LC 180 - 280

The impulse generator.

High flexibility

Wet and dry machining

Energy and resource efficiency

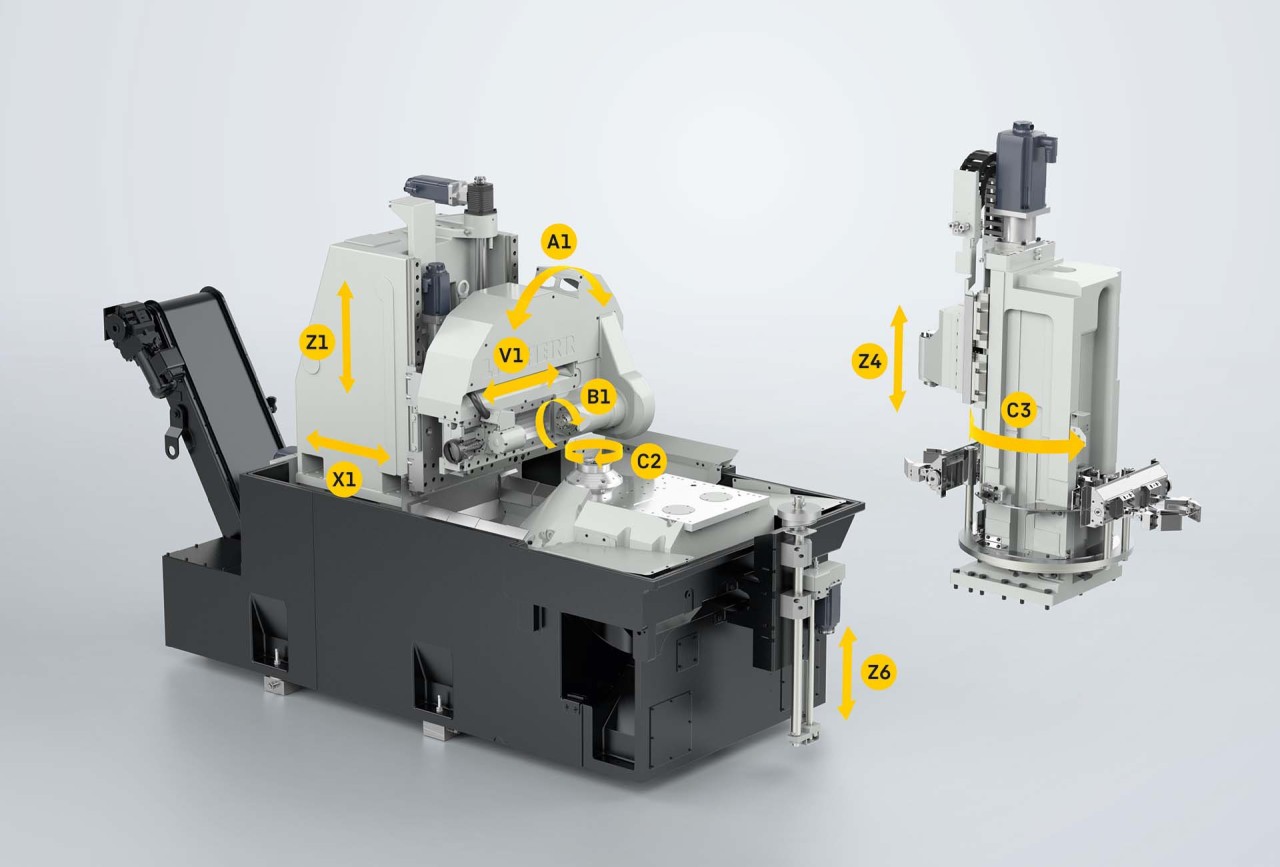

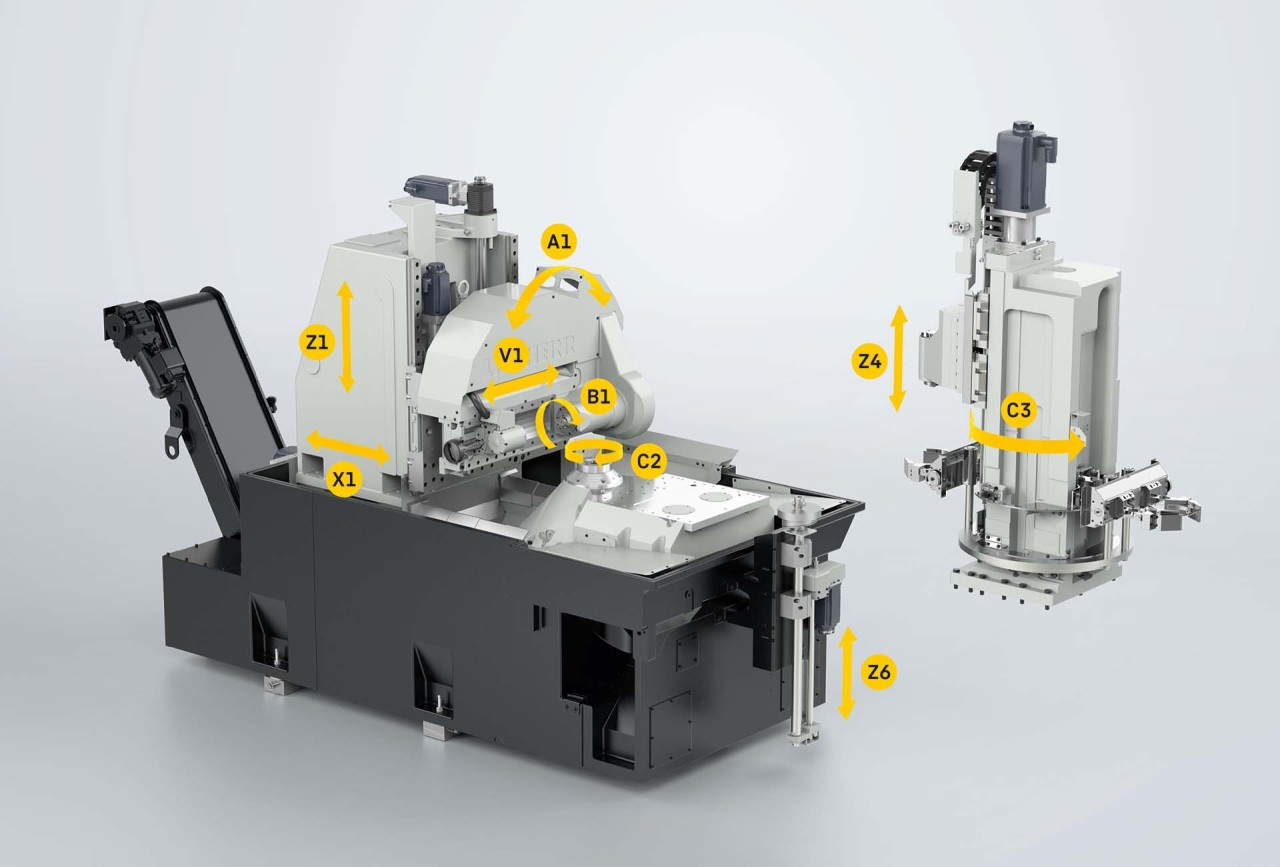

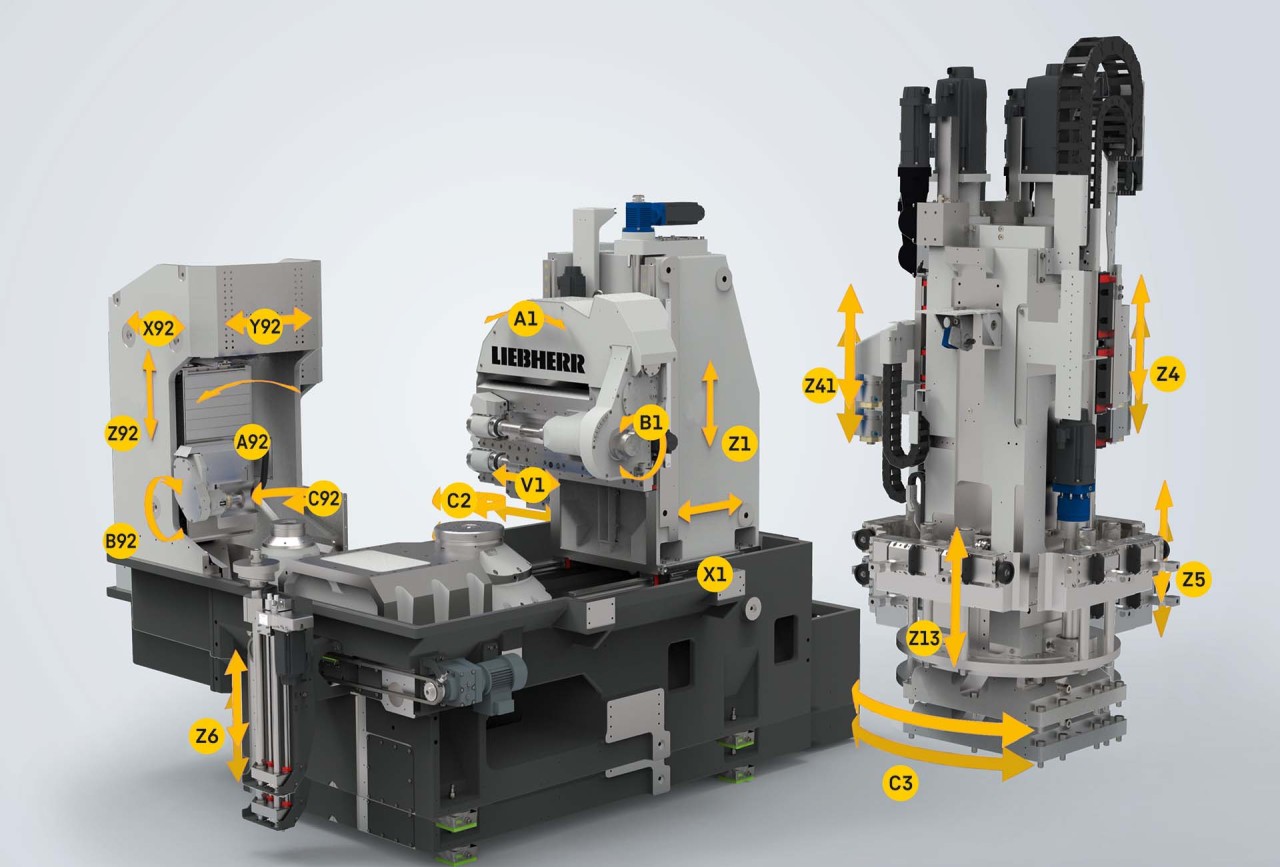

