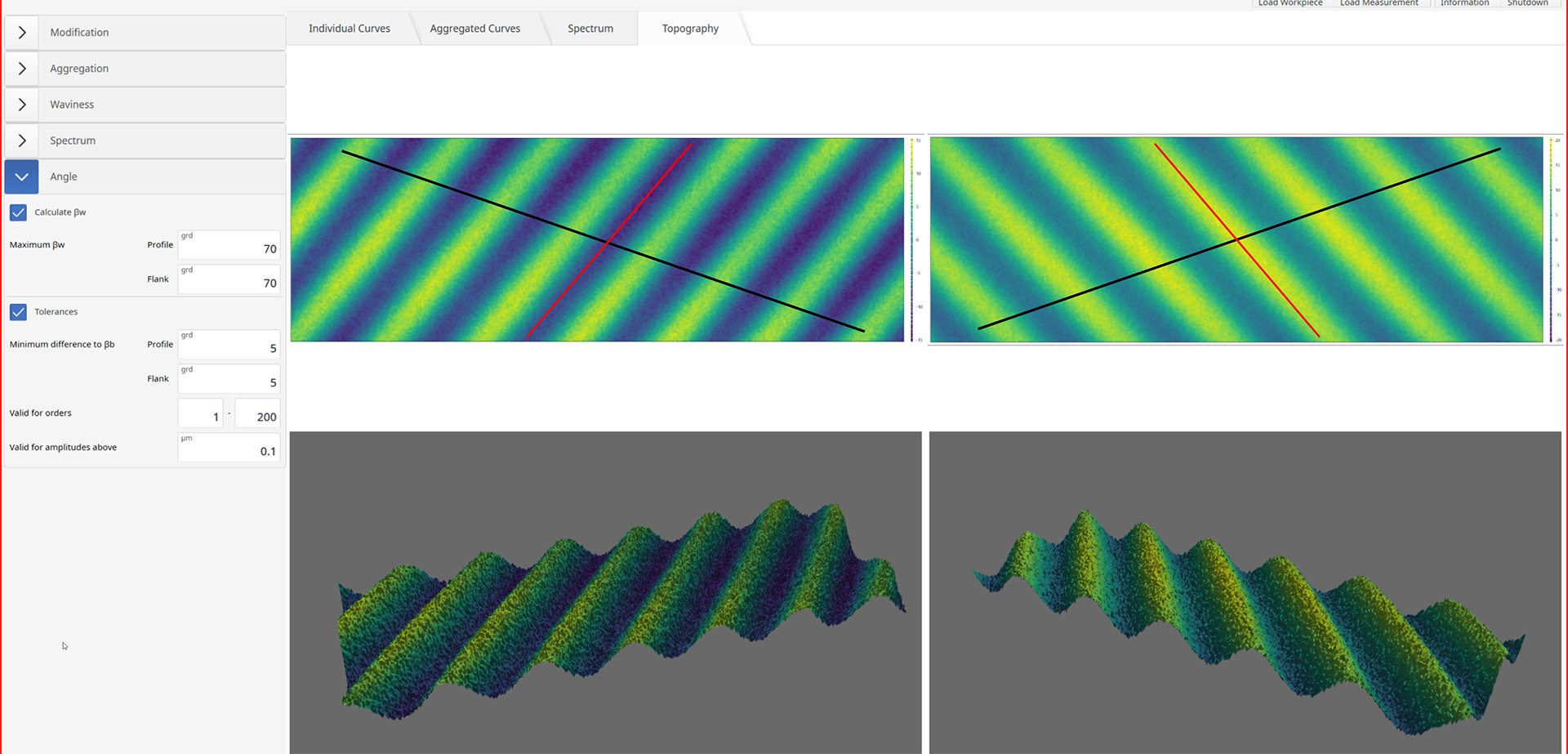

Progressive measurement solution: Patent application for faster and more precise results

