Robot vision technology packages - LHRobotics.Vision

An eye for detail

The technology packages

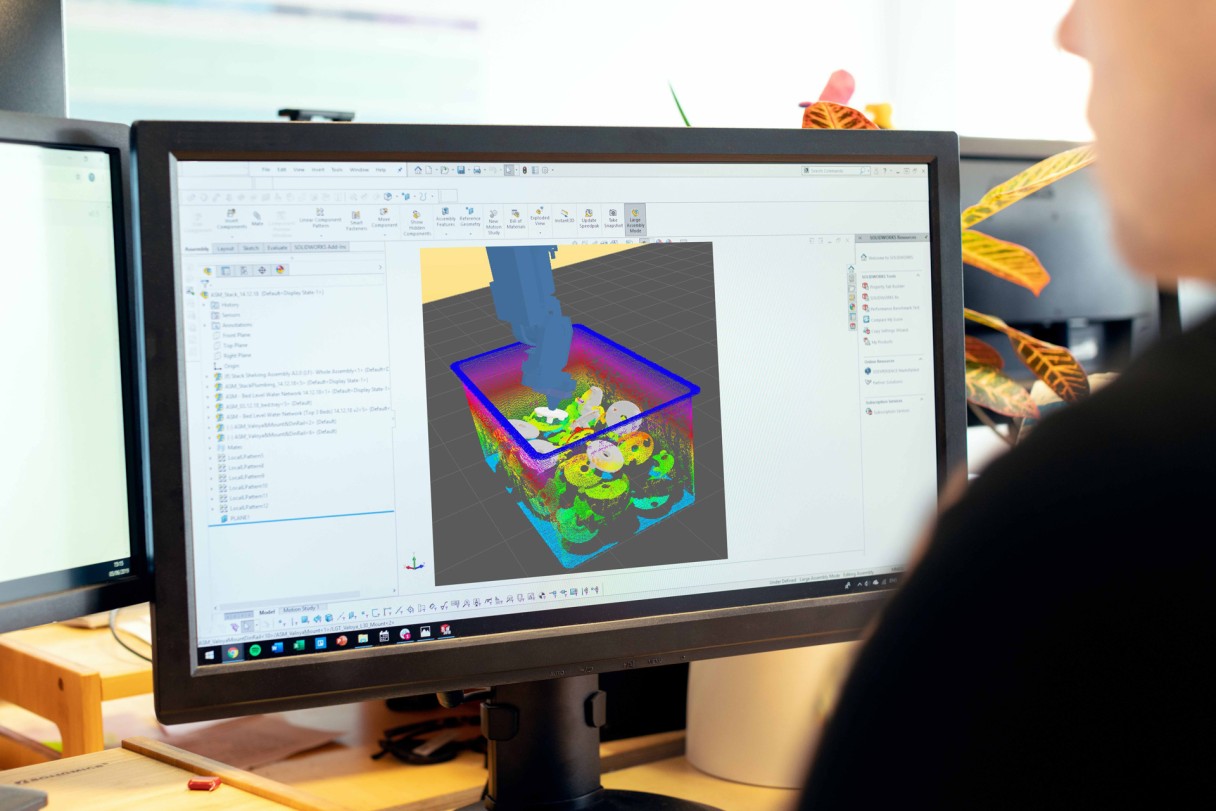

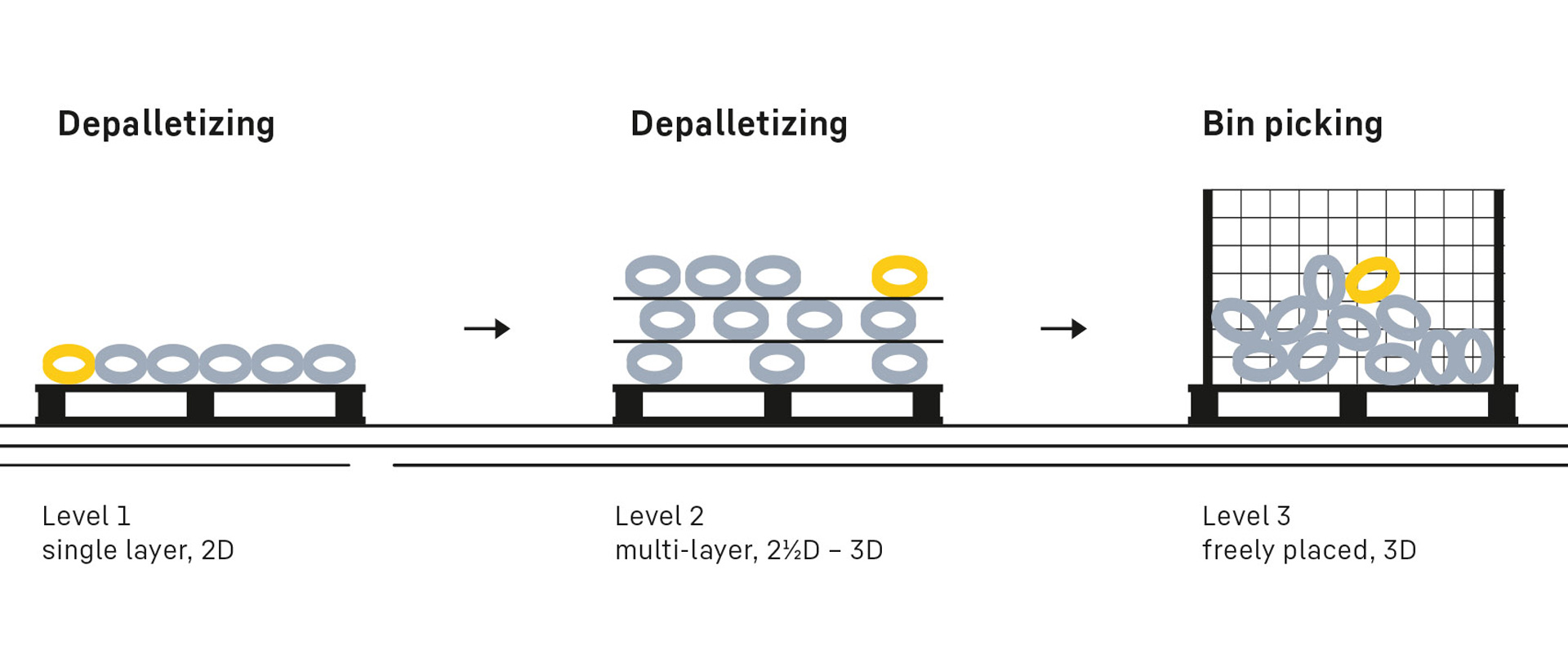

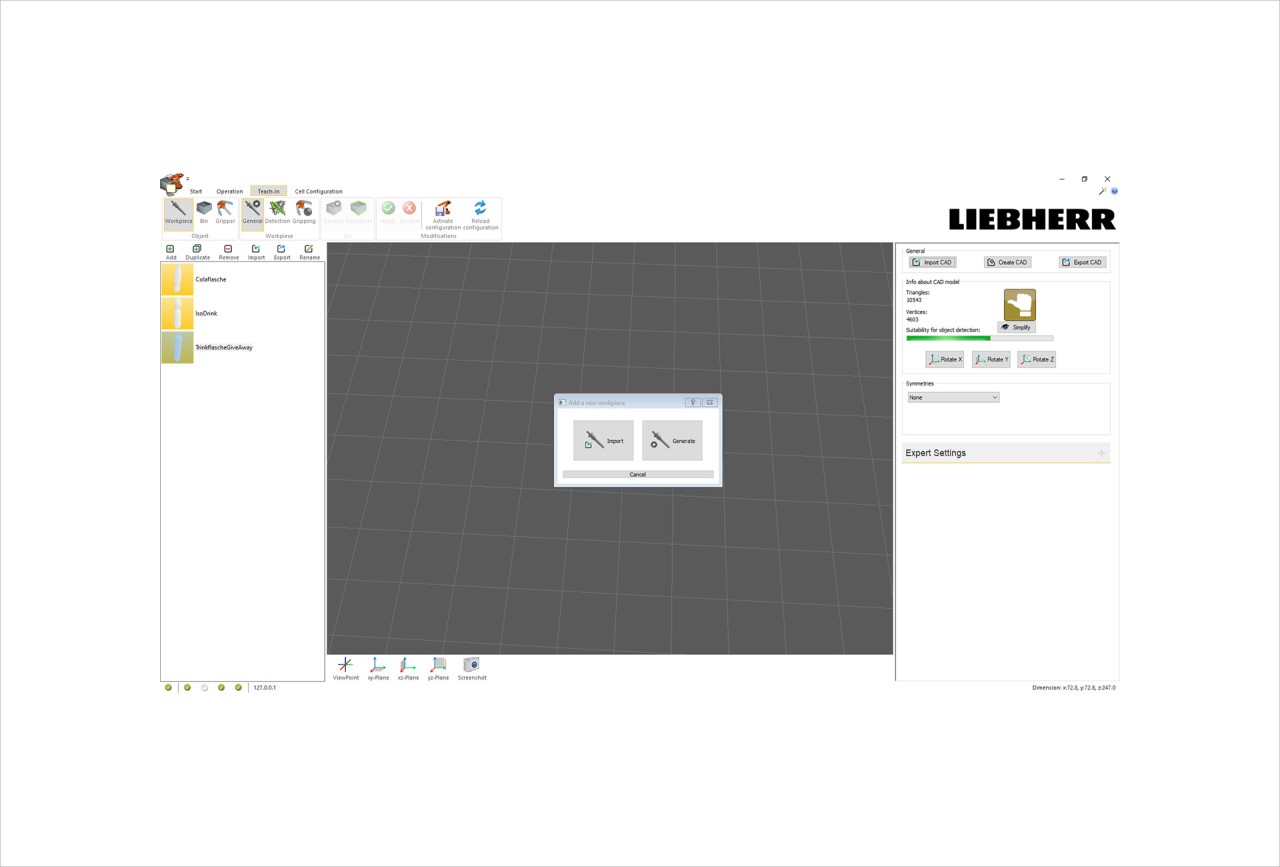

