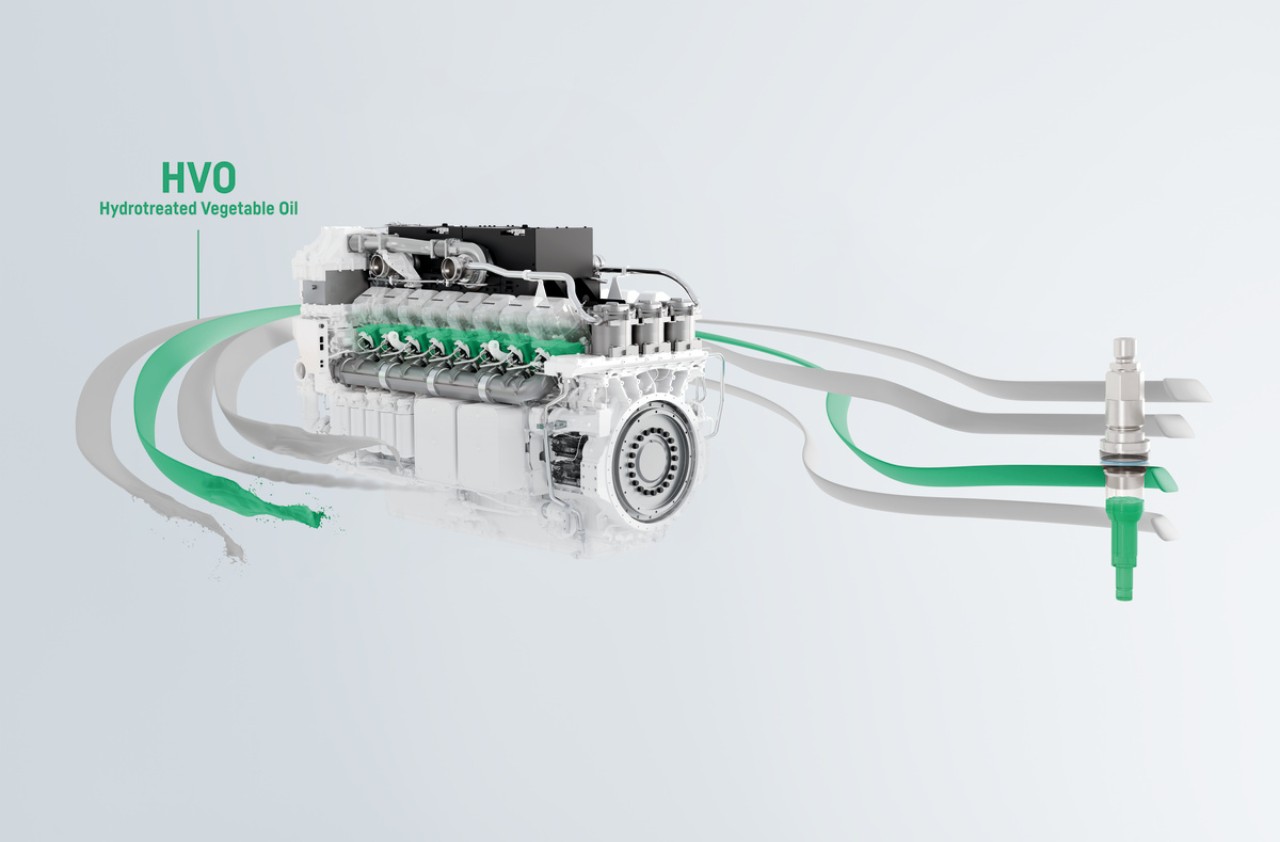

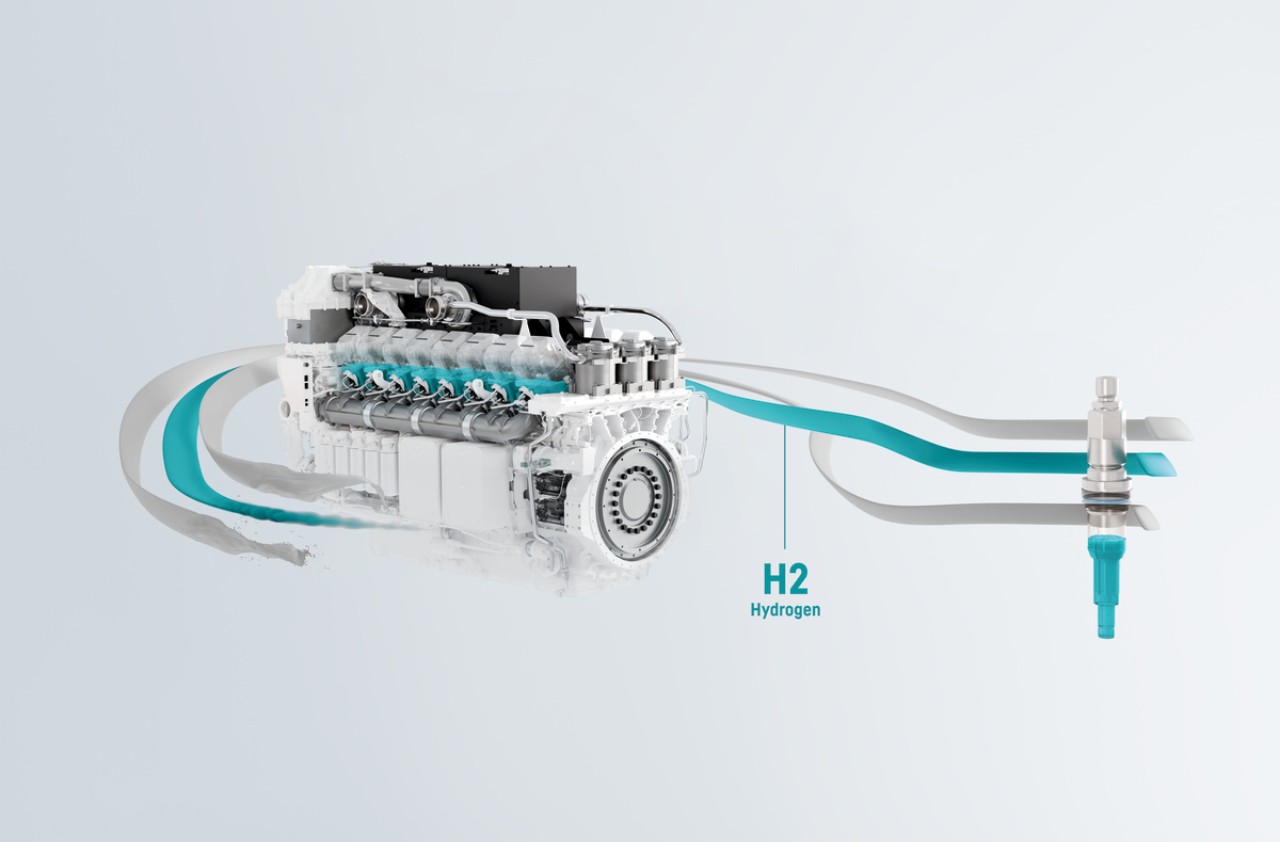

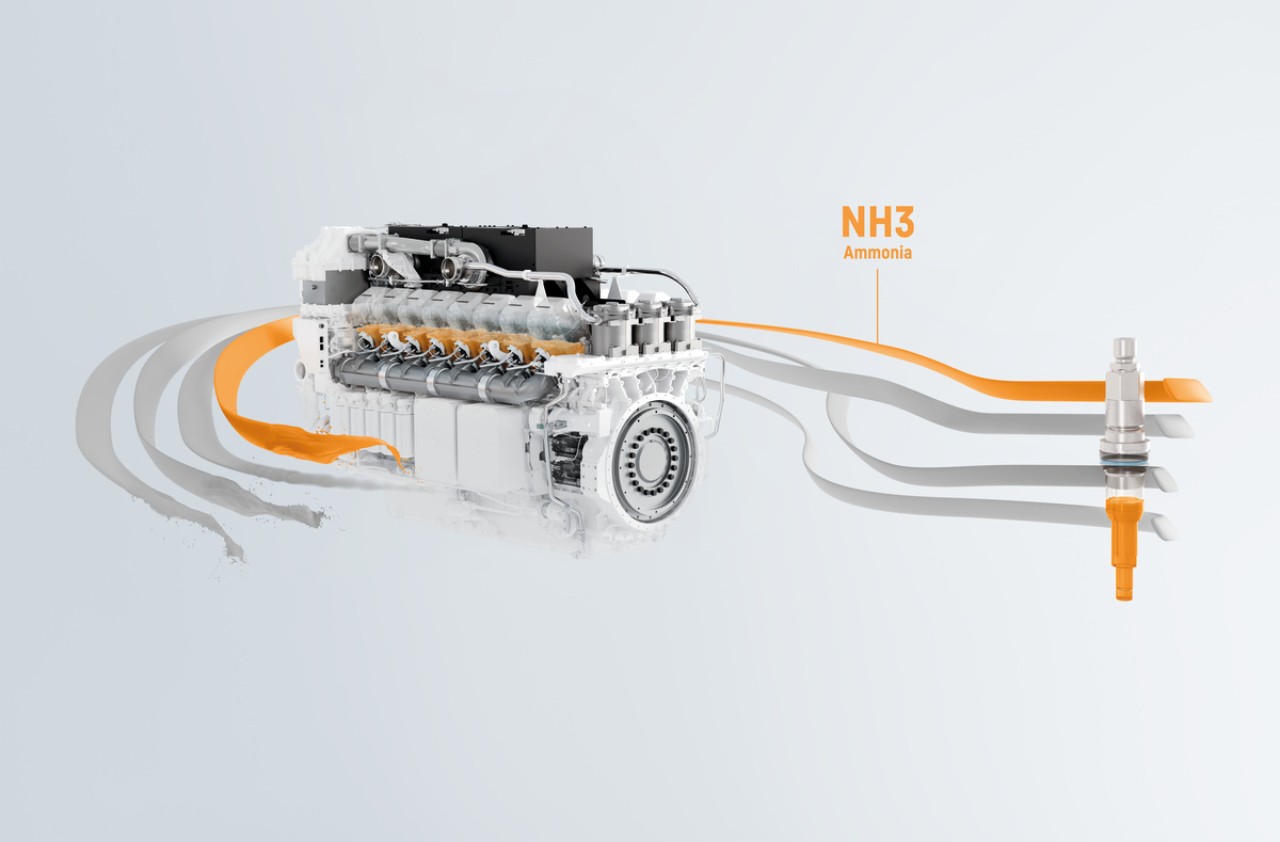