Machine concept

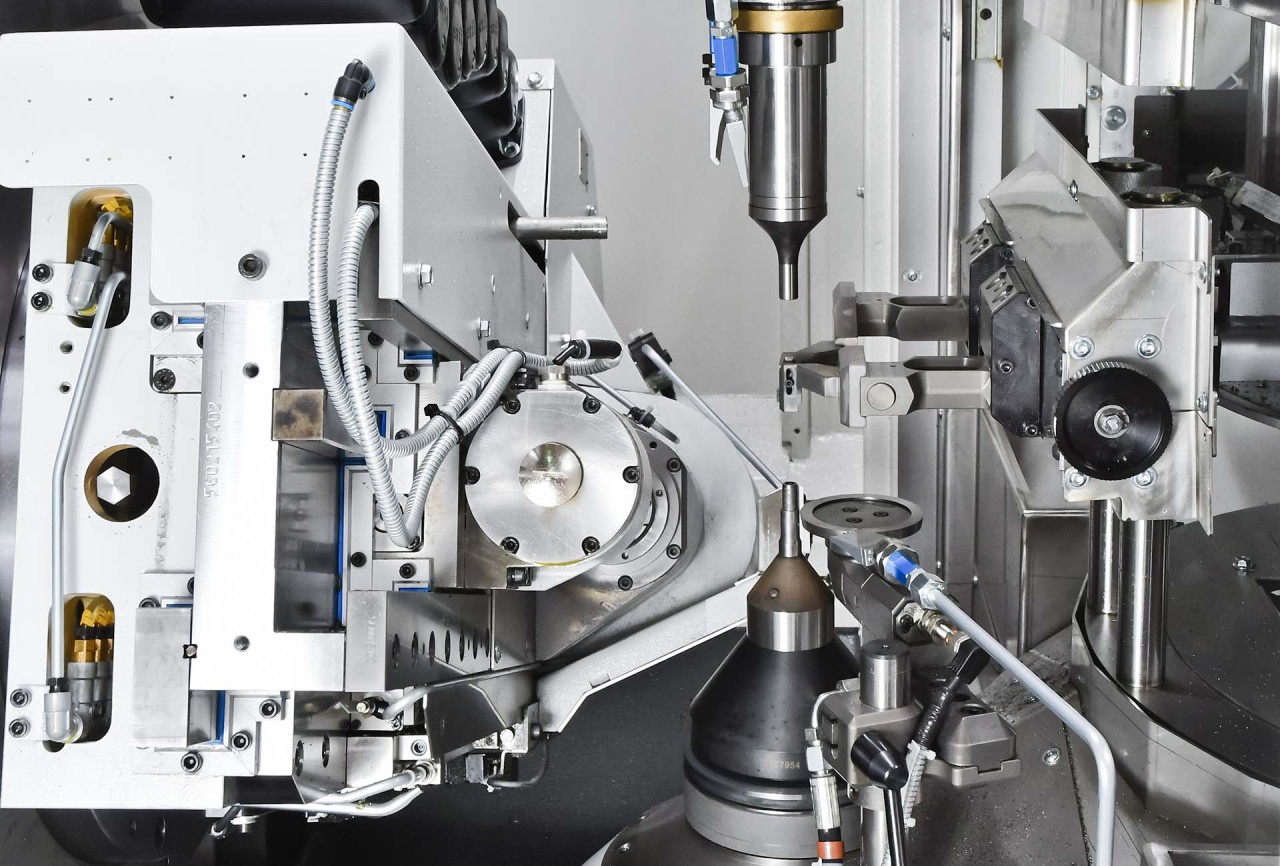

The new LC 180 / 280 machine platform allows for a modular design. This means many different technological applications or customer-specific requirements can be implemented. Liebherr gear hobbing machines are optimally customized to the requirements of universal usability. The high-performance gear hobbing machines are productive and manufacture in the highest quality with maximum availability.

- Optimized base frame rigidity thanks to FEM simulation

- Thermosymmetric machine design and integrated temperature compensation ensure consistent high quality

- Fundamentally optimized chip removal system

- High flexibility for various processes:

