Products

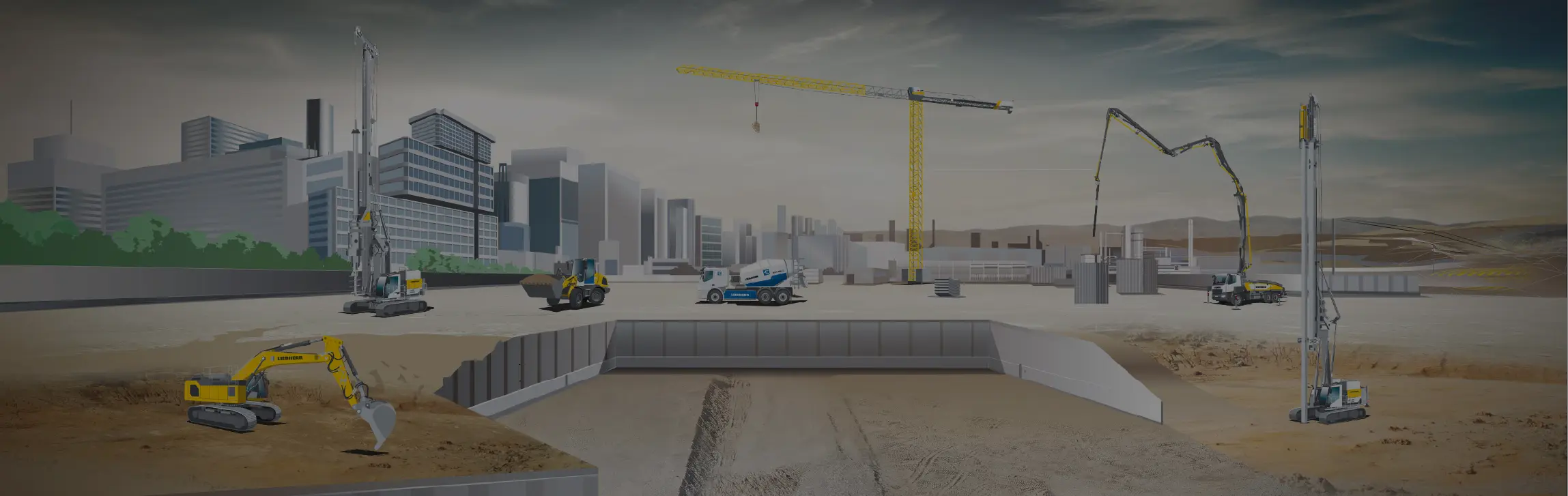

For 75 years, Liebherr's range of products and services has been broad and sophisticated. Its design and technology is orientated around practical deployment scenarios throughout the world. Continually growing innovative strength and an uncompromising commitment to quality safeguard the highest level of benefit to the customer in all product areas.