Like new, only better – giving used components a second life

Age before beauty: in Liebherr’s Ettlingen plant (Germany), new life is breathed into used engines, gearboxes and other drive components. This saves resources, energy and money. Compared with producing from scratch, this uses significantly fewer raw materials and leaves a much smaller carbon footprint.

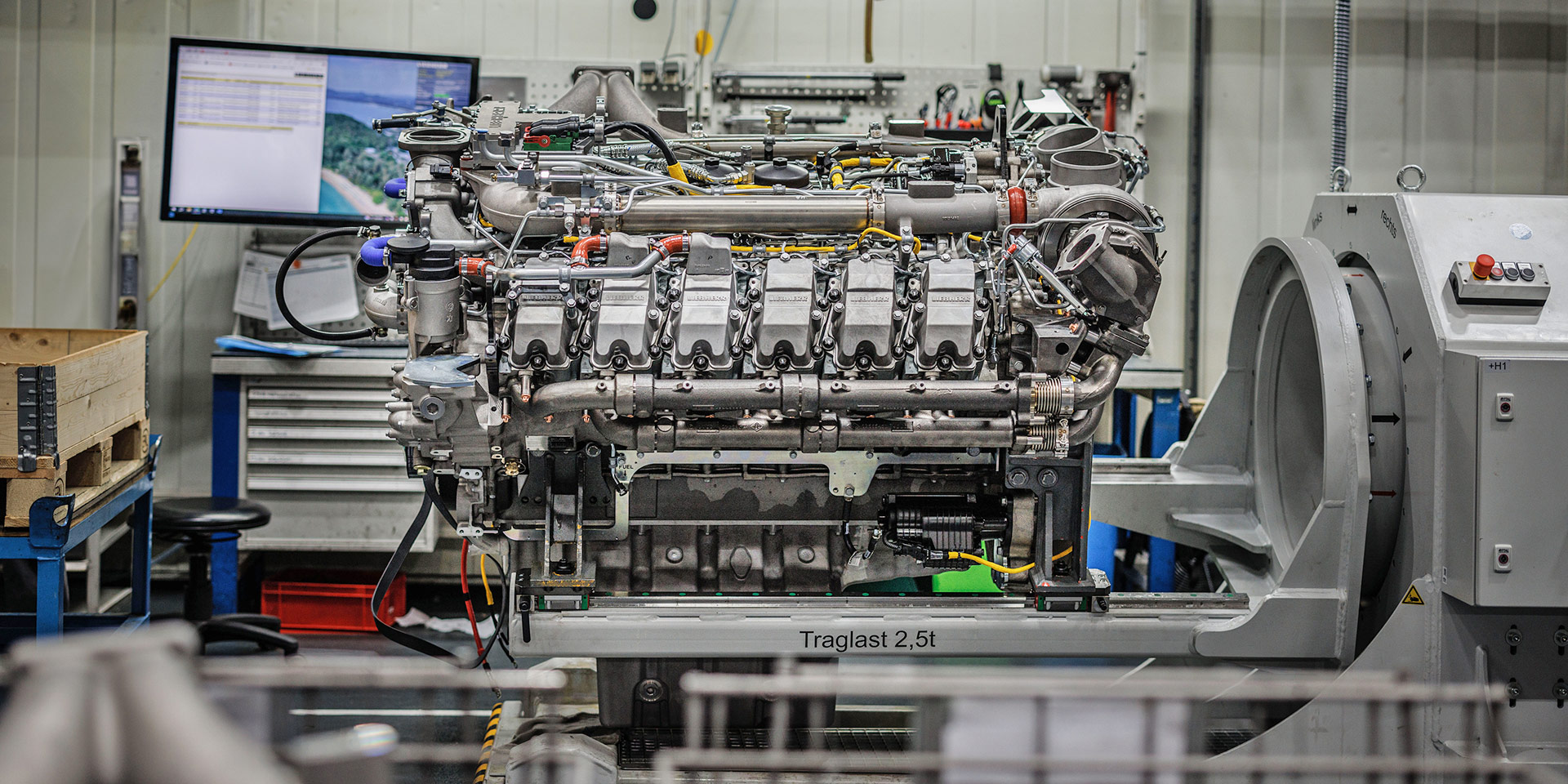

A lifetime of working on the construction site inevitably leaves its mark on equipment: rusting metal, cables showing their age, corrosion spots, scratches and scrapes. Not to mention grease and dirt all over. Even after several years of operation, the diesel engine of the material handling machine from a steelworks is still an impressive and considerable unit, but it’s not likely to win any beauty contests. Nevertheless, Nina Wirth, product manager at Liebherr-Ettlingen GmbH, was delighted to see the engine arrive in the plant hall on a transport frame. ‘You can see that this workhorse has already lived quite a life,’ says Wirth, while she inspects the crankcase for any cracks or holes. ‘And it’s our job to make sure that life doesn’t end here.’ Let Operation ‘Reman’ commence!