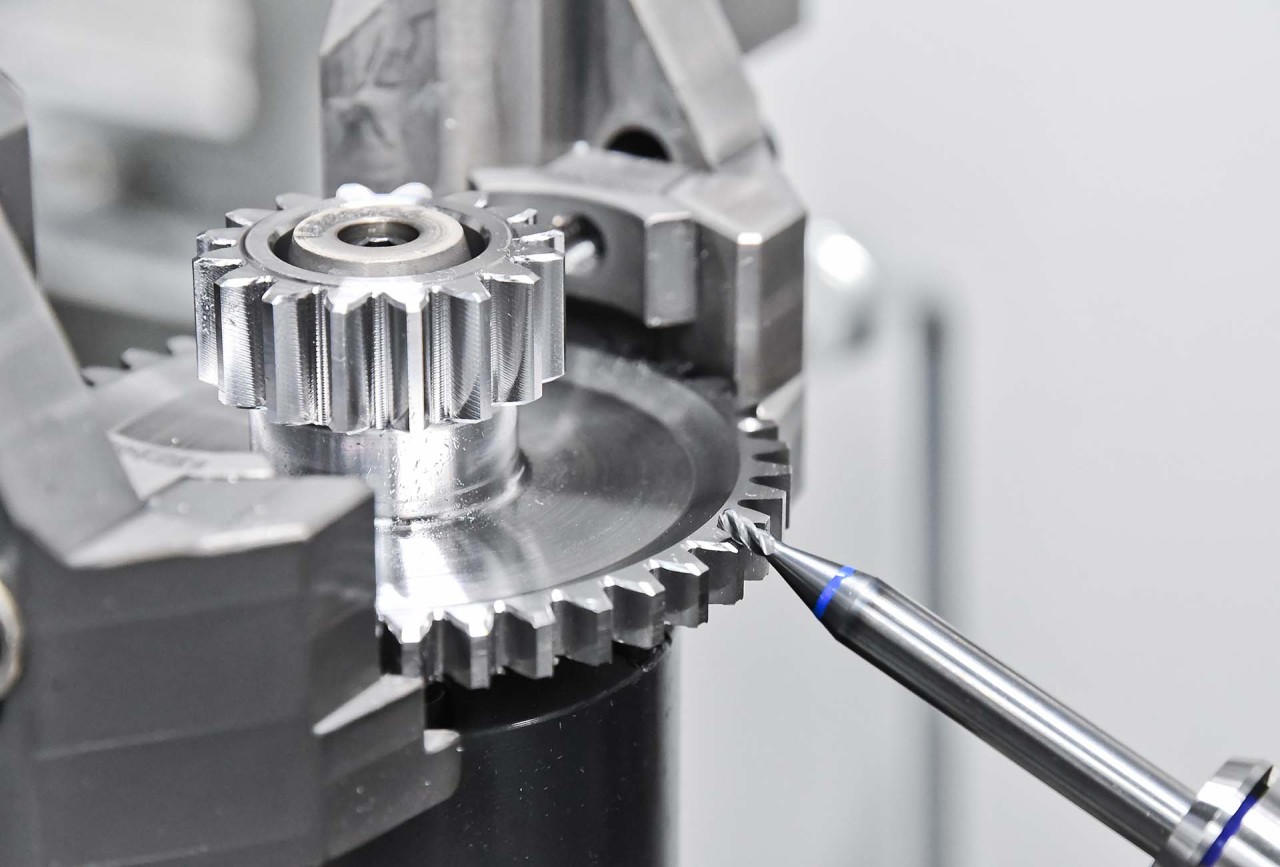

- Gears, shafts, worm gears

- Cluster gears

- Skive hobbing/finish cutting

- Position dependency

- Milling of special profiles

- Wet and dry machining

- Hook-ready machine with a low space requirement, suitable for easy transfer

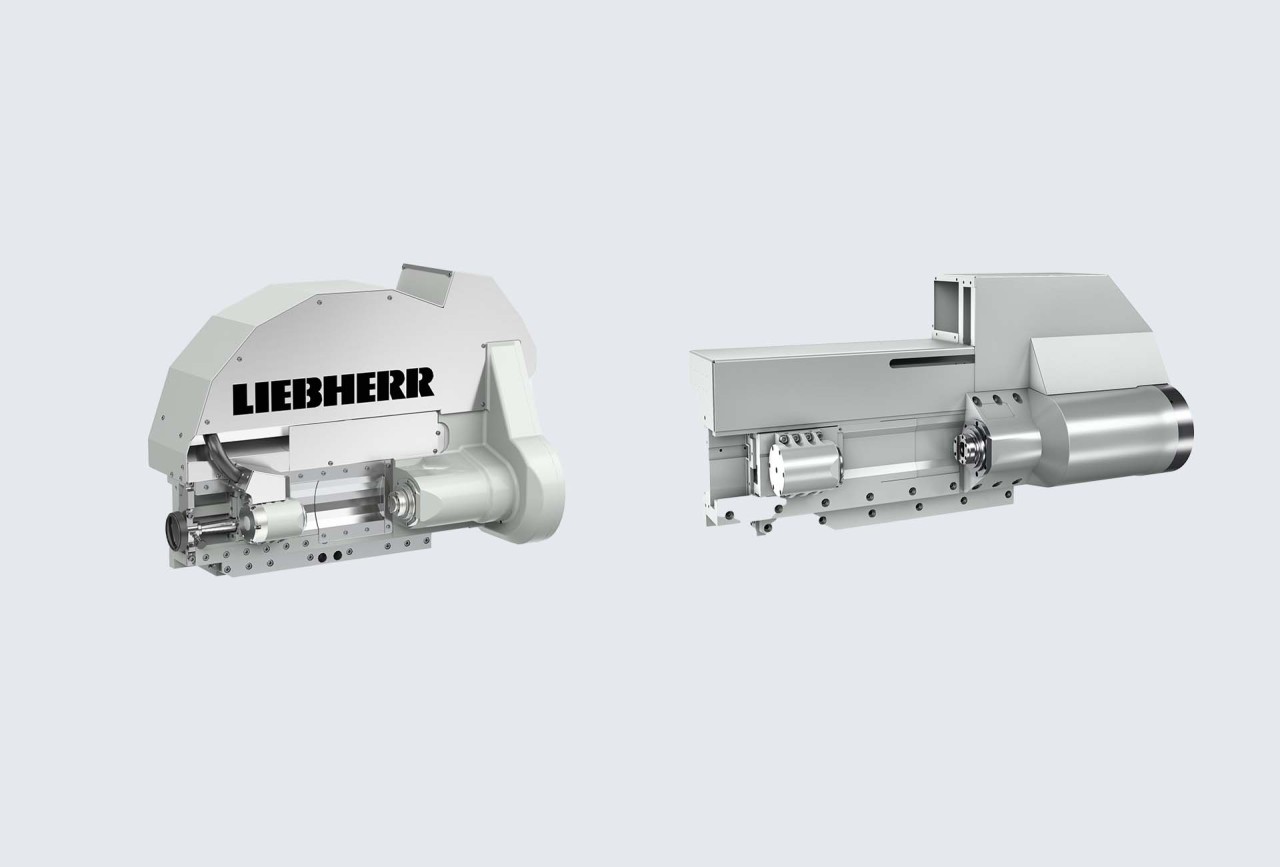

Gear hobbing machine LC 280 α

01/03

Gear hobbing machines 180 / 280 (DC)

01/05

01/03

01/02

Technical data

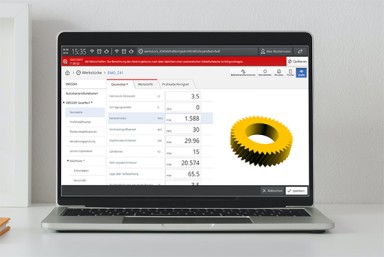

| Module | 4.00 - 6.00 mm |

| Workpiece diameter | 180 - 280 mm |

Variants

| Variants | LC 180 α | LC 280 α | LC 180 | LC 280 | LC 280 DC | LC 280 DC |

|---|---|---|---|---|---|---|

| Module (mm) | 6.00 / 4.00 | 6.00 / 4.00 | 6.00 / 4.00 | 6.00 / 4.00 | 6.00 / 4.00 | 6.00 / 4.00 |

| Workpiece diameter (mm) | 180 | 280 | 180 | 280 | 180 | 280 |

| Axial travel (mm) | 400 | 400 | 400 | 400 | 400 | 400 |

| Shift distance (mm) | 200 | 200 | 200 | 200 | 200 | 200 |

| Hob diameter (mm) | 150 | 150 | 150 | 150 | 150 | 150 |

| Hob speed (min-1) | 2,250 | 2,250 | 2,250 / 6,000 | 2,250 / 6,000 | 2,250 / 6,000 | 2,250 / 6,000 |

| Table speed (min-1) | 250 | 250 | 250 / 800 | 250 / 800 | 250 / 800 | 250 / 800 |

| max. module ChamferCut chamfering (mm) | — | — | — | — | 5 | 5 |

| max. tool speed ChamferCut machining head (mm) | — | — | — | — | 2,000 | 2,000 |

| max. tool diameter ChamferCut (mm) | — | — | — | — | 130 | 130 |

| max. tool clamping length (bore-type cutter) (mm) | 236 | 236 | 236 | 236 | 236 | 236 |

| max. tool clamping length (shank cutter) (mm) | 360 | 360 | 360 | 360 | 360 | 360 |