Become independent of time, place and resources

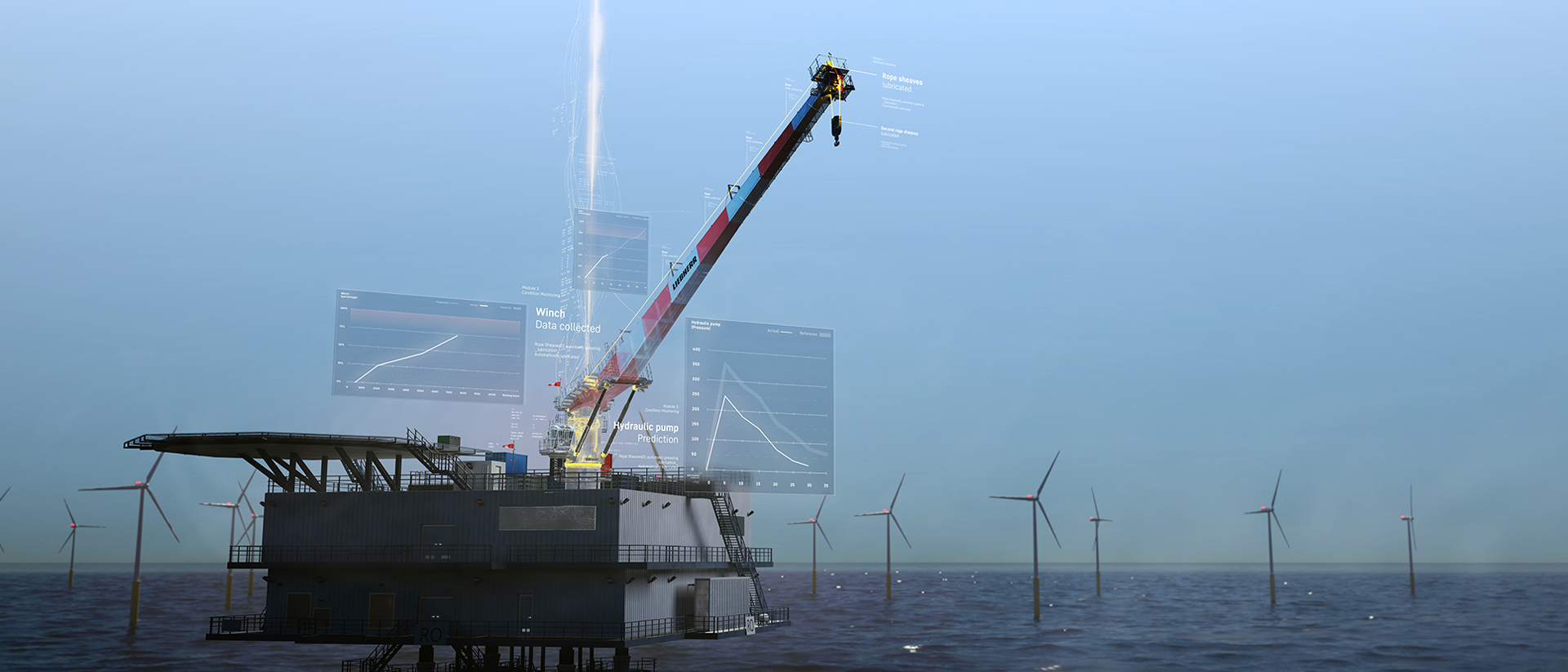

Liebherr Intelligent Maintenance (LiMain) is a new level of independence for manned and unmanned platforms, that offers increased crane availability at lower costs. LiMain is a fully digital, remote and semi-automatic maintenance system, which saves investments and resources for the platform operator.

The LiMain Modules

The key element of LiMain is the modular system architecture. Platform operators can choose from various modules and so determine the degree of autonomy and scope of intelligent maintenance for the crane.