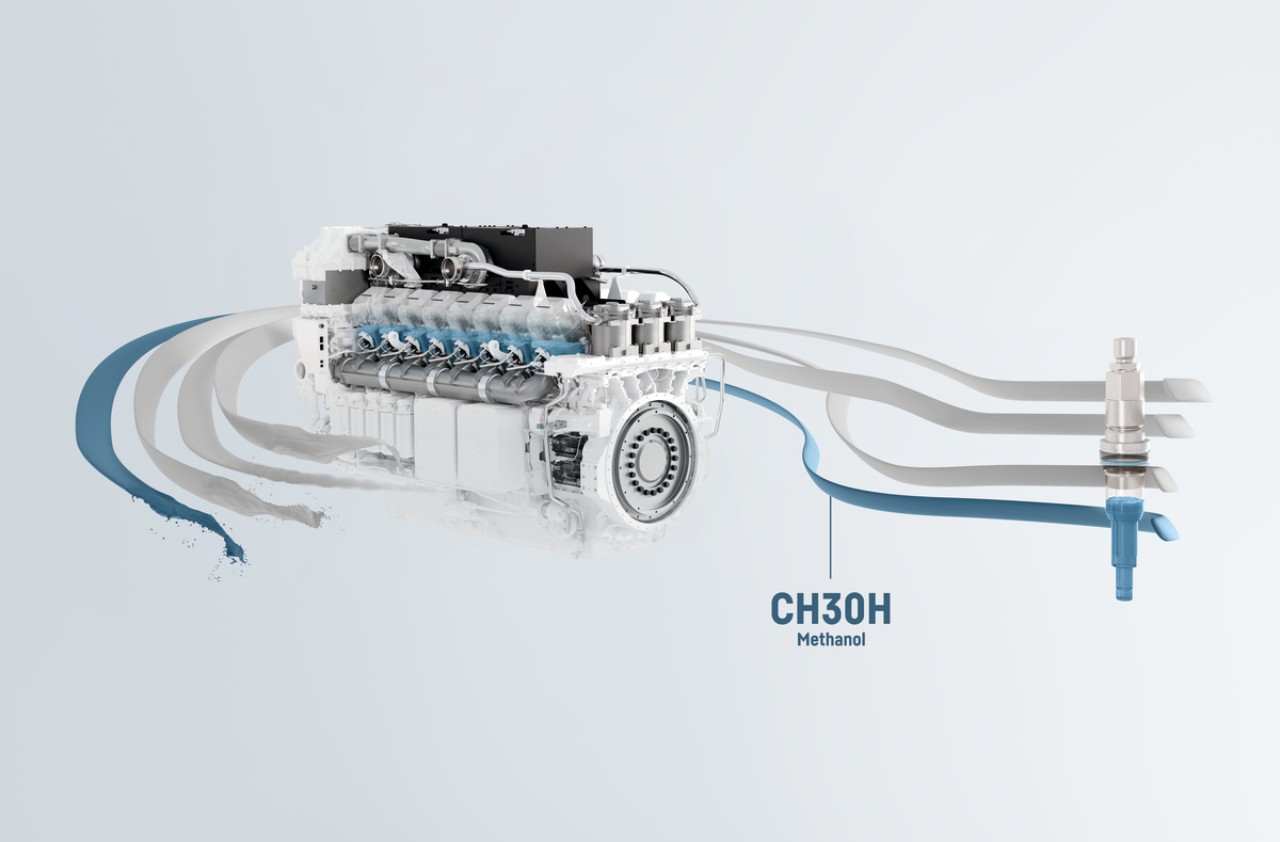

Open-technology approach

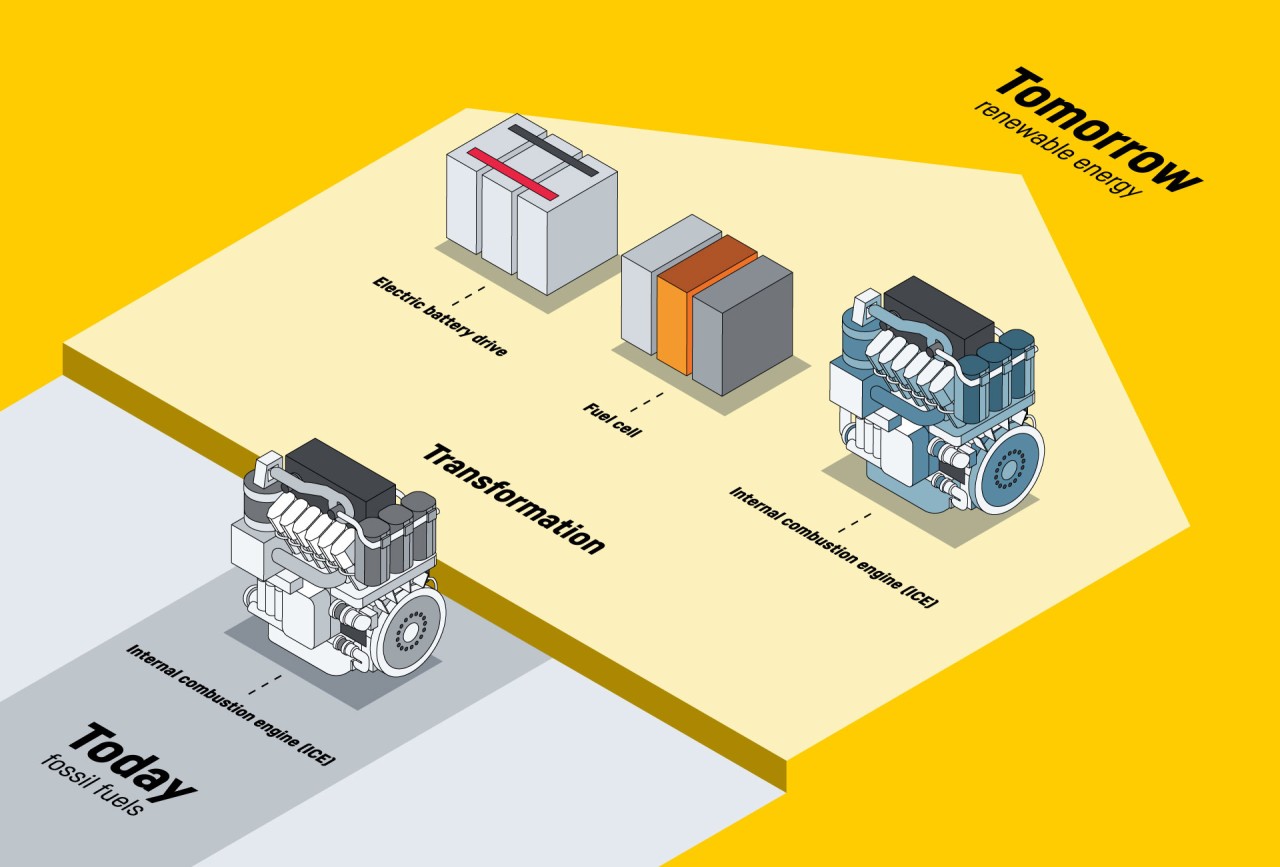

