tonnes |

| Outreach | 35 metres | 40 metres | 48 metres | 54 metres | 61 metres | 66 metres |

| Hoisting/lowering speed | up to 90 m/min | up to 115 m/min | up to 120 m/min | up to 120 m/min | up to 120 m/min | up to 140 m/min |

| Bulk material handling (*Performance data under ideal conditions.) | up to 600 t/h | up to 800 t/h | up to 1,500 t/h (2,000 with Pactronic) | up to 1,500 t/h (2,000 with Pactronic) | up to 1,800 t/h (2,300 with Pactronic) | up to 1,800 t/h (2,300 with Pactronic) |

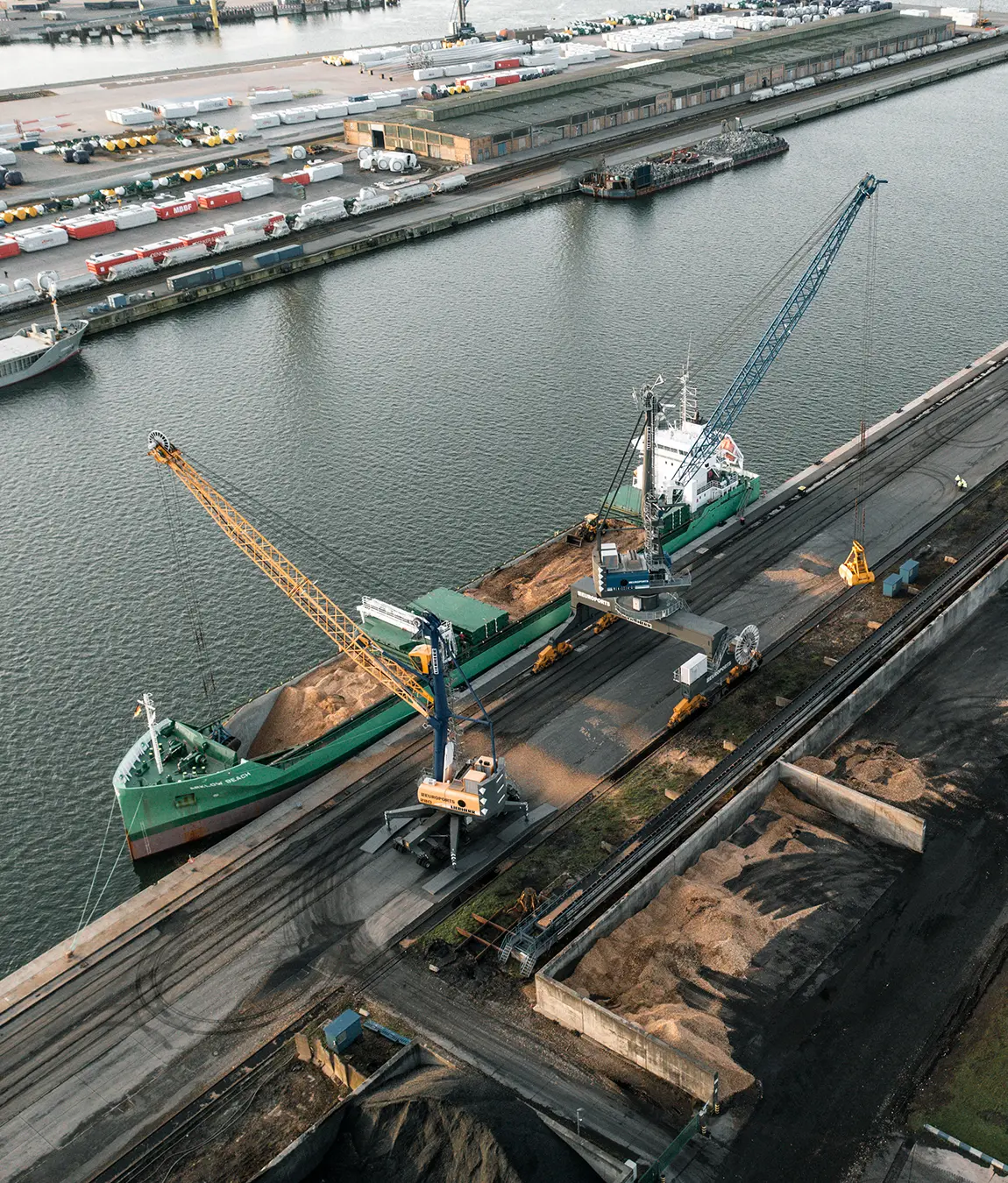

Our portal slewing cranes in action

Versatile drive systems

Electric drive

Diesel-hybrid

Reasons to choose the portal solution

High performance

Tailor-made design

Turnkey solution

Narrow finger pier

Infrastructure compatibility

Rail-connected berth

Assistance systems and digital solutions for portal slewing cranes

LPS application areas: Supporting a wide range of cargo types

Container handling

The LPS is built for terminals managing general cargo and complex heavy-lift operations. With safe working loads of up to 308 tonnes and a choice of lifting attachments such as hooks, spreaders, and grabs, it handles oversized items including project cargo, machinery, and steel components with precision. Alongside this versatility, the LPS supports efficient intermodal transfer of steel coils, billets, and plates between vessels, railcars, and trucks, reducing handling steps for steel terminals that process both raw materials and finished products. This combination of high lifting capacity and adaptability makes the LPS a reliable solution for ports requiring flexibility across diverse cargo types.

Bulk material handling

High-volume bulk handling is at the core of the LPS, delivering turnover rates of up to 2,300 tonnes per hour. SmartGrip technology ensures optimal grab filling, reducing overloads. The LPS adapts seamlessly to food-related cargo such as raw and refined sugar, soybeans, and grain. Its quick-change lifting attachments allow terminals to switch between bulk, bagged, or containerised goods, supporting flexible operations as market demands shift. This blend of speed, precision, and adaptability makes the LPS a trusted solution for ports managing diverse cargo flows.

General cargo and heavy lifts

Efficient container handling is a core strength of the LPS, supporting smooth intermodal operations across ships, trains, and trucks. Advanced slewing and hoisting systems enable rapid, precise positioning, ensuring containers are loaded and unloaded with minimal delay. This precision reduces vessel and carrier turnaround times, helping terminals maintain high productivity in demanding environments. The LPS is designed for adaptability, allowing seamless integration into existing port layouts and supporting the movement of containers between different transport modes without disruption. Its robust construction and reliable performance make it a trusted solution for ports where intermodal efficiency and operational flexibility are essential.

