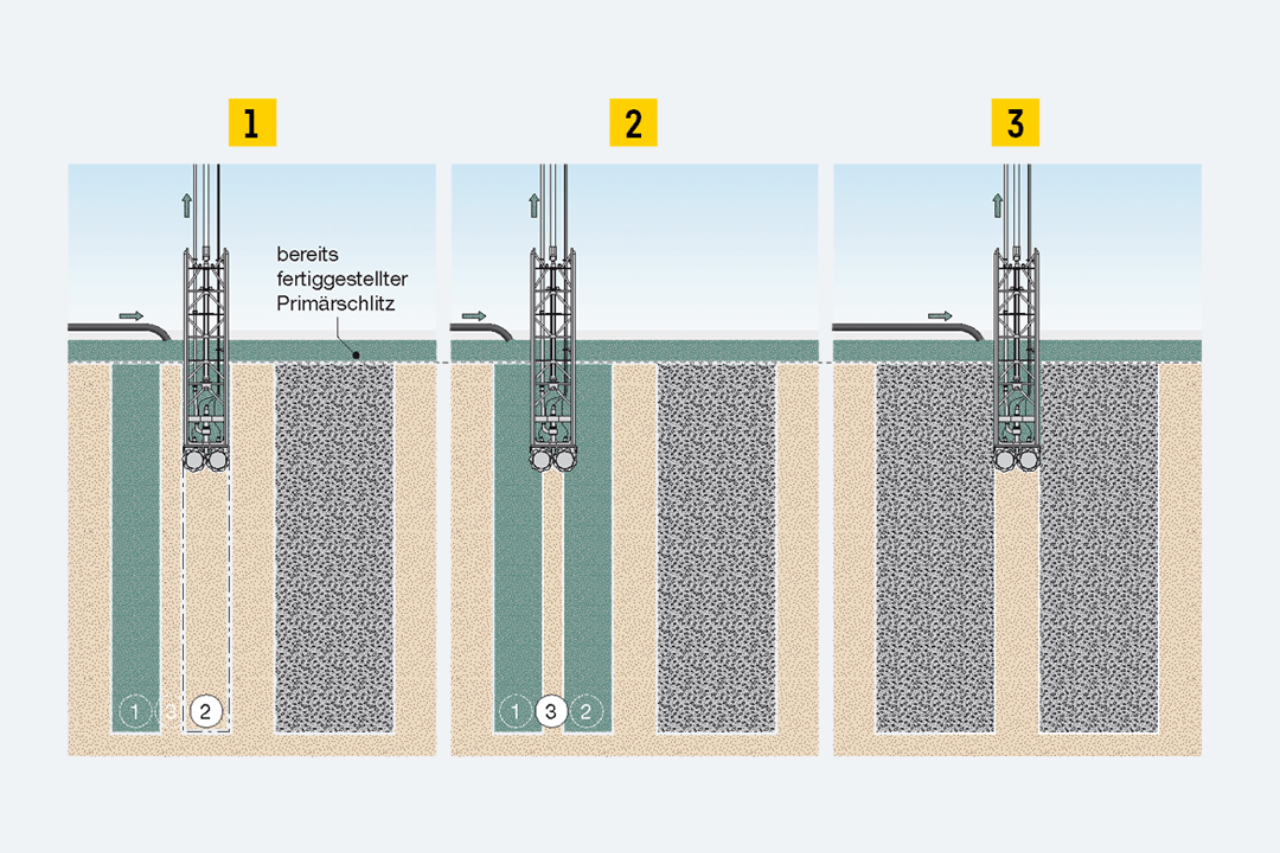

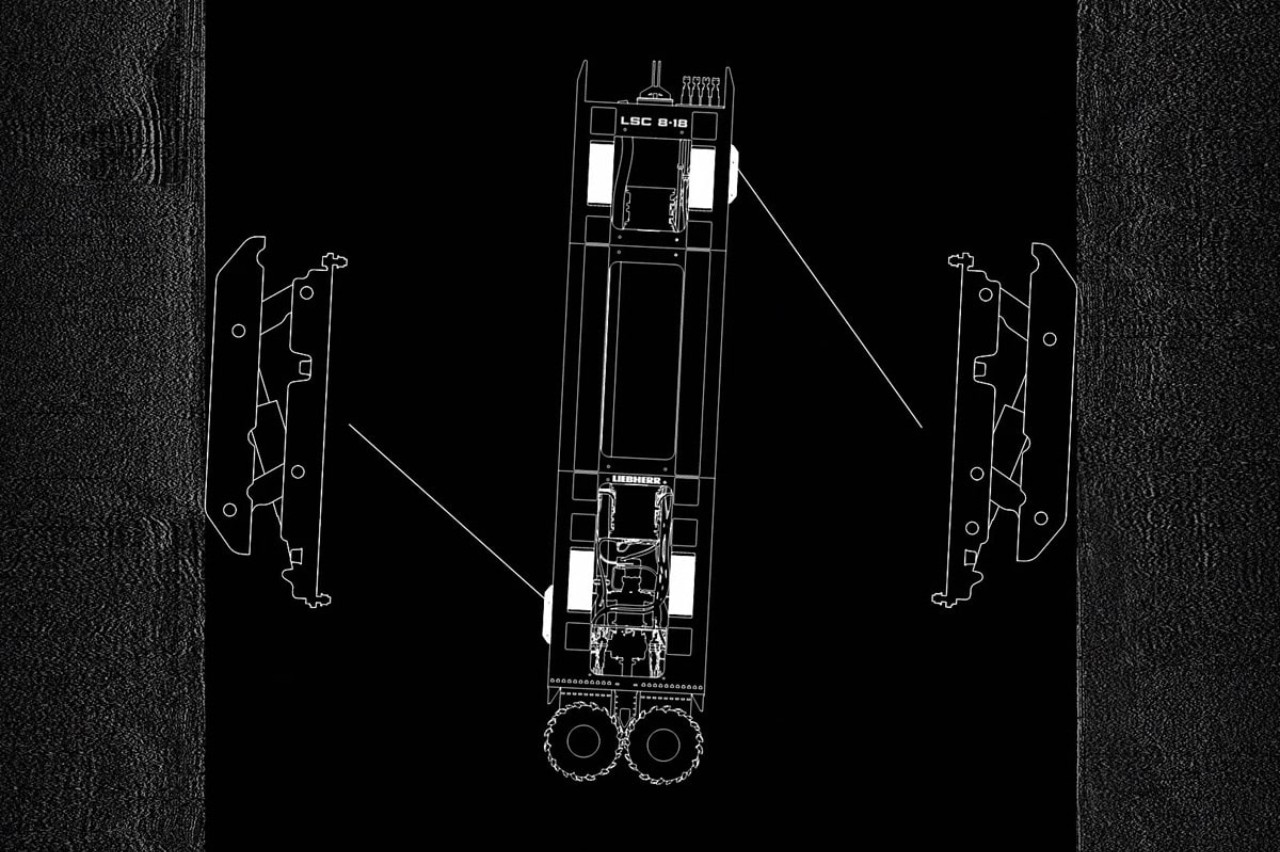

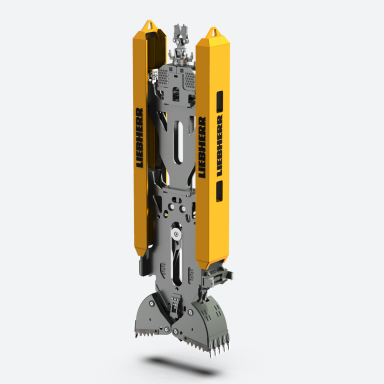

Hydromills are used for very deep trenches and, above all, for very hard building ground. Unlike the grab a hydromill works continuously during excavation. With the help of cutting wheels the building ground is broken up and crushed. A pump inside the hydromill creates an upward flushing circuit out of the trench via hose lines. The loosened cuttings can so be conveyed out of the trench with the support fluid that is pumped to the surface. Thus contaminated support fluid is then cleaned in a treatment plant and fed into the trench again.

01/07

Animated video

Hydraulically driven hydromills produce slurry walls.

