LTM 1150-5.4E

Mobile crane

LTM 1150-5.4E – Zero emission, full power.

Based on our LTM 1150-5.4, we have given this all-terrain crane a hybrid drive. The LTM 1150-5.4E has an electric drive, which allows crane movements to be carried out CO2-emission-free and with reduced noise emissions. With its integrated battery, the crane can work autonomously for up to four hours without a power connection. On the other hand, a low electric grid connection on the job site is sufficient to develop the full crane performance - as the battery serves as an efficient buffer. Our LTM 1150-5.4E therefore meets the requirements of "zero emission construction sites", combines sustainability with maximum efficiency and comes with numerous pioneering technologies on board.

Max. load capacity - 150 t

150 t

Telescopic boom - 66 m

66 m

Max. hoist height - 92 m

92 m

Max. radius - 72 m

72 m

Number of axles - 5

5

Zero emissions:

Full power:

Simply quiet:

It couldn’t be simpler:

Supplied from the site:

Crane operations with a battery pack:

Photo gallery

Technical data

| Max. load capacity | 150 t |

| at radius | 3.00 m |

| Telescopic boom from | 12.30 m |

| Telescopic boom up to | 66.00 m |

| Lattice jib from | 2.90 m |

| Lattice jib up to | 26.00 m |

| Drive engine/make | Liebherr |

| Drive engine | 6-Zylinder-Diesel |

| Drive engine/power | 400 kW |

| Number of axles | 5 |

| Drive/Steering standard | 10 x 6 x 10 |

| Drive/Steering option | 10 x 8 x 10 |

| Driving speed | 85.00 km/h |

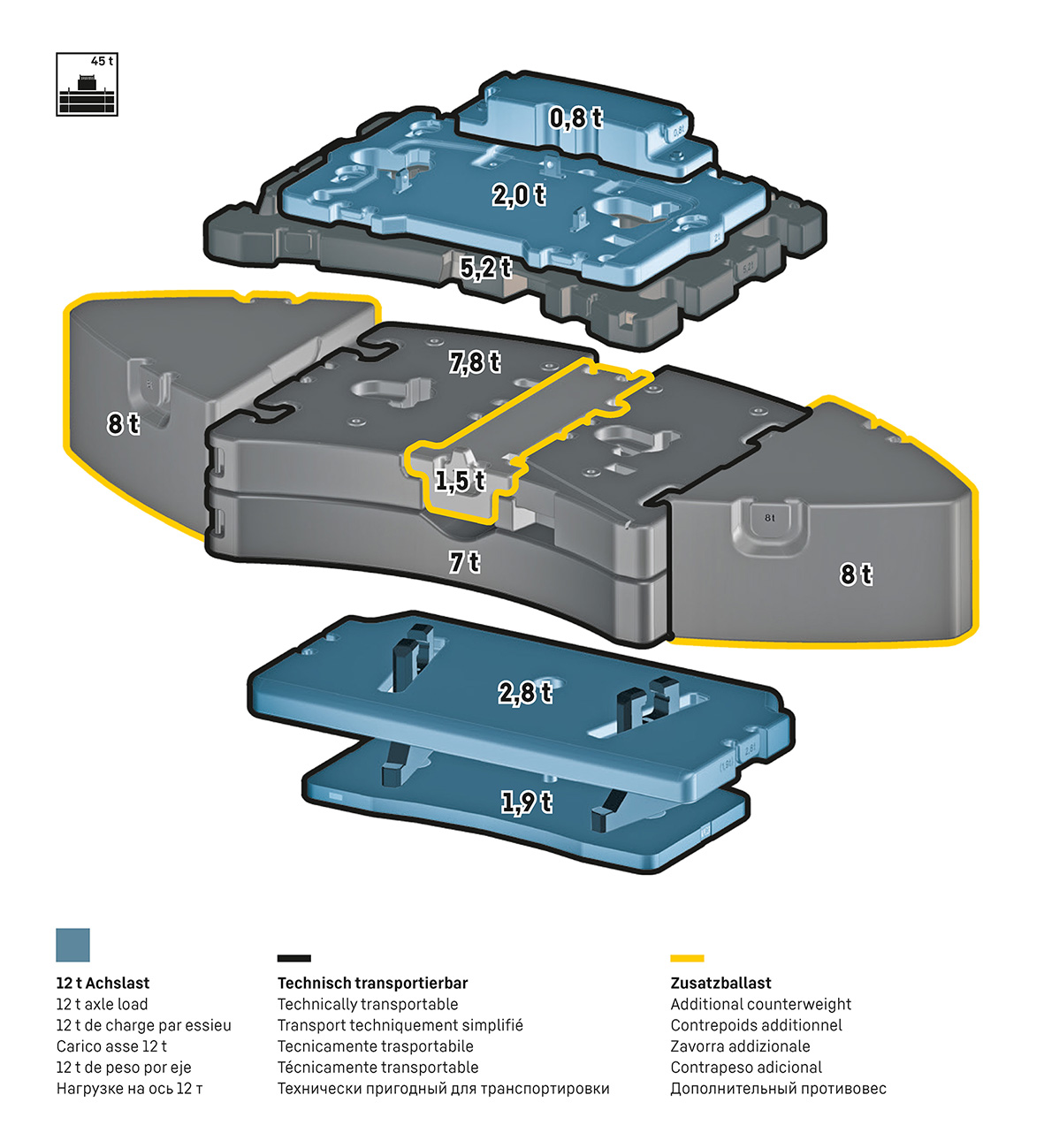

