4 minutes - magazine 02 | 2025

A giant in a (not so) small format

When a Liebherr LTM 11200-9.1 raised its mighty boom in 2025 at the Swiss Museum of Transport in Lucerne, a murmur rippled around the four-metre-high hall.

After months of painstaking work, Peter Howald is bringing his technical masterpiece to life. What for many is “just” an impressive exhibit, for the Swiss model builder represents passion, technical inspiration and a piece of a childhood memory.

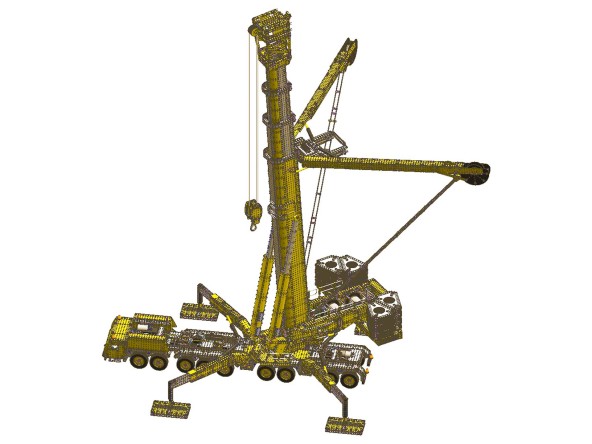

When the LTM 11200-9.1 model is fully extended with its telescopic boom and luffing jib, the crane reaches a hook height of seven metres.

From his parents’ construction yard to the modelling table

Even as a small boy, Peter Howald would accompany his dad, who owned a construction company in the Bernese Oberland, to construction sites. He was especially fascinated by the giant mobile cranes, usually from Liebherr, that were used in the construction of prefabricated houses. Howald’s professional career, however, did not take him into his parents’ business, but rather into mechanical engineering. Today, the mechanical engineer builds plants for the automotive, pharmaceutical and food industries. However his technical heart still continues to yearn for heavy-duty equipment – and especially for the LTM 11200.9-1. So when an article appeared in a trade journal in 2018 about that same crane, Howald seized the moment.

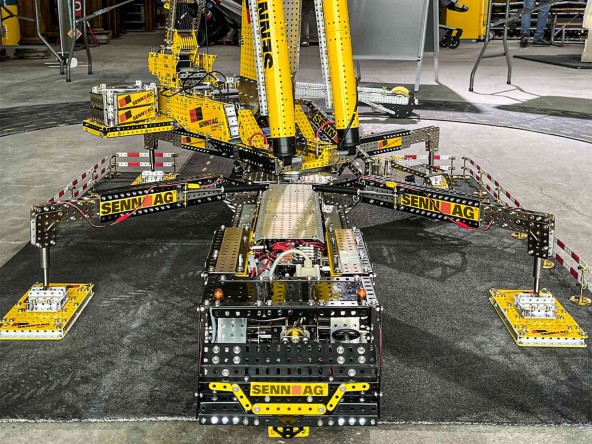

The finished model crane weighs 120 kilograms and supports itself just like its larger counterpart.

Two years in the planning, 30,000 parts

What followed was a major technical project on a small scale. The planning phase took two years. Using YouTube videos and data sheets from liebherr.com, the designer created a detailed 3D map on a 1:14.5 scale. The construction materials consist of classical elements from the Meccano metal construction kit. Since the toy manufacturer was no longer producing many of the original parts, compatible components from other manufacturers, such as Stokys, were used too. The process of procuring the parts from all over the world took over a year, until one day a package weighing 150 kg was delivered. On seven workbenches in the basement, 30,000 parts were constructed over 4.5 years to create a model crane weighing 120 kilograms that is astonishingly identical to the original in terms of its technical complexity.

The finished model crane weighs 120 kilograms and supports itself just like its larger counterpart.

Technology like on the original

Nine steering axles, four of them powered, a steplessly telescoping boom with three pull-outs (T3 version), a functioning Y-guying system and a luffing jib that allows a hook height of up to seven metres. The supports can be telescoped, just like on the original, and can be individually controlled. The crane lifts itself up completely from the wheels and stands stable on its supports.

From the light and sound module to telescoping functions and onwards to crane cab movement, the model is controlled via a 48-channel wireless remote control. Even crab steering is possible. The counterweight – 200 tonnes on the original – is simulated with a weight appropriate to the model at 50 kilograms. “The kinematics are incredibly instructive,” says the designer. “Whether it be on the original or the model – there are enormous forces at play. The two cylinders that lift the boom, for example, each deliver a force of 1,000 Newtons.”

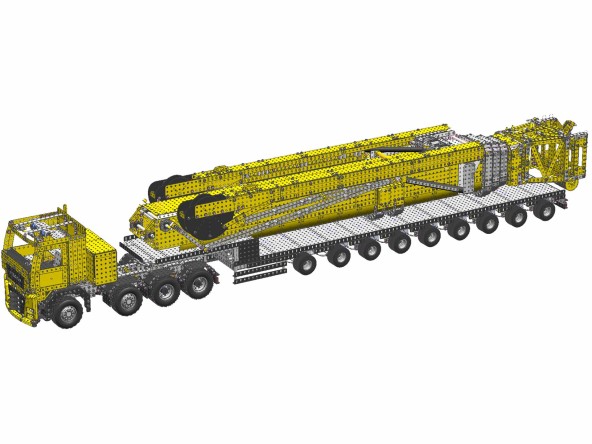

This is true for both the LTM 11200-9.1 and the associated truck fleet.

Presentation and feedback

Howald unveiled the model to the public for the first time this year in Lucerne. The Swiss firm Senn AG – once itself an owner of a real LTM 11200-9.1 – sponsored the model’s journey to the Museum of Transport. Today, the steel construction and crane company’s logo graces Howald’s model. Setup on site took many hours, and the model builder was ably assisted by his wife. “Model building isn’t really her thing,” says Howald, adding with a smile: “Even though I couldn’t convince her to spend months working in the basement, she was fully on board with the setup.”

Ideas for the future

A giant like this 9-axle model doesn’t get to the construction site all on its own. Not even as a model. So Howald is currently working on a fleet that will later comprise seven trucks, designed to transport the crane parts. The first transporter with a steered 9-axle trailer is already finished and is being used for the entire telescopic boom. If everything goes smoothly, the crane and its fleet should be exhibited at an excavator museum in the Zürich region in April 2026. There, Howald is keen to inspire younger visitors with the possibilities of technical model building too. The “Swiss Amateur Metal Model Builders” (AMS) association, to which Howald belongs, is struggling to recruit new members. His hope: “If you show what you can technically achieve with metal construction kits such as Meccano and Stokys, maybe the fascination will return.”

This article was published in the UpLoad magazine 02 | 2025.