LiDIA - engine diagnostic solution

Maximise your productivity with LiDIA

Increase overall equipment effectiveness

Reduce costs

Add value to your operations

Decrease carbon print

Enhance engine’s health with condition monitoring

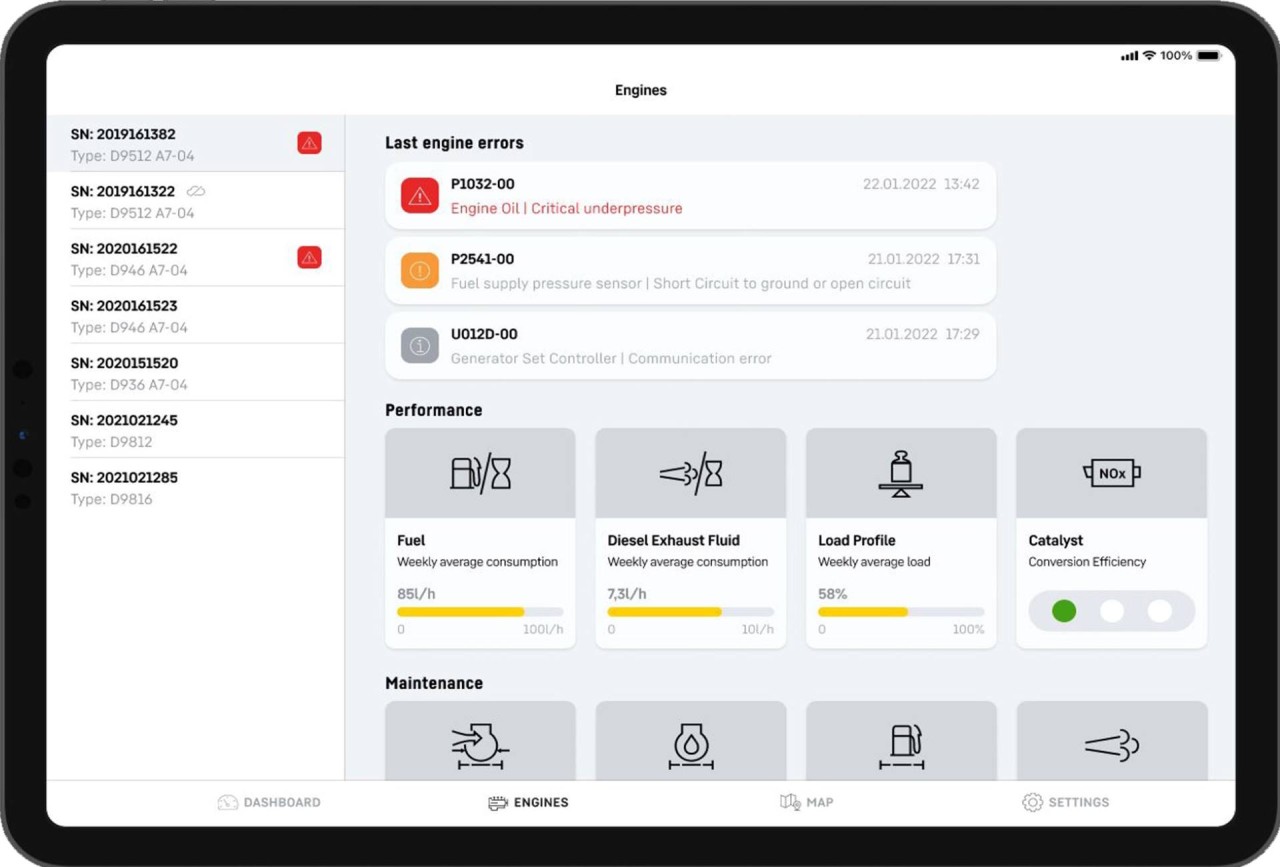

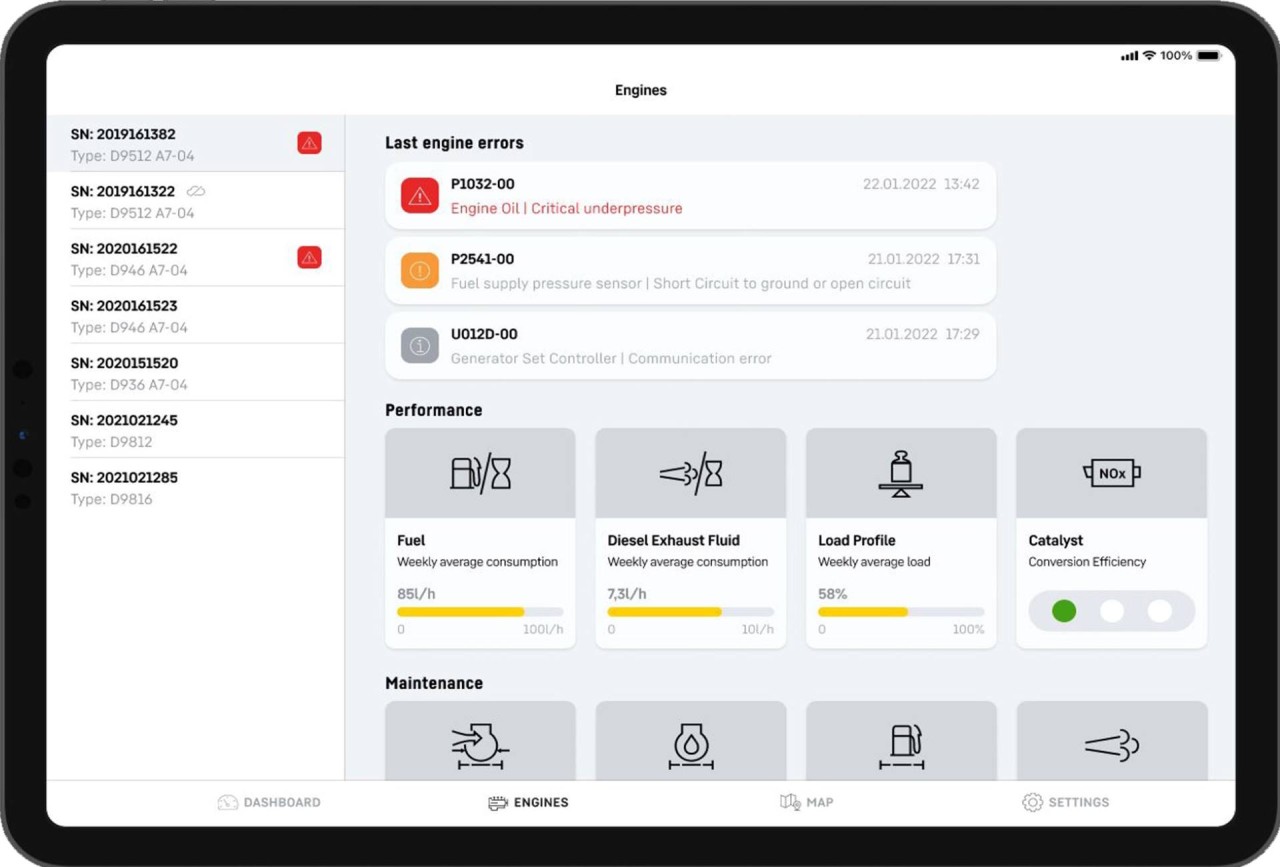

Liebherr’s engine condition monitoring provides meaningful insights in form of various Key Performance Indicators (KPI) on the engine’s current health, performance and maintenance; the KPIs can be delivered to a tablet as an application or to the customer’s backend through a web service (API)

How does it work?

Liebherr’s engine condition monitoring collects data to monitor crucial operating parameters such as oil pressure and a counter displaying the remaining hours to an oil change, load profile, fuel consumption analytics, cooling temperature profile, cooling fault indicator, and a counter displaying the remaining hours to an air filter change.

Gain visibility into the real-life status of your engine

Engine condition monitoring allows the user to gain visibility into the real-life status of the equipment in order to plan downtime and repair work more dynamically. The condition monitoring provides the data on the engine’s geo-localisation and delivers live notifications of engine faults. This also helps to reduce overall maintenance costs and allows optimisation of spare part inventory by enabling preventive maintenance based on the engine’s actual needs.