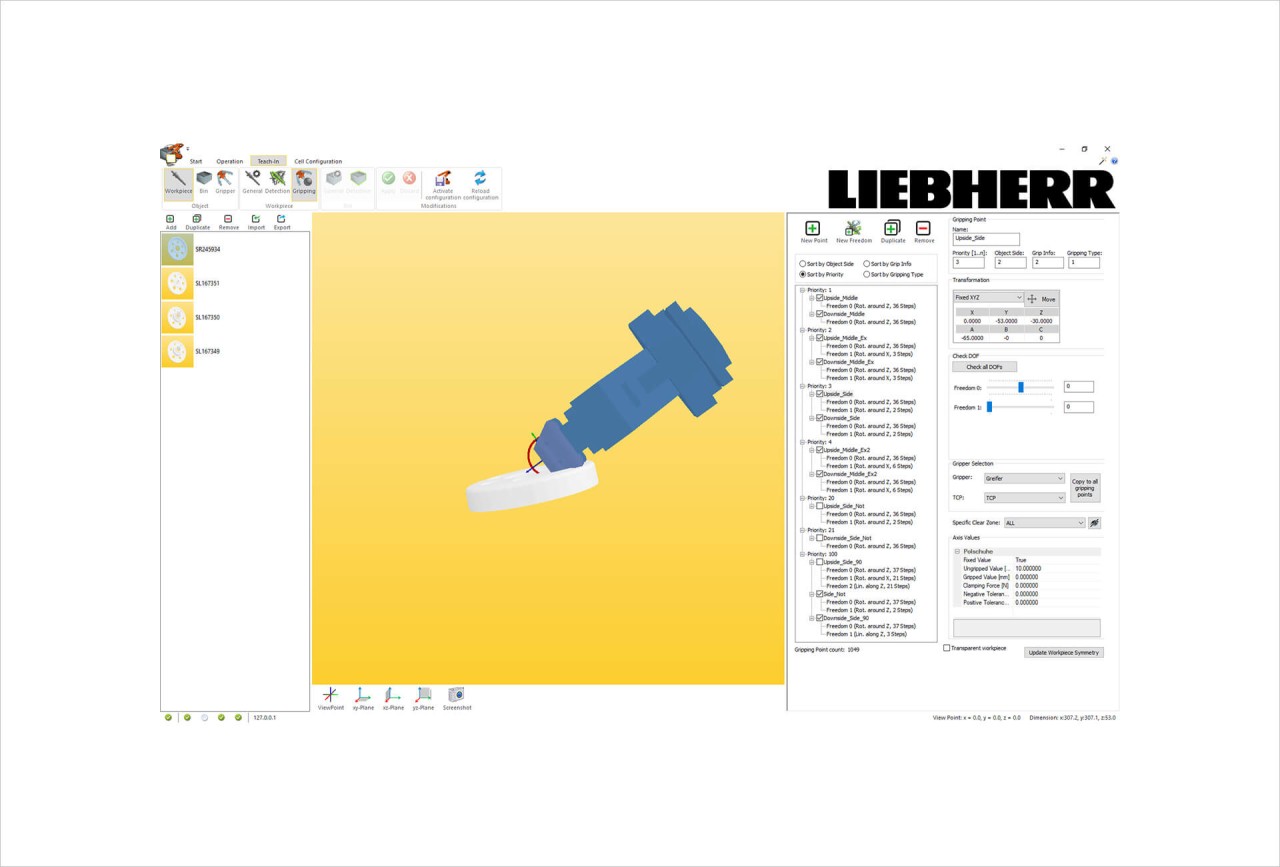

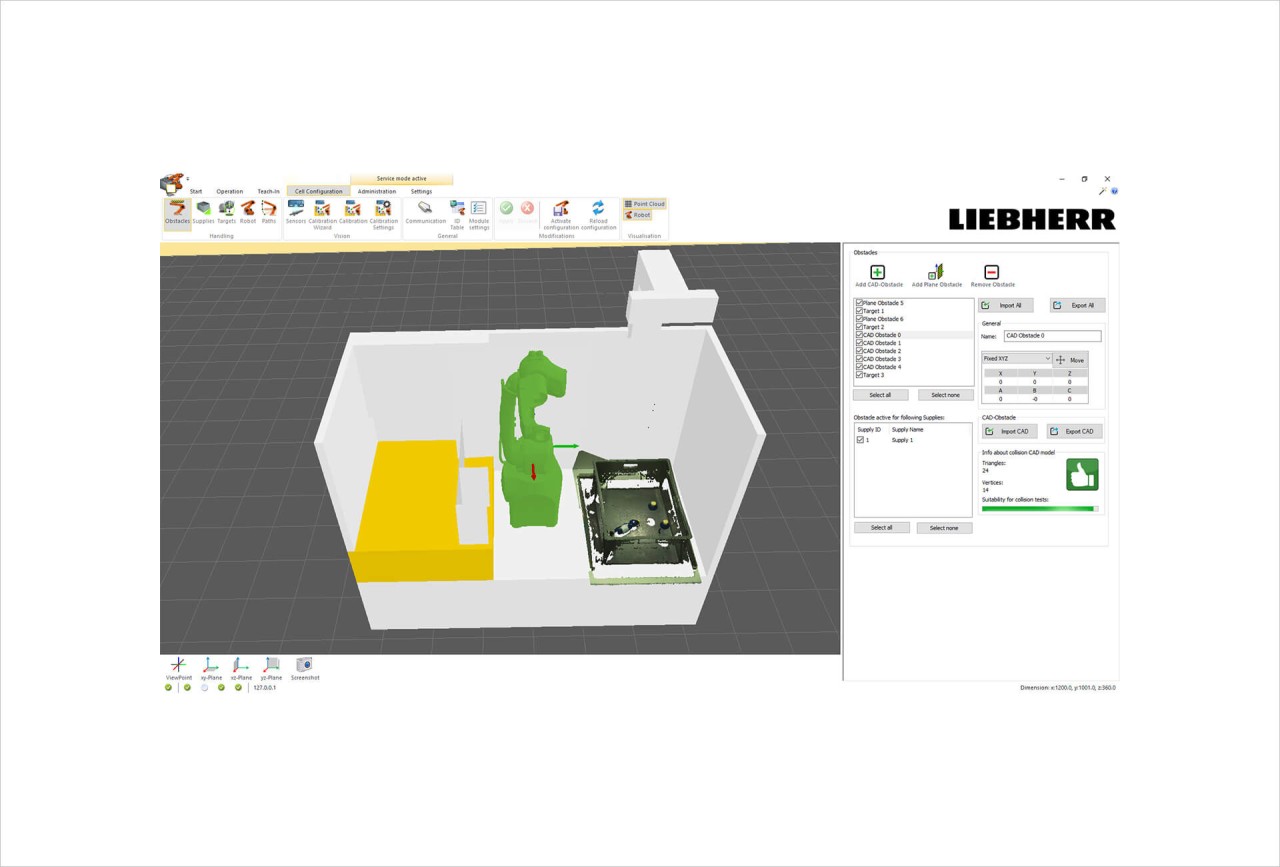

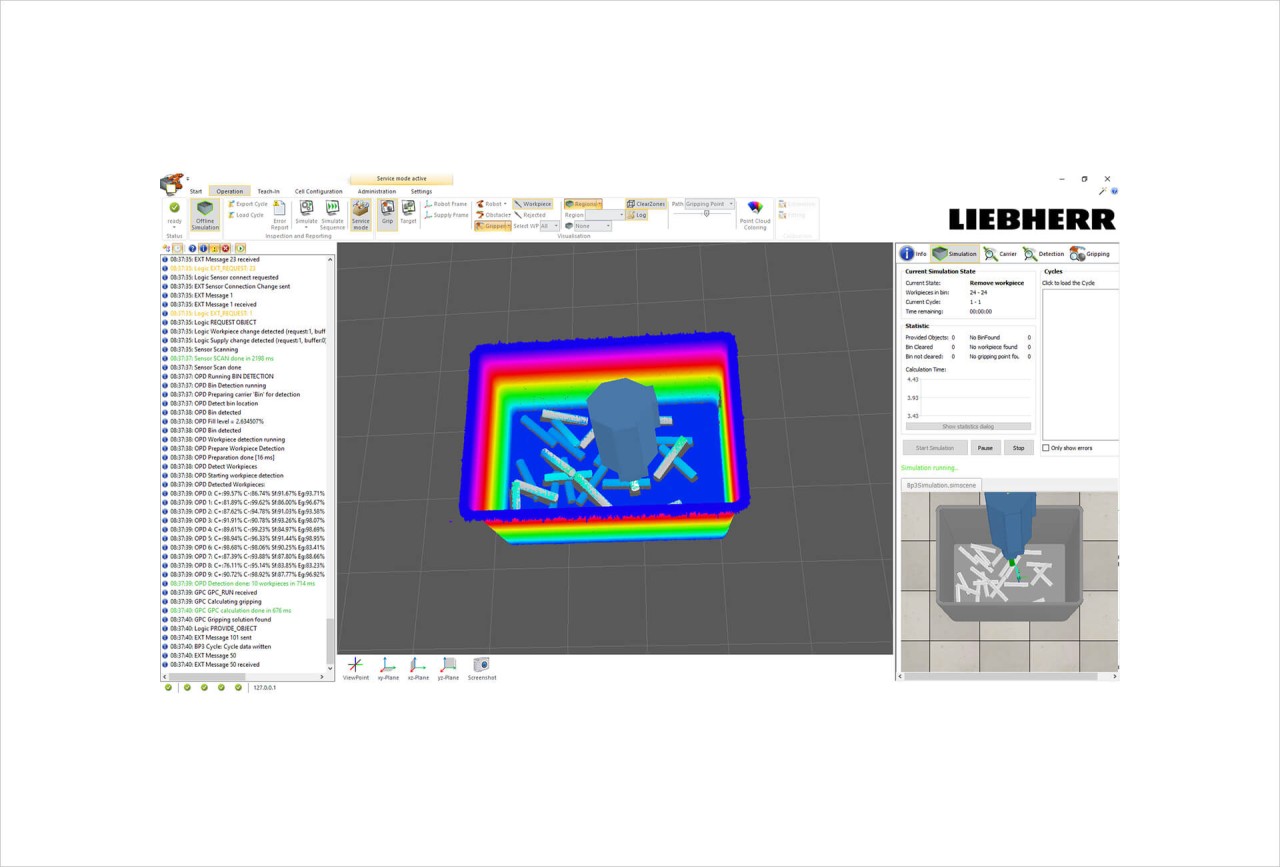

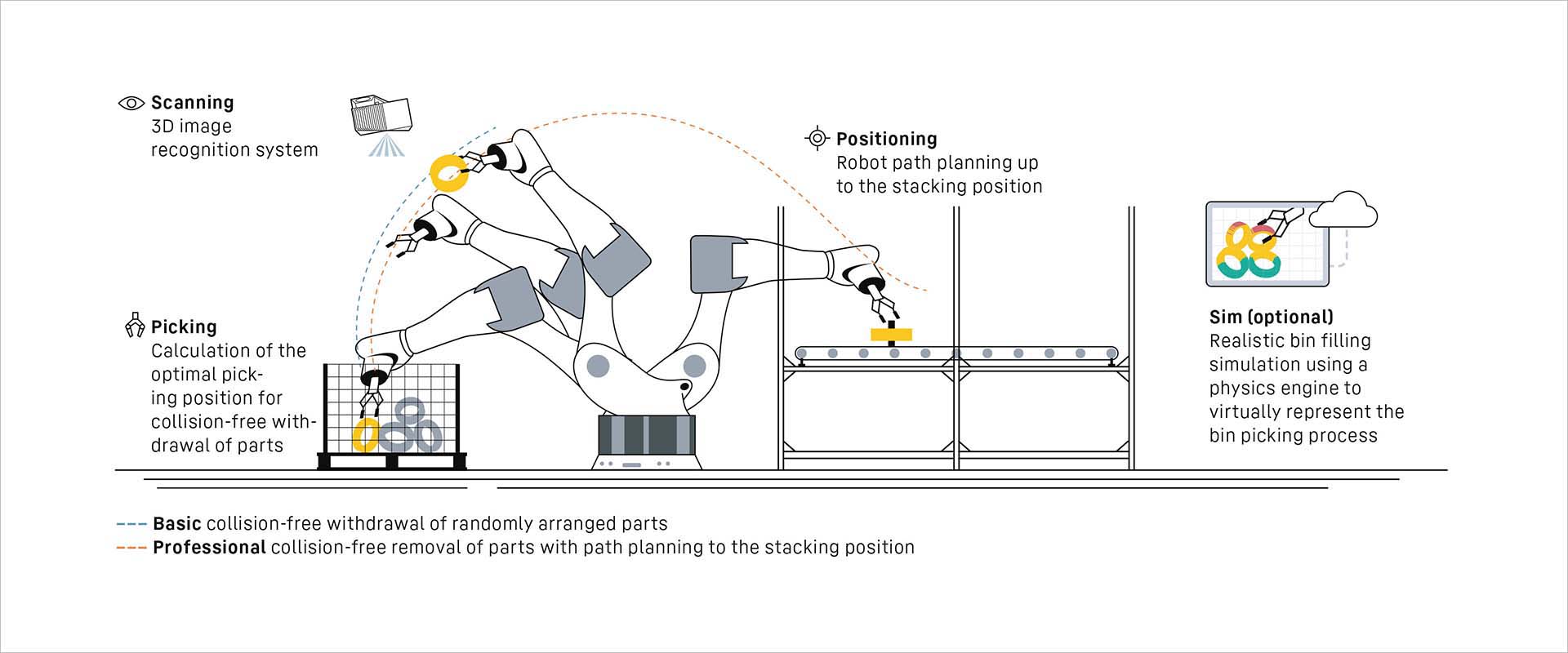

