Material handling machines

Mobile material handling machines

Material handlers with wheeled undercarriages are characterised by high flexibility and exceptional mobility. Ideal for demanding tasks where both heavy loads have to be handled and long distances have to be travelled. The choice of different tyres means that the optimum tyres can be selected for the respective operating conditions. In combination with various stabiliser variants, they not only offer excellent stability, but also impressive loads and reach. The precise steering and high working comfort round off the outstanding performance.

Crawler material handling machines

Tracked material handlers set the standard for exceptional performance with their modern, robust and innovative design. The precise crawler undercarriage not only gives these machines excellent traction on a wide variety of ground, but also allows them to move effortlessly. At the same time, the advanced crawler undercarriage of the material handlers ensures a safe stand, no matter how difficult the ground. Performance and versatility go hand in hand in material handlers with crawler tracks to ensure smooth goods handling.

Electric material handling machines

Electric material handlers set a new standard for sustainability in the industry. With their powerful electric motor, they work completely emission-free with power from various sources. The Liebherr frequency inverter further optimises energy efficiency. In addition to stationary use, various cable variants and a battery-powered version enable flexible use on site. The machines not only impress with their low-noise and emission-free operation, but also with their low energy and service costs. In view of growing environmental awareness and stricter emission standards, electric material handlers offer a future-proof solution for efficient and environmentally friendly work processes.

Attachments for material handlers

Liebherr develops and manufactures innovative attachments and quick-coupling systems to the highest quality standards. The choice of the right attachment has a decisive influence on the success of a project. Practical experience and continuous development ensure that Liebherr attachments are always state of the art.

Quick coupling systems

Liebherr has developed the MH 40B Solidlink and MH 110B Solidlink quick-change systems for replacing suspended working tools from the cab in a matter of seconds. During the coupling process, all hydraulic and electric lines are connected or disconnected at the push of a button. This allows the working tool to be quickly and flexibly adapted to the material to be handled. This increases the productivity and efficiency of the handling machine enormously.

Multi-tine grabs

Liebherr orange peel grabs are designed and built for tough scrap handling. The four different tine shapes, specially designed for the nature of the scrap, ensure optimum penetration and safe gripping of the scrap. Depending on the machine size, material shape and composition, four- or five-tine grabs are also available. A robust yet lightweight design ensures a long service life in this tough operation.

Clamshell buckets

Clamshell buckets ensure economical handling of bulk materials of all kinds. For coarse-grained bulk material or light material, the grab can be equipped with bulk trays, while for solidified materials, such as frozen coal, grab shells with teeth are available. Due to the high filling level, the optimal shaping of the shells and the low curb weight, highest productivity is guaranteed. The right clamshell grab with a variety of options is available for every handling machine.

Sorting grabs

The sorting grab is the classic attachment for use in recycling and sorting operations. The grabs are designed for effective loading, feeding of sorting, shredding and processing plants as well as for sensitive and precise separation of recyclable materials. Depending on the machine type, application and material, there is a choice of four different sizes, each with three shell versions.

Wood grabs

The wood grabs are the tailor-made solution for effective timber handling. Various grab shapes ensure fast and safe transport or handling in timber yards, sawmills or in industry. The grabs are developed for a wide range of quantities and types of timber. Wood moving and handling machines and LogHandlers can be equipped with Liebherr wood grabs.

Applications

Scrap handling

Liebherr material handlers master the toughest challenges of the metal processing industry in scrap handling. With a focus on robustness and reliability, they are designed for extremely demanding tasks. From the precise sorting, collecting and loading of mixed scrap to the efficient feeding of shredders, shears and presses, our material handlers set standards in industrial material handling. Performance and economy are integral components of Liebherr's innovative solutions.

Port handling

Liebherr characterises cargo handling in the port with efficient solutions. Our powerful port material handlers enable the fast and efficient handling of bulk and general cargo, including project unloading. Specially adapted material handlers fulfil the growing requirements of port logistics. Sophisticated construction and weight-optimised design ensure maximum efficiency and performance at minimum cost per tonne of material handled. Flexible cab elevations ensure optimum visibility, while modular machine superstructures offer a wide range of undercarriage options. Liebherr port material handling excavators set standards for optimised port logistics and material handling.

Waste management

Liebherr material handlers are at the forefront of the ever-changing waste management industry. They master the challenging task of loading, sorting and loading recyclable materials in the recycling cycle. Whether wastepaper, waste wood, rubbish, used tyres, scrap or construction waste - our robust material handling machines are up to the diverse challenges of the recycling industry. They enable the safe feeding of shredders and screening machines, the loading and unloading of lorries, wagons and containers as well as the precise sorting, separating, packaging and handling of recyclable materials. Our material handlers also prove themselves as reliable partners in resource-saving waste utilisation in indoor applications with electric drives.

Timber handling

Liebherr's robust material handlers master the challenges of timber handling with flying colours. From loading onto lorries, ships and wagons to transporting and sorting logs, we offer customised solutions for sawmills, log yards and timber ports. Our material handling machines combine powerful engines with intelligent controls for precise and efficient work.

Liebherr also offers special log loaders for pick and carry tasks in timber logistics.

