LC 600 - 2000

The heavyweight.

Highlights

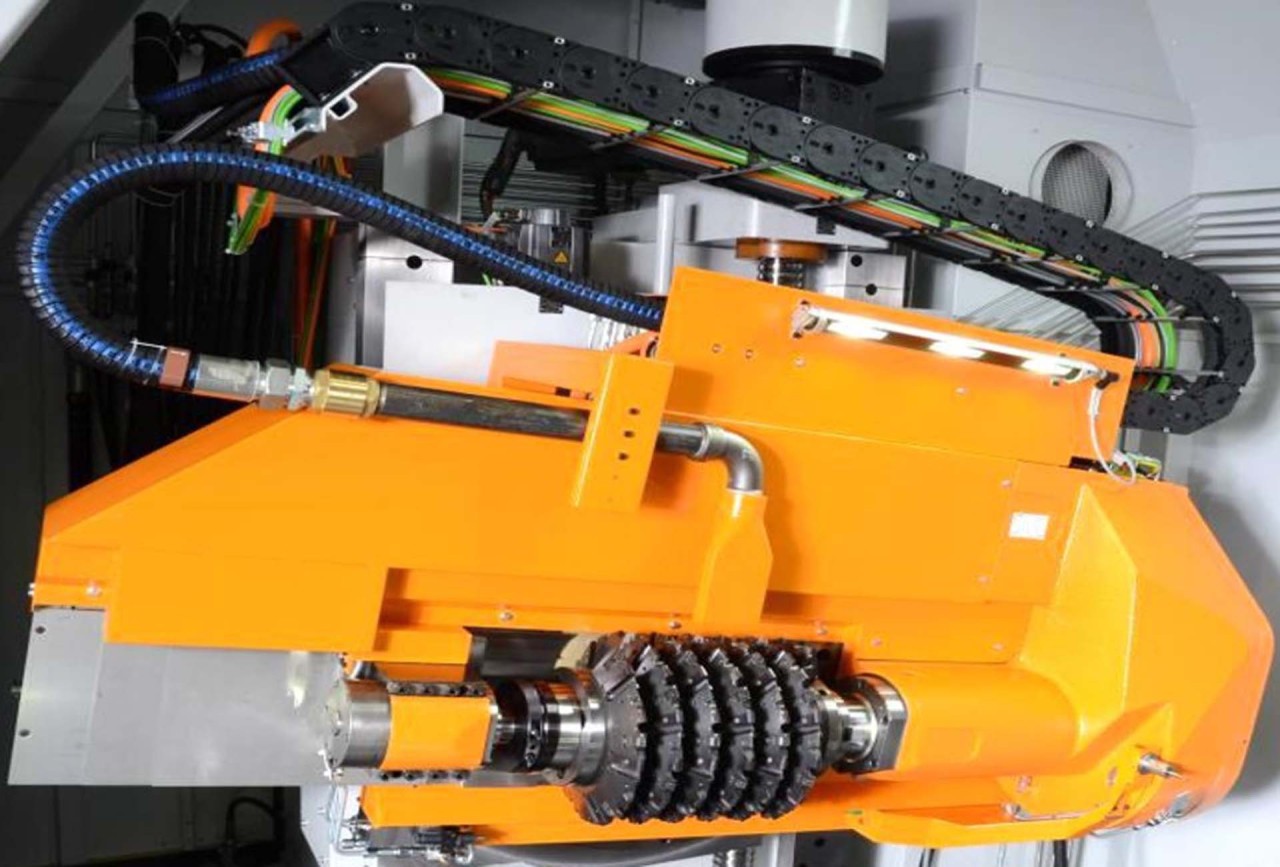

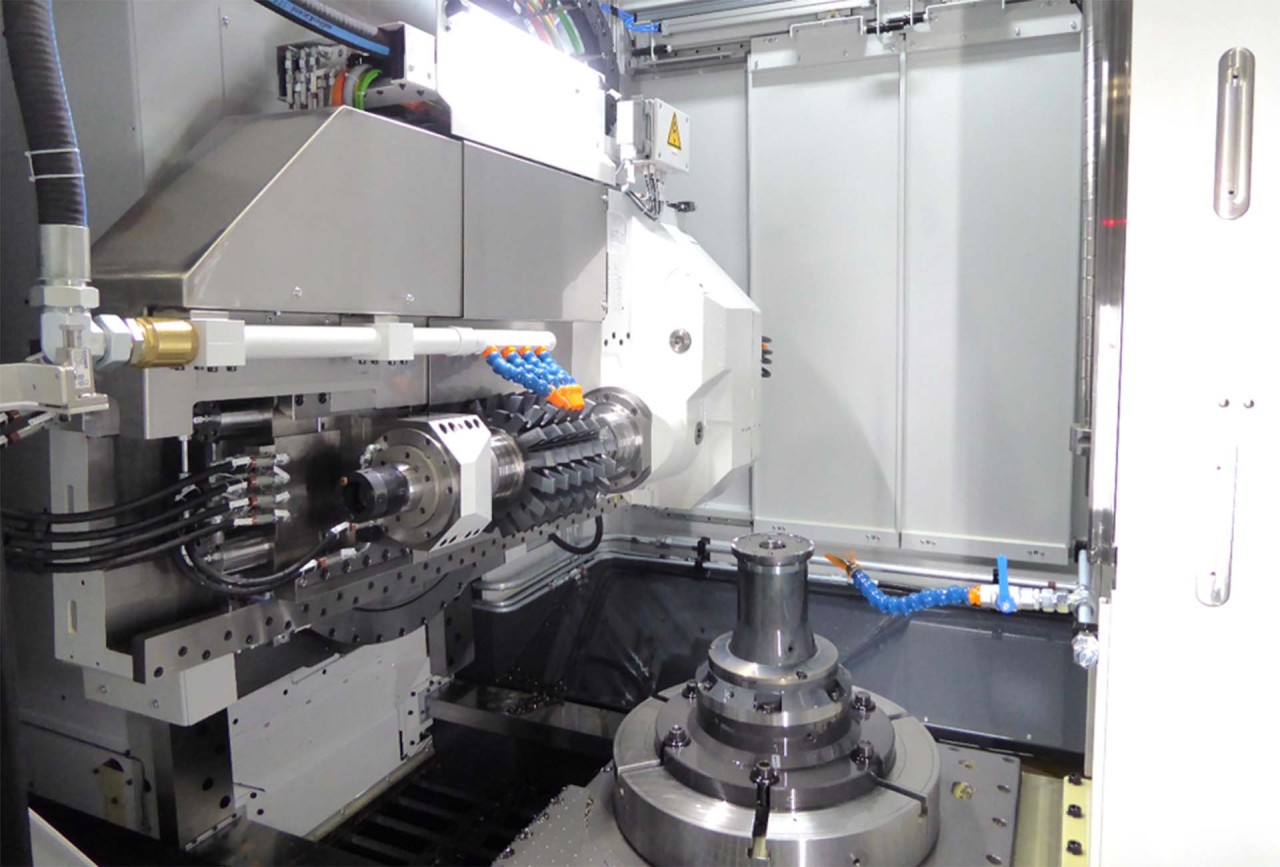

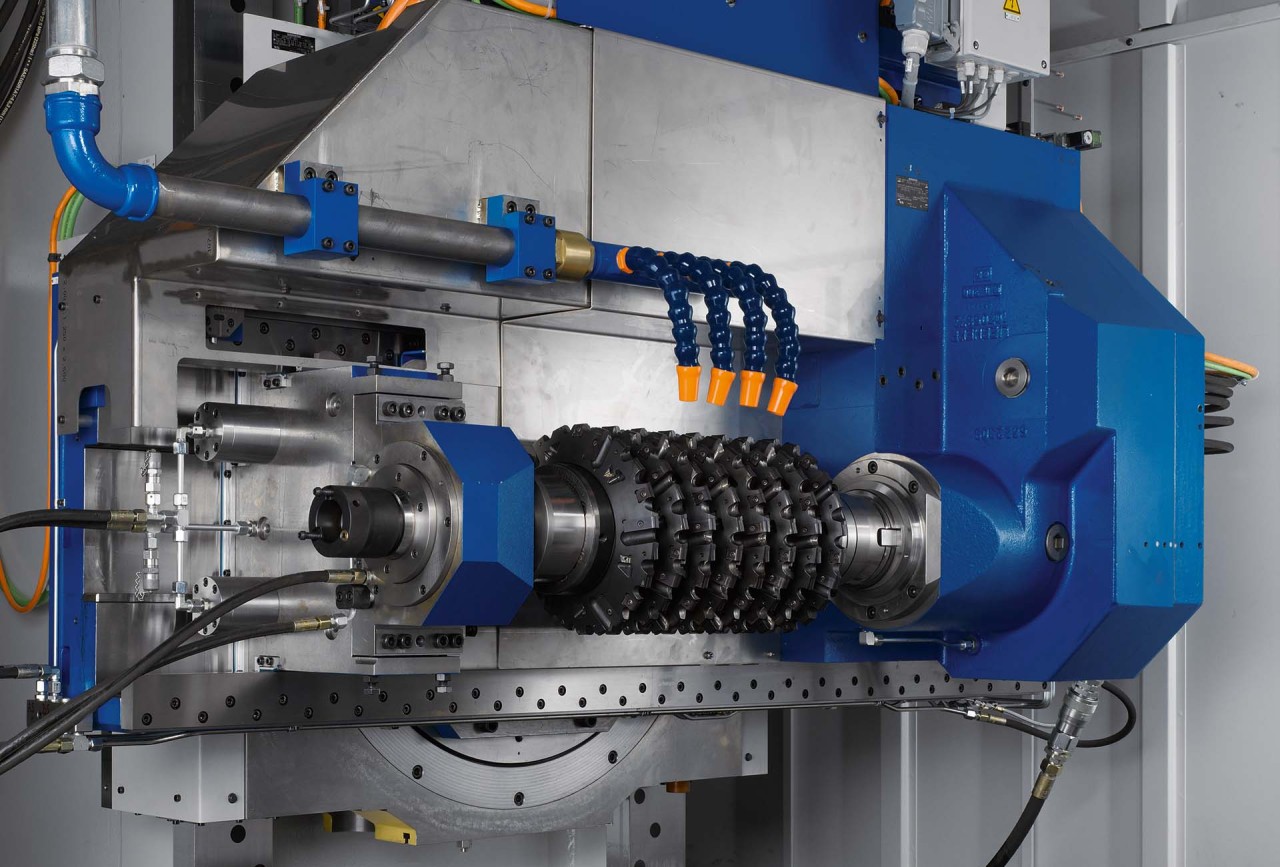