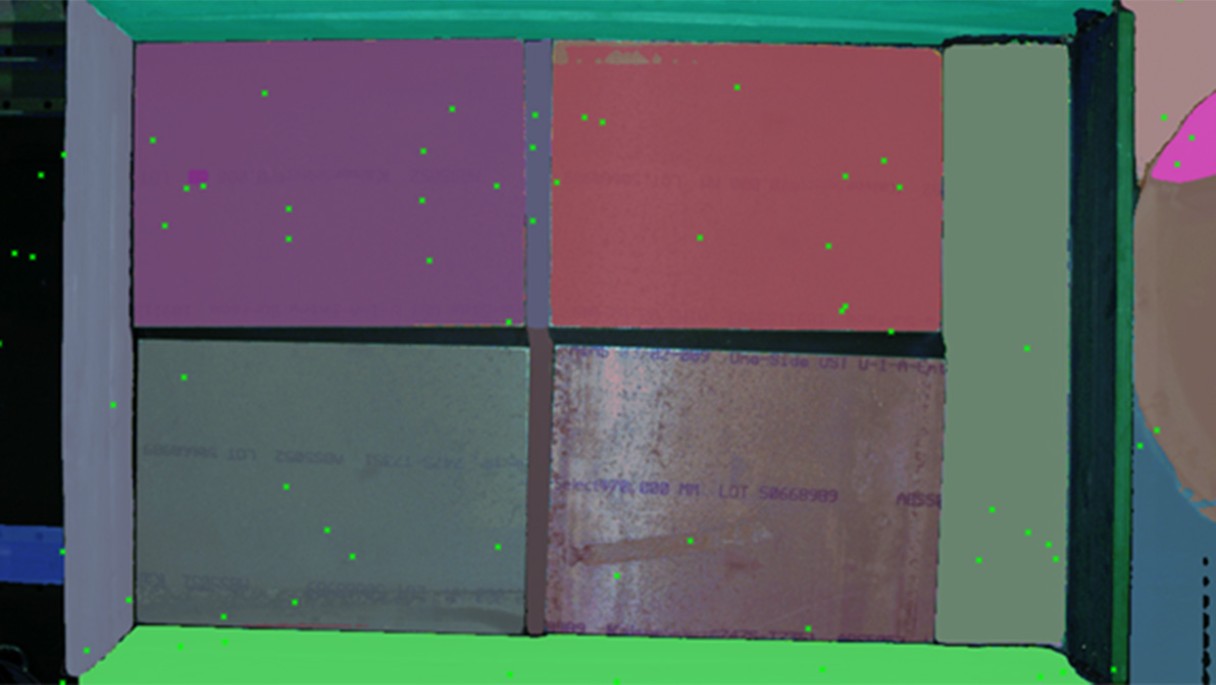

The technology packages consist of a projector-based vision camera system for optical data collection and software for object identification and selection, collision-free withdrawal