In every great machine, there are great components

The new Liebherr ADT TA 230 Litronic went into serial production. The dump truck was designed for maximum productivity, featuring a payload of 28,000 kg and a max. dump body capacity of 18.1 m3. These impressive characteristics are possible thanks to the extremely robust and reliable components by Liebherr.

They operate smoothly on any terrain, under the toughest environmental conditions, while lifting extremely heavy loads.

Learn more about Liebherr components, and how we can bring your machine to the next level.

D956 diesel engine

Under the ADT’s hood lies a 6-cylinder Liebherr diesel engine with a power output of 265 kW and an impressive torque of 2,520 Nm. On top, the engine is fitted with a Stage V after treatment system. This heavy-duty engine is designed to perform continuous operation at full load. The engine’s automatic 8-speed power shift transmission allows excellent power transfer.

D956 diesel engine

Features

- Common rail injection system by Liebherr

- Turbo-charged and after-cooled

- Reduced emissions Stage V

- Emission control Liebherr-SCRFilter technology

D956 diesel engine

Technical data

- Rating per ISO 9249 265 kW (360 HP) at 2,100 RPM

- Model Liebherr D956

- Type 6 cylinder in-line

- Bore/Stroke 130/150 mm

- Displacement 12.0 l

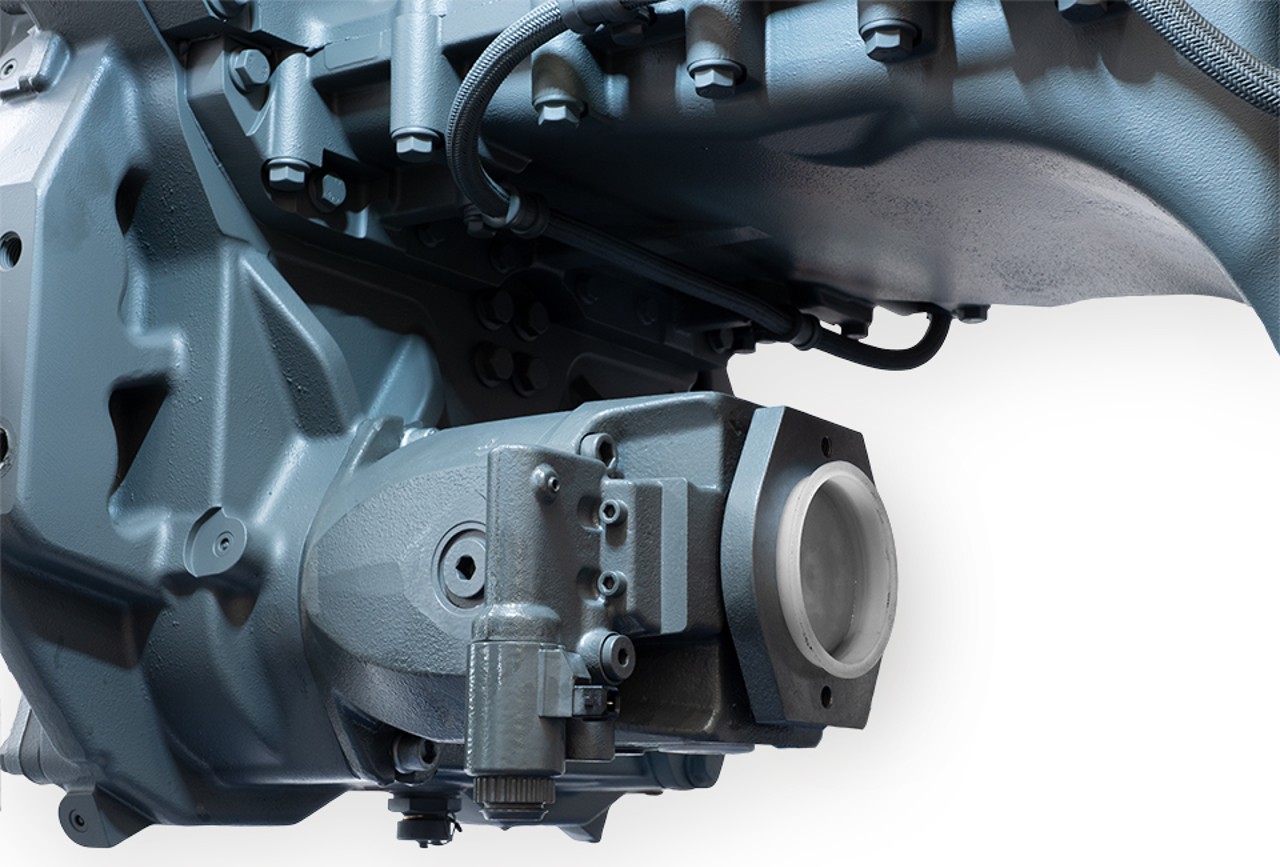

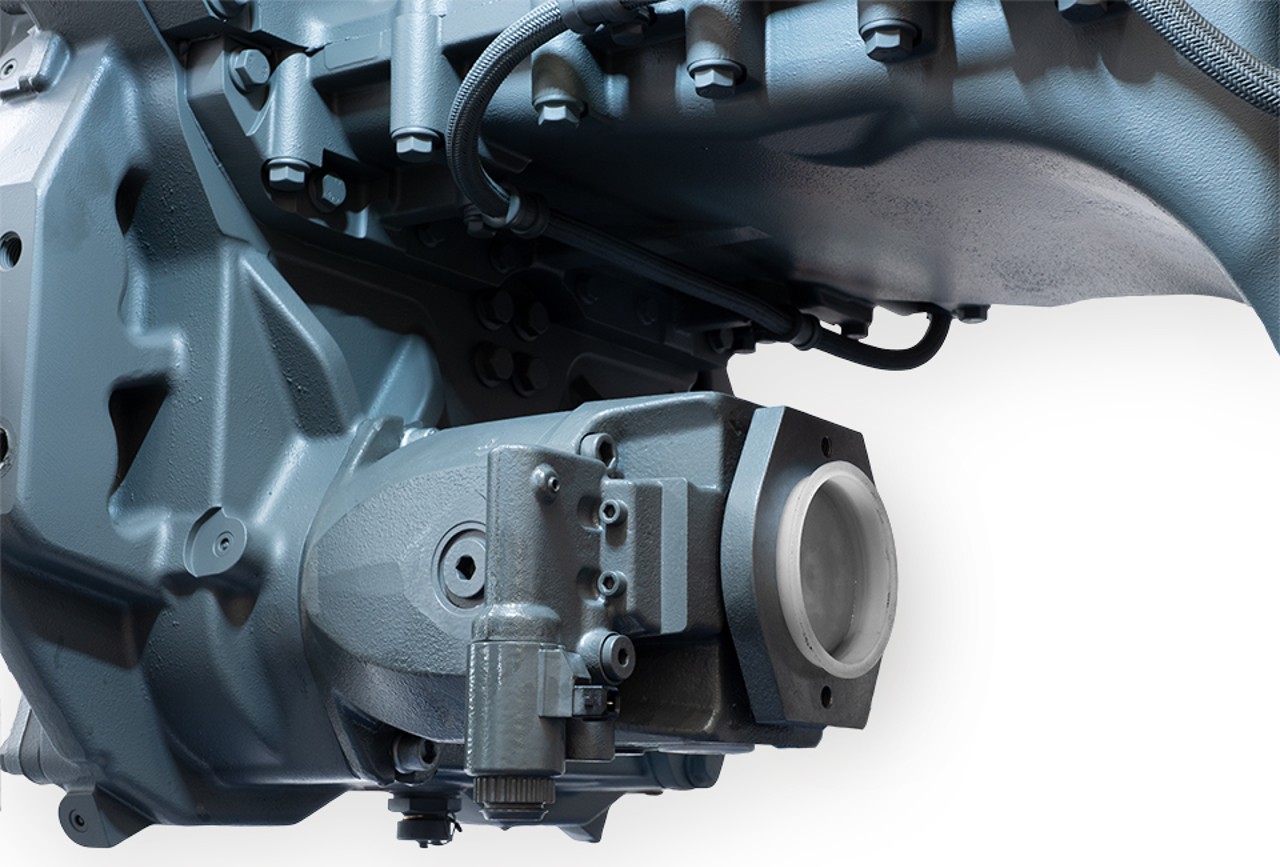

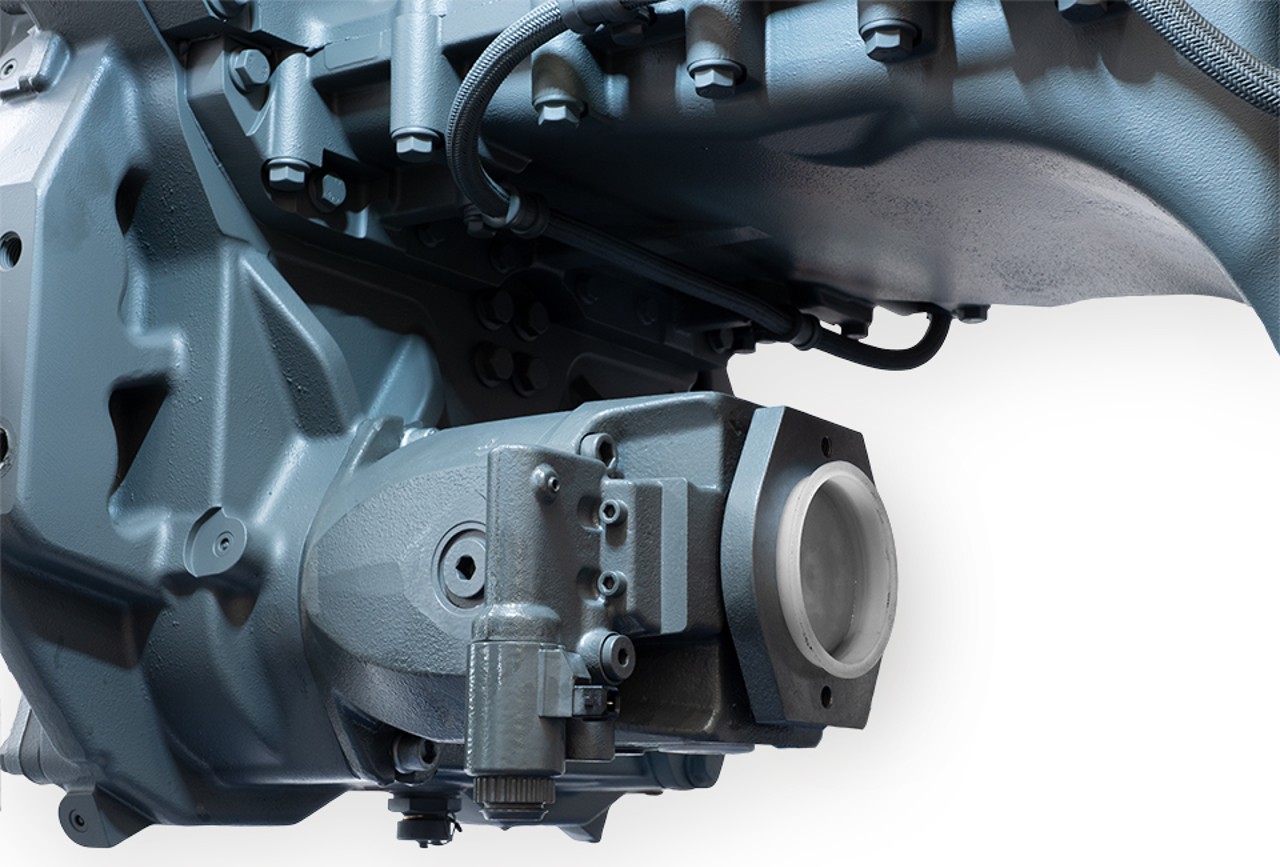

LH30VO axial piston pumps

Three robust Liebherr axial piston pumps LH30VO with a nominal pressure of 280 bar, support the optimal operation of the ADT.

Two of the variable displacement pumps in the size 45 ccm power the cooling systems. They ensure the ideal performance of the intercooler and the hydraulic system and thereby make sure that the best operating conditions for both the diesel engine and the hydraulics are available. A further LH30VO in the size 85 ccm drives the machine’s steering and supports the powering of the equipment in order to operate efficiently and lift the dump body within 12 seconds.

LH30VO axial piston pumps

Features

- High flexibility and availability

- Designed as a modular system

- Various control combinations possible

- Flexible through-drive concept even when the product has already been built-in

- Optimised fit for power take-offs

LH30VO axial piston pumps

Technical Data

- Hydraulic components: axial piston pumps

- Circulation: open

- Adjustability: variable

- Nominal pressure: 280 bar

- Maximum pressure: 320 bar

- Nominal sizes: 28 / 45 / 85

- Areas of application: agriculture and forestry / building construction and civil engineering / machinery and plant construction / maritime applications / mining / special vehicles