Enhance engine’s condition with LiDIA

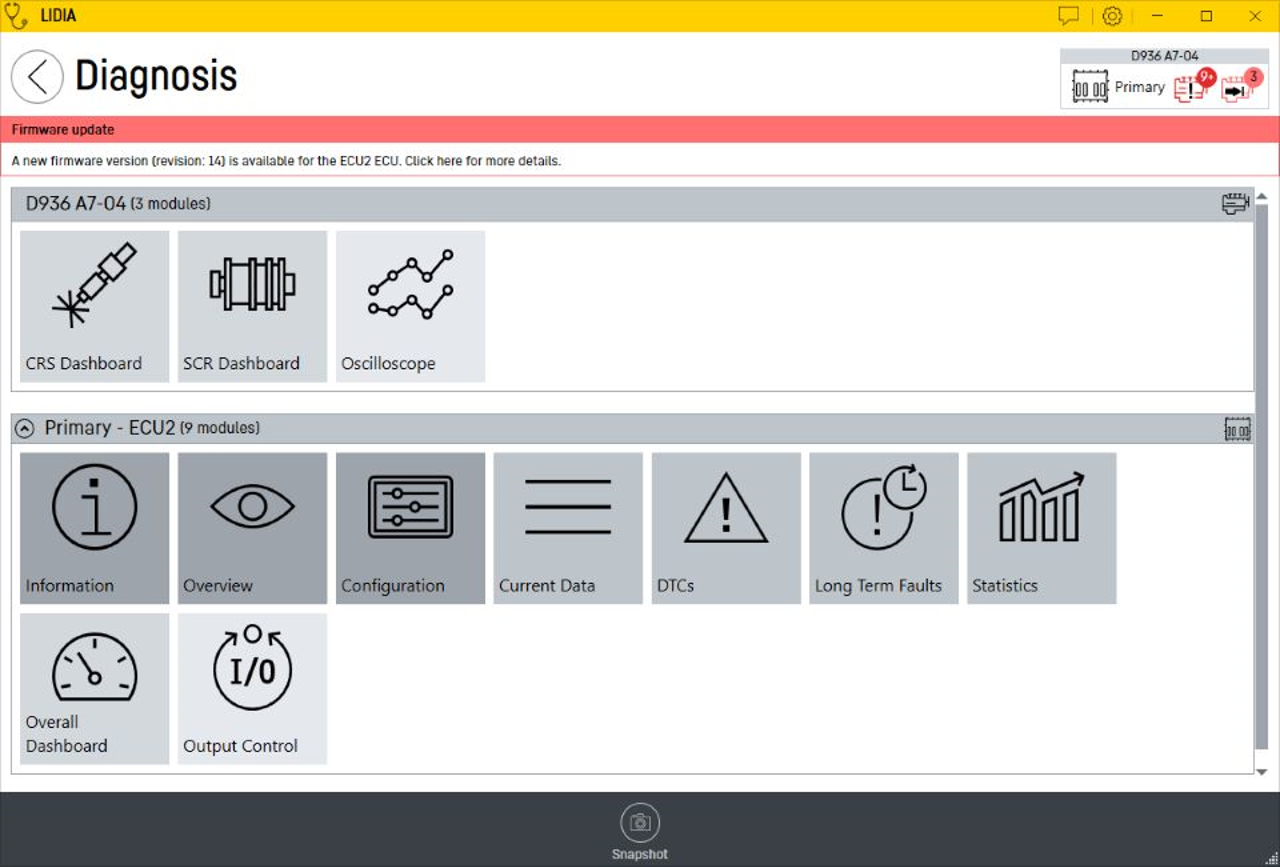

LiDIA is an intuitive and user-friendly engine diagnostic solution, which requires no configuration, facillitates access to the engine environment, and reduces the complexity of diagnostic procedures to the essentials. LiDIA offers a rapid overview of all information on the engine system: status, diagnostic trouble codes, active limitations and failure reactions.

Discover LiDIA's functions

- Permanent link to the production server

- Visualisation of subsystems (injection, exhaust gas aftertreatment, etc.)

- Automatic recognition of control devices

- Continuous expansion of functionalities – plug-in based system

- Clear visualization of test sequences in system tests

- Easy production of an ECU protocol

- Management of different roles

- Secured and protected tool

- 24/7 centrale database access

Unlocking the potential: LiDIA's applications across the engine lifecycle

LiDIA was designed for daily within the engine assembly, machine integration to in-use maintenance, troubleshooting, customer service support until remanufacturing, it is all LiDIA, ensuring full diagnostic support across the entire engine lifecylce.

In the extended version, it enables access to a variety of specific diagnostic functions for combustion engines. The focus here was on producing an intuitive user concept. The Snapshot function makes it easy to forward diagnostics data to colleagues in customer services, or to save data for subsequent processing. A core component of LiDIA is the central production database, which will provide direct access to most recent engine firmware releases.

Features that make a difference

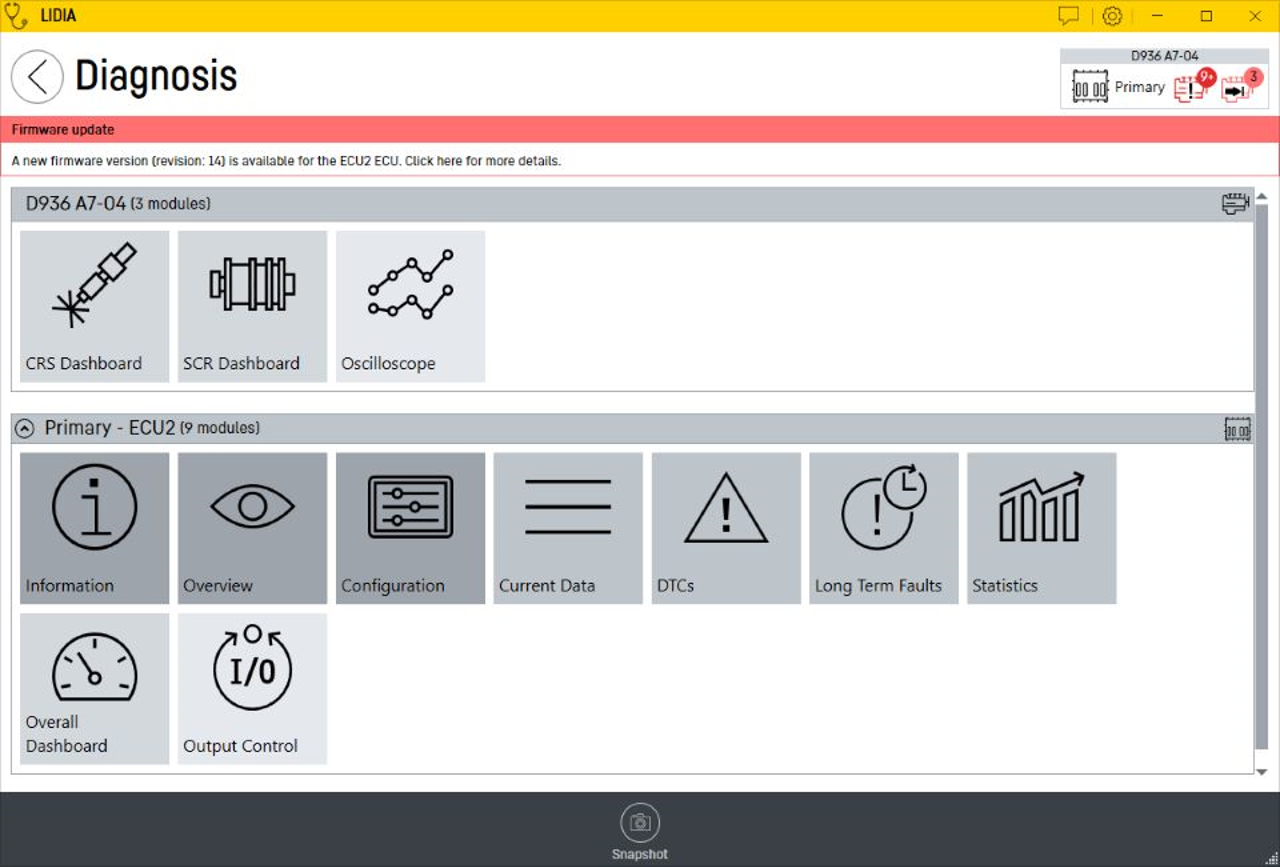

Diagnosis

Retrieve many information, configure your engines and run test routines

Update proposal

Obtain and upload automatically the latest available version of the firmware for the whole system.

