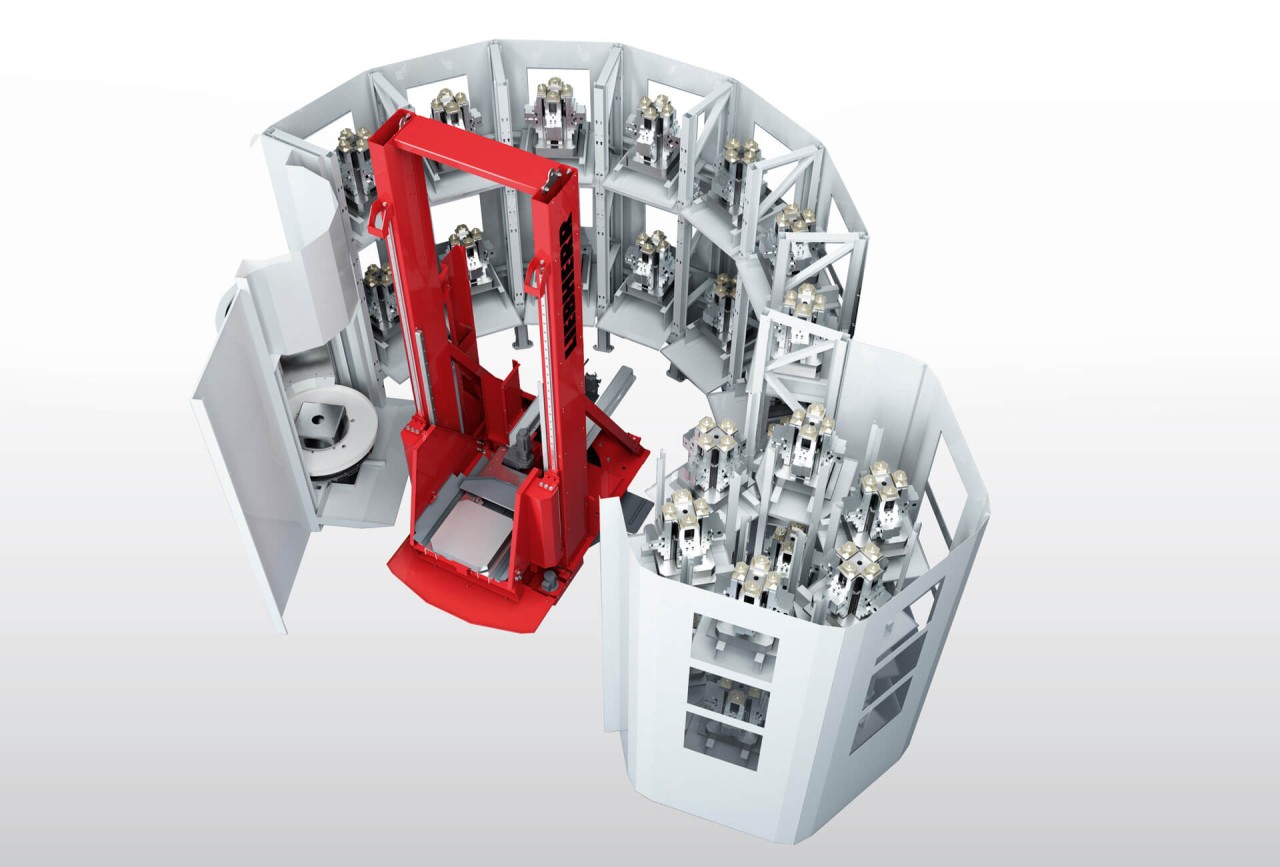

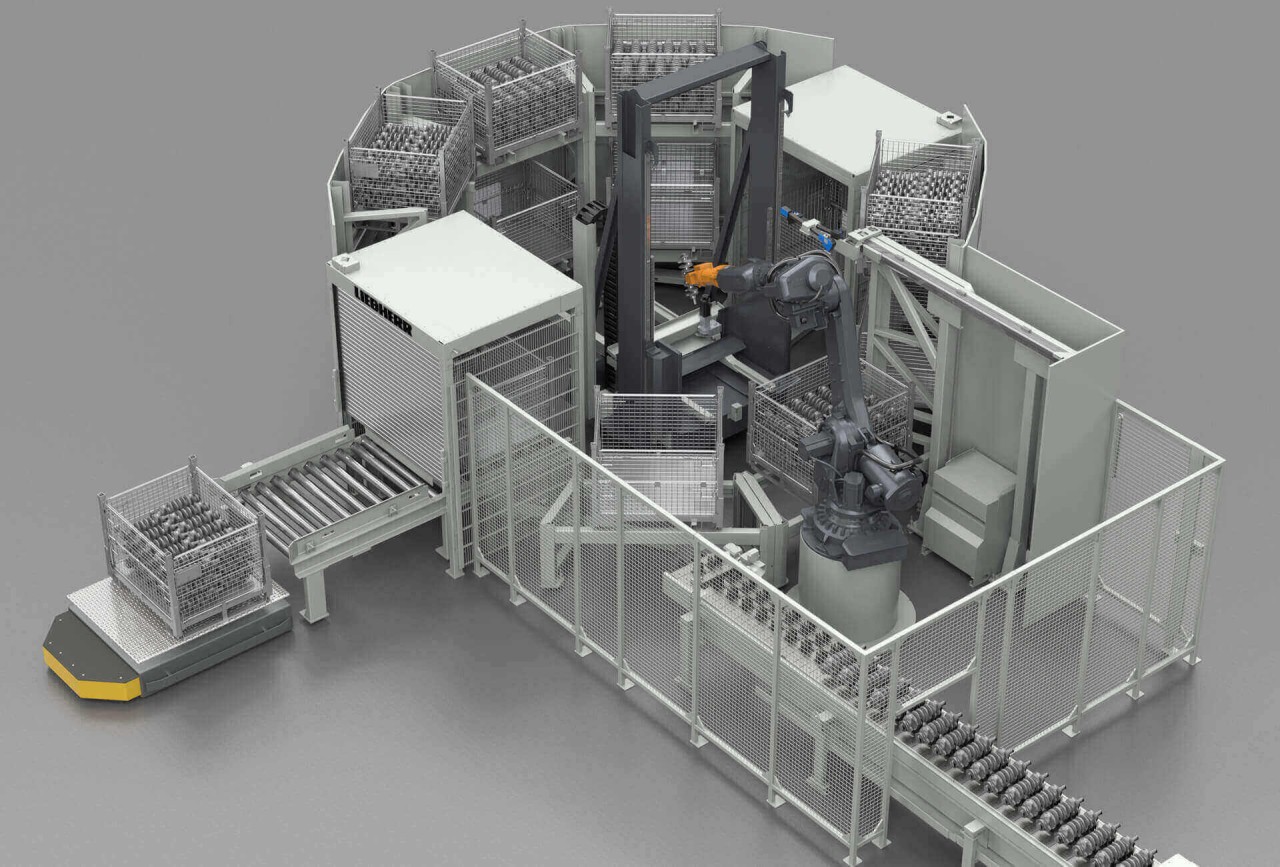

RLS Rotary Loading System

Looking for a compact pallet handling system for automating just one or two machining centers? Then the RLS is the uncomplicated and space-saving solution for you.

