About IMRO

IMRO Maschinenbau develops and manufactures machines and systems as well as the latest recycling processes with a focus on separation technology. The solutions are customised to the requirements of the companies and enable efficient and sustainable recycling concepts.

Industry

Machine

Liebherr product

Initial Situation

Recovering valuable materials successfully

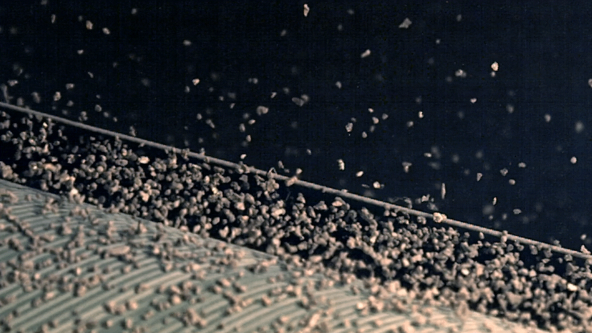

Countless waste products, production residues, and other material streams contain valuable non‑ferrous metals such as aluminium or copper. To recover these, highly specialised separation systems are employed. A central role is played by the NF separator: it uses eddy current technology to separate non‑ferrous metals precisely from heterogeneous material streams and make them reusable.

Challenge

High rotational speeds, extreme forces – a demanding rotor environment

In the NF separator, a rapidly rotating magnetic rotor generates the required pole‑change frequency. The pole changes and the resulting eddy currents in the non‑ferrous metals create a repulsive force that ejects the affected particles from the material stream. At speeds of up to 3,800 rpm, enormous centrifugal forces act on the magnets and the construction. Conventional stainless‑steel casings tend to deform (ovalisation), leading to imbalances, unstable machine operation, increased wear, and the need to replace bearings prematurely. For modern recycling plants, this is neither efficient nor economical in the long term.

Solution

CFRP rotor winding: stable, precise, magnetically compatible

Our specially wound CFRP bandage encases the magnetic rotors so that the magnets remain securely in position even at the highest rotational speeds. Carbon‑fibre reinforced plastic offers high strength with minimal deformation at low wall thickness and does not affect the magnetic fields. The result is a perfectly round, lightweight, and permanently stable rotor casing that ensures smooth, low‑vibration operation.

Application

Greater precision in IMRO’s eddy current separator

The CFRP‑wound magnetic rotor is used in IMRO’s NF separators. Thanks to the stable rotor geometry, the distance to the outer GRP casing can be reduced – increasing the magnetic effect on the material. This enables even more precise separation of the smallest non‑ferrous metals and sustainably improves the recycling rate.