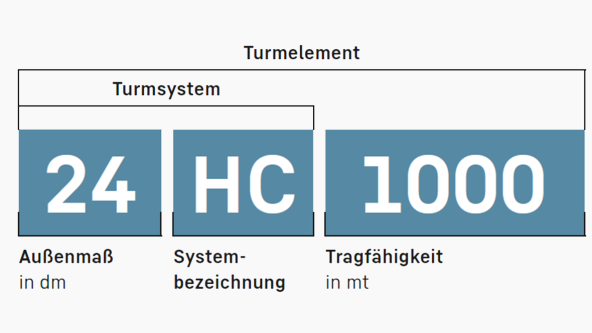

Our tower systems offer the right solution for every challenge. Discover the flexibility each system offers and combine them to maximise lifting capacities. The tower systems' logically structured designations show key characteristics at a glance for extra clarity. Increasing external dimensions increases the tower's lifting capacity but also the space required at the tower's base. Find the right solution for your crane to make your projects a success.

Our tower systems

Download

Further details on our tower systems are available in our brochure.

Site-specific crane foundations

Every construction site has its own challenges. We offer several different options to make sure our cranes can be optimally positioned on your construction site:

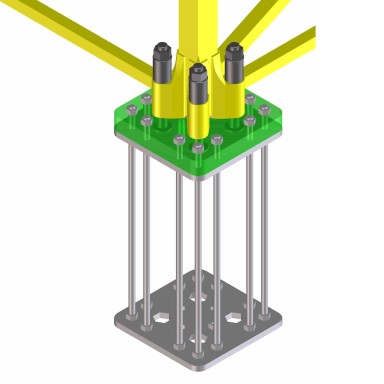

If space is very limited, our cranes can be mounted on foundation anchors. These are set in concrete in the building’s foundation.

Designed for repeat use, as part of the anchor is reusable. More sustainable than standard foundation anchors, as they reduce the amount of steel required and minimise transport costs.

The use of a cruciform base is a particularly efficient foundation solution in terms of transport and assembly.

Our customers can rely on various options to compensate for unevenness, including screw jacks, support pads and pyramidal supports.

The only way to move a crane under load is to use an undercarriage on rails. This allows the crane’s working range to be extended.

Climbing on/inside buildings

Climbing is the solution when a project's requirements can’t be met using a crane's possible free-standing hook height. Two options are available here:

Climbing on the building

The crane is set up outside the building. Tie-ins are used to secure the crane to the building for structural stability. This allows the crane to grow upwards parallel to the building.

Climbing inside the building

The crane is positioned inside the building, for example in a lift shaft. As construction progresses, the crane can be climbed upwards with the help of a hydraulic power pack. The crane is then secured in the building using climbing collars.