PHS Allround pallet handling system

Configuring individual systems with standardized modules?

The PHS Allround from Liebherr makes it possible.

The PHS Allround from Liebherr makes it possible.

Liebherr automation for flexible manufacturing

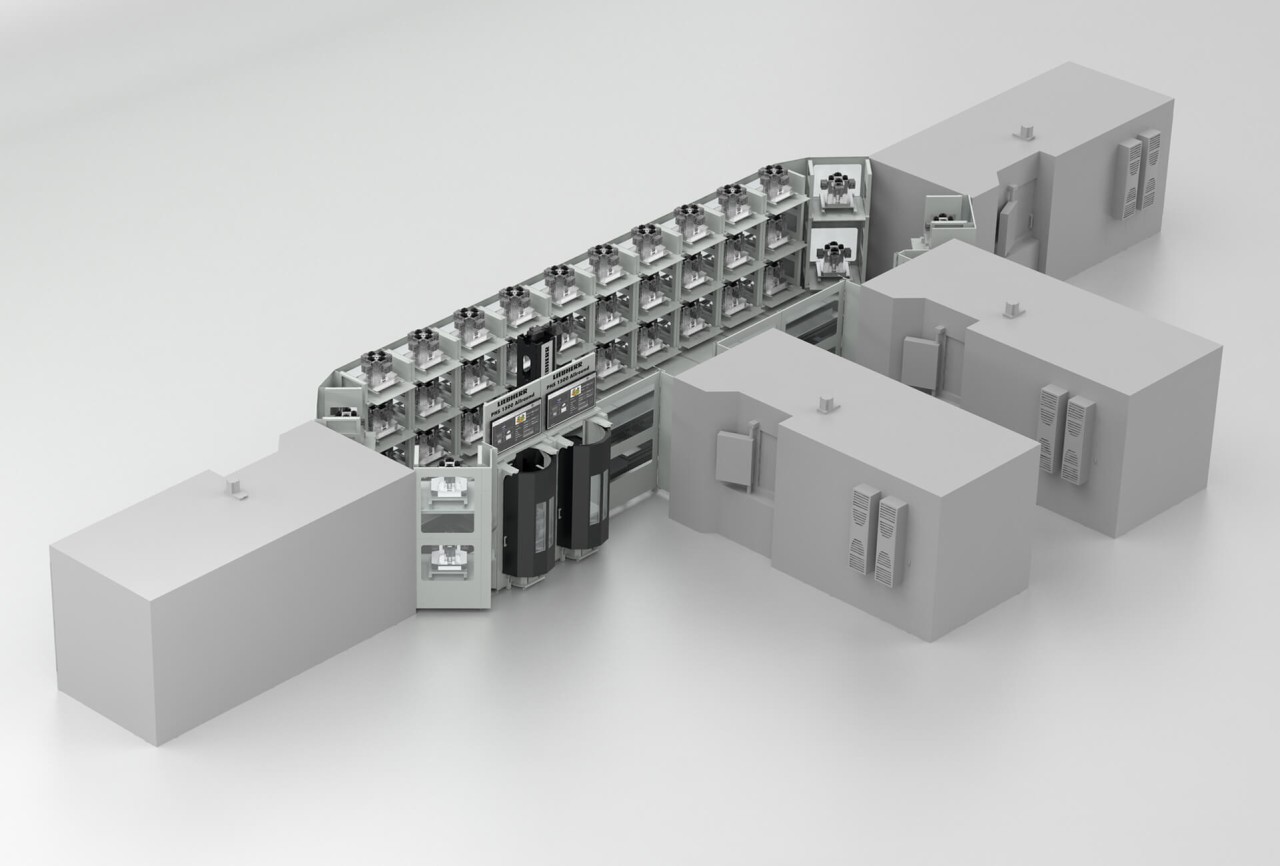

