4 minutes - magazine 02 | 2025

Zero emissions, full power: World premiere for mobile crane twins

It was without doubt one of the highlights of Bauma 2025: the Liebherr LTM 1150-5.4E. Sporting the characteristic white-and-blue paintwork of electrically powered Liebherr machinery, it stood opposite its conventionally powered twin the LTM 1150-5.4.

LTM 1150-5.4E – one crane, two drives

Both world premieres. Both filled with HVO at the Liebherr Plant in Ehingen. Both with the new driver assistance systems for increased safety on the road. But only one with an electric engine and battery pack.

With battery pack: The LTM 1150-5.4E celebrated its world premiere at Bauma.

Product Manager Julian Rapp was usually also found on and in the LTM 1150-5.4E – deep in conversation with crane operators from all over the world. “On construction sites, there are more and more regulations relating to ‘local zero emissions’ and the issue of noise reduction is also gaining importance. So the interest in our electric 150-tonne crane was tremendous. We’ve had really positive feedback about our concept and even sold some cranes directly at the trade show.”

Julian Rapp, Product Manager, Mobile Cranes

Electric drive offers flexible use

Both on and off road, a 400 kW (544 HP) combustion engine with exhaust gas level 5 delivers powerful propulsion. The engine is fully compatible with hydrogenated vegetable oil (HVO) and, compared to operation with diesel fuel, cuts CO₂ emissions by up to 90 %.

In crane operation, the choice between the combustion engine or the 111 kW electric motor allows flexible use. The newly developed drive guarantees unrestricted crane operation with virtually the same performance as the 6-cylinder combustion engine.

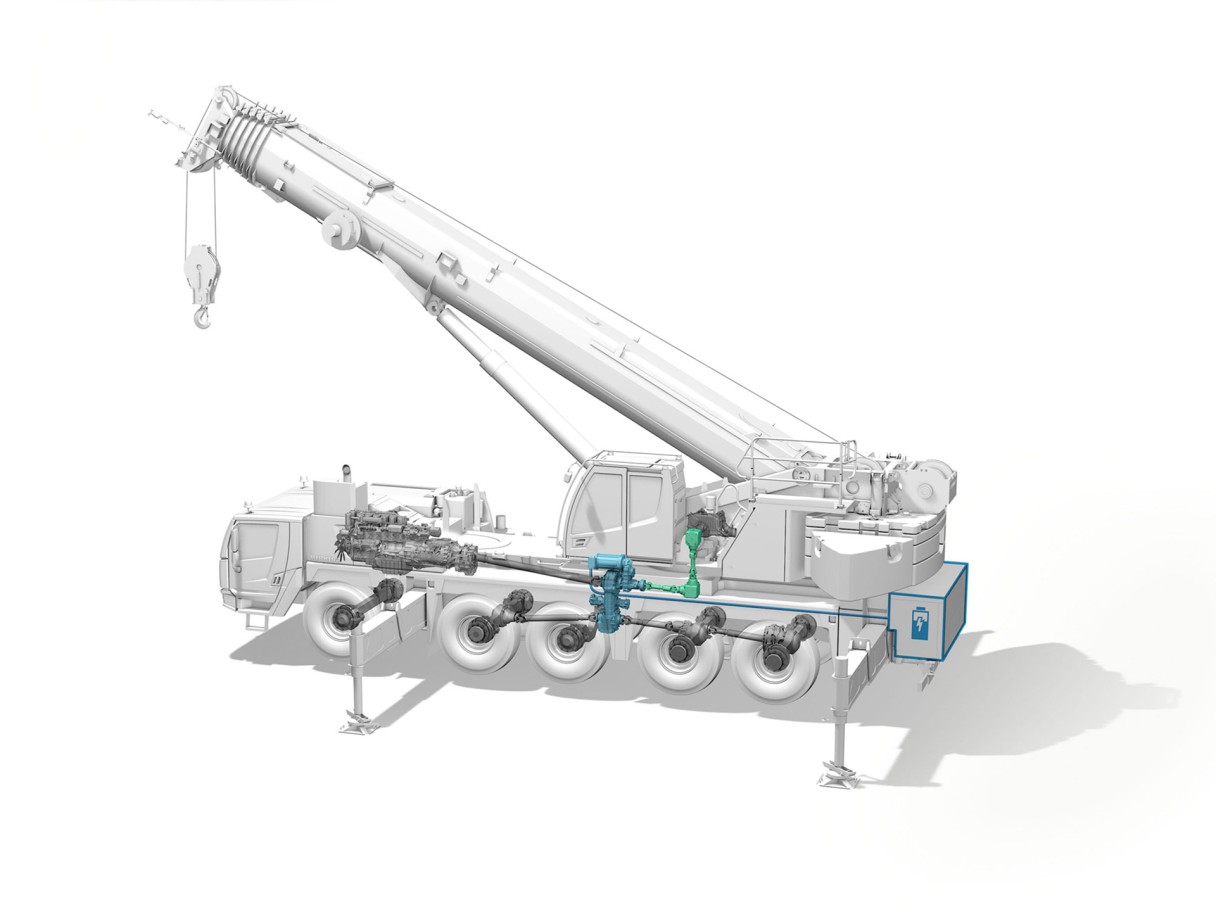

The electric motor uses the existing gear shafts to transfer the power to the consumers in the crane superstructure. “The electric motor’s distributor gear is integrated between the chassis distributor gear and the gear shafts to the superstructure. This clever yet simple solution enables the operator to switch flexibly between diesel-hydraulic power and electro-hydraulic power,” explains Julian Rapp. “If the high voltage system fails, we can operate the superstructure via the mechanical shaft at the press of a button, just as with a standard crane. With other concepts on the market, the crane can only operate if the electricity is working.”

The concept of our electric- powered LTM 1150-5.4E impresses with its superlative flexibility.”

Mobile crane with battery pack

The drive concept for the LTM 1150-5.4E builds on the proven technology of the Liebherr LTC 1050-3.1E compact crane, albeit with a crucial upgrade – an integrated battery pack. “This concept brings with it two key advantages. Firstly, with its integrated battery, the crane can operate autonomously for up to around four hours without a power connection. Secondly, a small connected load, some 16 respectively 32 Amps, is enough to allow the crane’s full power to be unleashed – since the battery serves as an efficient buffer. The crane draws high currents for peaks in performance from the battery, which is permanently recharged by the on-site electricity supply,” explains Rapp.

“We decided to position the 98 kWh battery pack on the back of the chassis so that all of the components can be stowed away securely in a box.” Rapp explains why this is an advantage with regard to the crane’s “second life”: “If electric propulsion isn’t in demand on the used crane market, or if the battery is no longer economically renewable at some point, then the battery pack can be removed and the machine operates just like the standard LTM 1150-5.4 crane”.

The tremendous flexibility around charging the battery also impressed our customers at Bauma: whether with alternating current from a CEE high-power socket with 64 Amps and 44 kW of power, whether with a standard Schuko socket, or with direct current via a modern CCS plug for fast charging with up to 80 kW. This offers significantly more versatility than our competitors.

Flexible drive concept

The electric motor drives the gear shaft to the pump distributor gear in the superstructure via a distributor gear. The battery pack is stowed at the back of the vehicle.

This article was published in the UpLoad magazine 02 | 2025.