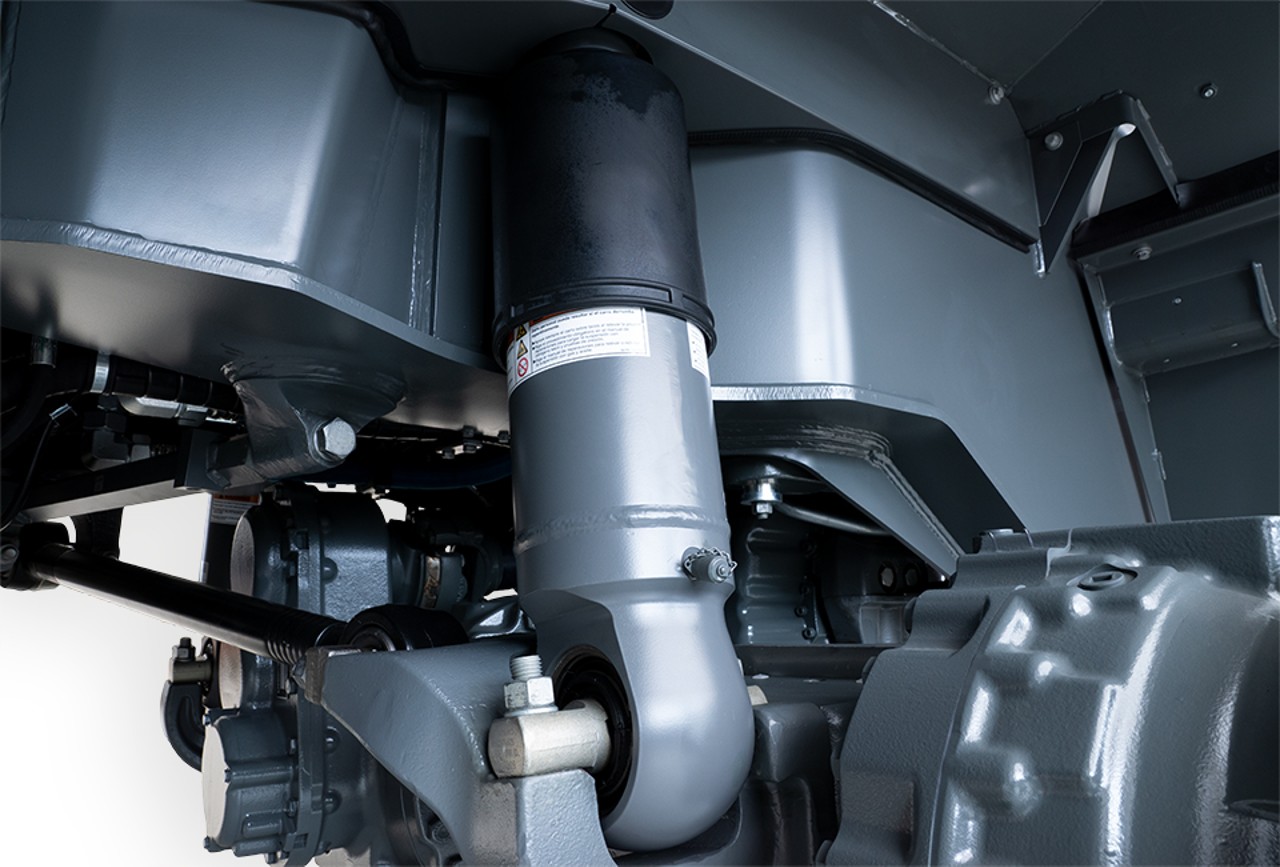

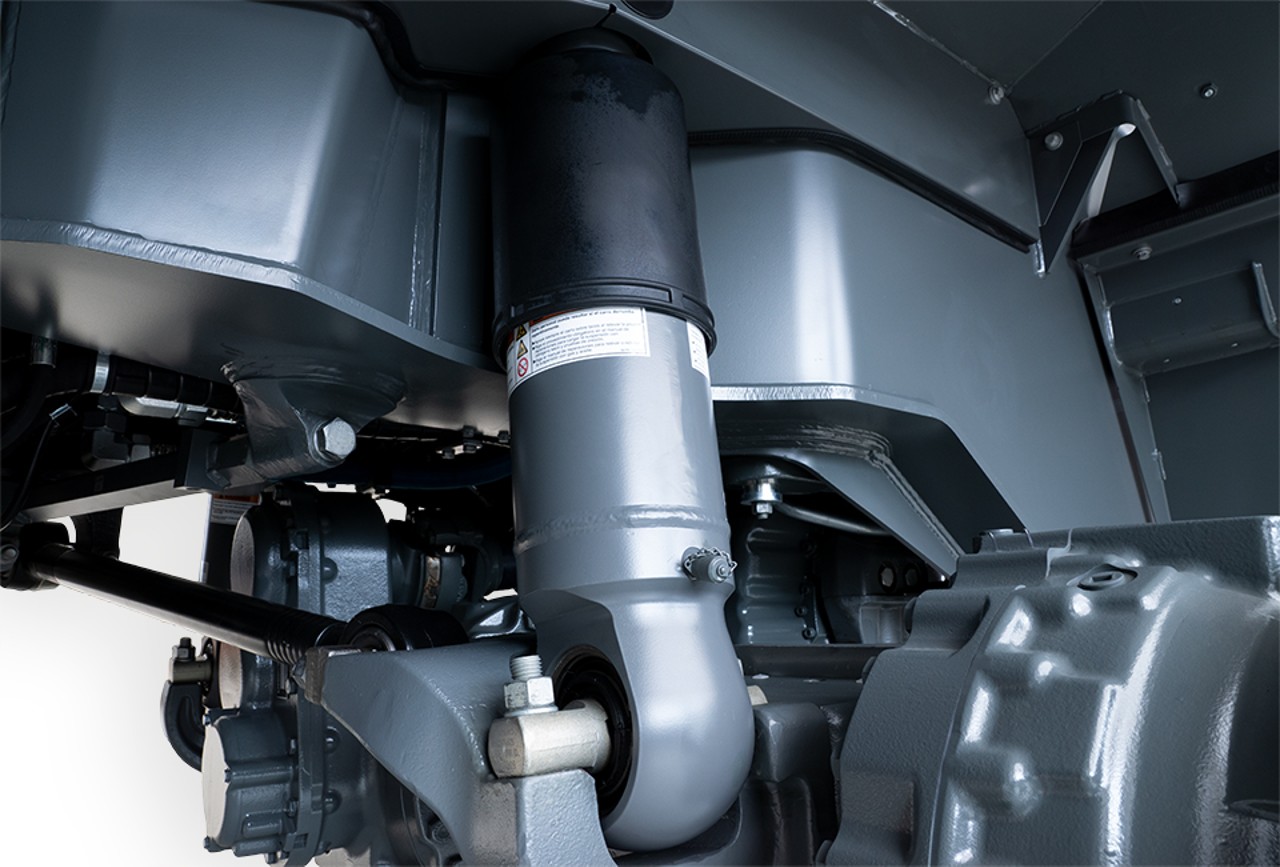

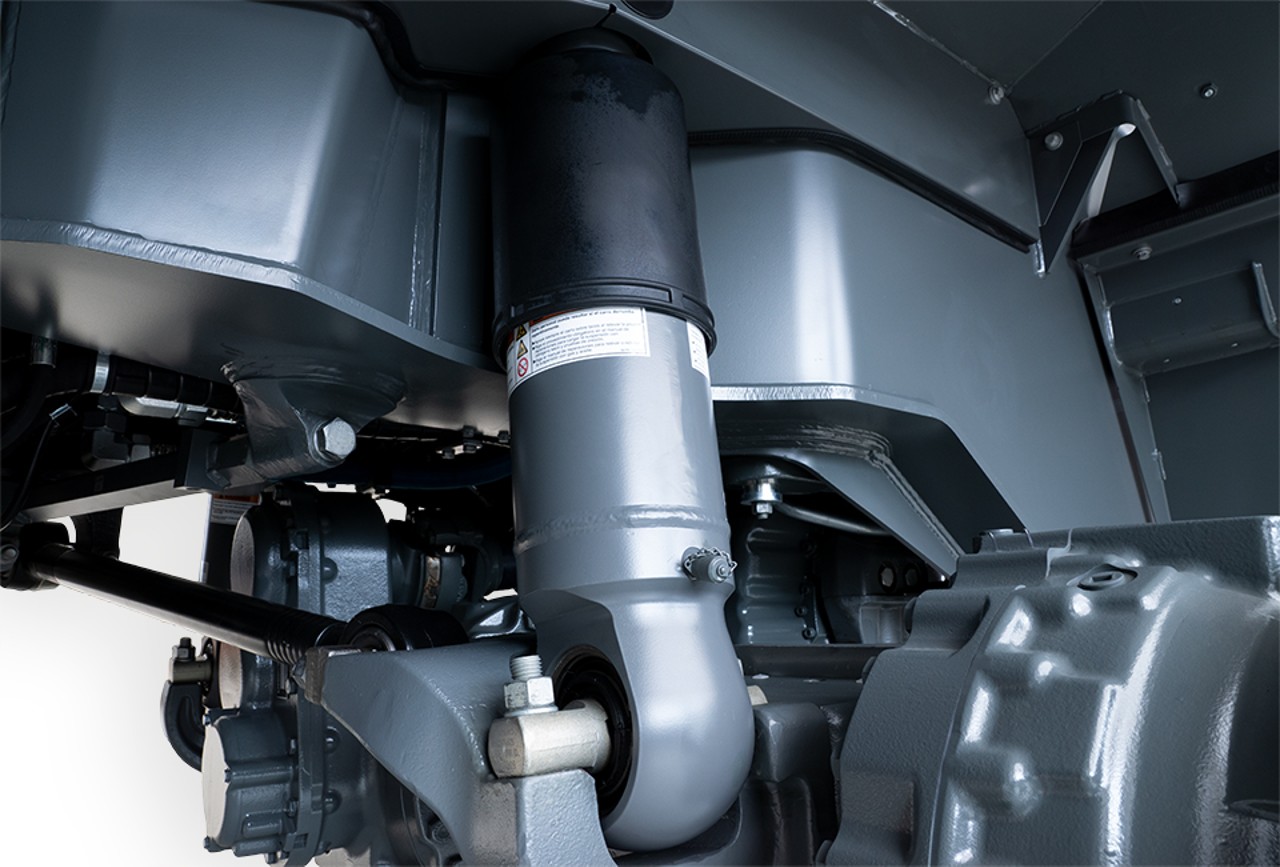

Shock absorbers

Installed on the front axle of the TA230, two shock absorbers do not only reduce vibrations, but also the forces acting on the chassis, as well as the entire application during operation. They, thus, represent essential and safety-relevant components for the end unit and support a comfortable driving experience. The damping effect is controlled by the individual preload with nitrogen, which ensures the optimum spring effect of the respective wheel side. Thereby, the component can withstand static and dynamic forces of up to 250 kN.

Shock absorbers

Features

- Designed for low-temperature conditions down to -40°C

- Operation without external pressure accumulator

- Self-sufficient shock absorber, which is not dependent on the oil circuit of the application

- Maintenance-free design

- Higher quality piston rod coating of nickel and chrome for heavy applications

Shock absorbers

Technical Data

- Piston: 150 mm

- Piston rod: 110 mm