MyLiebherr as your personal customer portal

- Individual management of your machines

- Ease of contact with your Liebherr service partner

- Straightforward and secure management of your customer data

- Instant access to the latest documentation and parts list of your machine

- Simple parts ordering from your Liebherr service partner

FAQ

Portal slewing cranes offer a space-saving design by operating on rails, which keeps the quay clear for other activities. They provide excellent lifting capacity and outreach while ensuring smooth, efficient cargo handling. Their elevated structure allows trucks and rail wagons to pass underneath, optimising terminal logistics. This configuration is ideal for ports with limited space or high traffic, combining flexibility with robust performance for long-term operational efficiency.

Yes. Liebherr portal slewing cranes can be tailored to meet specific operational needs. Options include but are not limited to customised portals and outreach configurations to suit terminal layouts. Additional features such as specialised lifting equipment, various drive systems, and assistance packages can also be integrated. This flexibility ensures optimal performance for diverse cargo types and site conditions, delivering a solution that aligns precisely with your operational requirements.

Portal slewing cranes require a rail-mounted foundation designed to support the portal structure and ensure precise alignment. The installation process includes preparing the boogy system according to their rails. Liebherr provides detailed specifications and guidance during planning. To define exact requirements, we offer a comprehensive survey that captures site conditions and operational needs, ensuring a tailored solution for efficient and safe installation.

Liebherr offers advanced digital solutions through its LiDAT data management system, providing real-time monitoring of crane performance, energy consumption, and maintenance status. Additional features include remote diagnostics, predictive maintenance tools, and integration with terminal management systems. These solutions help optimise operations, reduce downtime, and support data-driven decision-making for improved efficiency and reliability.

Yes. Liebherr portal slewing cranes are designed with future adaptability in mind. Many components and systems can be upgraded, including drive technology, digital monitoring tools, and automation features. Our engineering team evaluates each retrofit to ensure compatibility and performance benefits. To define the best upgrade path, we recommend completing our technical survey, which helps identify opportunities for modernisation based on your operational requirements.