Nine million – that's how many hours Liebherr’s D9512 internal combustion engine has been working under the bonnet of R 9100 and R 9150 mining excavators around the world. The 12-cylinder D9512 is specifically designed to withstand extreme outside temperatures and high altitudes with low atmospheric pressure – making it the perfect solution for the challenging environments found on mine sites.

Applications

Locations

Machines

Reliability and strength all over the world

Karunia is a mining contractor based in Indonesia’s East Kalimantan region. The company provides its contracting services at Tabang mine – an open-cut thermal coal mine located in the Kutai Kartanegara Regency of East Kalimantan – and employs a fleet of 27 Liebherr machines, including 3 R 9100 G6 excavators equipped with the D9512 engines. In fact, the R 9100 was the first Liebherr machine to arrive on site in 2021.

Conditions at Tabang mine can be difficult. Temperatures can reach

40 °C and there is a lot of dust in the pit. Despite these conditions, the

R 9100s have impressed Karunia with their exceptional productivity, low fuel consumption, reduced noise and easy-to-maintain D9512 engines under the bonnet. Particularly as these machines operate in two 12-hour shifts every day, reaching almost 550 hours per month.

The engine of the R 9100 is solid and strong, and its durability is high. Our operators are also happy with this unit.

Moolmans is one of the largest mining contractors in Africa and is based in South Africa. The company is responsible for the extraction of waste material as well as zinc and lead ore at Gamsberg mine in the Khai-ma district of Northern Cape, South Africa. The abrasive nature of the rock, the large volume of dust and the high temperatures make life on site incredibly challenging. However, the Liebherr fleet at Gamsberg mine is more than equipped to handle the intensity.

Moolmans currently operates three R 9150 G7 excavators with the D9512 engine to load material. The company appreciates the durability, reliability and robust design of these machines as these attributes make them particularly well suited to the harsh conditions of Gamsberg mine – especially as these machines run in a rhythm of two 12-hour shifts per day through severe conditions with a 90 % availability rate.

We chose the R 9150 because of the reliability and reputation of Liebherr. As soon as we started setting them up correctly, we started seeing up to 35 % higher hourly output than we had anticipated.

Customer testimonials

Karunia, Tabang mine − Indonesia

See how our R 9100 G6 handles the high temperatures at Tabang mine site in Indonesia.

Shanghai Electric, Thar Block-1 mine − Pakistan

Find out how our R 9100 G6 thrives in the middle of the Thar Desert in Pakistan.

Powered by D9512

When two Liebherr factories combine their expertise!

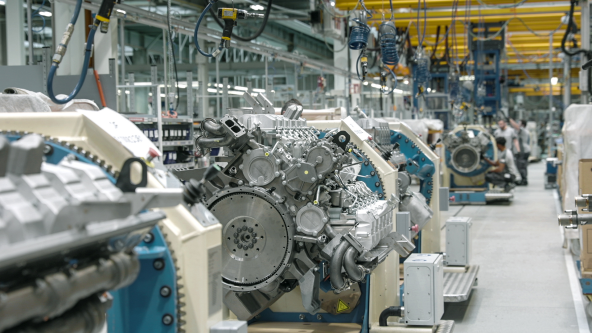

To build engines for mining applications, the people involved need to have a comprehensive understanding of the conditions found on site and what’s expected of the machines powered by the engines. For Liebherr, that meant combining the expertise of Liebherr-Mining Equipment Colmar, our production facility for mining in eastern France, with that of Liebherr Machines Bulle, our production facility for diesel and gas engines in Switzerland.

The team from Liebherr-Mining Equipment Colmar understands what it is customers need from mining excavators like our R 9100 and R 9150, which are powered by the D9512 engine. This is because the French production facility is the epicentre for Liebherr’s development and manufacturing of these mining machines and so understand how crucial excavators are on a mine site. If they stop, the whole mine comes to a standstill, resulting in lost productivity and delays in the production schedule. Liebherr-Mining Equipment Colmar understands this, as well as the difficult working conditions, extreme temperatures and high altitudes found on site. This is why they were the ones to draw up the specifications for the D9512 engine and provide these to Liebherr Machines Bulle.

Mining conditions are tough on the engines. Our machines may operate in temperatures ranging from −40 °C and up to 55 °C as well as from sea level and up to more than 5,000 m elevation. You cannot get the right engine if you don’t first have a clear vision on what it should look like and what features it should have.

A sneak peek of our Colmar facility

Go behind the scenes of Liebherr-Mining Equipment Colmar, France, where our R 9100 G6 and R 9150 G7 excavators are designed and manufactured.

During the development phase for the D9512 engine, Liebherr Machines Bulle collaborated with Liebherr-Mining Equipment Colmar as well as different Liebherr sales and service companies around the world to field test new parts for the engine when necessary. This comprehensive development process is to guarantee that these engines provide optimal reliability.

The team at Liebherr Machines Bulle – made up of over 100 experienced engineers – is responsible for the design and validation of Liebherr engines, ensuring that internal combustion engines being used in mining applications provide maximum availability. The team also designs and produces its own components, such as injectors and electronic control units, that are used in these engines.

The D9512 has been developed specifically for mining industry machines with effectively components that can meet the durability and availability requirements specific to this industry.

Hear from our experts at Liebherr Machines Bulle

Hear from the personnel at our factory in Bulle, Switzerland, who design and manufactured our D9512 engine.

See what the team from Bulle has to say!

Hear from the personnel at Liebherr Machines Bulle, Switzerland, that design and manufactured our D9512 engine.