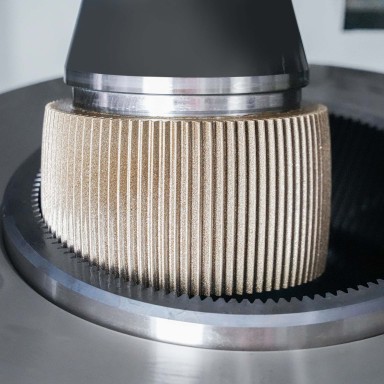

SkiveFinishing®: Innovative and precise

SkiveFinishing® is a new method for efficiently hard machining high quality internal gears. It combines the flexibility of gear skiving with the advantages of non-dressable CBN tools. An innovative CBN tool by Liebherr-Verzahntechnik GmbH ensures a long tool life and even enables profile modification.