HS 8300 mining dragline

Performance

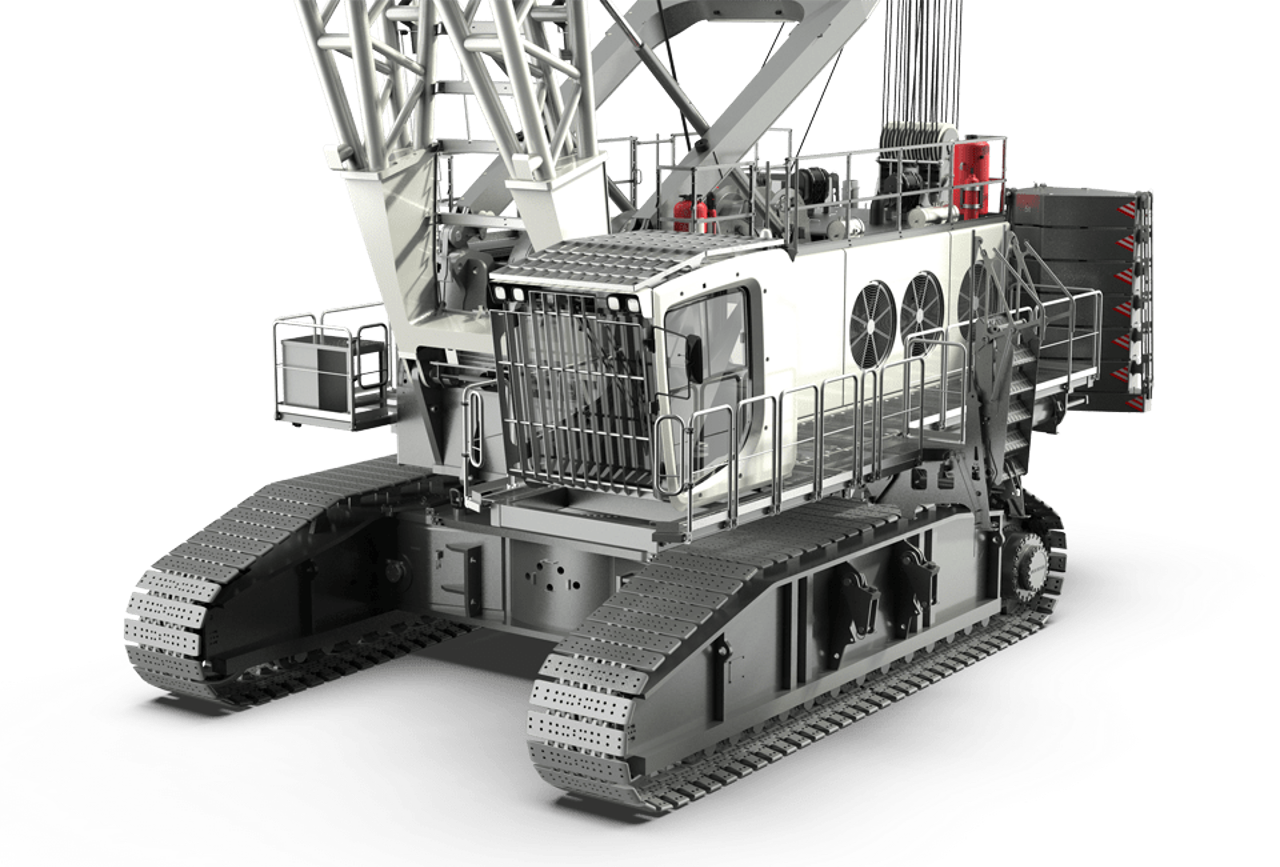

The mining dragline HS 8300 has been designed to meet the tough conditions in mining environments. The machine delivers power and performance with low cost per ton and high turnover rates. The interlock control system allows for power regeneration in dragline operation, reducing fuel consumption as well as wear and tear of the free-fall winch.

approx. 364 t

802,483 lbs

Liebherr V12

(induction engine available)