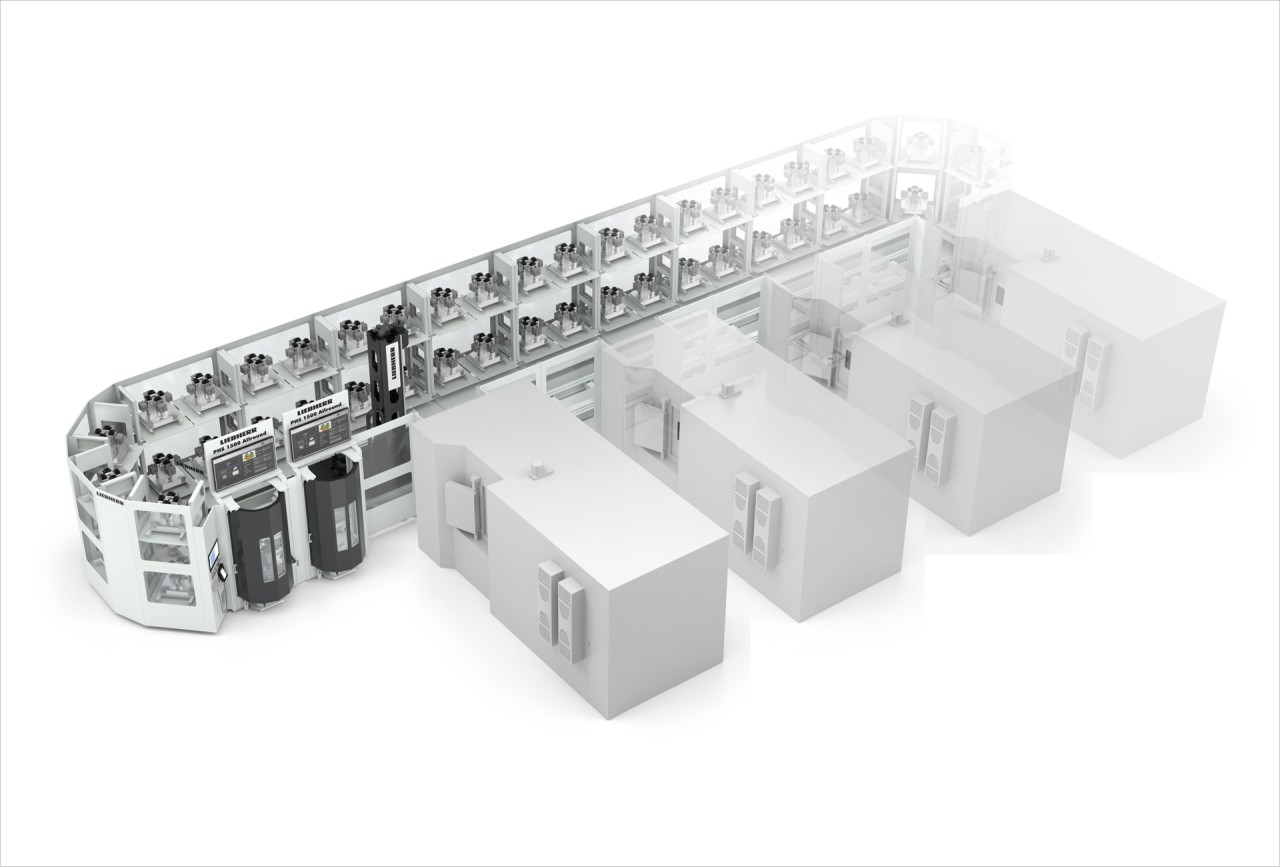

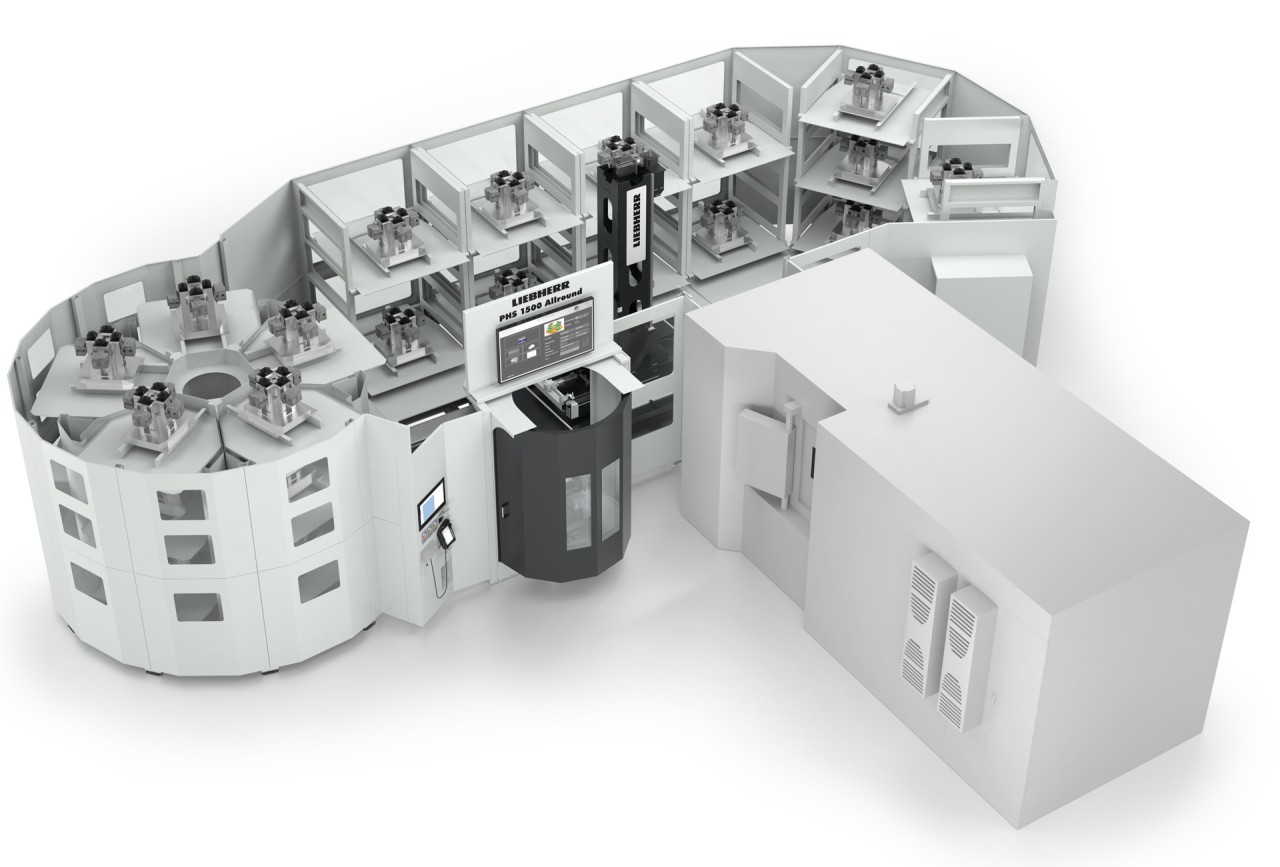

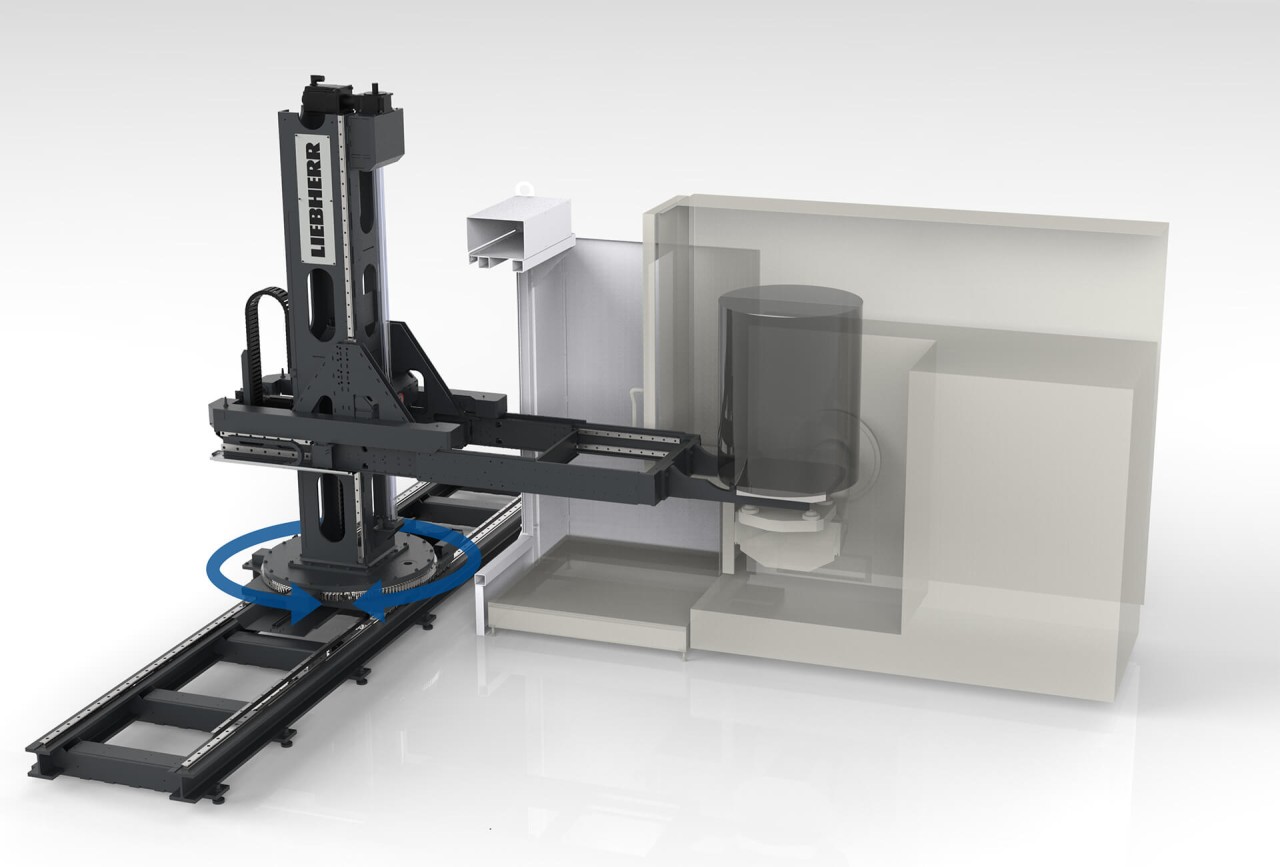