Current status

Identify quickly if there are active Diagnosis Trouble Codes (DTC)

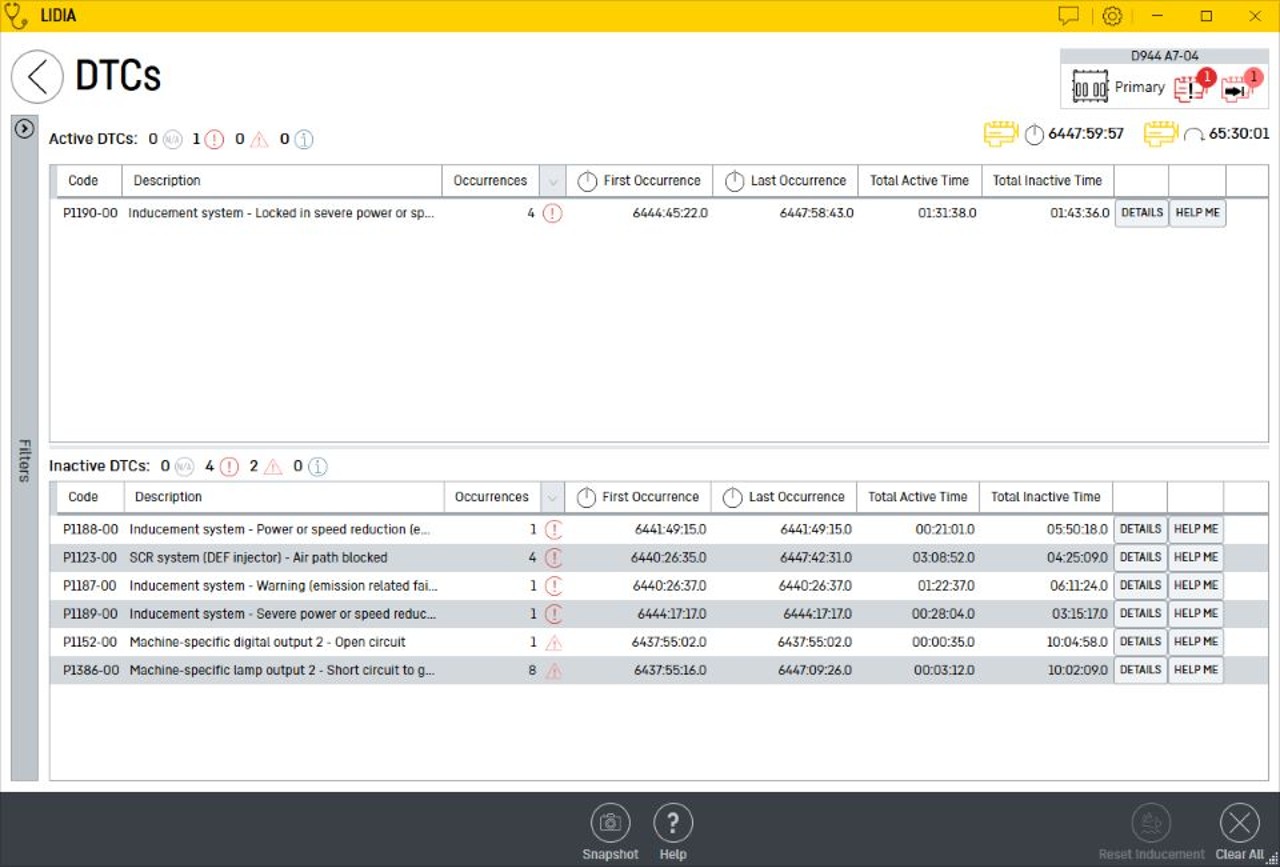

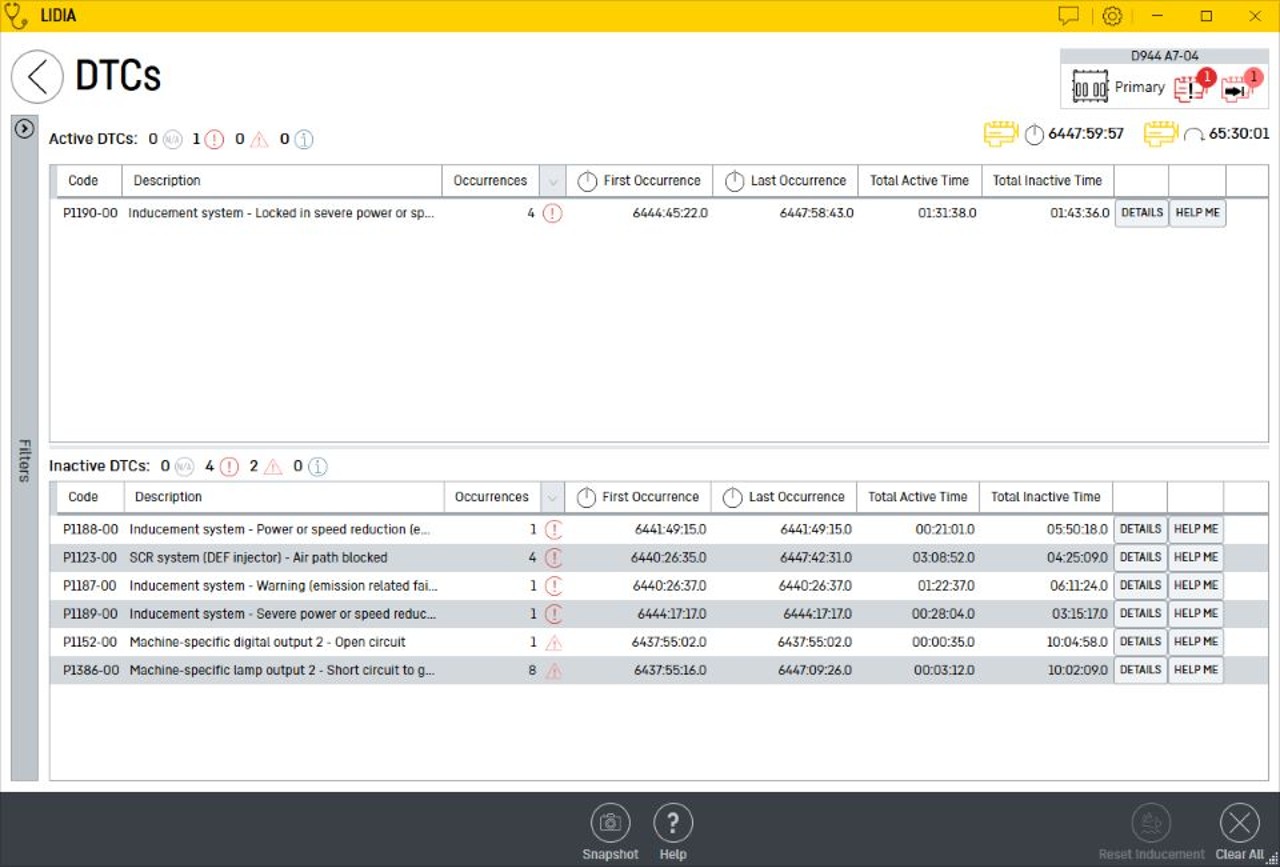

Diagnosis Trouble Code

List all errors raised by the embedded software, and get access to help full freeze frame information, guide, references and useful schematics to solve the issue.

Common Rail System Dashboard

Maintenance dashboard, and dedicated routines such as click test, cylinder cut off, etc.