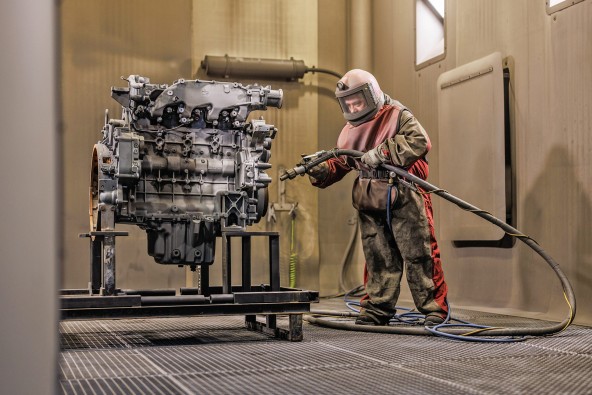

‘Remanufacturing is fundamentally different to recycling,’ explains Wirth, as the oil-covered engine enters the steam jet booth. ‘Whilst recycling involves an energy-intensive process of melting used materials back into raw materials, remanufacturing focuses on continuing the use of the existing structures. We take components, such as engines, gearboxes and hydraulic pumps, take them apart, clean them, inspect them, if necessary refurbish them and then reassemble them.’ The aim is to restore or even exceed the original functionality and quality.

More than 20 years serving the circular economy

Ever since 2004, the Ettlingen Liebherr plant in the district of Karlsruhe (Germany) has been specialising in remanufacturing, or ‘reman’ for short. ‘Back then, remanufacturing procedures were relatively unknown to many market players,’ explains Daniel Schöninger, managing director of Liebherr-Ettlingen GmbH. The notion of giving entire machine components a second life was initially met with questions over quality – questions that needed answering. In the years since, however, manufacturers and machine operators alike have changed their minds and have come to see it from a more holistic view. In fact, the first-rate quality of reman products is, quite rightly, rarely questioned now.

The ‘Handbook of Sustainable Engineering’, published by Joanne Kauffman and Kun Mo Lee, provides us with the explanation: ‘Remanufacturing, a process whereby used products are restored to ‘good-as-new’ working order with the corresponding guarantees, is considered a more sustainable manufacturing method, because it can be cost-effective and better for the environment than conventional manufacturing.’ In Europe today, remanufacturing makes up roughly two per cent of the manufacturing sector – representing a revenue of around 8.7 billion euros in Germany alone.

A study by Germany’s VDI Competence Centre for Resource Efficiency predicts that, if current conditions prevail, the remanufacturing sector will grow by more than 50 per cent across Europe by the year 2030 to 46 billion euros. If political and economic conditions become more favourable, however, market researchers forecast the sector will triple in size. Even now, the savings associated with remanufacturing are tremendous: an in-house study by Liebherr revealed that it uses up to 78 per cent fewer raw materials and 66 per cent less CO₂ in direct comparison with new production.

Liebherr Reman – eight steps to a second life

1. Pre-cleaning: dirt, oil and deposits are removed using steam jets and sand blasting.

2. Disassembly: the components are broken down into their individual parts.

3. Deep cleaning: individual parts are cleaned with maximum precision.

4. Diagnostics: every part is inspected to identify any wear or damage.

5. Mechanical processing: where necessary, individual parts are refurbished

6. Assembly: the components are put back together.

7. Testing: every unit is run through tests in line with series production standards.

8. Painting and delivery: the finishing touches before the product goes to the customer.

Save money, drive down CO2 emissions

‘Reman pays off,’ attests Daniel Schöninger. ‘By using this alternative to new parts, we can lower the costs of spare parts by between 25 and 50 per cent. That also filters through to the life cycle costs. Just by reconditioning combustion engines, we can reduce raw material consumption by up to 78 per cent. When the effects of transportation and scrap rates are taken into account, CO2 emissions are 52 per cent lower than with the manufacture of a new part. That is a very sizeable contribution to the circular economy and a perfect win-win-win situation: for manufacturers, for customers and for the environment.’

Liebherr – and Liebherr customers – demand high quality from products and services. ‘We are approaching reman with a requirement for production that matches new-part quality,’ explains Daniel Schöninger. However, this does of course mean that the design, material quality and processing of new parts must ensure a long service life in the first place, so that disassembly, cleaning and restoration preferably only require the replacement of typical wear parts.

Maintenance and repair for added value that lasts

The engine of the material handling machine is already fully dismantled after its initial clean. Now, the Ettlingen-based team can inspect the pistons, piston rods, cylinder heads, etc. and, where necessary, replace parts. Badische Stahlwerke GmbH, a steelworks company based in Kehl (Germany), where the excavator worked in tough conditions alongside various Liebherr wheel loaders, is turning to remanufacturing for both economical and ecological reasons. ‘In Europe, especially in Germany, we are witnessing a transformation, shifting towards the manufacture of “green,” i.e., zero-emissions, steel,’ explains a representative from the steelworks. He also added that this extended beyond merely production processes. There are numerous building blocks that make sustainable steel production possible. The in-house goods handling is an important factor in this: ‘[…] When it comes to maintenance and repair, we look no further than the reconditioned reman components from Liebherr. Firstly, because they provide the same quality as new parts but at a lower price, and secondly, because they are an excellent fit for our environmental and sustainability philosophy of a “steelworks of the future”.’ The result is smooth processes, reduced costs and an active contribution to the circular economy.

‘And what’s great is that some of the scrap steel that goes into the steel plant as a raw material comes from the unusable components of the Liebherr reman programme,’ notes Daniel Schöninger. And that’s precisely what they mean at the Liebherr plant in Ettlingen when they say: like new, only better.

At a glance: Liebherr reman in facts and figures

Products

- Combustion engines

- Fuel injection technology

- Hydraulic pumps and motors

- All types of gearbox

- Hydraulic cylinders

- Rope winches

- Electronics

- Various individual parts

> 15 sites around the world

> 550 employees around the world

7,500 components refurbished per year, as well as countless individual parts