of parts, and robot path planning to the stacking point.

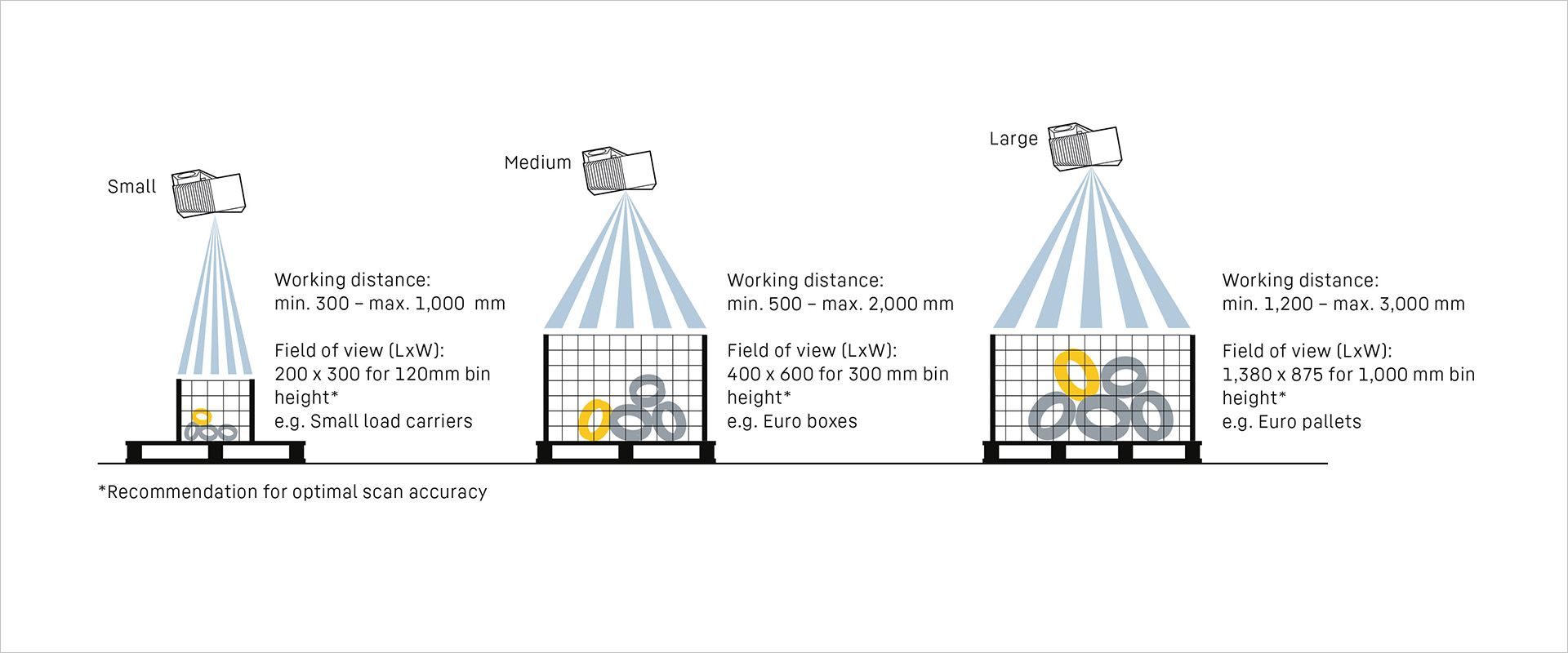

Projector-based vision systems with different image field variants for every application

Software

Basic license

The more cost-effective basic license is suitable for customers who only need to roughly set the gripped workpiece down. A stacking plan is not necessarily required for this. Due to the lack of robot model and obstacles, it is also suitable for customers who place less value on collision checking outside the bin, for example in cases where the gripper is never able to fully enter the bin.