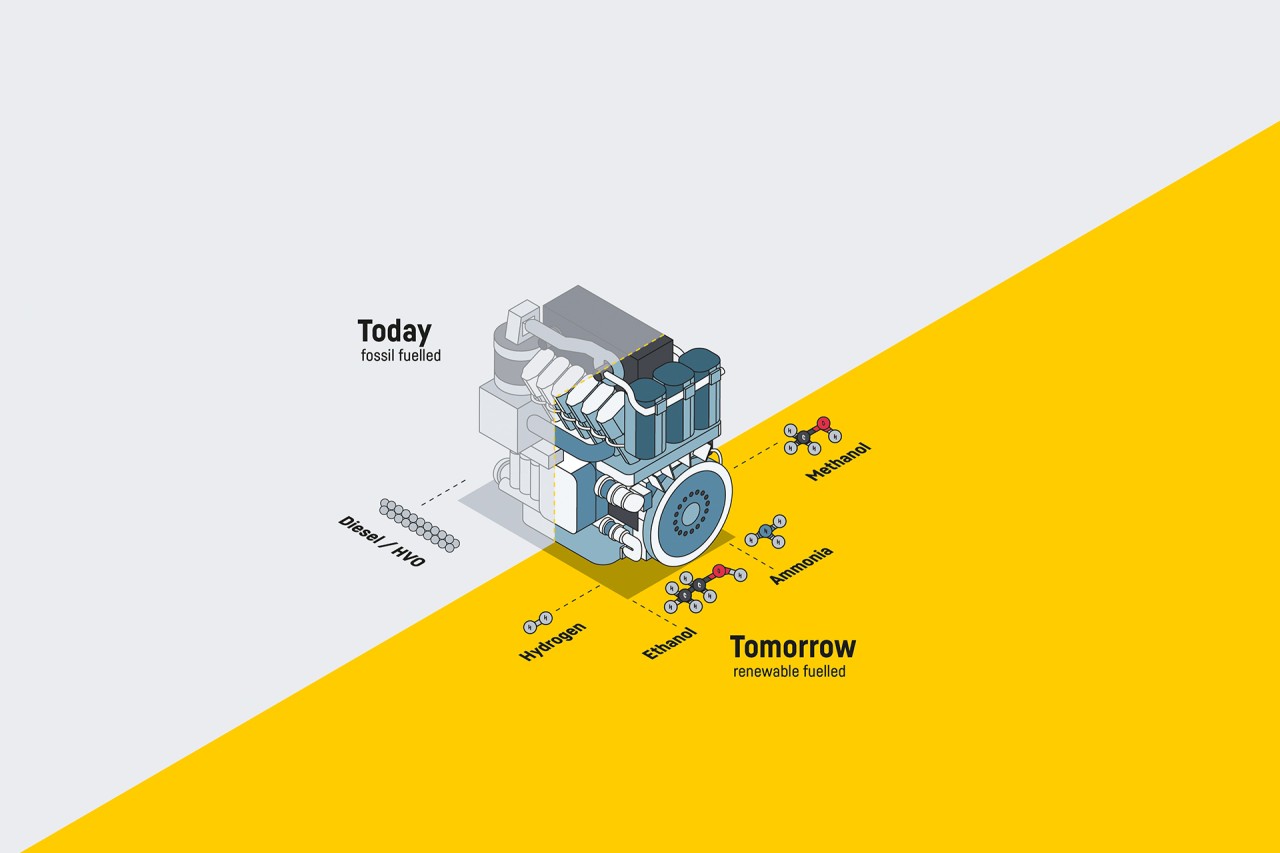

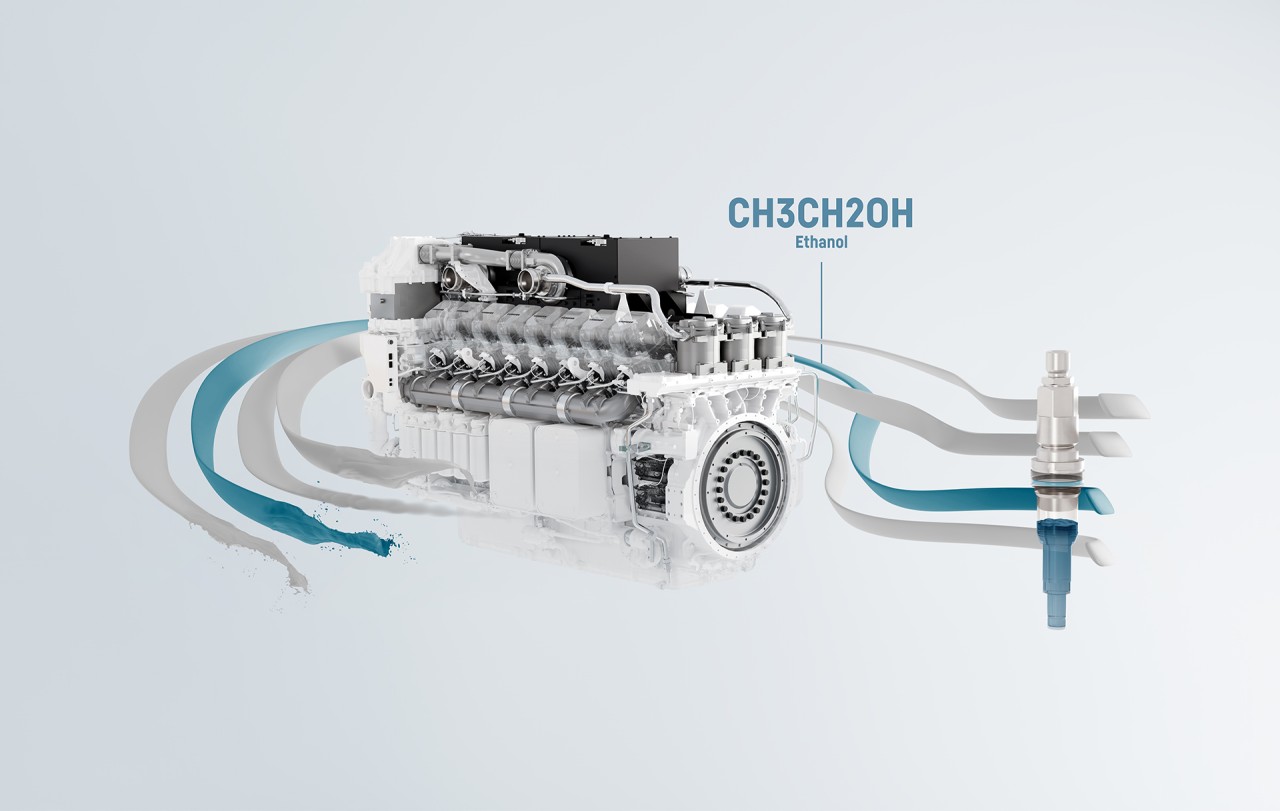