| Total ballast | 45.00 t |

Downloads

Videos

Zero emission, full power

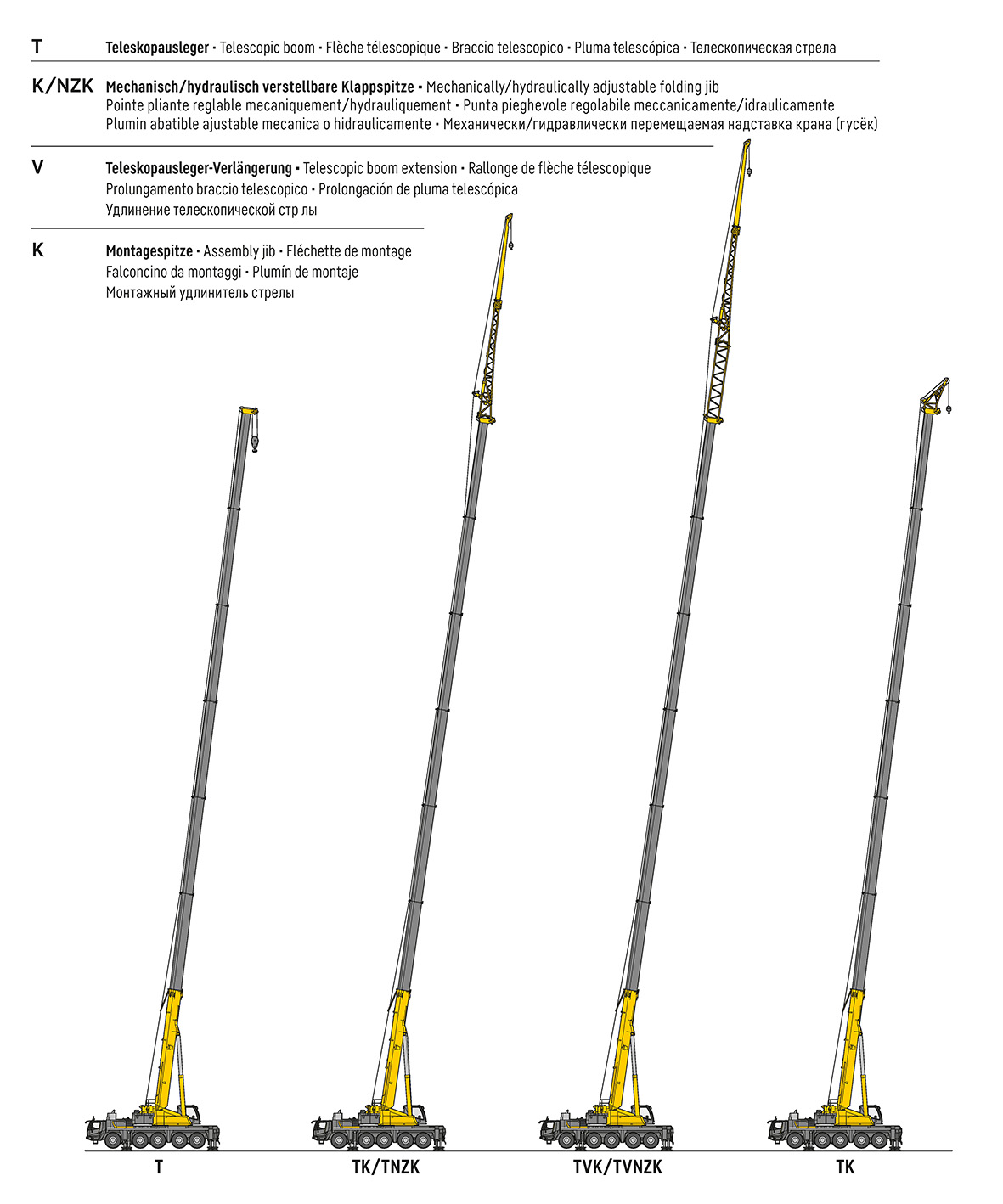

Boom/jib combinations

Boom/jib combinations

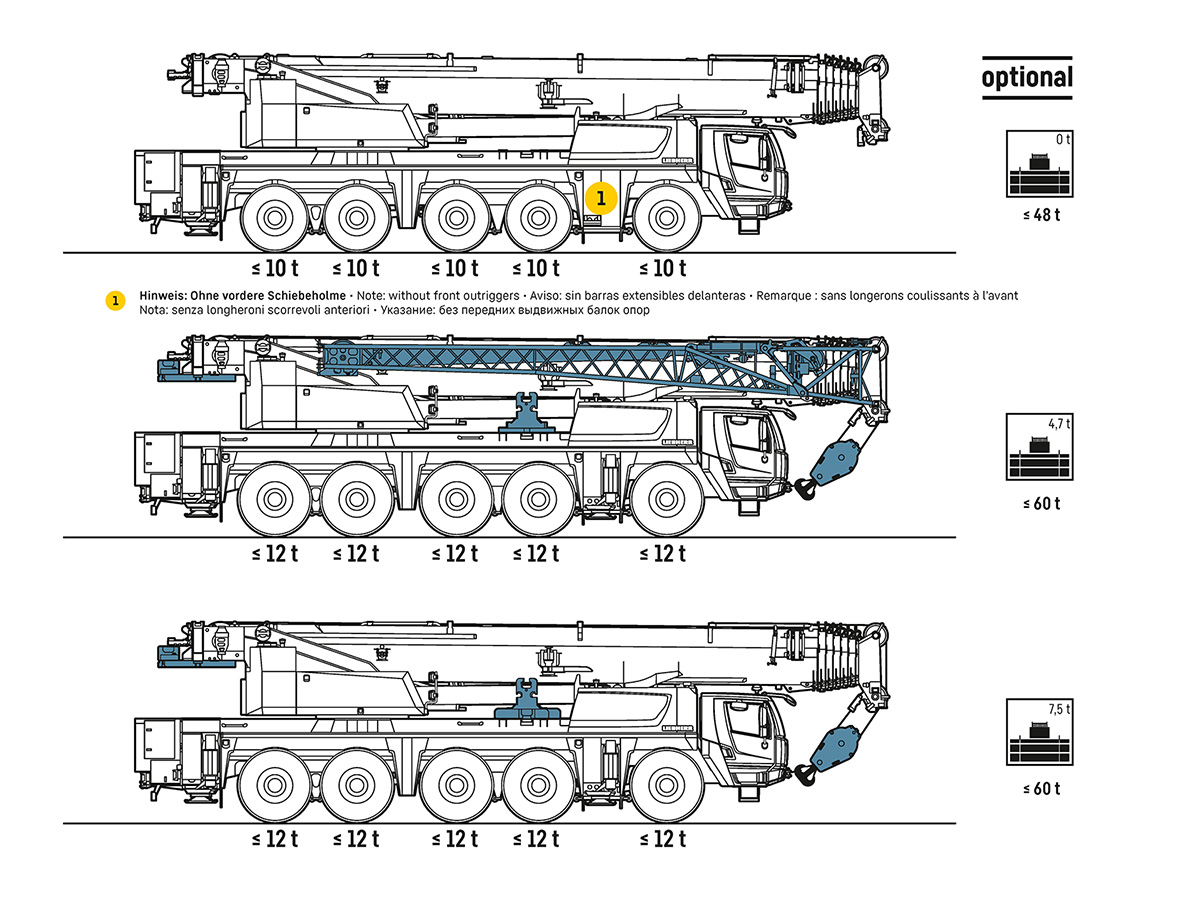

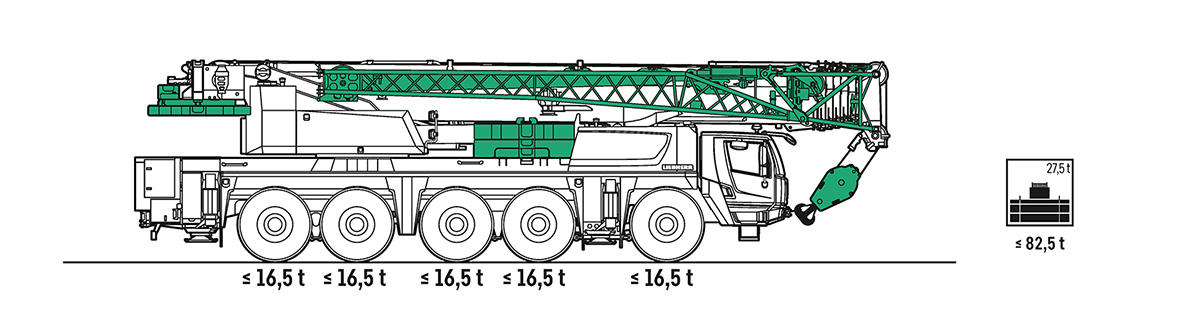

Driving conditions

On-road driving

Jobsite driving

Ballast systems

Coutnerweight

Technology

ECOmode

ECOdrive

Single-engine concept

Hillstart-Aid

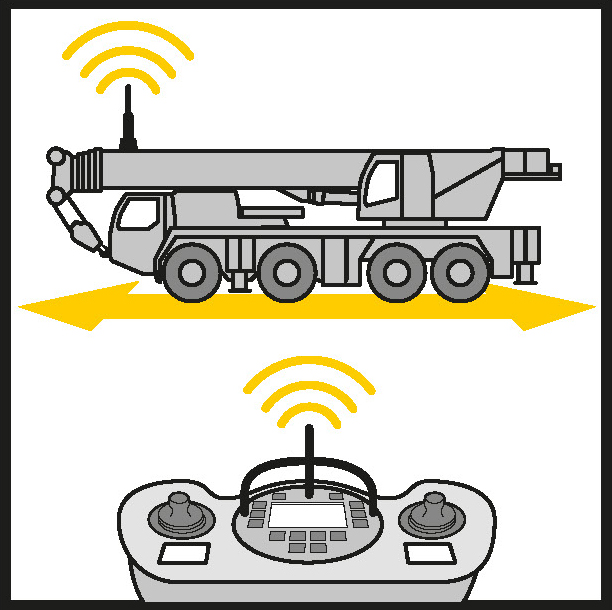

RemoteDrive

LICCON3

VarioBase®

AutoBallast

WindSpeed load charts

HVO ready