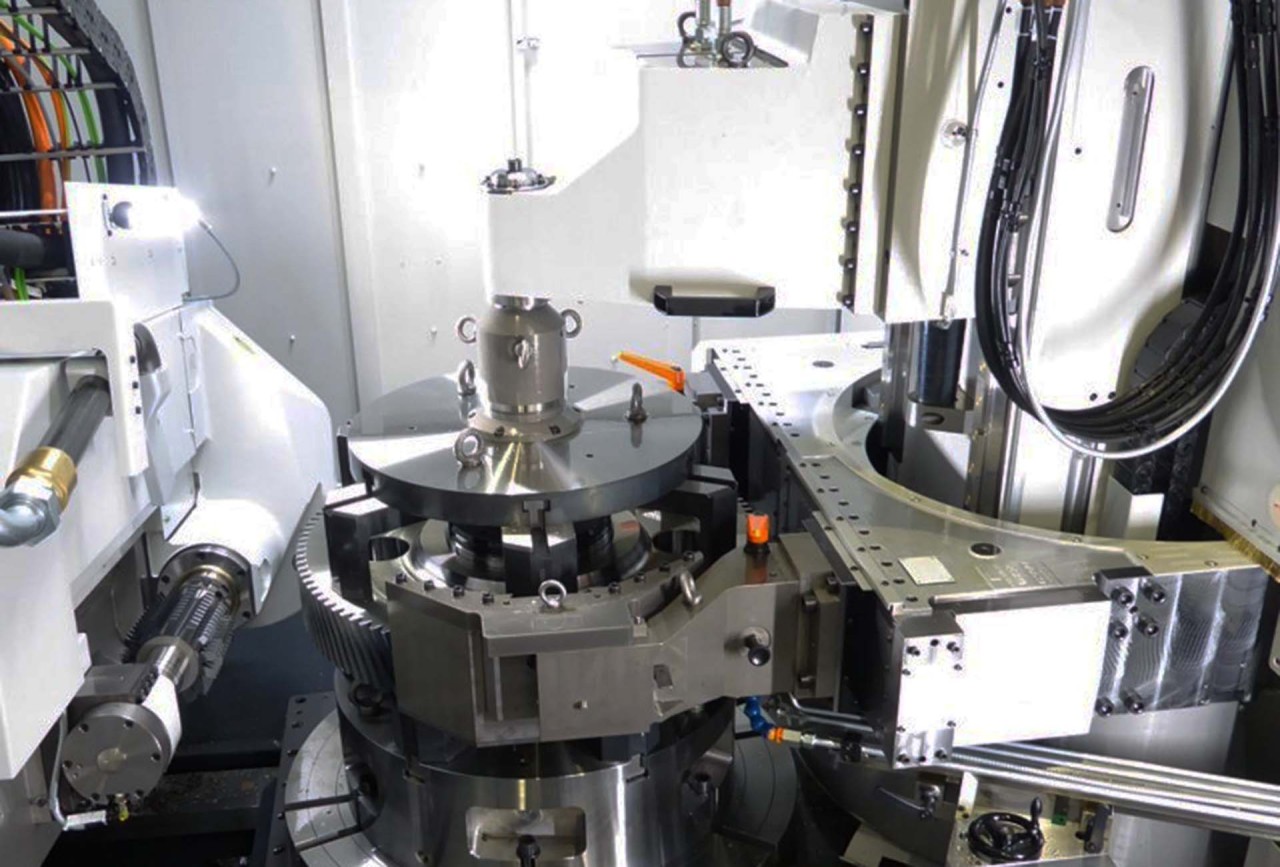

The high-performance LC 600 - 2000 gear hobbing machines feature a high degree of flexibility in the gear cutting of cylindrical gears and shafts. The modular machine concept takes into account the diverse requirements of different industries.