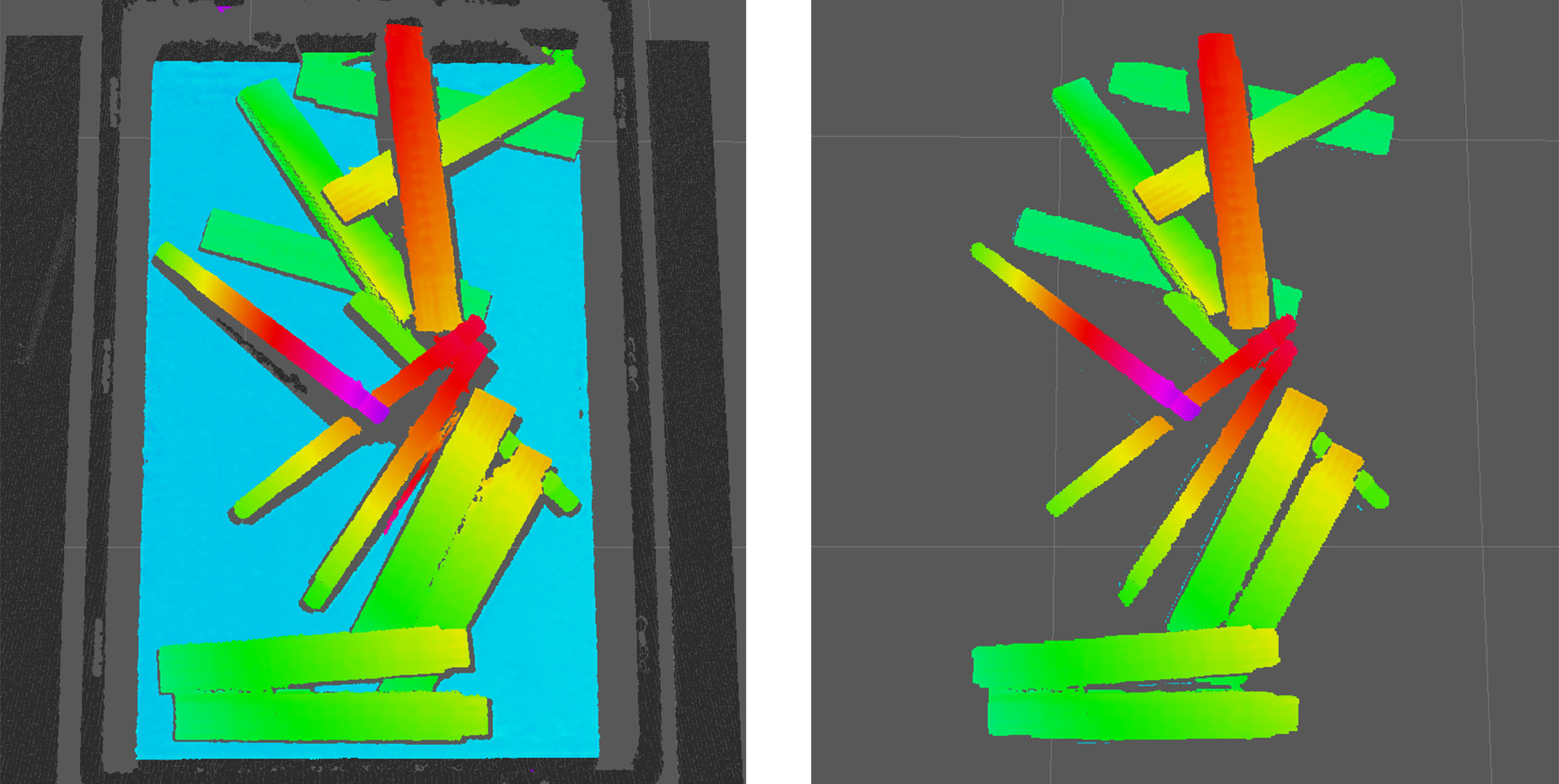

Waviness on tooth flank surfaces is a significant factor in noise developing in gearboxes. Liebherr-Verzahntechnik GmbH has therefore filed for a patent for a new measurement method, which produces more precise and meaningful results with less labor required.