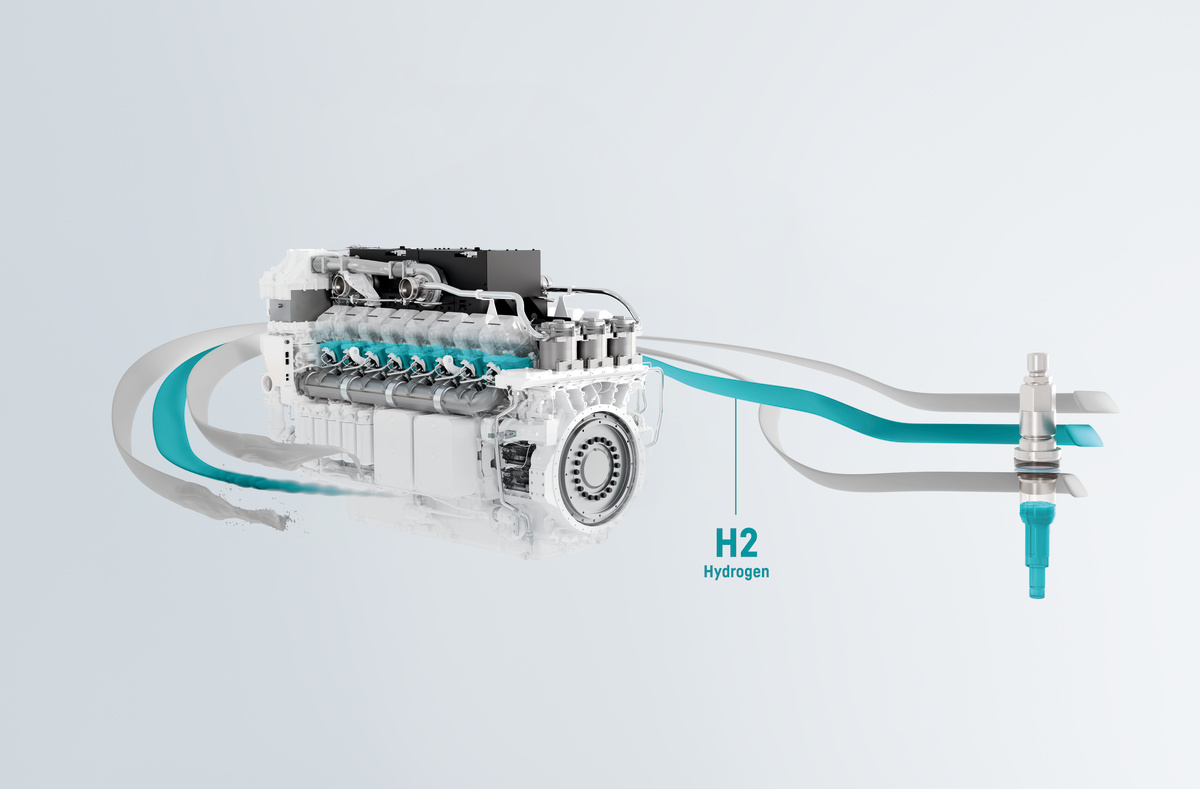

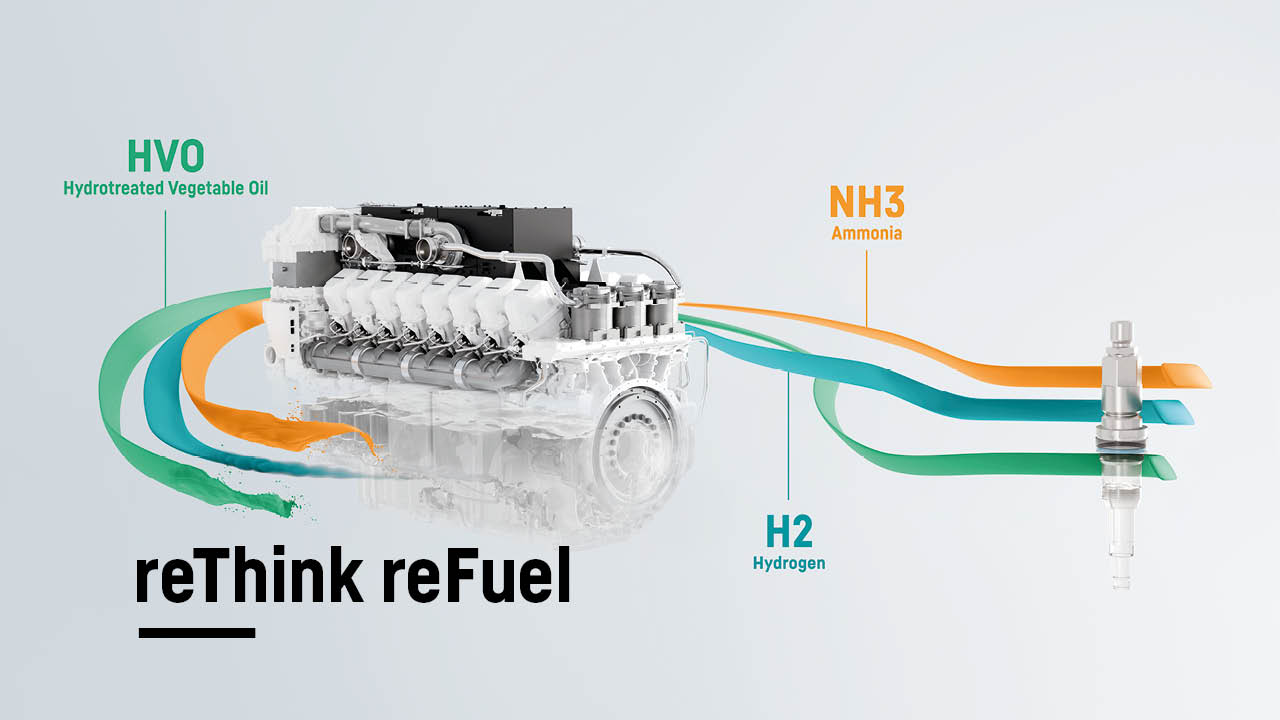

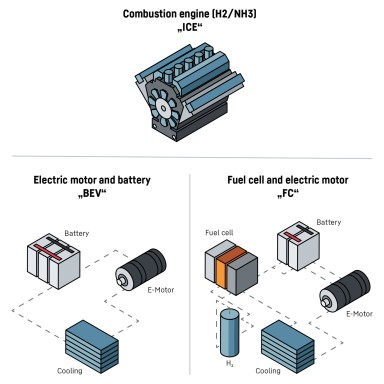

The reduction of global greenhouse gases is a significant challenge of our generation. Striving to reach net zero emissions in the future, Liebherr works on alternative and climate-friendly powertrain concepts.