DTC

Diagnosis trouble codes (active and passive DTCs) with corresponding details and help content, such as schematics

Get access to troubleshooting content

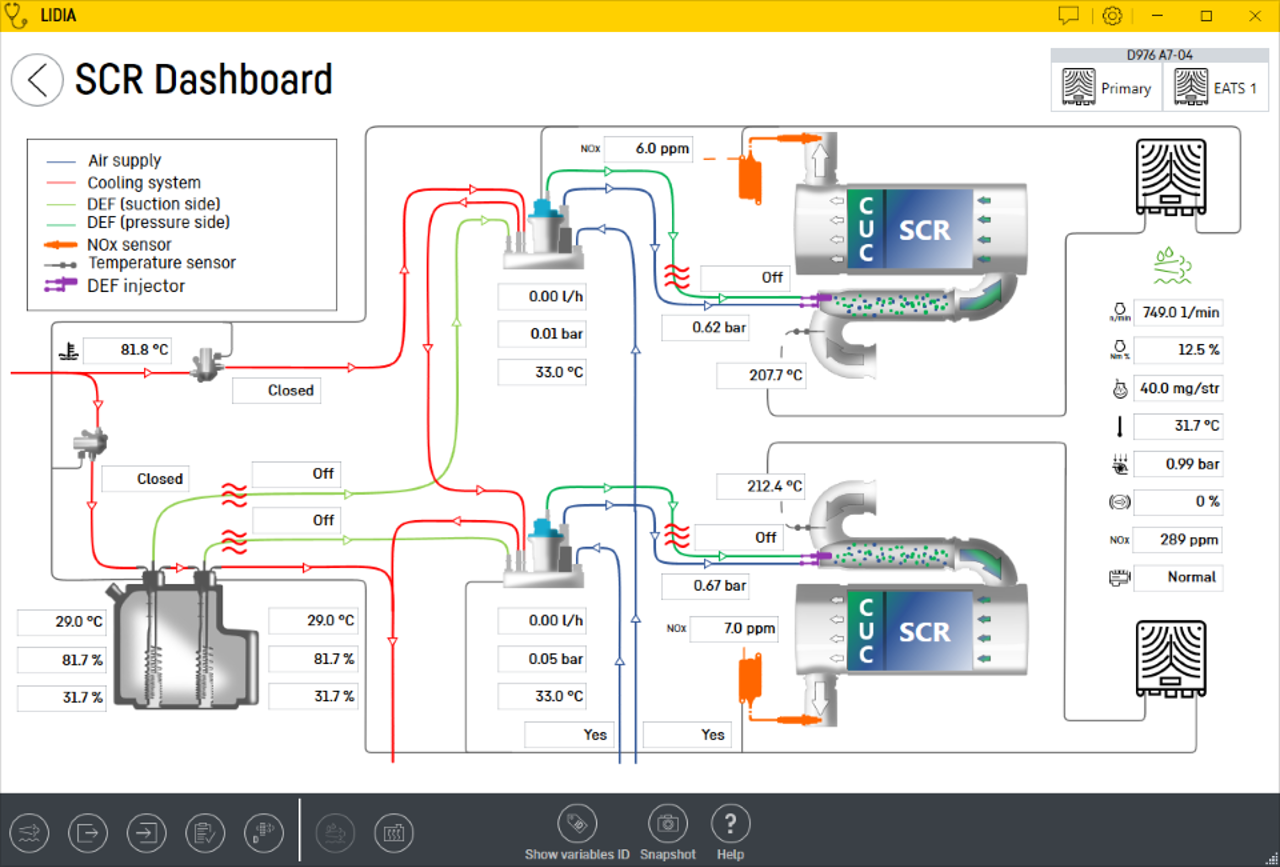

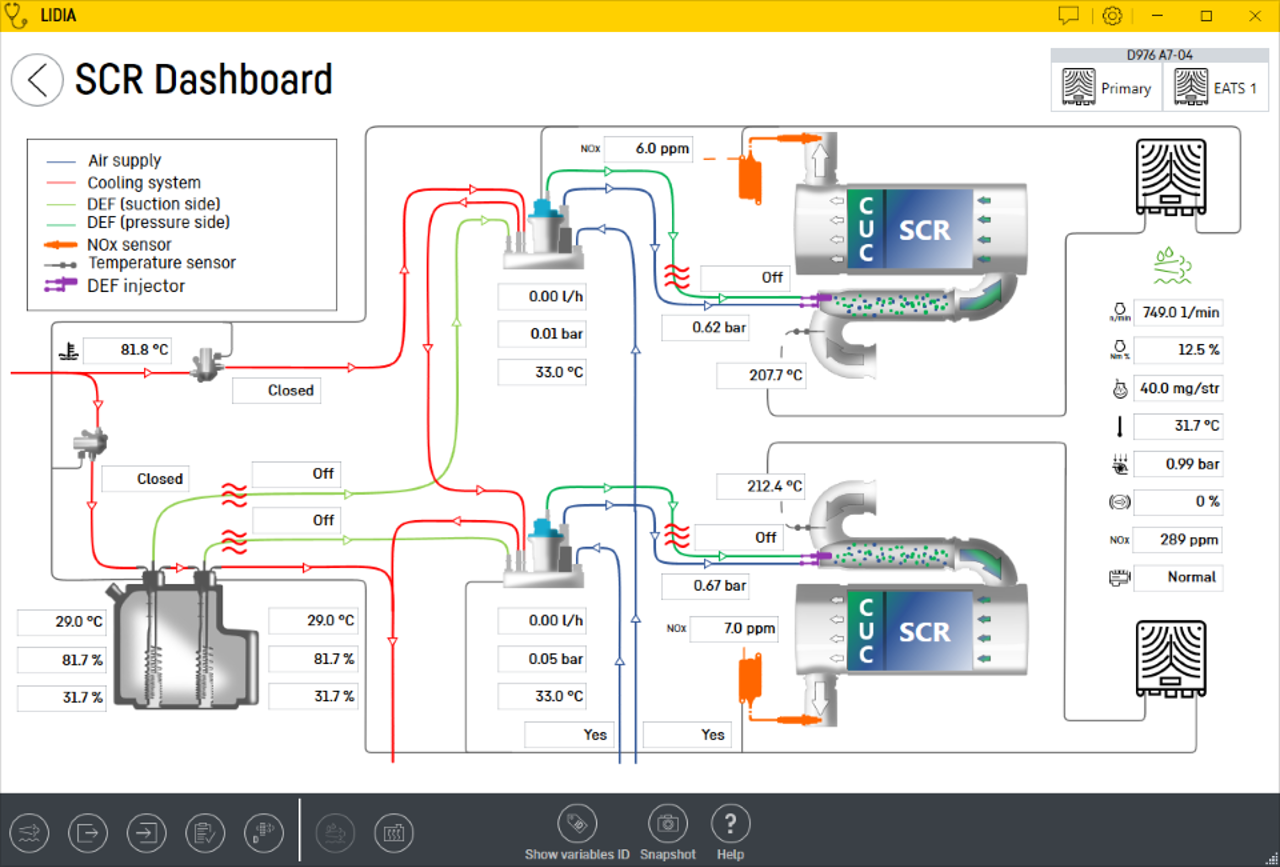

SCR Dashboard

Launch maintenance routines with easy to understand schematics.

Engine After Treatment System Dashboard depending of your configuration.

Get access to maintenance dashboard, and dedicated routines such as Air system check, DEF filling check, Ventilation check, Deposit cleaning, Coolant heating test.