Tree care

Liebherr offers customised material handling machines for a wide range of tasks in the forestry and timber industry. Whether maintaining forest paths, working on embankments, clearing roads and paths or felling problem trees - our material handlers are ready and waiting. With the right machine and attachments, trees and embankments can be processed efficiently and safely from a distance. The Solidlink quick coupling system enables the attachments to be replaced quickly and precisely, so that the material handlers can be used flexibly for various tasks such as pruning, clearing, milling and mulching.

Job reports

Material handling machines in operation

We let deeds speak for themselves and present our material handlers in action at the customer's site. Convince yourself of the massive handling capacity and the limitless application possibilities in the various industries.

We decided in favour of the LH 26 M because it fits perfectly into our range of services. We use the material handling machine for waste wood processing, recycling and composting. It is also used from time to time for tree felling work.

Andreas Mayer, general manager at the Leutkirch recycling centre

MyLiebherr - One portal, all services

Enter the digital Liebherr service world with the Liebherr customer portal and benefit from our extensive service range and additional offers.

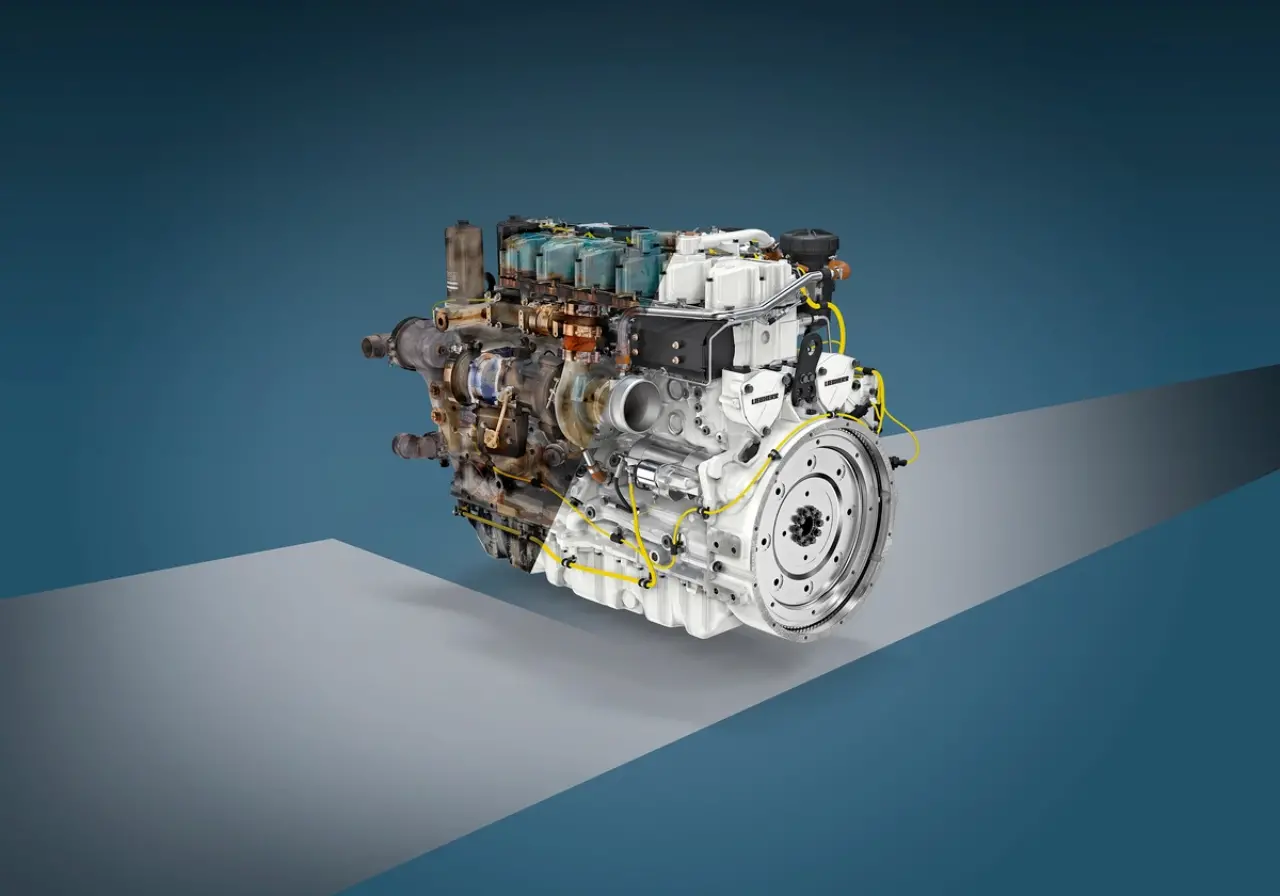

Ready for a second life - The reman programme

With our three-stage Reman programme, we remanufacture your used components into as-new parts in accordance with industrial standards. Benefit from our Reman programme and make an important contribution to conserving resources.

Smart products for smooth processes

To work even more efficiently, we offer digital applications that make it possible to carry out your complex tasks and work processes in a sustainable, cost-saving and safe manner.

We are constantly developing our range of products and services, focussing on your needs and offering the best solutions for you and your machines.