The basic license allows a restricted version of LHRobotics.Vision to be run. The following functions are not included in the basic license:

- Creation of stacking points and thus path planning for stacking purposes

- Addition of obstacles

- Addition of a robot model

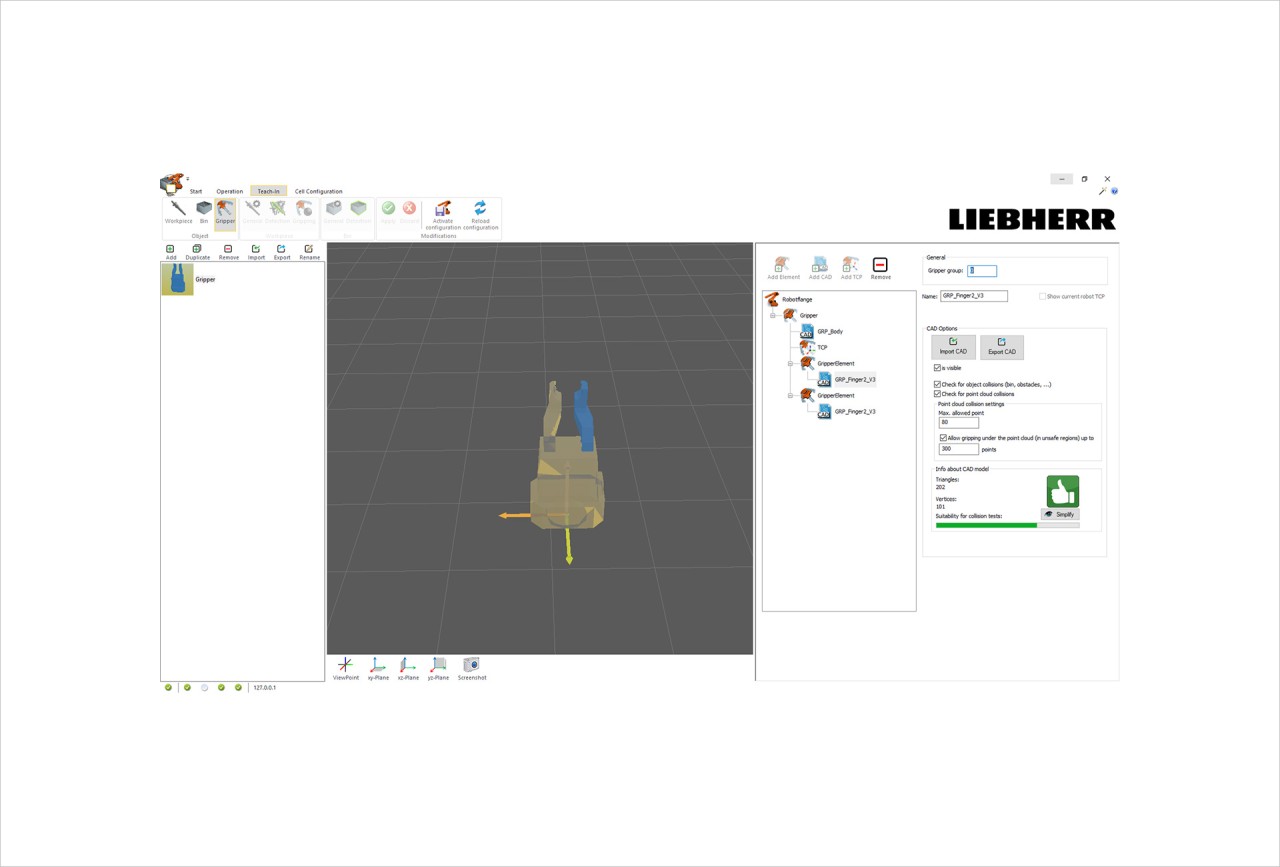

Professional license

The professional license offers unrestricted use of the LHRobotics.Vision software. This license is particularly suitable for customers who place value on full collision checking of the path from removal to possible stacking