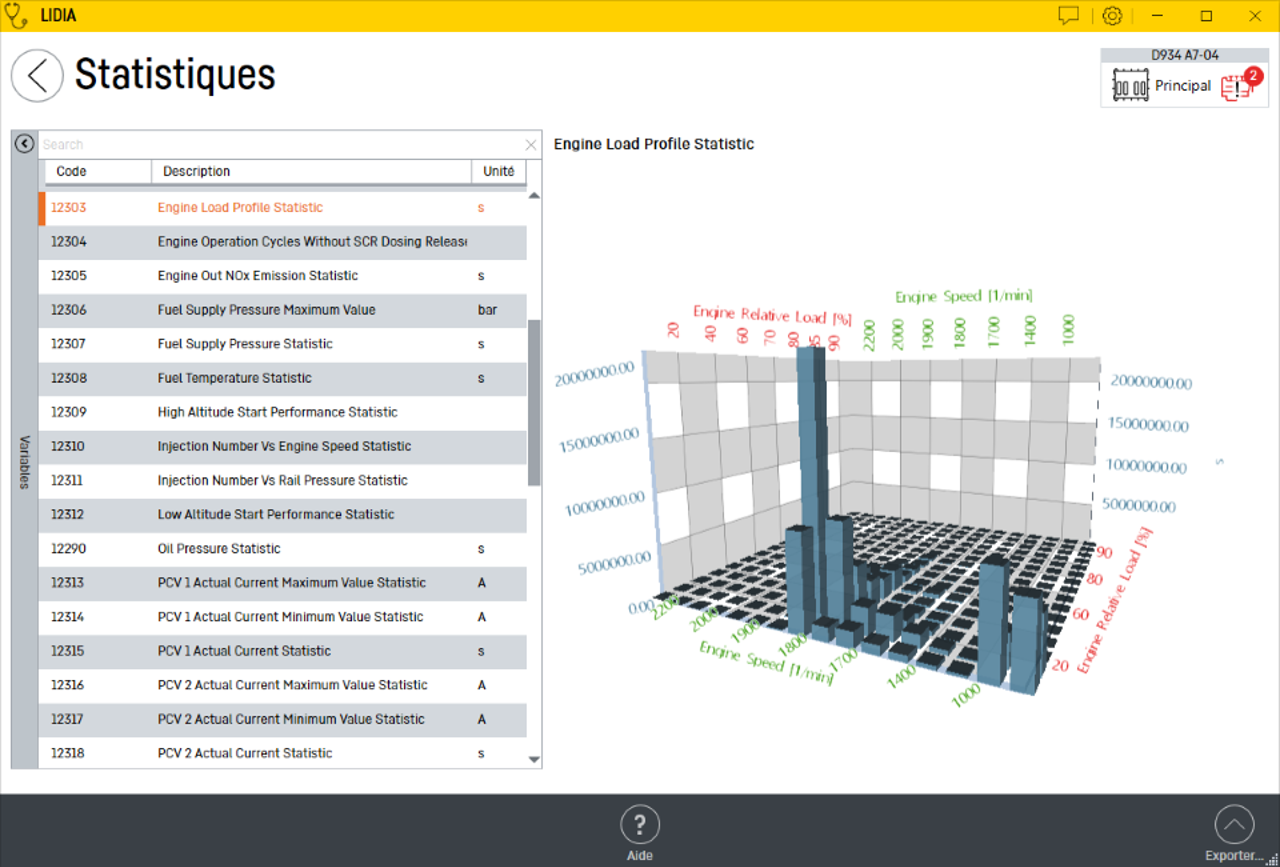

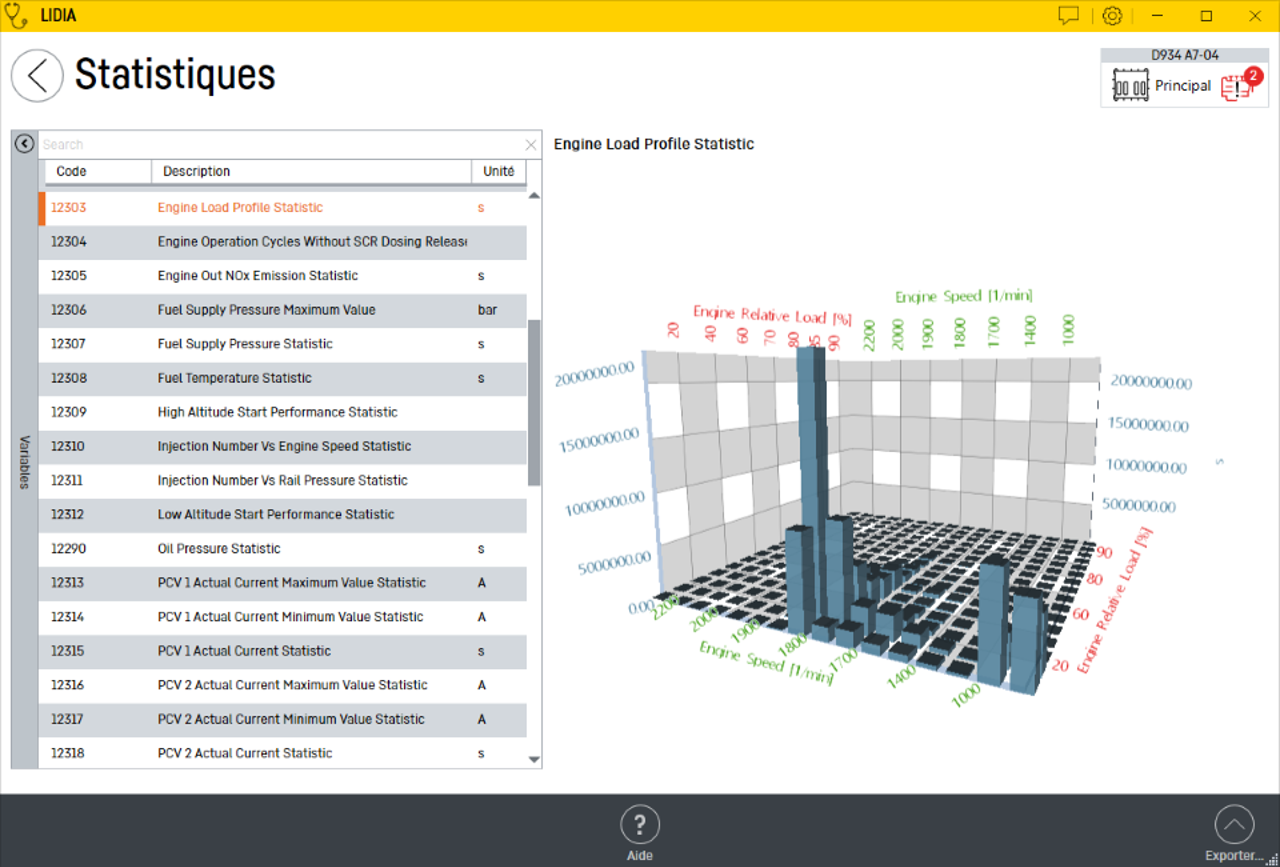

Statistics

1D, 2D and 3D display of statistical data on the system and its components for the entire life cycle.