Module - 16.00 - 27.00 mm

16.00 - 27.00 mm

Workpiece diameter - 600 - 2,000 mm

600 - 2,000 mm

Flexibility

Large dimensions

Reliability

Machine concept

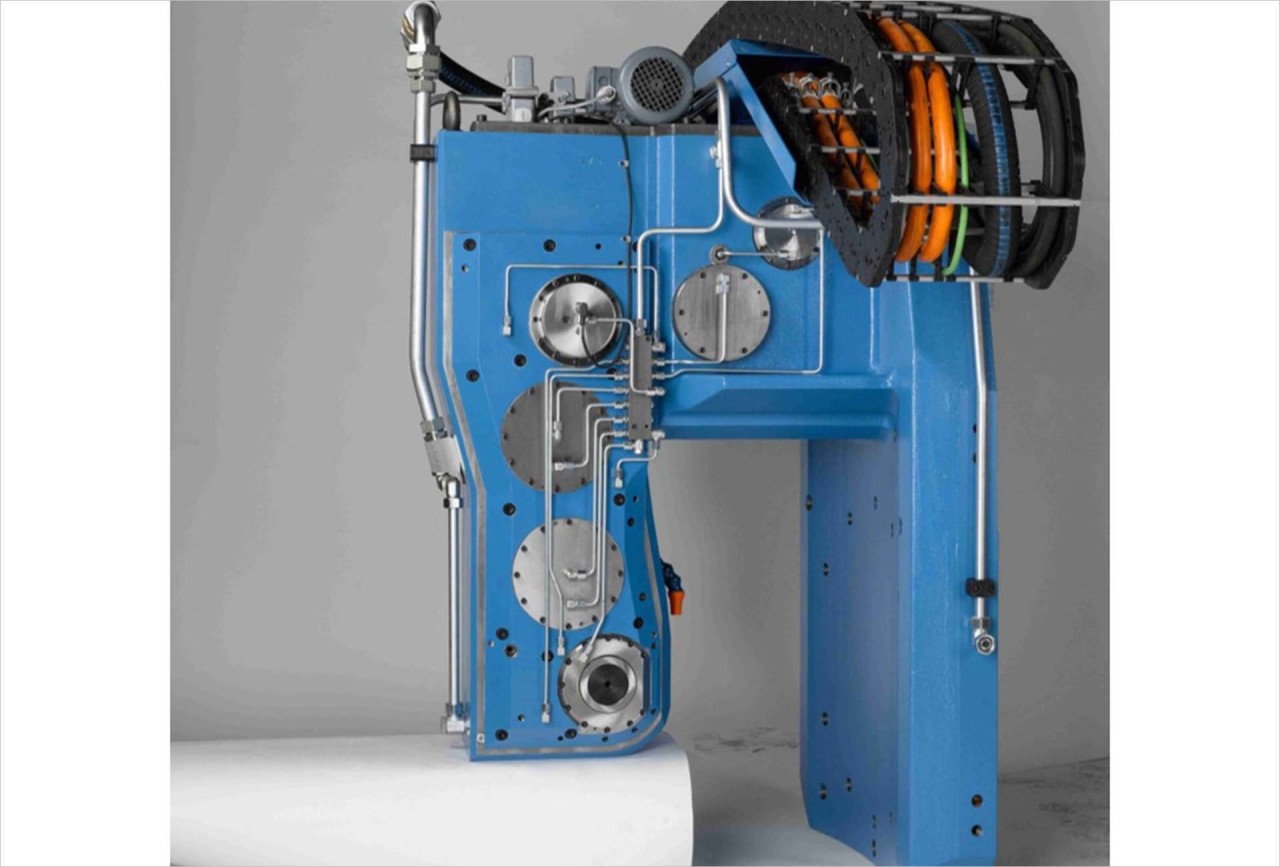

For the development of this machine series, the characteristics of the very successful new machine generation from Liebherr was systematically transferred to the application of the universal machines LC 600 LC 2000.

The necessary flexibility for different applications is achieved with a two-piece machine bed. With this concept, the machines can be optimally configured to customer-specific requirements. The self-supporting, very rigid design allows a machine installation directly on the floor, without a special foundation.

Chip removal is accomplished through the machine bed with the chip conveyor arranged lengthwise. The machine bed and the laterally arranged coolant lubricant tanks hold approx. 800l of coolant.

Highlights of the Liebherr LC 600 - 800 gear hobbing machine

Highlights of the Liebherr LC 600 - 2000 gear hobbing machine

Technical data

| Module | 16.00 - 27.00 mm |

| Workpiece diameter | 600 - 2,000 mm |

Variants

| Variants | LC 600 | LC 700 | LC 800 | LC 1000 | LC 1200 | LC 1400 | LC 1600 | LC 1800 | LC 2000 |

