4 minutes - magazine 02 | 2024

Is it a safety risk if a support lifts off the ground during crane operations?

The load and radius are well within the load limit. Everything is in the green zone – at least thatʼs what the crane control system indicates.

Nevertheless, looking at the supports gives you a sinking feeling in your stomach: one of the four support legs has clearly lifted off the ground. Joachim Henkel, Head of the Structural Engineering Department, explains why this is no cause for concern.

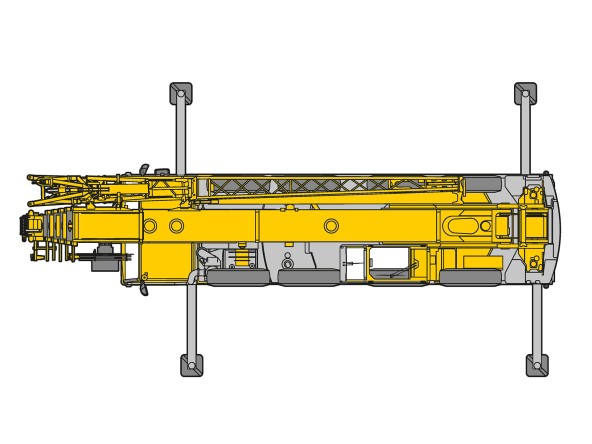

Crane with H-supports

Have you ever thought about why some dogs lift one leg when peeing and do their business on the other three legs? The answer is simple: because they can. And thatʼs exactly how it is with supported mobile cranes. They can perform their work safely on either four or three support legs. Exactly when and how far a crane support will lift off the ground depends on various factors.

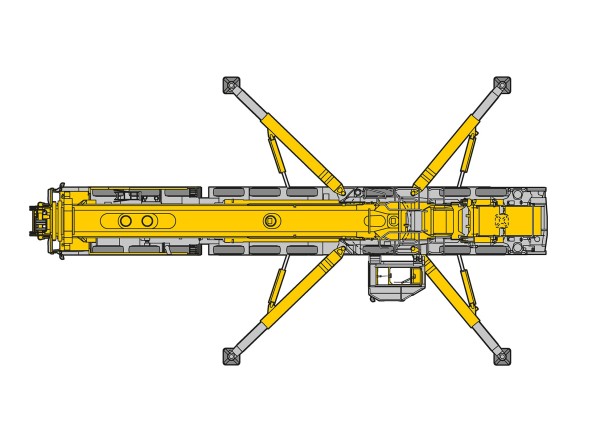

Crane with star-shaped supports

In principle, the phenomenon of “support lift” is unavoidable with modern mobile cranes and is largely due to their lightweight construction and the use of high-strength fine-grained structural steels. Due to the high potential stress ratio of these steels, the elastic deformation in the load-bearing steel structure of the craneʼs chassis also increases. This phenomenon makes support lift more likely. Each supported mobile crane has a working area in which all four supports will remain on the ground, even if the superstructure rotates 360°. The smaller the load radius, the sooner all supports are in contact with the ground. If the crane driver increases the radius and turns the superstructure so that the boom is positioned over the support furthest away from the centre of rotation, the diagonally opposite support may be completely unloaded and thus lifted clear off the ground. Although the crane is now only standing on three supports, it is stable and can continue working in accordance with the load chart.

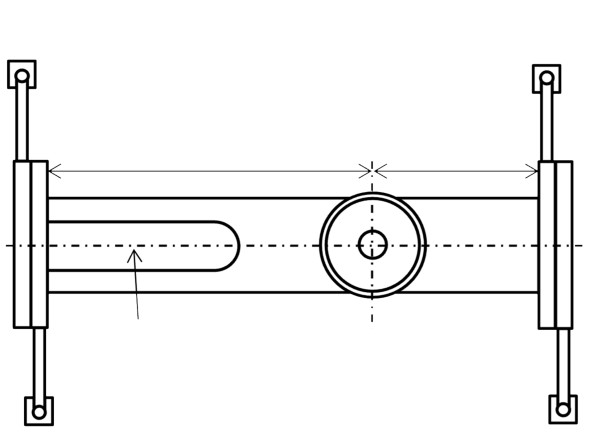

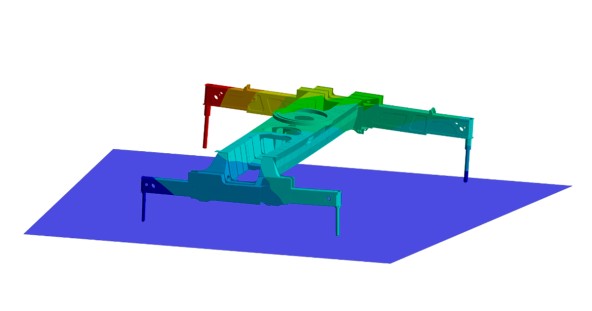

Vehicle frame with H-support

In general, cranes with H-shaped supports are more prone to support lift than those with star-shaped supports. This is because the load-bearing ratios of the front and rear supports are almost identical in a star-shaped support arrangement.

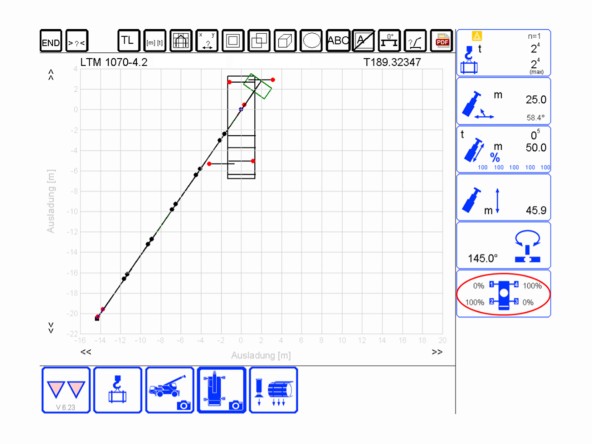

VarioBase® with “exotic” support geometry and boom positioned over the front right support. The rear left support will have a strong tendency to lift.

This is not the case with H-supported cranes, whereby the supports with a shorter distance to the superstructureʼs centre of rotation – usually the rear ones – tend to lift off the ground. This is especially likely if the superstructure is rotated so that the boom is positioned above one of the front supports. The reason for this is that the front section of the load-bearing vehicle frame is longer and can therefore flex more easily under load than the significantly shorter, and therefore stiffer, rear section. If the vehicle frame has an opening at the front to accommodate the engine and transmission, it will flex even more when under load. This will cause the rear support to lift more under load.

FEM simulation of “support lift”

The engineers at Liebherr keep the phenomenon of “support lift” firmly in mind when developing a new crane type. Using computer-aided simulations, we try to counteract support lift via appropriate design steps as early as possible in the development phase – as far as the constraints allow.

What causes support lift?

- Type of support: H-supported cranes are more likely to be affected than cranes with star-shaped supports

- VarioBase® with an “exotic” support geometry (see illustration)

- The front section of the vehicle frame is significantly longer than the rear section

- High load capacity utilization

- Large load radius

- Low ballast weight on the slewing platform

- Superstructure angled diagonally to the support base with the boom over one support

This article was published in the UpLoad magazine 02 | 2024.