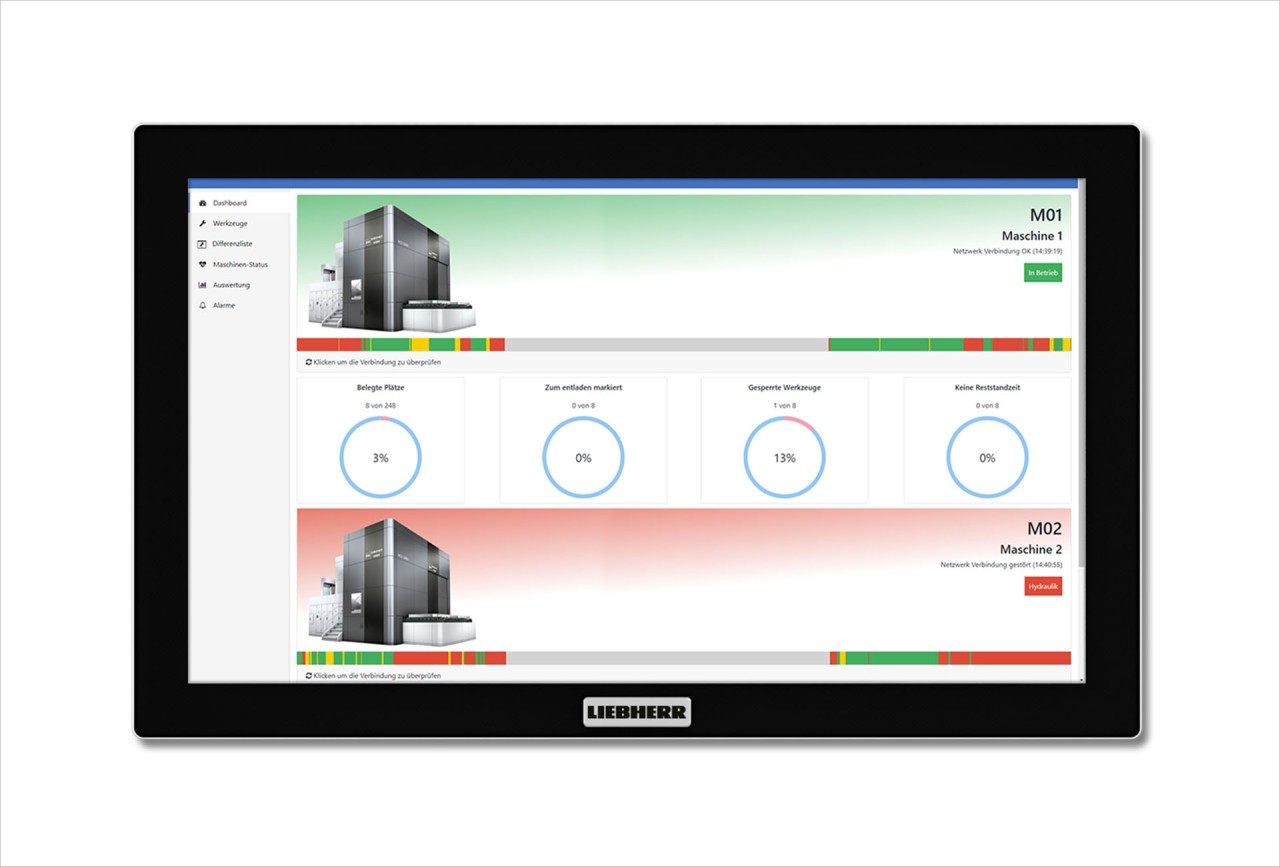

Liebherr automation for flexible manufacturing

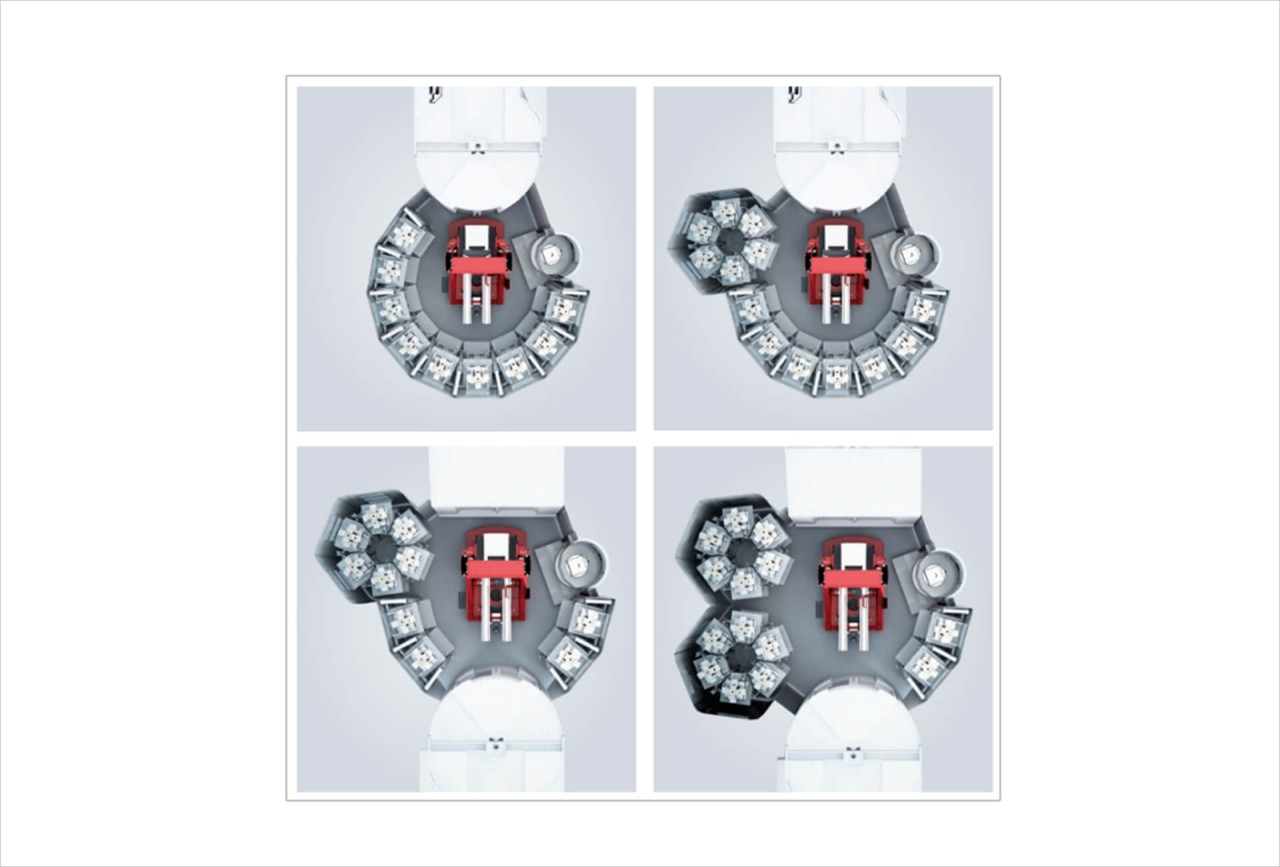

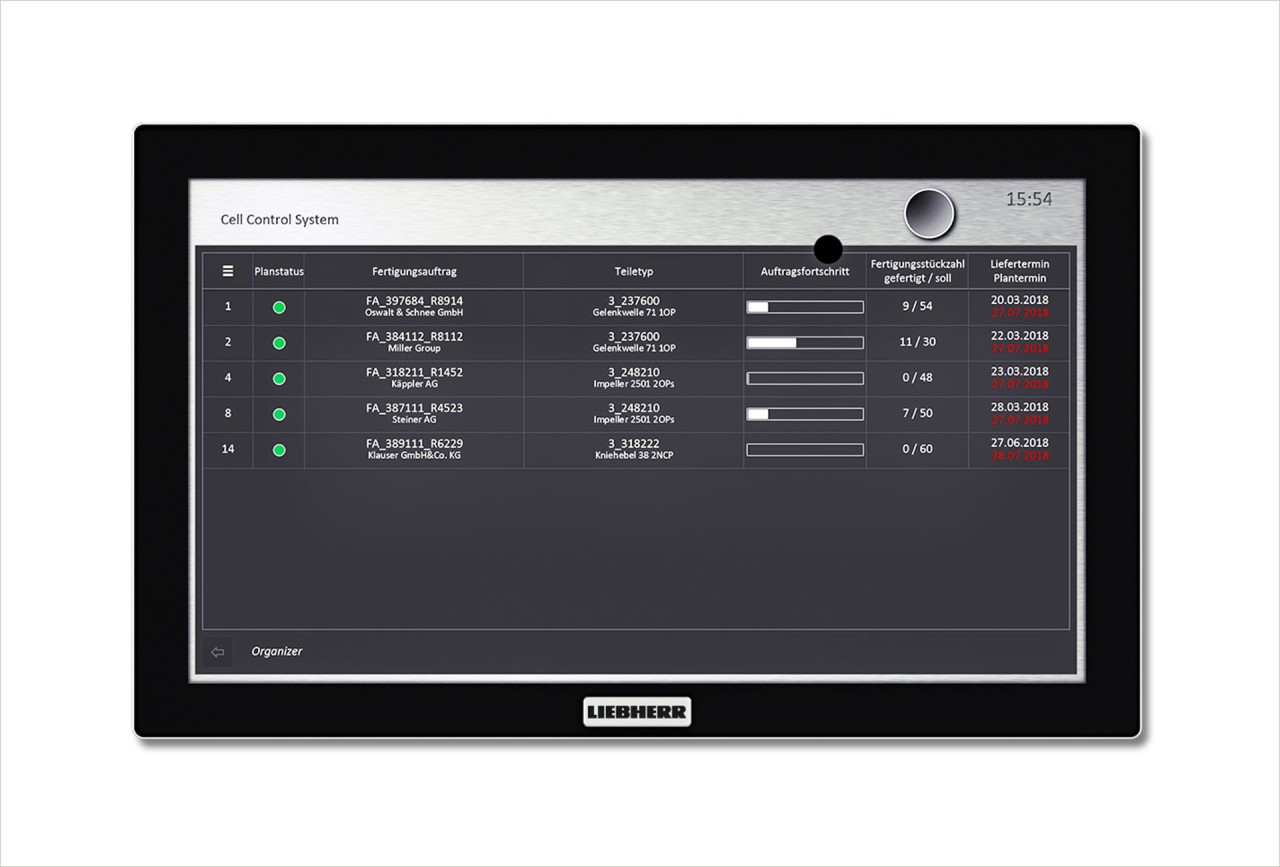

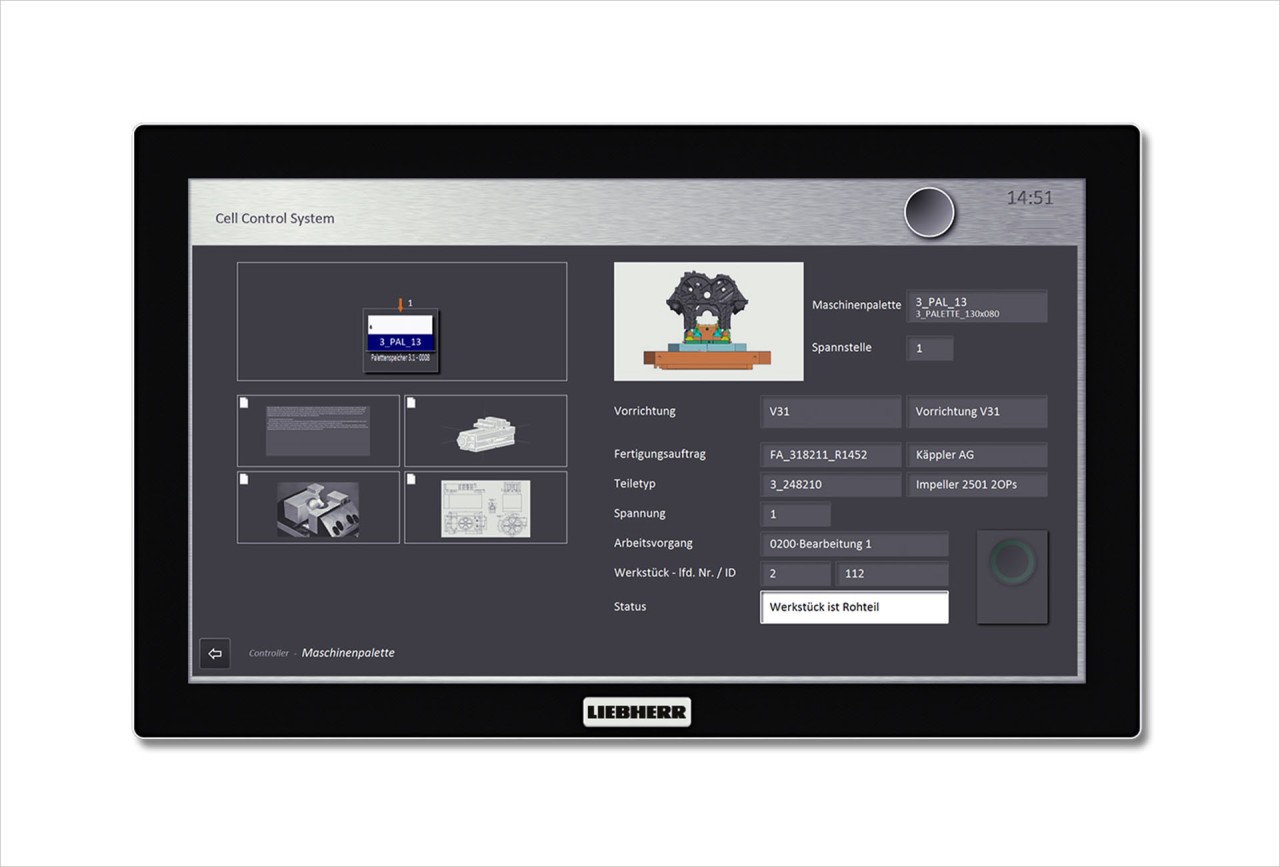

Pallet handling systems are constructed either as circular or linear storage systems. Whereas linear storage systems offer a large stock of parts for extensive unmanned manufacturing times and a large number of machines, round variants impress, above all, with their compact design. This is true of our Liebherr Rotary Loading System RLS, which has a high storage density and a small footprint. An RLS automates one to two machining centers and is therefore the ideal system solution for inexpensive entry into highly efficient manufacturing.

01/03

Animation of the rotary loading system RLS

01/04

Have we sparked your interest? Here's where you can find more information about our products:

Results 1–2 of 2