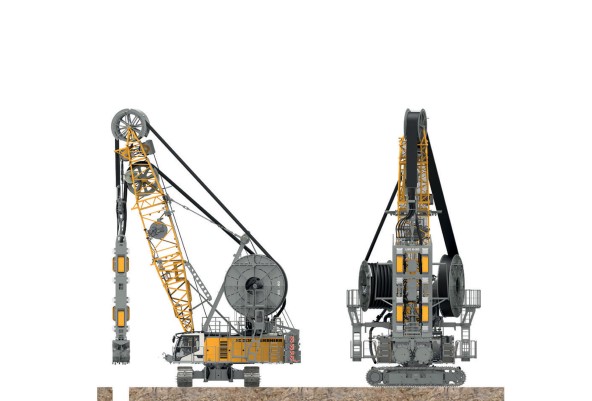

Like a hot knife through butter

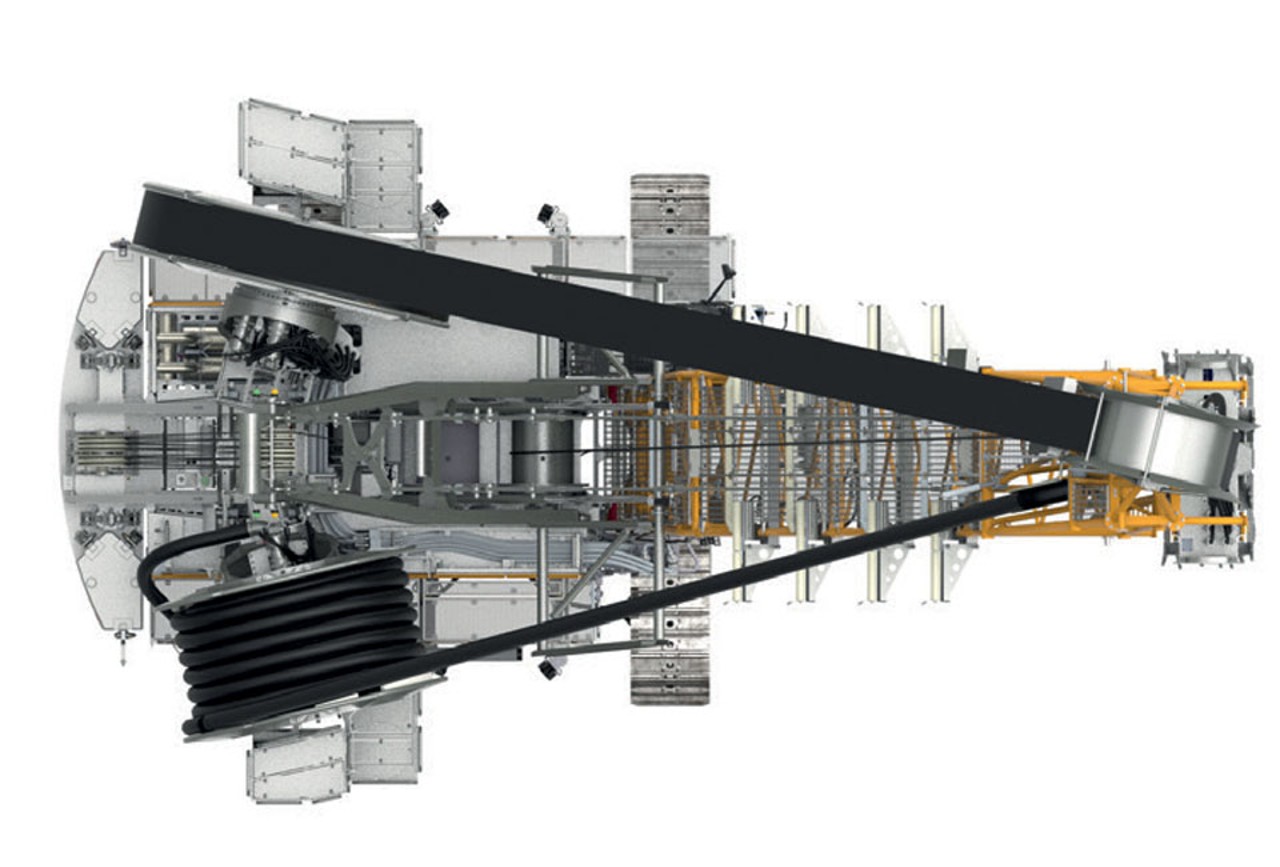

The innovative slurry wall cutter from Liebherr is used when particularly large trench depths are required and the subsoil is extremely hard. Unlike a grab, the diaphragm wall cutter works continuously during excavation. The existing subsoil is loosened and crushed by rotating cutter wheels.