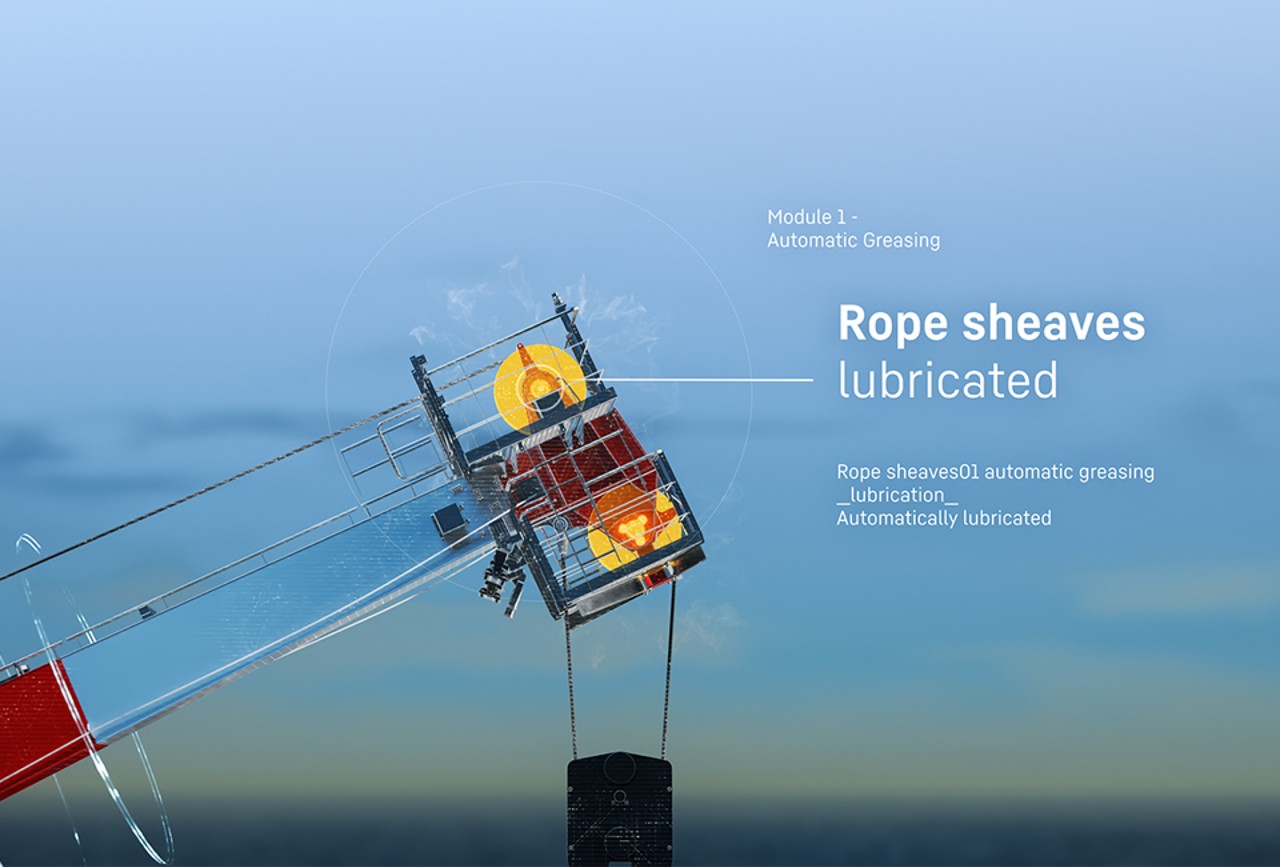

Automatic

greasing

Condition

monitoring

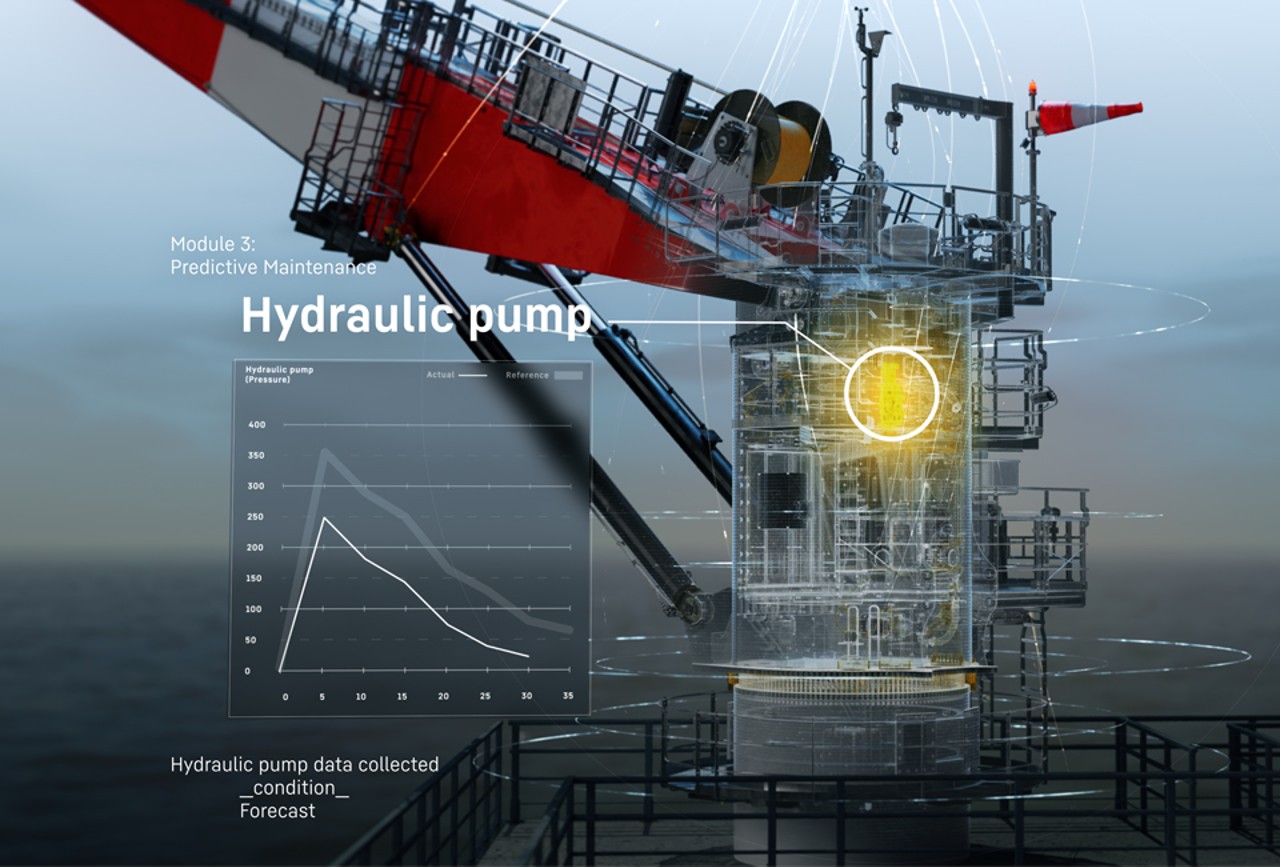

Predictive

maintenance

Remote

maintenance cycle

LiMain: Enter the new age of maintenance

LiMain will change the way you think about maintenance

In cooperation with the customer, we will design a tailor-made solution for the individual requirements of the offshore platform, its environment and the crane. Customers can choose the modules that are most suitable for their needs. After delivery and assembly, the platform operator can subsequently monitor and maintain the entire offshore crane fleet from the office.

Liebherr-Rostock GmbH

Liebherrstraße 1

18147 Rostock

Germany

- phone: +49 381 6006 5301

- email: [email protected]

This project is co-financed by the European Union from the European Regional Development Fund.

Operational Programme Mecklenburg-Vorpommern 2014-2020 - Investing in Growth and Employment