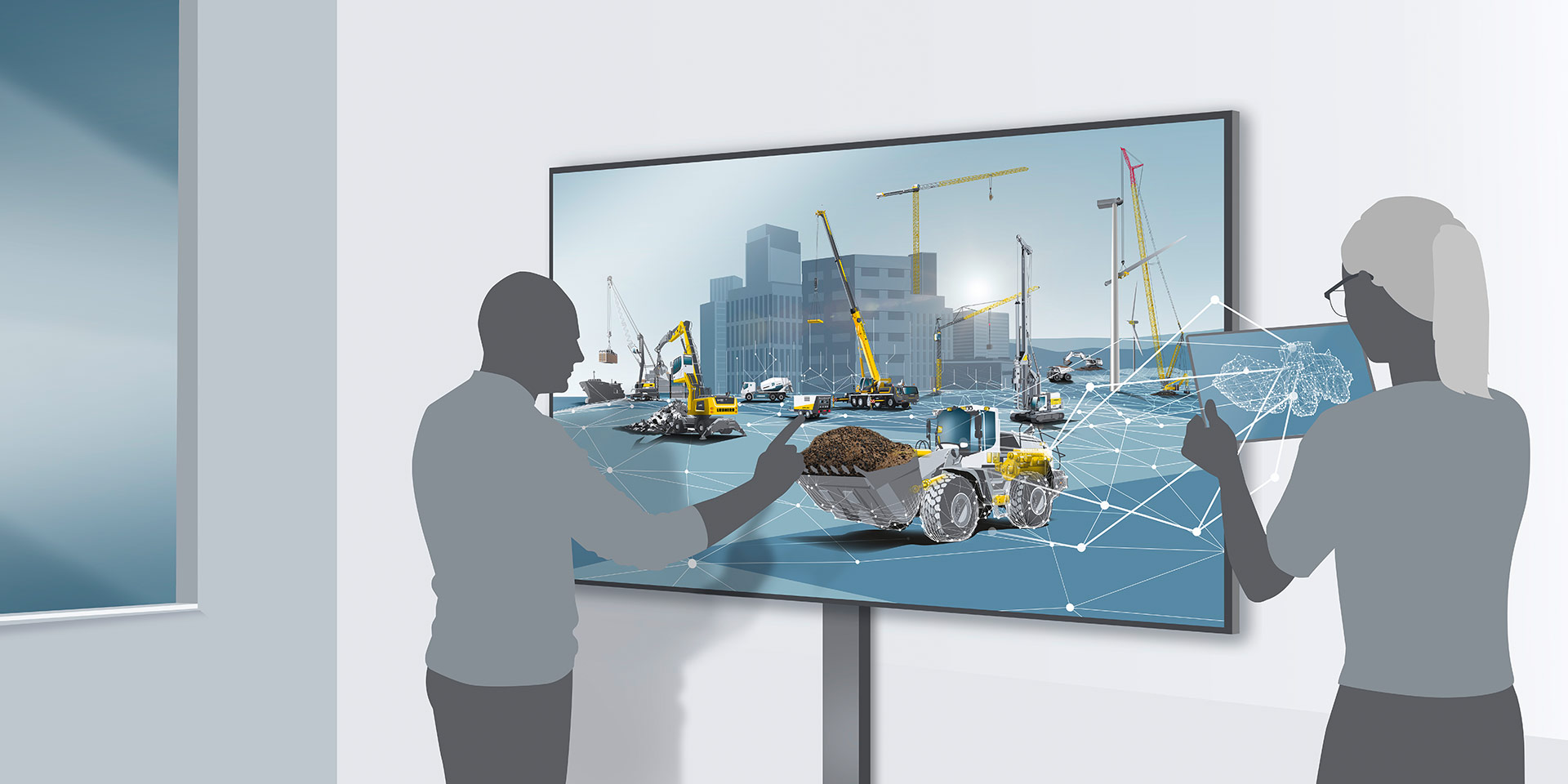

Networked into the future

Liebherr Connect connects people, Liebherr products and their environment into a high-performance system. The result: future viability, time and cost savings, safe and convenient operation and efficient machine management.

The morning on the construction site begins as usual – and yet everything is different. Before the work starts, the team checks the construction machinery fleet together on the tablet: fuel level, battery status, maintenance instructions, upcoming tasks and so on. All with just a few taps on the display. All equipment is ready. They are ready to go.

In some cases, the operator no longer even has to get into the cab – thanks to intelligent networking, one or the other Liebherr machine can already be conveniently and safely controlled from a distance. What may sound like science fiction is already a reality on some construction sites today. This is made possible by Liebherr Connect.

A new level of construction site management

‘Construction sites are complex ecosystems with numerous machines and equipment from different generations and with different drive concepts. Added to this are tight schedules, high-cost pressure and increasing efficiency requirements,’ says Marcel Flir, head of digital business and strategy at the Liebherr Group. ‘The solution: intelligent, location-independent networking. Whether it's in the city or in remote areas, when every minute counts, data on machine conditions, operating times and maintenance requirements is crucial for minimising downtime and increasing productivity.’

In addition, automation is playing an increasingly important role: ‘The connection to digital solutions will enable more and more processes to be remotely controlled or even carried out autonomously in the future using new technologies such as AI pattern recognition.’

‘Digital transformation has long been a reality and a decisive success factor,’ says Flir. And that's exactly what Liebherr Connect is all about: ‘Optimal networking with digital services and analysis tools.’

With Liebherr Connect, Liebherr machines can be networked with a wide range of digital solutions and services that are provided via the MyLiebherr customer portal or in the app stores. This gives machine owners and their teams simple, secure and reliable access to comprehensive machine data at all times. ‘This raises the productivity of a construction site to a new level,’ says the expert. But the connectivity solutions can do much more than ‘just’ network the construction site – they also put the cost-effectiveness of machines and machine fleets on a new footing.

Broadly scalable connectivity solutions

The technological connectivity solutions behind Liebherr Connect were developed together with cybersecurity specialists, design engineers and service experts from across the Group. This ensures that both Liebherr's B2B and B2C customers benefit optimally from the advantages of intelligent networking.

Right from the start, Liebherr focused on an open architecture that is compatible with common fleet and asset management systems. ‘Our connectivity solutions allow seamless integration into existing fleets – from individual machines to large fleets,’ Flir continues. Operators of a wide range of machine types benefit from this: from earthmoving machines to mining equipment, tower cranes to mobile harbour cranes and mobile and crawler cranes.

For Marcel Flir, it is clear: ‘The future of the construction site is digital and networked – Liebherr Connect is a key factor here.’ This progress in digitalisation can already be felt on more and more construction sites.

Q&A

Liebherr Connect stands for intelligent machine networking. It allows for the real-time exchange of data and is therefore the basis for optimising operating processes and costs.

- Increased efficiency: data helps to optimise the operating status and identify bottlenecks at an early stage.

- Reduced costs: precise analyses improve the planning of maintenance intervals and reduce downtimes.

- Sustainability: intelligent fleet management reduces CO2 and noise emissions, and minimises the ecological footprint.

The connectivity solutions are already integrated in various Liebherr machines, but can also be retrofitted accordingly for generations of devices already on the market.

Thanks to a wide range of connectivity solutions, machines are connected to digital solutions that are made available via the MyLiebherr customer portal or in the App Stores.

Liebherr Connect is the basis for new technologies such as autonomous operation, AI-supported maintenance and networked machine operations.