Cutter wheel drive

Bite lengths

Slurry wall thickness

Max. working depths

The one-stop solution

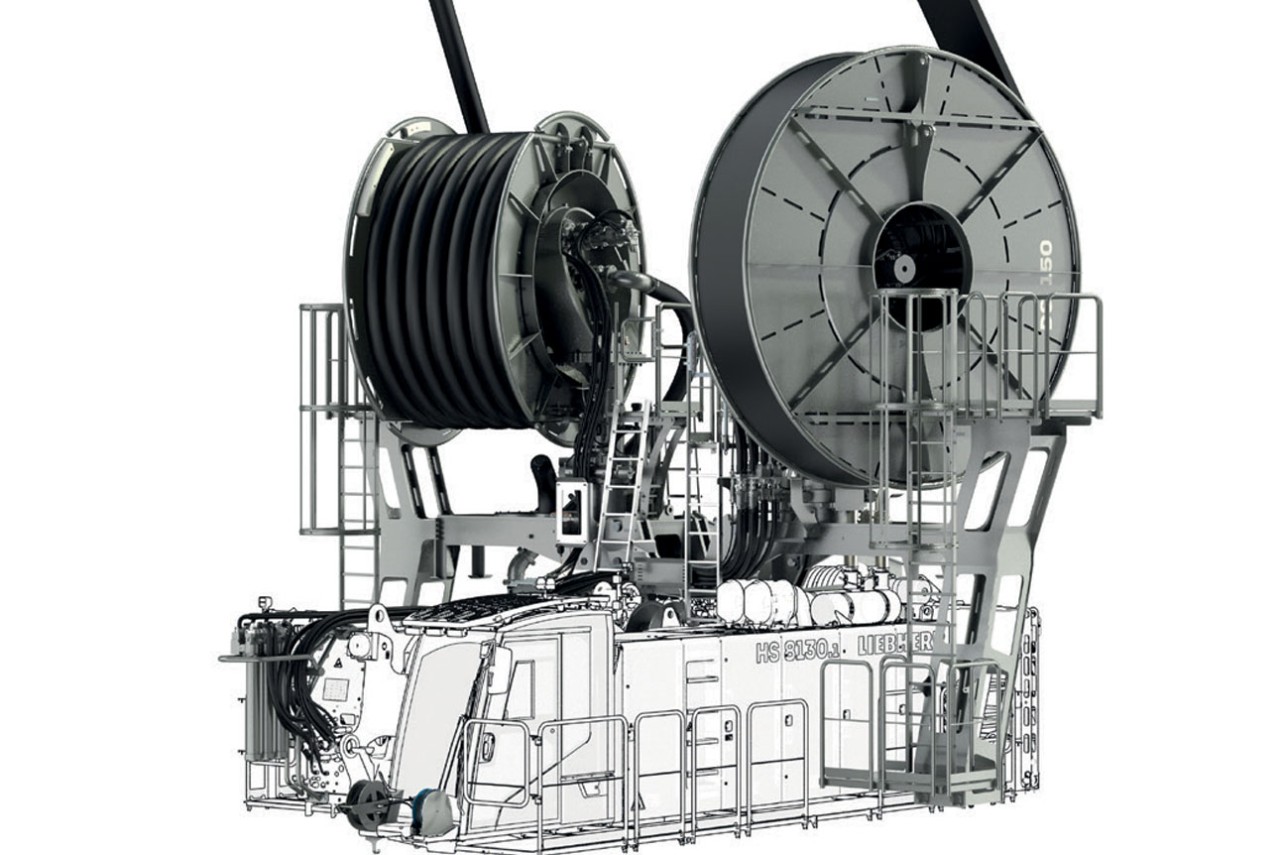

The Liebherr slurry wall cutter package consists of the new LSC 8-20 hydromill trench cutter, the proven HS 8130.1 duty cycle crawler crane, the DS 150 hose drum system and a corresponding separation plant. Nevertheless, the HS 8130.1 maintains its multifunctionality and can also be fitted with slurry wall grabs, casing oscillators and tamper weights. This combination makes the package especially suitable for deployment in urban areas and has been optimized to enable quick and precise work.

Functionality

4C Power - pay per use

Liebherr offers the ‘4C-Power’ pay-per-use business model for the cutter wheel drives, whereby the customer only pays for the cutter wheel drives per working hour. The advantage for the customer is that the costs are transparent and there are no surprises. The fee covers all the costs of the cutter wheel drives: overhaul, service and transport are included. Workload and usage determine the price.

Verticality assistant

The assistance system is fully integrated for monitoring and logging the cutting process. Cutting reports for complete documentation, traceability and transparency at the construction site can be created at the push of a button.

Modularity

The Liebherr diaphragm wall cutter has a modular design so that customers can customise the setup to meet their individual requirements and technical challenges.

For construction sites with limited height, the modular cutter frame can be shortened by four metres.