1250 kW

1675 hp

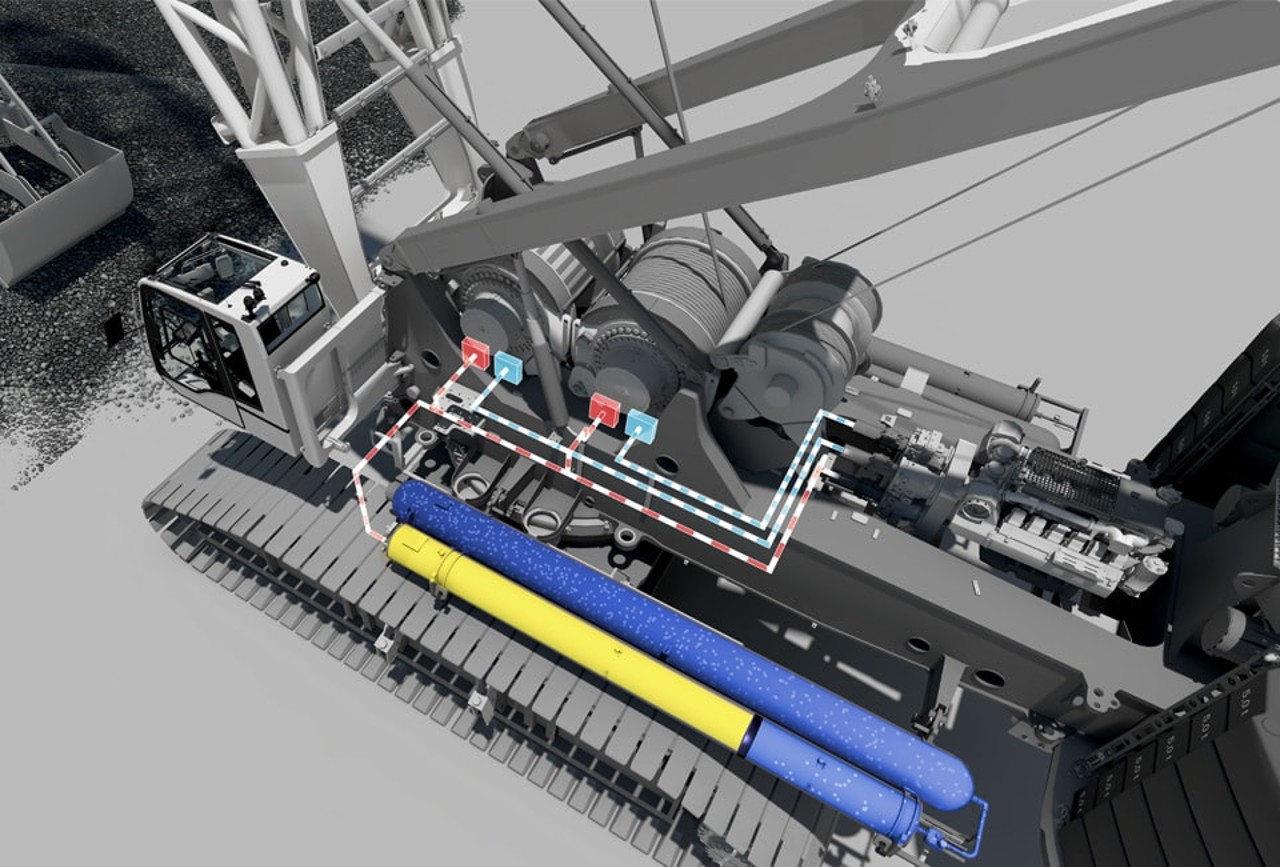

with hybrid drive

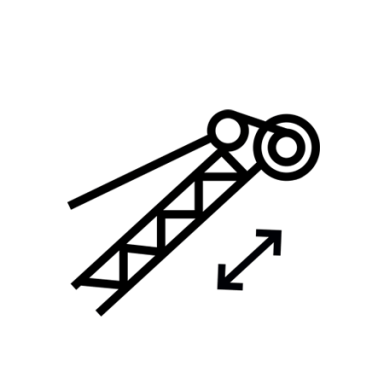

up to 50 m

164 ft

up to 11.5 m3

15 yd3

1.56 kg/cm2

153.0 kPa

according to

EN 474-1

and

EN 474-12

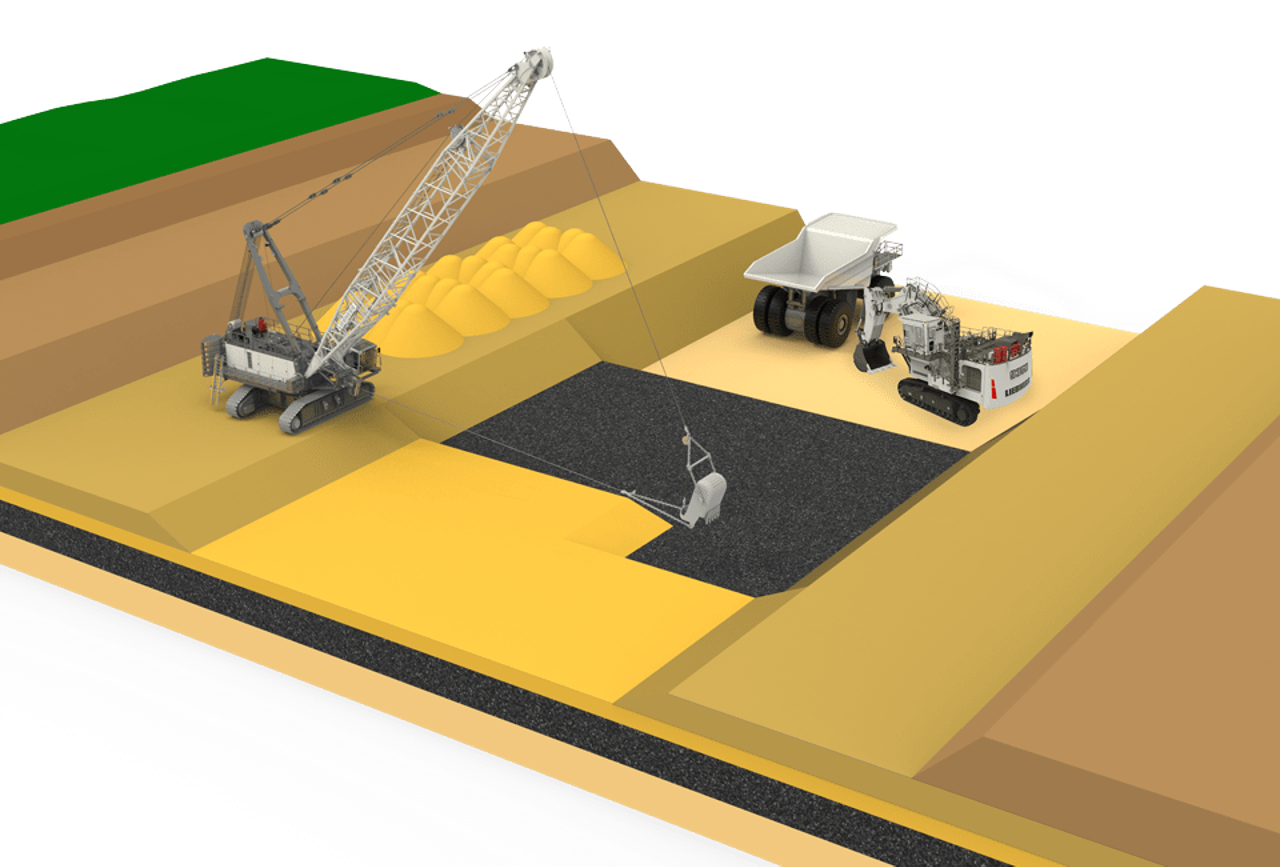

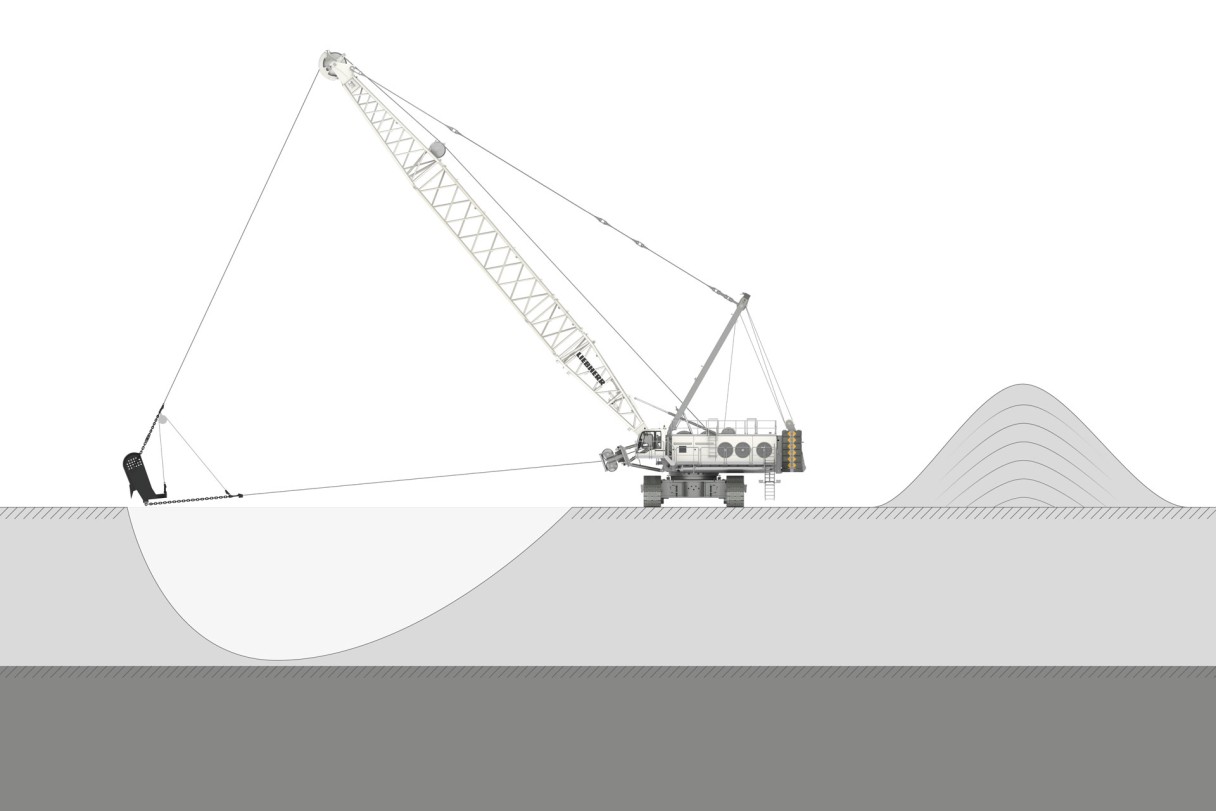

The dragline excavator

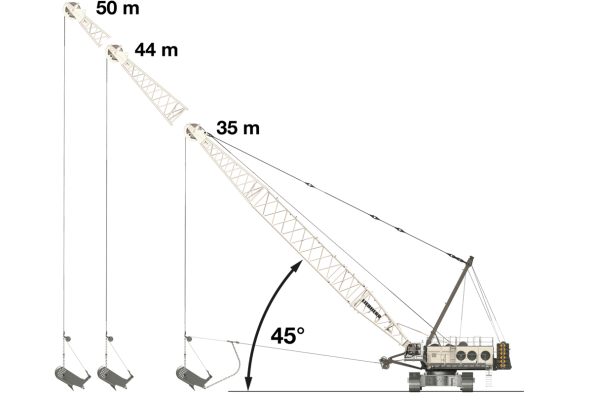

Digging ranges

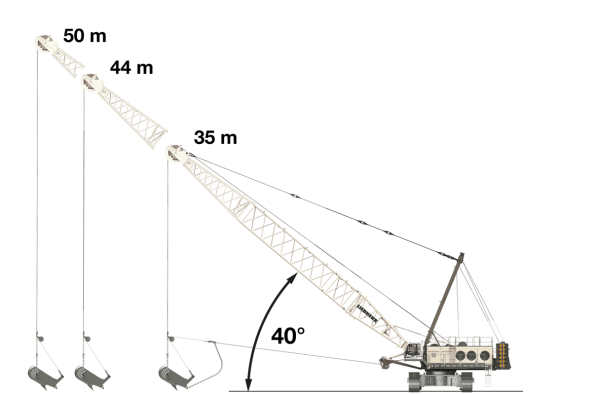

Digging and dumping ranges at 40° boom angle

at an assumed density of 1.6 t/m³ and a fill factor of 100 %

| Boom length | 35 | 44 | 50 | m |

| GP - General purpose bucket | 11.5 | 7.6 | 4.6 | m3 |

| HD - Heavy duty bucket | 11.1 | 7.3 | 4.2 | m3 |

| XHD - Extra heavy duty bucket | 10.7 | 6.9 | 3.8 | m3 |

| Load capacity | 30.0 | 19.2 | 11.2 | t |

| Digging/dumping reach* | 29.8 | 36.7 | 41.3 | m |

| Digging depth | 14.9 | 18.4 | 20.6 | m |

| Dumping height | 16.1 | 24.0 | 28.6 | m |

| *the reach is calculated from the rotation centre of the machine. | ||||

Limestone extraction

MINING POWER

Designed for maximum service life.

Adapted rope speed for optimum filling of the bucket and fast working cycles.

Hybrid drive lowers fuel consumption and operating costs.

Robust steel construction and components from Liebherr reduce wear and downtime.

Using data transmission for quick reaction to our customers’ requirements.

Safety systems protect operator and machine during operation.

Engines from Liebherr ensure reduced emissions and fuel consumption.