- Installation length: 610 mm

- Stroke: 150 mm

MTG IoT gateway

High-performance electronics are also a decisive factor for a smooth operation of the ADT TA 230. The IoT gateway MTG ensures reliable interconnection of the machine and forms the basis for the use of LiDAT.

LiDAT, Liebherr’s data transmission and location system, enables efficient management, monitoring and control of the entire fleet in terms of machine data collection, data analysis, fleet management, as well as service.

MTG IoT gateway

Highlights

- Future-proofing and flexibility through open programmability

- Easy cloud connection and edge computing for data pre-processing

- Data security with our chain-of-trust concept

Technical Data

- Processor: Freescale i.MX 6

- Software build system: Linux / Yocto 2.0 Jethro

- Hardware security: ECDSA-256 / SHA-256 / AES-256

MDC3 digital smart camera & DC5 display controller

Furthermore, a Liebherr high-resolution 9-inch touch display-controller with an integrated rear camera view simplifies operation. The MDC3 digital smart camera offers the best HD image quality in any lighting situation, including fast readjustment for light-dark transitions without flutter. This enhances the visibility in the rear area of the machine and increases the quality of work.

Another key factor in the first-class cabin are the ergonomically arranged controls, including the keyboards from Liebherr.

MDC3 digital smart camera

Highlights

- True-colour and detailed HD images even under challenging lighting conditions

- Robust solution for demanding environmental conditions

- Several smart functions to process the image in the camera itself

Technical Data

- Resolution: max. 1,280 x 960 px

- Colour resolution: 24 bit HDR

- IP rating: IP67, IP6K9K in accordance with ISO 20653

DC5 display controller

Highlights

- Easy to read even in strong sunlight

- Reliable display in the driver's cab, courtesy of its high protection class, even under the most demanding conditions of use

- The existing DC5 portfolio offers an optimum platform for cost-optimised adaptations

Technical Data

- Processor: i.MX6 quad core

- Resolution: 1,280 x 800 px

- Temperature range: -30°C to +70°C