Artificial intelligence lights the way

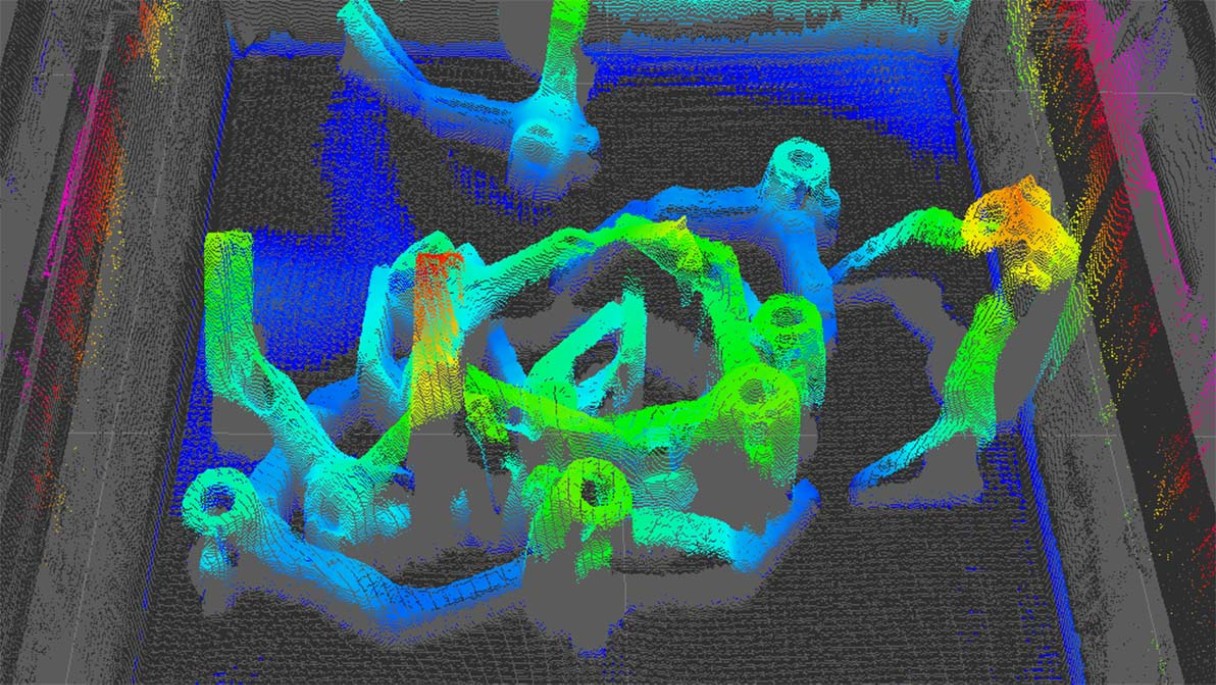

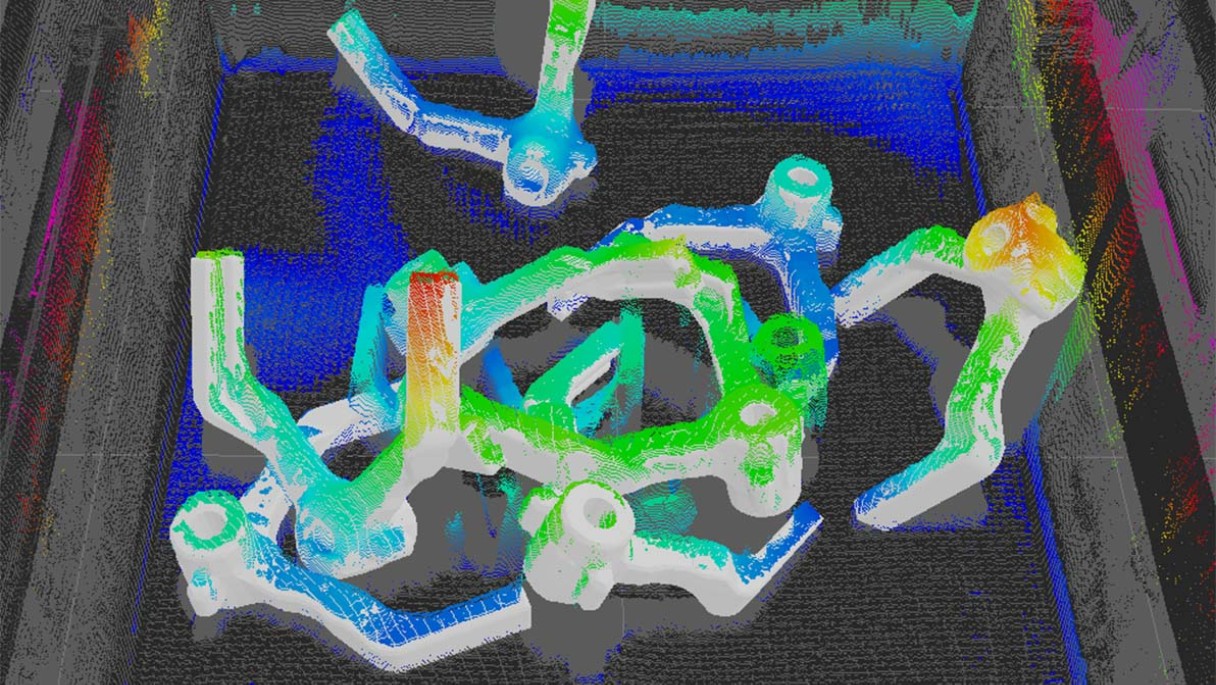

Artificial intelligence comes into play with the release of software version 3.4. In previous versions, you selected the parameters for part recognition yourself. Now this can now be optimized automatically.

For this feature the operator simply needs to generate a few camera scans and classify their point clouds. Simply, designate where a part is actually located and where it isn't. The software then knows where it needs to search for something – and optimizes the search parameters in multiple loops so that as many workpieces as possible are identified. The system learns more with every “round of calculations” and improves itself – genuinely intelligent.

Liebherr – LHRobotics.Vision – How to implement bin picking in 4 steps

Your contact for robot vision technology packages

We are happy to answer any questions about the robot vision applications.

Jürgen Groß

Sales Director Cells & Flexible Manufacturing Systems, Automation Systems, E-Mobility

Liebherr-Verzahntechnik GmbH

Kaufbeurer Straße 141

87437 Kempten

Deutschland

Tel.: +49 170 950 09 89

E-Mail

Further information on our vision systems

Read interesting articles from our customer magazines and press releases