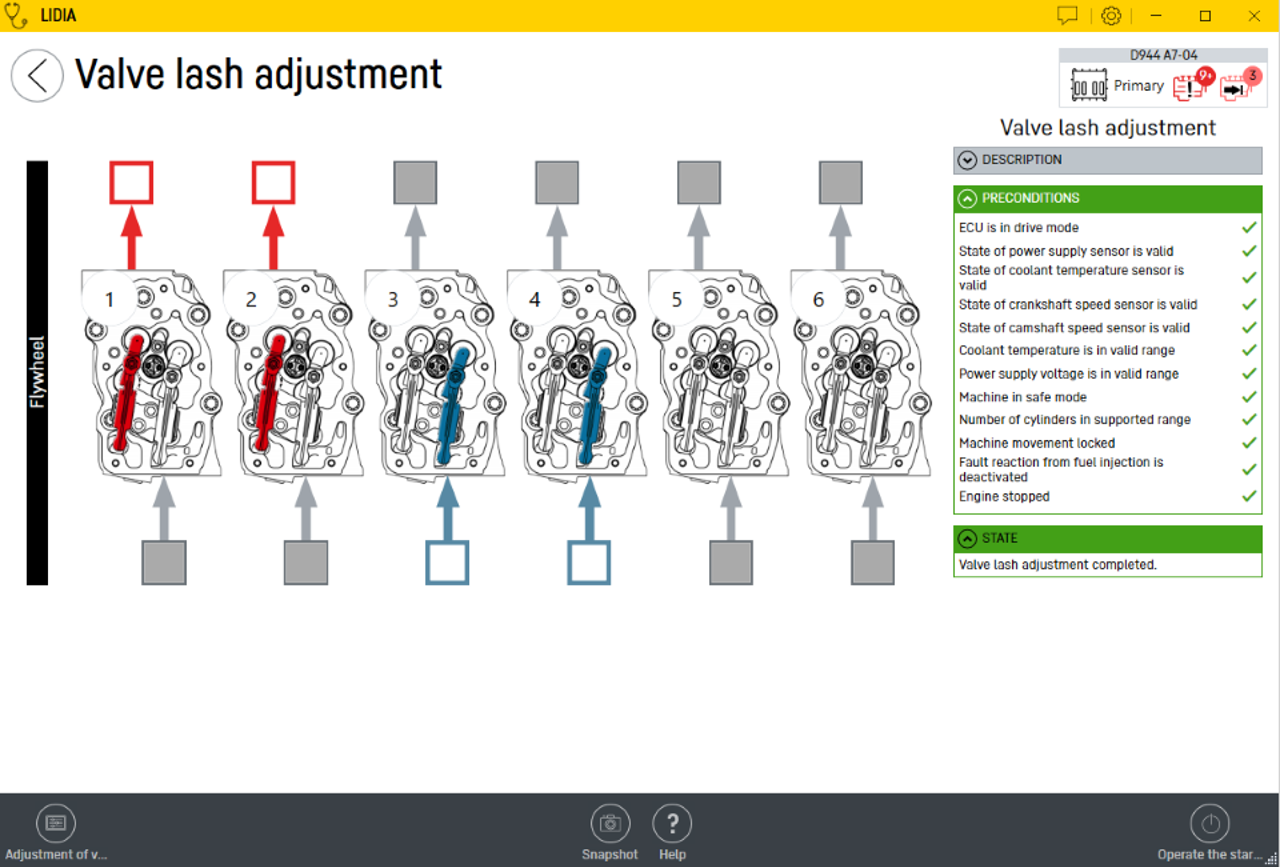

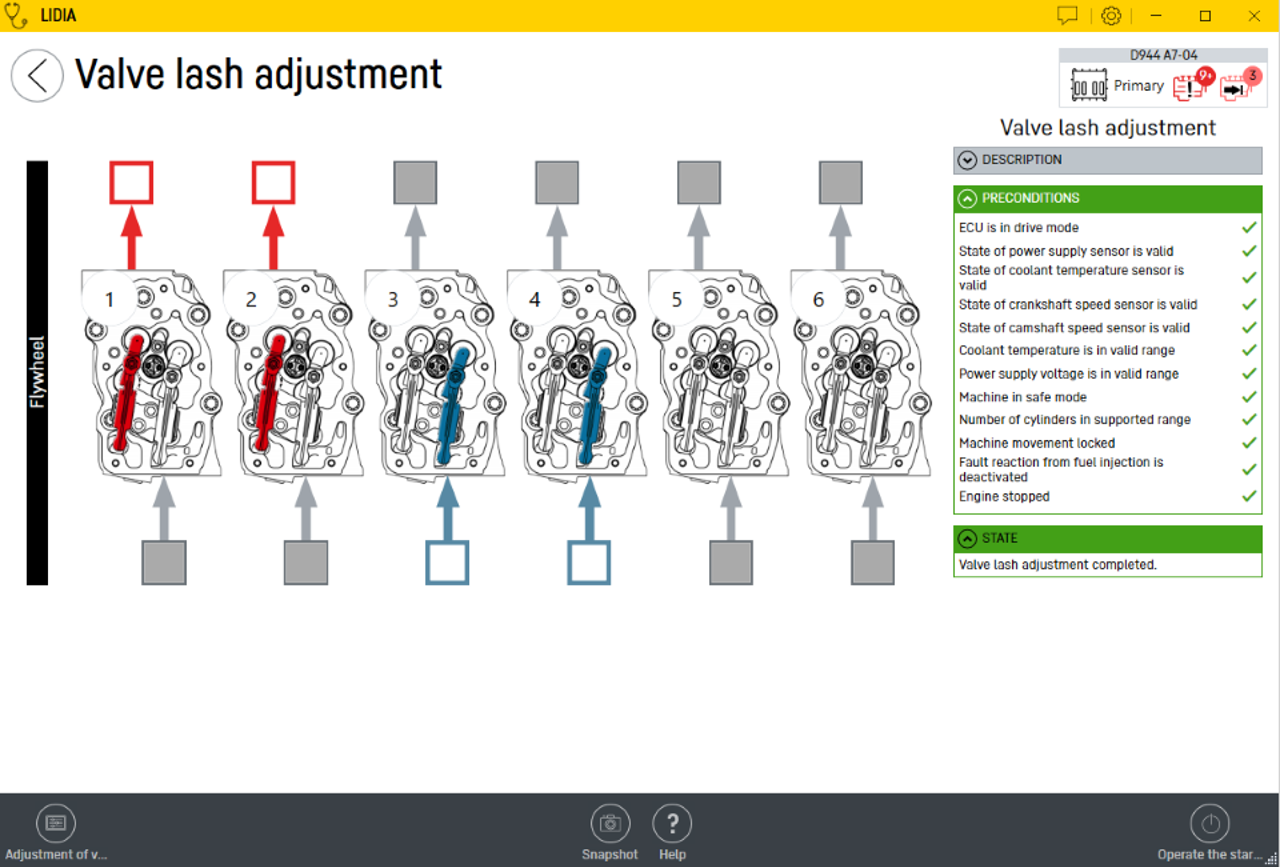

Save time and effort by letting the engine positioning itself so only one technician can adjust the valve lashes.