|---|---|---|---|---|---|---|---|---|---|

| Module (mm) | 16.00 / 22.00 / 27.00 | 16.00 / 22.00 / 27.00 | 16.00 / 22.00 / 27.00 | 16.00 / 22.00 / 27.00 | 16.00 / 22.00 / 27.00 | 16.00 / 22.00 / 27.00 | 16.00 / 22.00 / 27.00 | 16.00 / 22.00 / 27.00 | 16.00 / 22.00 / 27.00 |

| Workpiece diameter (mm) | 600 | 700 | 800 | 1,000 | 1,200 | 1,400 | 1,600 | 1,800 | 2,000 |

| Axial travel (mm) | 1,000 / 1,400 | 1,000 / 1,400 | 1,000 / 1,400 | 1,000 / 1,400 | 1,000 / 1,400 | 1,000 / 1,400 | 1,000 / 1,400 | 1,000 / 1,400 | 1,000 / 1,400 |

| Shift distance (mm) | 200 / 300 / 320 | 200 / 300 / 320 | 200 / 300 / 320 | 200 / 300 / 320 | 200 / 300 / 320 | 200 / 300 / 320 | 200 / 300 / 320 | 200 / 300 / 320 | 200 / 300 / 320 |

| Hob diameter (mm) | 300 / 315 / 450 | 300 / 315 / 450 | 300 / 315 / 450 | 300 / 315 / 450 | 300 / 315 / 450 | 300 / 315 / 450 | 300 / 315 / 450 | 300 / 315 / 450 | 300 / 315 / 450 |

| Hob speed (min-1) | 270 / 1,000 | 270 / 1,000 | 270 / 1,000 | 270 / 1,000 | 270 / 1,000 | 270 / 1,000 | 270 / 1,000 | 270 / 1,000 | 270 / 1,000 |

| Table speed (min-1) | 40 / 80 | 40 / 80 | 40 / 80 | 25 / 50 | 25 / 50 | 25 / 50 | 10 | 10 | 10 |