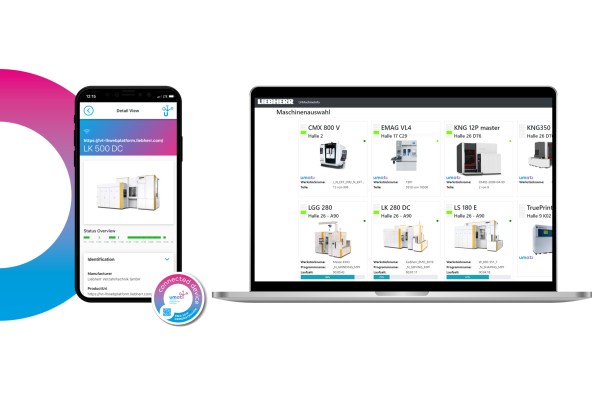

LHWebPlatform – the basis for your digitization projects

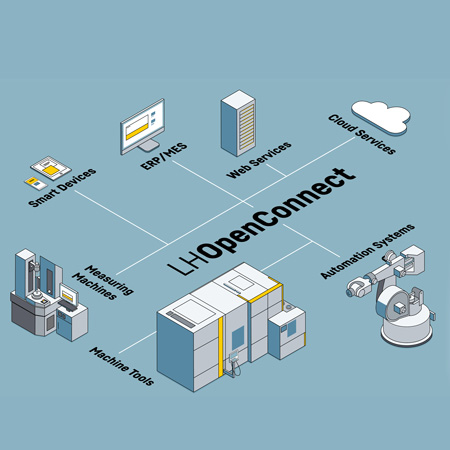

Liebherr offers a modular platform consisting of data profiles, interfaces and the various LHWebPlatform apps. These elements can be used to develop customized solutions which are tailored perfectly to the requirements of the customer. The spectrum of applications ranges from simple monitoring tasks to far-reaching industry 4.0 scenarios – such as process logging, manufacturing analysis and production optimization. A wide variety of transmission paths and protocols – from fieldbus (Profibus, Profinet) to OPC-UA or also umati – enable the connection of the machines, for example to your superordinate systems.

System information and live demo

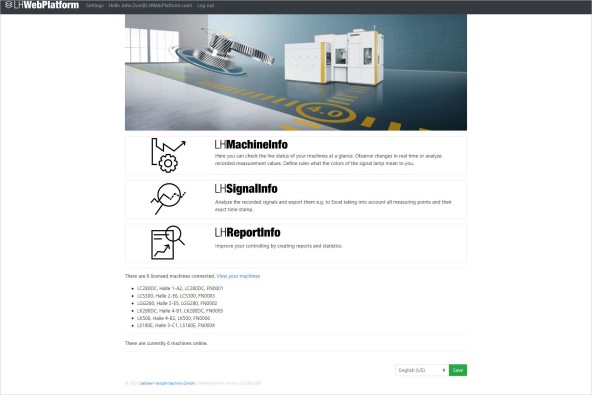

LHWebPlatform is a web application that runs with its database on customer (local) server hardware. Accordingly, the data is safeguarded against external access.

Machine data is never sent to Liebherr or the internet. One-click-setup makes it possible to set up the system without specialized expertise. The server only needs to be accessible from the connected machines.

The app is continuously developed and enhanced. To enable the app functionality, a license key must be provided.

LHWebPlatform applications

LHMachineInfo

The LHMachineInfo application offers many possibilities:

- See the live status of your machines in the field at a glance

- Monitor changes in your production in real time

- Get detailed information about each machine with the respective machine dashboard

- Select the data relevant for you from defined data profiles (Basic, Production, Process)

- Define your own signals via an intuitive logic editor and save them in a reserved area

- Visualize data on production status, manufacturing equipment and machining results

LHSignalInfo

The LHSignalInfo application offers many possibilities:

- Draw conclusions about the quality and efficiency of your machine and your production based on the evaluation of these signals

- Analyze the recorded signals and export them, for example to Excel, taking into account all measuring points and their exact time stamp

- Define your own rules, for example, what the colors of the signal light mean

- Choose from a variety of interfaces and protocols such as OPC UA, MT Connect, MQTT or umati

LHReportInfo

Improve your controlling by creating reports and statistics with the LHReportInfo.

In the next sliders you will discover the numerous overviews that LHReportInfo offers, such as a utilization overview, workpiece counter and many more.

LHEnergyInfo

Efficient monitoring of consumption with LHEnergyInfo

Discover the future of energy consumption monitoring with our LHEnergyInfo app. This innovative application gives you a constant overview of your current power and energy consumption data – whether it’s electricity, compressed air or cooling lubricant. Track your consumption over time and analyze the energy requirements for each workpiece. You can also view the energy costs and CO2 equivalents per workpiece at the same time.

Our app helps you monitor energy consumption in real time and analyze precisely where energy can be saved. That not only reduces your costs, but also makes a significant contribution to sustainability. Experience a whole new level of transparency and optimize your processes like never before.

Contact

Florian Schuon

Head of Digital Solutions

Liebherr-Verzahntechnik GmbH

Kaufbeurer Straße 141

87437 Kempten/Allgäu

Germany

Phone: +49 831 786 1523

umati

More information

Read interesting articles from our customer magazines and press releases