Ready for the booming air cargo market

After the air cargo market had to cope with a steep decline in business due to the COVID-19 pandemic, the situation has changed for the better: Air cargo services are in demand again, cargo volumes increase, and investments are made in cargo infrastructure and technology. Airlines react with expanding their logistic capabilities and their fleet. A very promising environment for companies like LHColus, a Brazilian provider of aeronautical engineering consulting services and Liebherr who have signed some time ago a Sole Distribution Agreement for LHColusʼ quick passenger to freighter conversion solution.

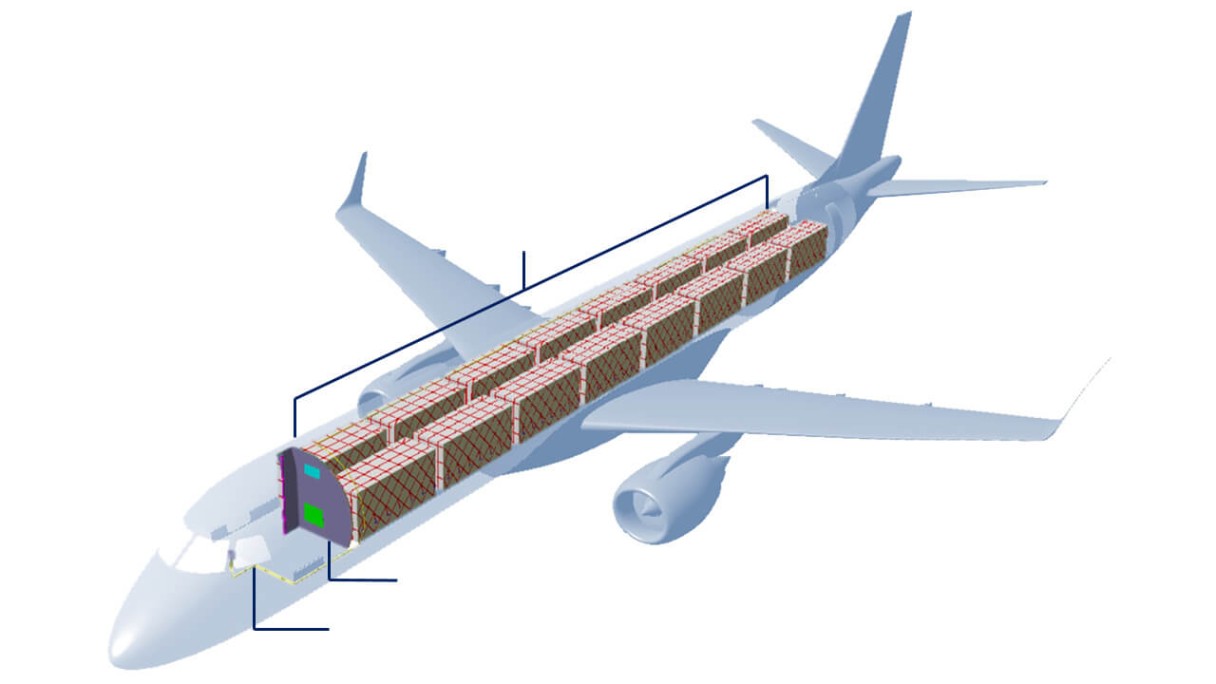

With the Class F Quick Change Solution, a passenger aircraft can be converted into a cargo aircraft within a very short timeframe. © LHColus

Liebherr Aerospace Saline Inc., service center of Liebherr-Aerospace in America, is the exclusive international distributor of the quick passenger to freighter conversion solution – also known as Class F Quick Change - developed and certified by LHColus Technologia Ltda in São José dos Campos (Brazil). Liebherr is responsible for the global distribution of the kit, excluding Brazil, through its worldwide customer services network, that provides sales and technical support.

The Class F Quick Change Solution

The Class F Quick Change is implemented by means of a simple, fast, and fully reversible modification on the aircraft. After its certification by ANAC, the Brazilian National Civil Aviation Agency, the solutionʼs efficiency and reliability had been field-proven with a sizeable Embraer E190 fleet operating for over two years in Latin America. More than 18,000 flight hours have been already accumulated and over 15.3 million (e-commerce) packages equivalent to 33,300 tons of payload have been transported. The solution is currently being certified by the FAA, the U.S. Federal Aviation Administration, for Embraer E190 aircraft and can be extended to other single aisle aircraft types.

In a simplified approach, the conversion requires the removal of all main cabin seats to make room for aluminum frames and independent fire-proof and smoke-contained cargo nets. The cargo is monitored by two fully independent IR cameras, which are designed to detect any heat sources, alerting the pilots in the cockpit.

The system also features a smoke barrier to isolate the main cabin from the front galley or cockpit area (a mandatory requirement) and cargo placards, which are used to indicate the maximum load height. The overhead bins remain in the aircraft during Class F operations and can be used for cargo (non-dangerous goods) packages.