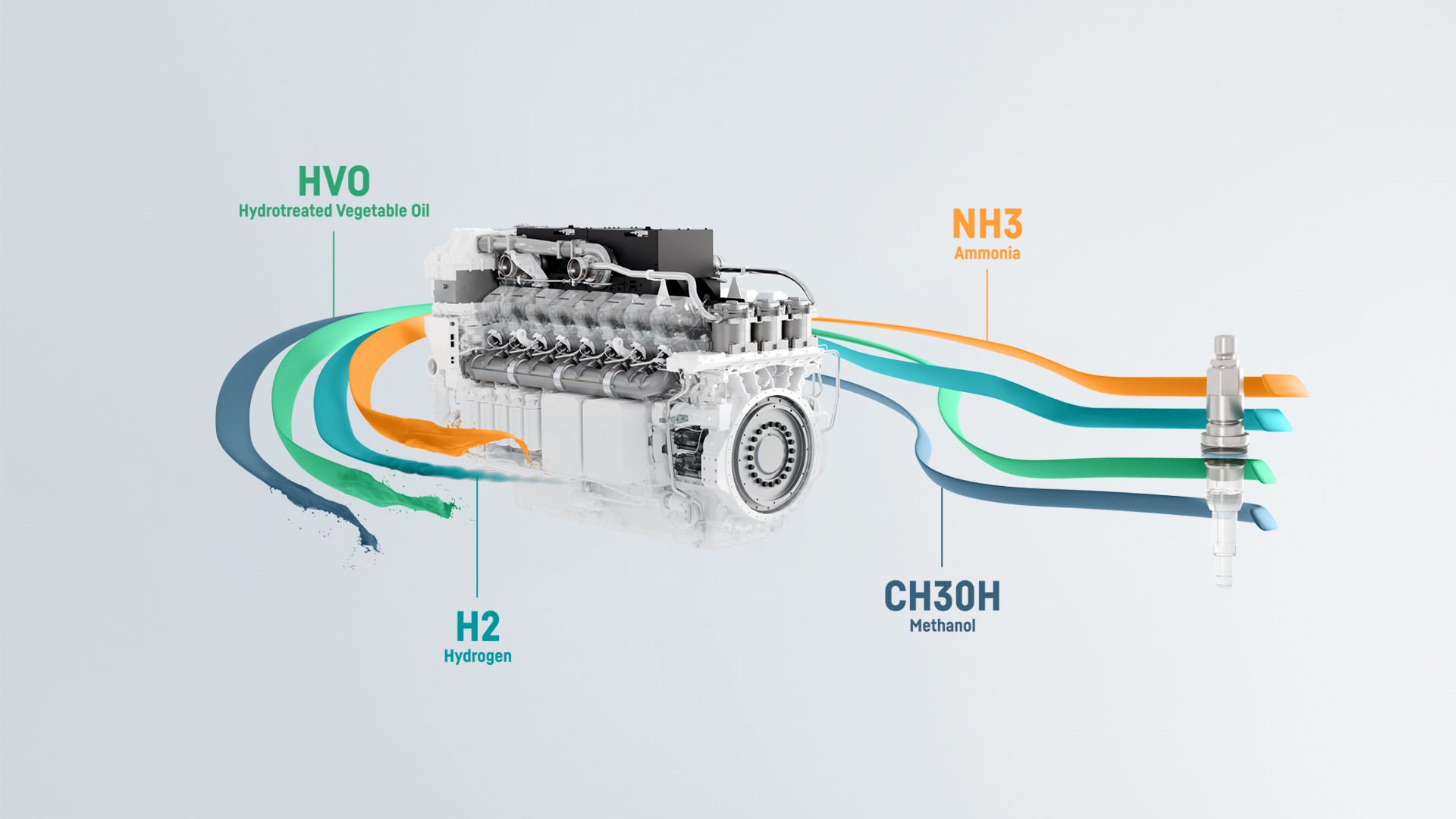

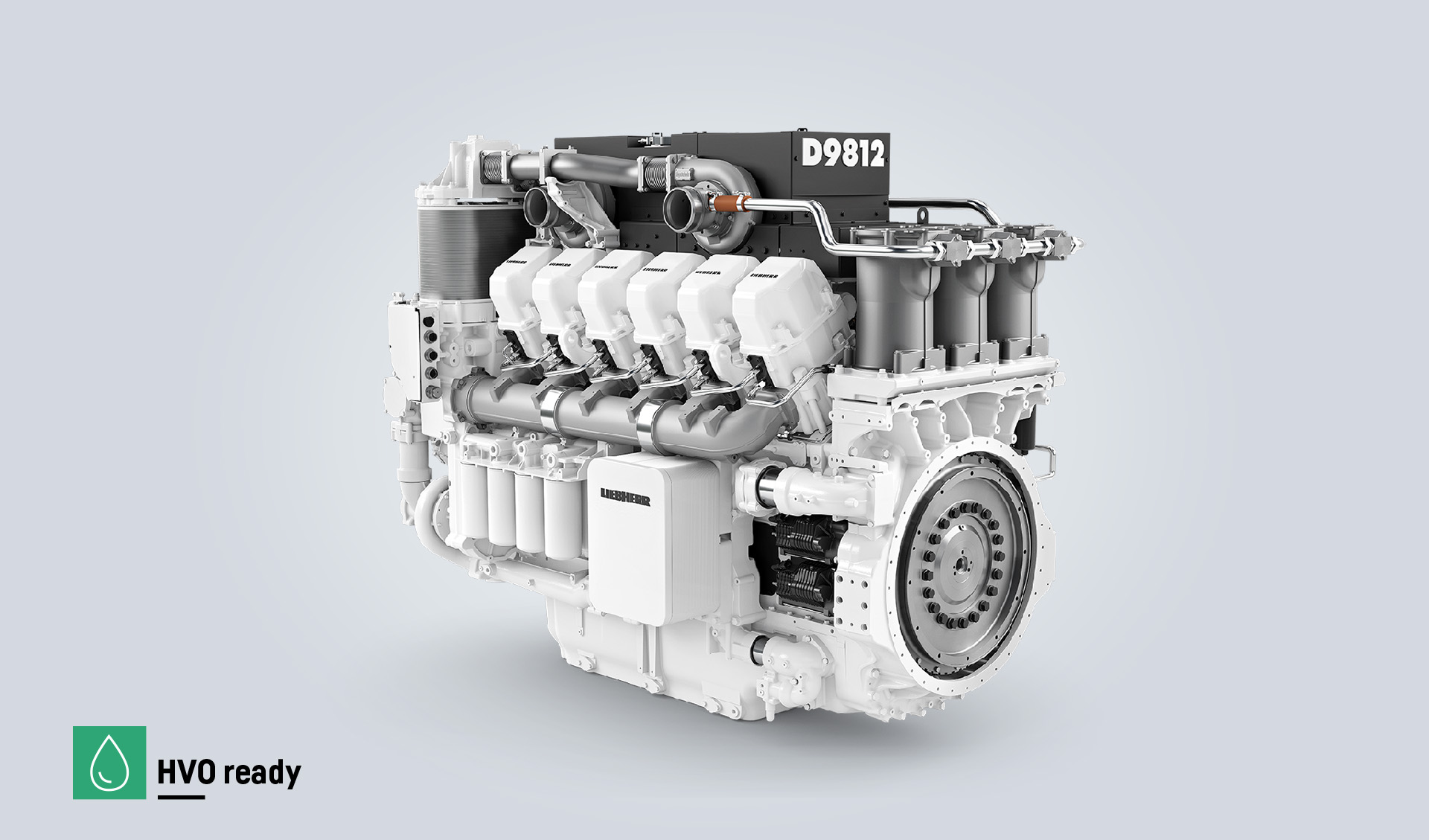

Thereby, the Liebherr team pursues an open-technology approach. In the field of internal combustion, the focus of the research and development activities lies on multiple solutions, depending on the needs different fields of application will require in the future.

