Liebherr combines sustainability and quality

Sustainability at Liebherr-Verzahntechnik GmbH is firmly rooted in all processes. Policies to conserve resources, increase energy efficiency and boost the circular economy are interconnected and incorporated directly into the products.

As early as the new machine development stage, Liebherr follows the most resource-efficient design process possible while still maintaining high machine functionality. Energy efficiency, a long-life cycle and reparability are integral to the process.

Resource-efficient product design

Modern drive systems work to minimize energy costs. The machines themselves are constantly being developed further: Design adjustments to the machine housing, for example, eliminated the need for the previously fitted soundproofing. This greatly increased recyclability while keeping the sound insulation at its current high level. Digital solutions such as the LHEnergyInfo app (read more here) enable energy consumption to be clearly logged and optimized in our own production, but also for our clients. As well as new machines, Liebherr also offers a Reman program for performing general overhauls on used machines, which not only extends life cycles, but also reduces material and power consumption considerably in relation to new production.

Resource-efficient manufacturing processes

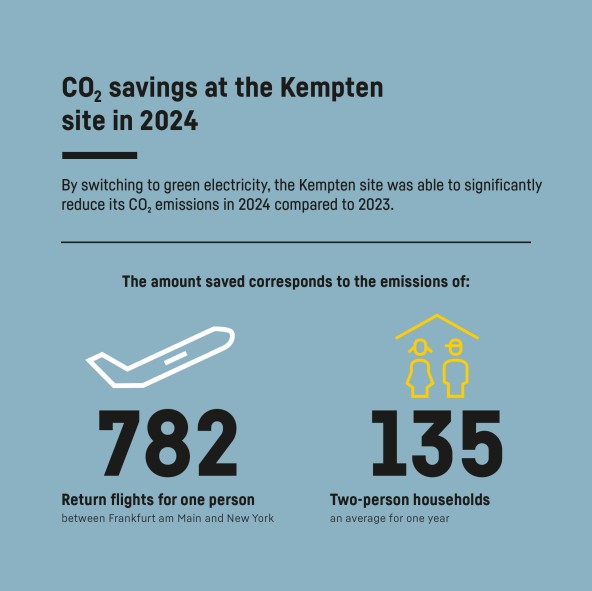

Production processes are also being meticulously optimized. This is continuously reducing the use of volatile organic compounds (VOC) during production, allowing a drop in their use by nearly 80% since 2007. Systems in the paint shop have been switched from gas to district heating. This is helping to reduce fossil fuel use and thus the CO2 footprint. At our Ettlingen (Germany) site, a new demineralization system in the electroplating facility ensures less water is used and processes remain stable. As a next step, a photovoltaic system with a power of around 2.5 MWp is planned for our Kempten (Germany) site, yet another measure in our targeted switch to renewable energies.

Sustainability as part of the corporate culture

Environmentally responsible behavior is demonstrated by employees’ active involvement in internal strategic campaigns aimed to reduce emissions in the long term. Training courses in line with ISO 50001 also promote awareness. The topic is firmly anchored in apprenticeships as well: Apprentices participate in programs like “Carbon Busters” run by the VDMA (German Mechanical and Plant Engineering Association) or search specifically for leaks in the compressed air supply during maintenance work. The apprentices’ annual tree-planting campaign to reforest the Allgäuer protection forest has been part of the sustainability drive for many years (see here).

Transparency through sustainability platforms

Sustainability is becoming ever more important in working with customers and partners. Independent evaluations from established rating platforms like EcoVadis or Integrity Next provide an insightful comparison into achievements in sustainability. Good results underline the significance of environmentally responsible behavior in the company. In addition to these platforms, Liebherr-Verzahntechnik GmbH also actively operates systems specific to the automotive industry such as SAQ/NQC.

Tim Langer from the Corporate Responsibility Team says: “All of this demonstrates that sustainability at Liebherr is not treated as an afterthought; products, processes and economic efficiency heavily depend on it.” All measures ultimately feed into each other and integrate themselves into the machines and systems. Product Manager Martin Schwarzmann adds: “Continuous improvement in sustainability is and will remain integral to further developing corporate processes and product design.”