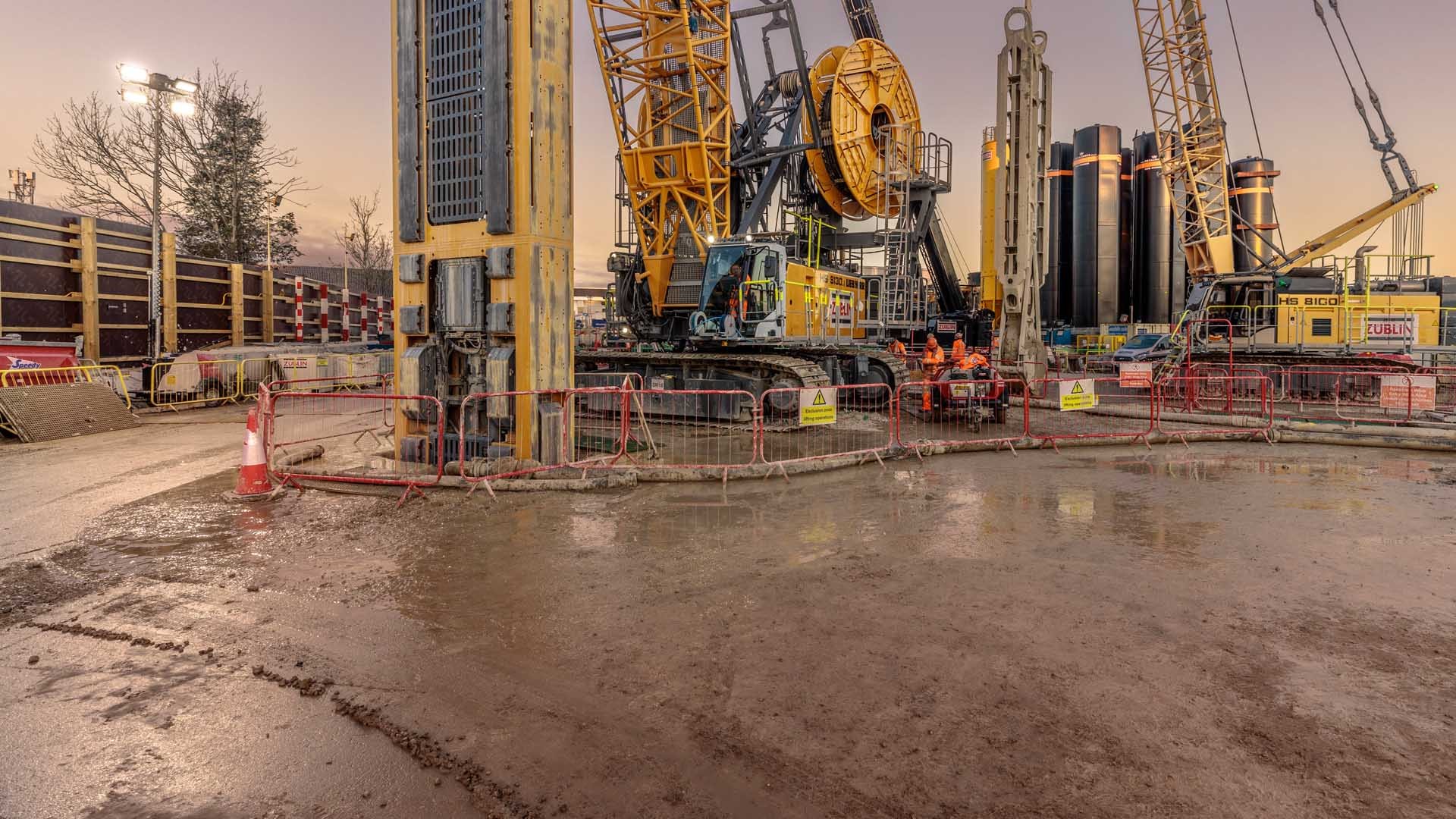

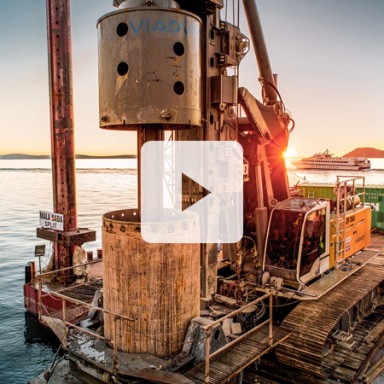

Slurry wall jobsite in Naples

Machines

Results 1-3 of 3