01/02

Powertrain solutions

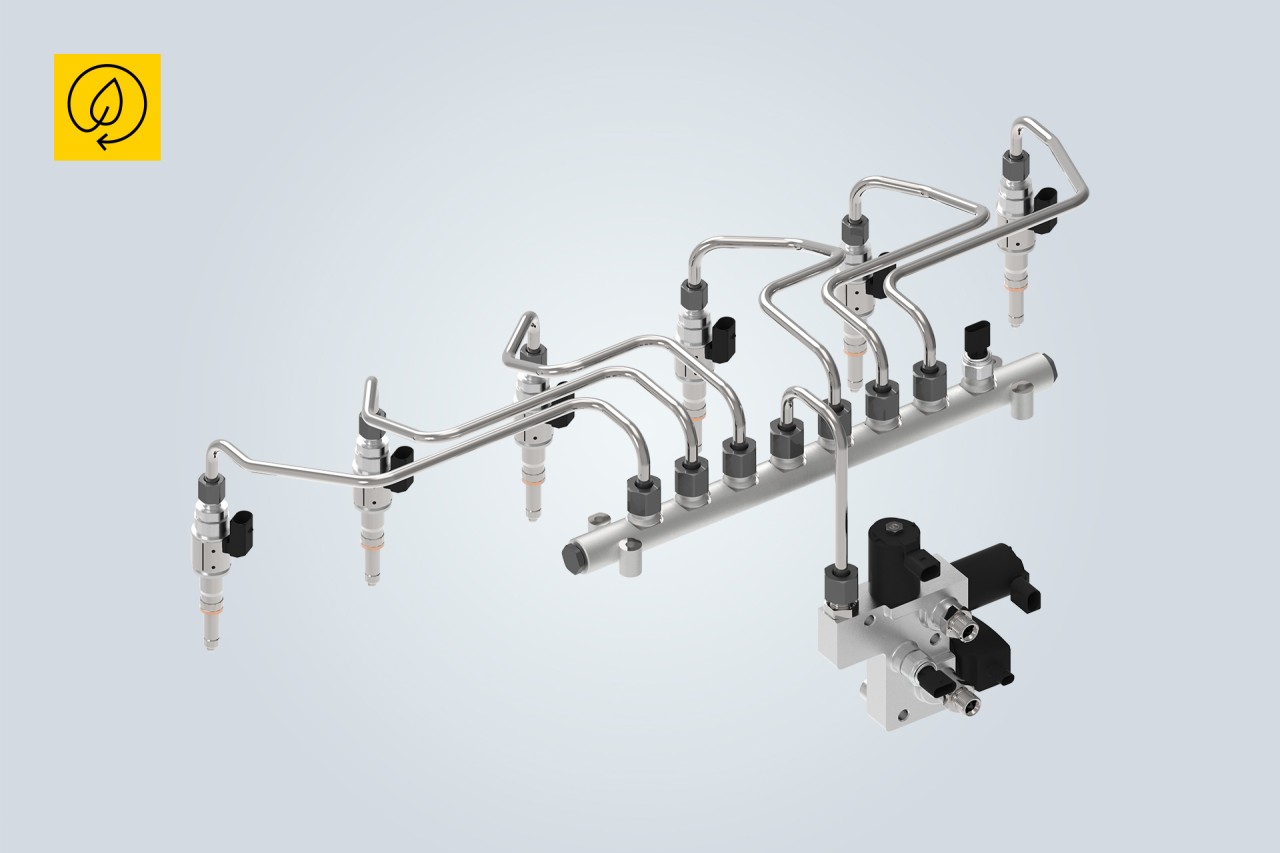

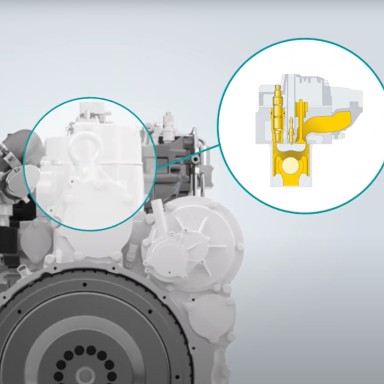

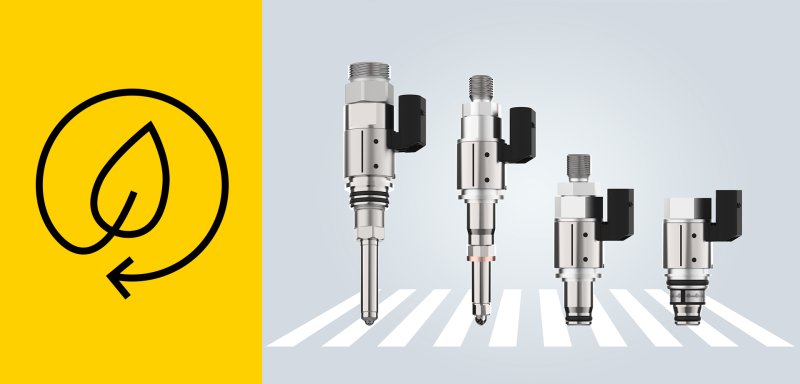

Fuel injection concepts

01/02

Highlights

Want to know more?

Contact our sales team or follow us on our LinkedIn channel