8 minutes - magazine 01 | 2025

Shaping the future of energy

The transition to green energy is a key topic of the present and of the coming decades. Necessary technological innovations and massive infrastructural changes pose major challenges for society.

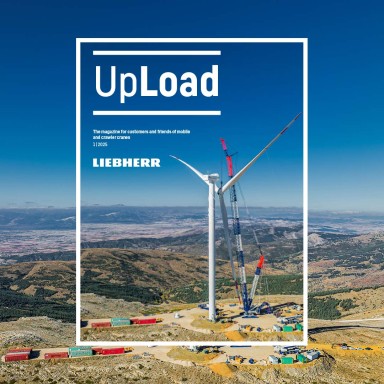

Achieving the energy transition. With cranes from Liebherr.

Demands are placed on us too, because cranes play a decisive role in the important contribution that renewable energies will make to our future. They are indispensable for the construction and maintenance of plants that utilise renewable energy sources.

Hydroelectric power: On the left, an MK 8Hydroelectric power: On the left, an MK 88 is shown building a foundation at the foot of the vast dam wall of the Grimsel lake reservoir in the Swiss Alps. All Liebherr mobile construction cranes can be operated at low noise level and without emissions at the construction site using electricity.8 is shown building a foundation at the foot of the vast dam wall of the Grimsel lake reservoir in the Swiss Alps. All Liebherr mobile construction cranes can be operated at low noise level and without emissions at the construction site using electricity.

The installation of solar panels on buildings, the construction of geothermal plants, the installation of efficient power lines or the redevelopment of mighty hydroelectric dams in the mountains – mobile and crawler cranes play a key role in almost all renewable energy projects. Of course, this applies in particular to the significant wind energy sector. Liebherr cranes are of vital importance here, both for offshore and onshore installations. Hundreds of mobile and crawler cranes from our factory in Ehingen are in use worldwide for the construction of onshore wind turbines. The dimensions of these systems have multiplied over the past decades. This places high demands on our design engineers, as our cranes have to keep pace with the growing demands on construction sites in terms of lifting height and lifting capacity.

Repowering: Even on the hilltops of the Black Forest in south-west Germany, ageing wind turbines have to make way for modern, more efficient systems. Here, an LTM 1750-9.1 is dismantling the complete blade star of a wind turbine that is over 20 years old. In its place today, a modern wind turbine with an overall height of 229 metres supplies four times the amount of energy.

Geothermal power: In 2023, a borehole was drilled at a depth of 4,500 metres south of Munich to tap geothermal energy. Numerous mobile cranes and mobile construction cranes from Liebherr were used in the construction of the plant. The images show an LTM1250-5.1 and an LTM 1130-5.1 during completion of the drilling rig of the geothermal plant, which is over 50 metres in height. (Photo: Eavor GmbH)

Next world record: 199 metre hub height

While wind turbines were still built on 30 to 40 metre high towers in the 1980s, tower heights reached the 100 metre mark at the turn of the millennium. Today, the industry has already exceeded 150 metres and currently has hub heights of 165 metres. Our LR 11000 crawler crane is the perfect choice for this. It provides all the necessary performance parameters at the construction site. The cover picture on the previous pages shows one of these 1000-tonne crawler cranes from the Austrian Felbermayr Group, which assembled two of these large wind turbines on the hills of the Black Forest in south-west Germany. Hub heights of up to 166 metres needed to be coped with here. However, this height is by no means the end of the story.

Picture: Eavor GmbH

“The hub heights are continuing to increase, that is quite clear. We have enquiries from the wind power industry for 2026 and 2027 for which installation heights of 185 metres need be achieved,” reports Marc Bernschneider, authorised signatory and field service manager at Thömen in Hamburg. Bernschneider should know, as the wind energy sector is an important market for the crane and heavy haulage company operating under the umbrella of the Hüffermann Group.

District heating: A superlative crane application was on show in Delft in the Netherlands last year. A total of twelve Liebherr mobile cranes were used to install a pipeline for the city’s district heating system.

“The LR 11000 will be able to handle a hub height of 180 metres for load cases of around 110 tonnes,” explains Nino Münch, product manager for crawler cranes at our company. “We at Liebherr are observing the market and its development with interest and great attention. We have been doing this for decades. Although we are of course constantly developing new, more powerful cranes, we are also continuously optimising existing crane types.

Electric drives: The Scandinavian countries are pioneers in the reduction of CO₂ emissions at construction sites. Electrically driven construction machinery is increasingly being used, as here in the Norwegian capital of Oslo. A Liebherr LTC 1050-3.1E compact crane is connected to the power supply.

These upgrades are essential to ensure that our customers can meet increasing requirements in the wind energy sector with their equipment sustainably and in the long term.” After all, the industry is characterised by high dynamics – height records for wind turbines usually don’t last long. Max Bögl, the major manufacturer of hybrid towers, is already working on the next world record in Sengenthal, Bavaria: A seven-megawatt plant with a hub height of 199 metres is to be implemented next year.

Stored energy: It looks like an oversized thermos flask: the energy storage facility in Heidelberg in southern Germany. The available volume of the thermally insulated cylinder holds 12,800 cubic metres of water at up to 115 degrees, which is fed in from the district heating system when there is a surplus. This thermal energy can be utilised as required and can compensate for peak electricity and heat demands. An LTM 1090-4.2 is assembling the final elements of the steel structure here, which is now used as a restaurant and viewing platform, at a height of over 50 metres.

Customised equipment

Experience shows that a new crane type or a further development of an existing model is required approximately every five years to be able to adequately cover the market. We have always achieved this at Liebherr. The development of the LG 1750 and LG 1800-1.0 lattice boom cranes can even be traced back to suggestions from the wind power industry. The same applies to the successful narrow-track versions of our powerful crawler cranes. In addition, we have developed rooster sheaves, fixed jibs and their geometry as well as reinforced boom systems according to the desires and requirements of our customers. The aim is to always provide customised and powerful equipment for crane work in the wind power sector. Another focus is on the environmental footprint of the cranes we build.

Wind power and hydroelectric power: An LTM 11200-9.1 during the erection of the tower of a wind turbine. A Liebherr telescopic crawler crane had previously been used to create a large water basin around the base. This combination of wind energy and pumped storage power station built by the Max Bögl company is for establishing a powerful electricity storage facility for flexible power supply.

This is also reflected by the fact that for some years now, all of our new mobile and crawler cranes can be run on pure HVO fuel made from hydrogenated vegetable oils, which results in a significant reduction in CO₂ emissions. We are also continuously expanding our range of electrically driven construction machinery throughout the Group. Small crawler cranes, hydraulic excavators and a large number of other Liebherr machines are already available with emission-free drives. The range of cranes with electric drives is also being expanded at the Ehingen plant. In Scandinavia, 20 LTC 1050-3.1E compact cranes are already in operation successfully in current mode. All MK mobile construction cranes can also be operated emission-free and virtually without noise using construction-site power. The new MK 120-5.1 will be one of over ten Liebherr machines with hybrid or all-electric drive on exhibition at the construction machinery trade fair in Munich. We will also be presenting the first electrically driven LTM mobile crane there. Therefore stay tuned.

This article was published in the UpLoad magazine 01 | 2025.