Manage spare parts, reset counters and allow their tracking from history

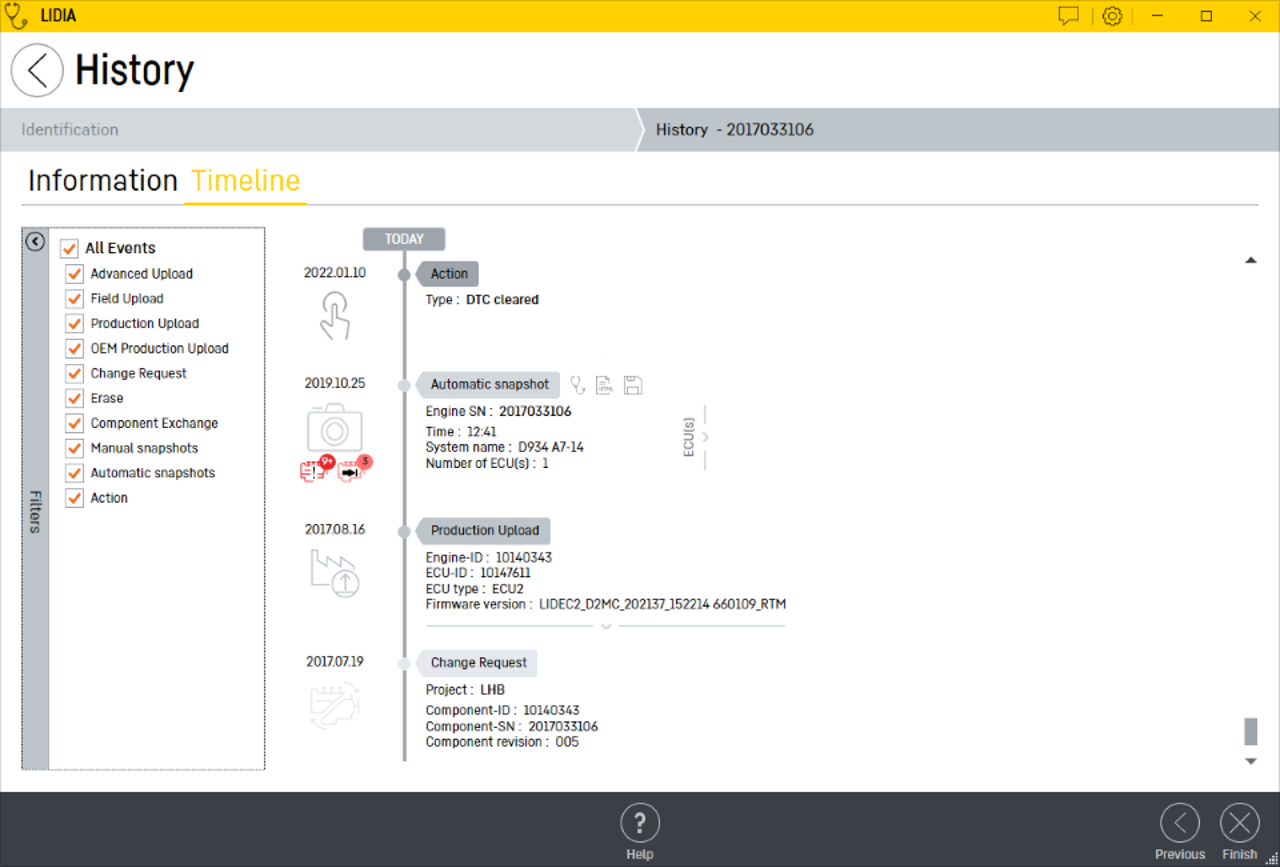

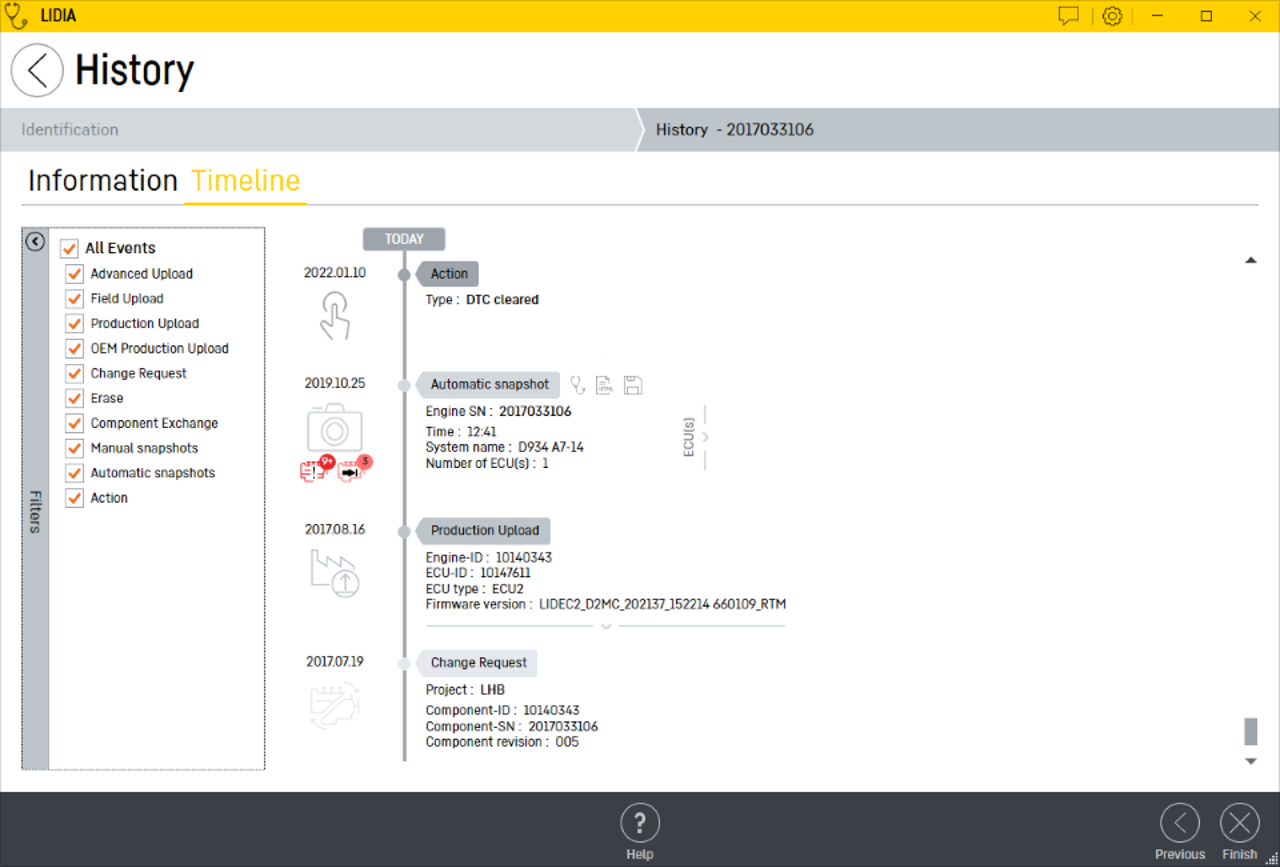

Retrieve information and events applied on your engines

1. Engine Information

Find information about requested engine serial number such as type, volume, certification, etc.

2. Snapshots

Open and get access to all variable, DTC, statistics as if you were the technician connected to the engine at that moment.

3. Filter

Check the desired type of events to easily filter the result.

Diagnosis

Diagnosis

Retrieve many information, configure your engines and run test routines

Update proposal

Obtain and upload automatically the latest available version of the firmware for the whole system.

Current status

Identify quickly if there are active Diagnosis Trouble Codes (DTC)

Diagnosis Trouble Code

List all errors raised by the embedded software, and get access to help full freeze frame information, guide, references and useful schematics to solve the issue.

Common Rail System Dashboard

Maintenance dashboard, and dedicated routines such as click test, cylinder cut off, etc.

DTC

Diagnosis trouble codes (active and passive DTCs) with corresponding details and help content, such as schematics

Get access to troubleshooting content

SCR Dashboard

Launch maintenance routines with easy to understand schematics.

Engine After Treatment System Dashboard depending of your configuration.

Get access to maintenance dashboard, and dedicated routines such as Air system check, DEF filling check, Ventilation check, Deposit cleaning, Coolant heating test.

Statistics

Helpful engine statistics

Valve lash adjustment

Save time and effort by letting the engine positioning itself so only one technician can adjust the valve lashes

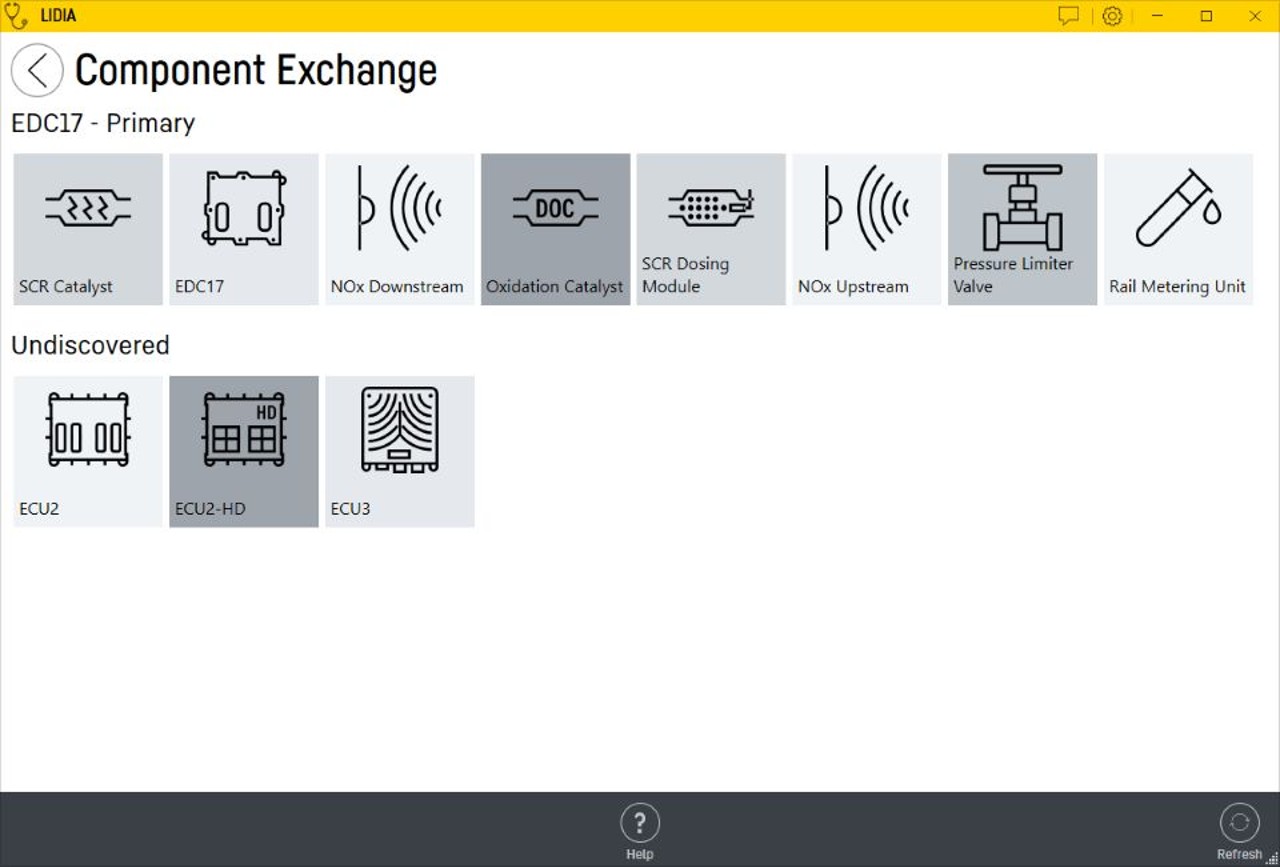

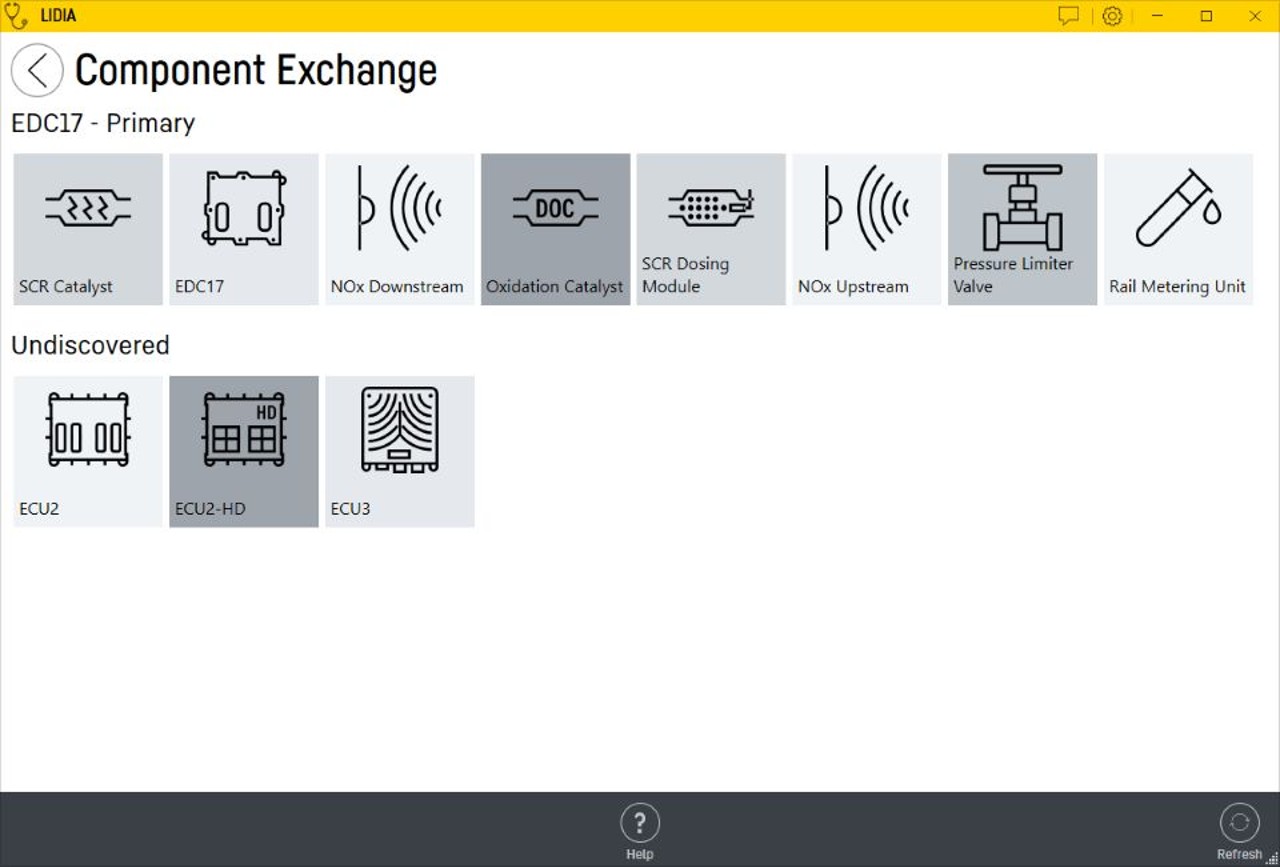

Component Exchange

Manage spare parts, reset counters and allow their tracking from history

History

Retrieve information and events applied on your engines

1. Engine Information

Find information about requested engine serial number such as type, volume, certification, etc.

2. Snapshots

Open and get access to all variable, DTC, statistics as if you were the technician connected to the engine at that moment.

3. Filter

Check the desired type of events to easily filter the result.

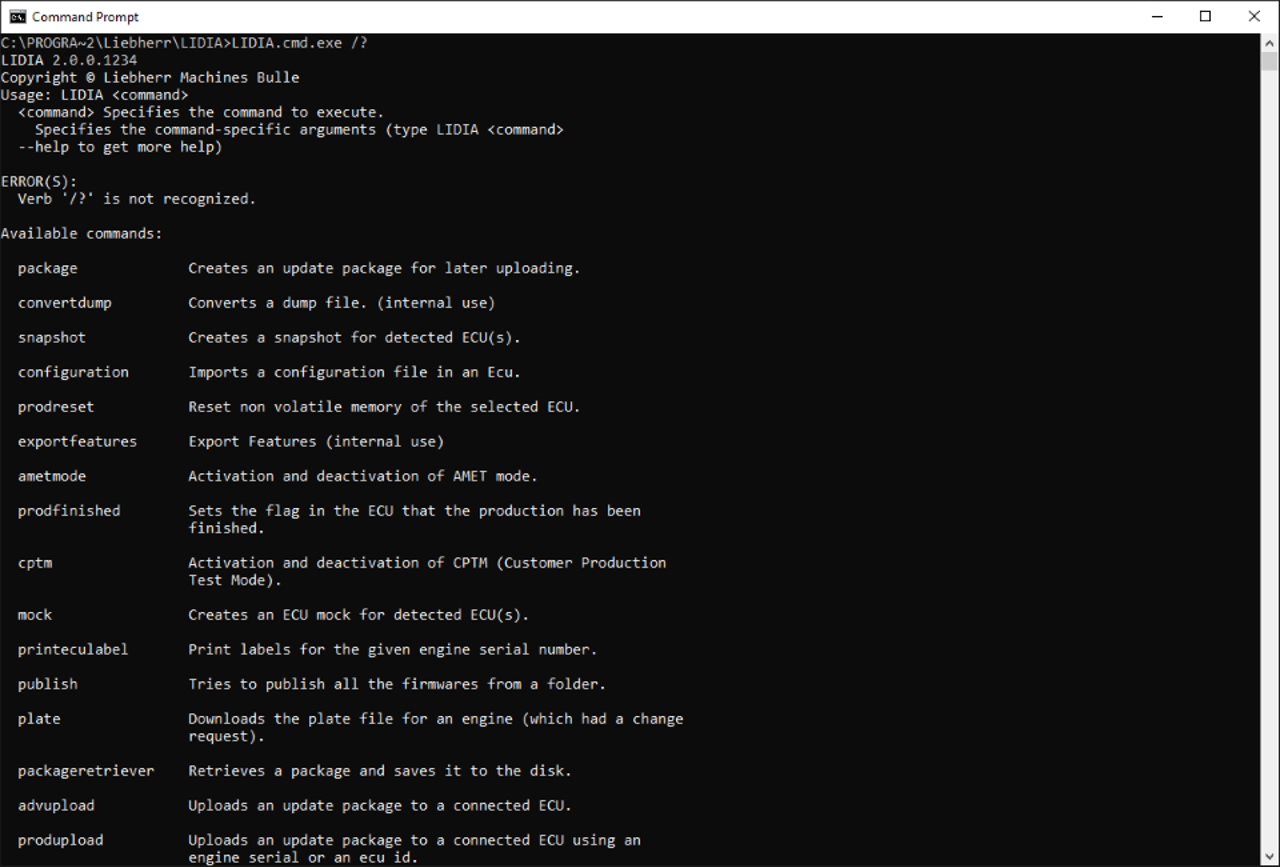

Automation

Pilot LiDIA using command line and integrate it in your system

First steps

MyLiebherr

Discover how it works (This is an example of a video integration)

Want to know more?

Contact our sales team via [email protected] or follow us on our Linkedin channel.