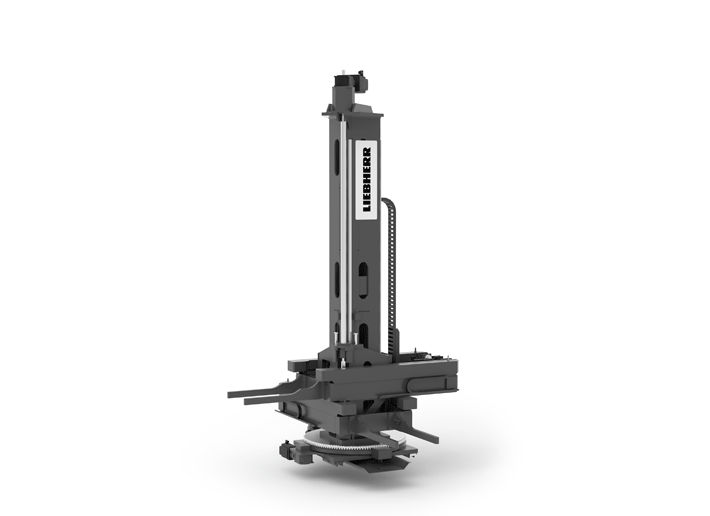

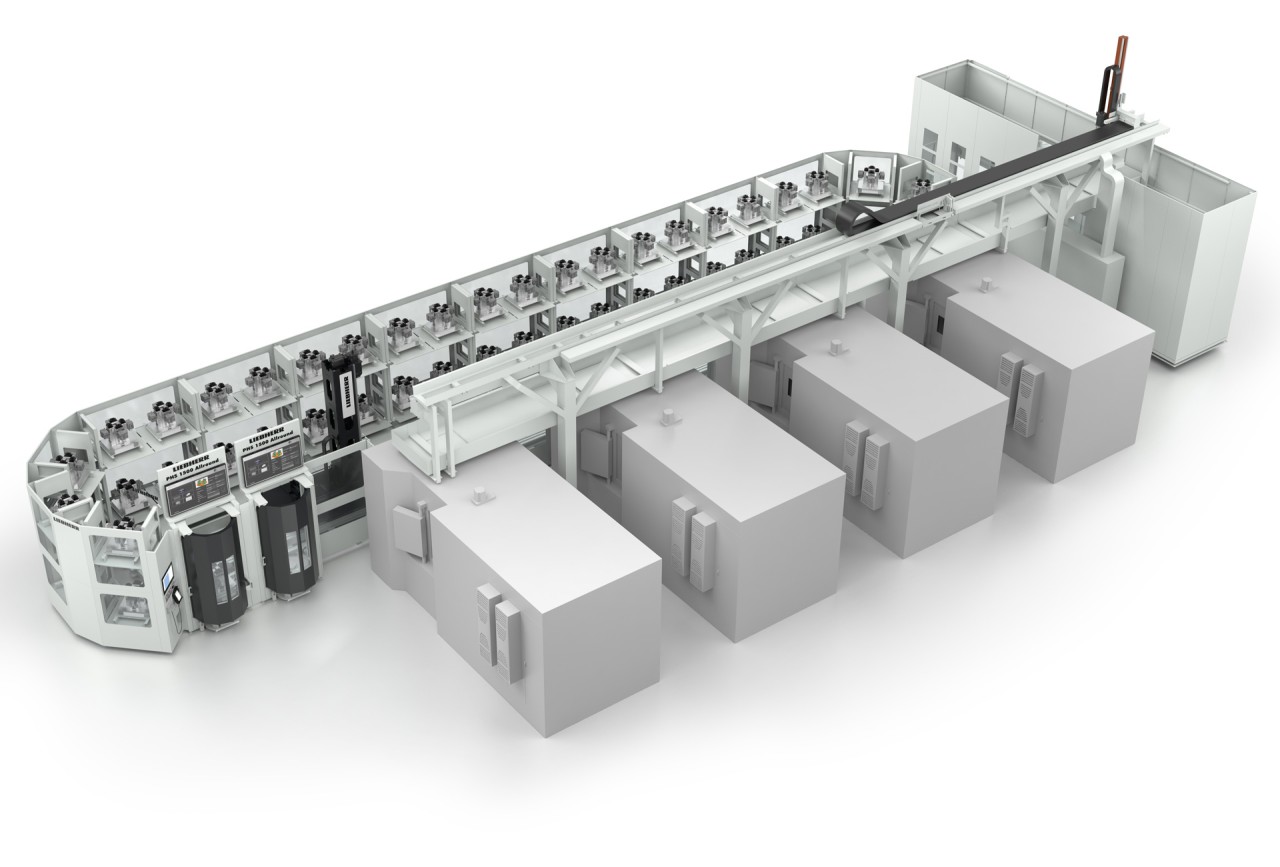

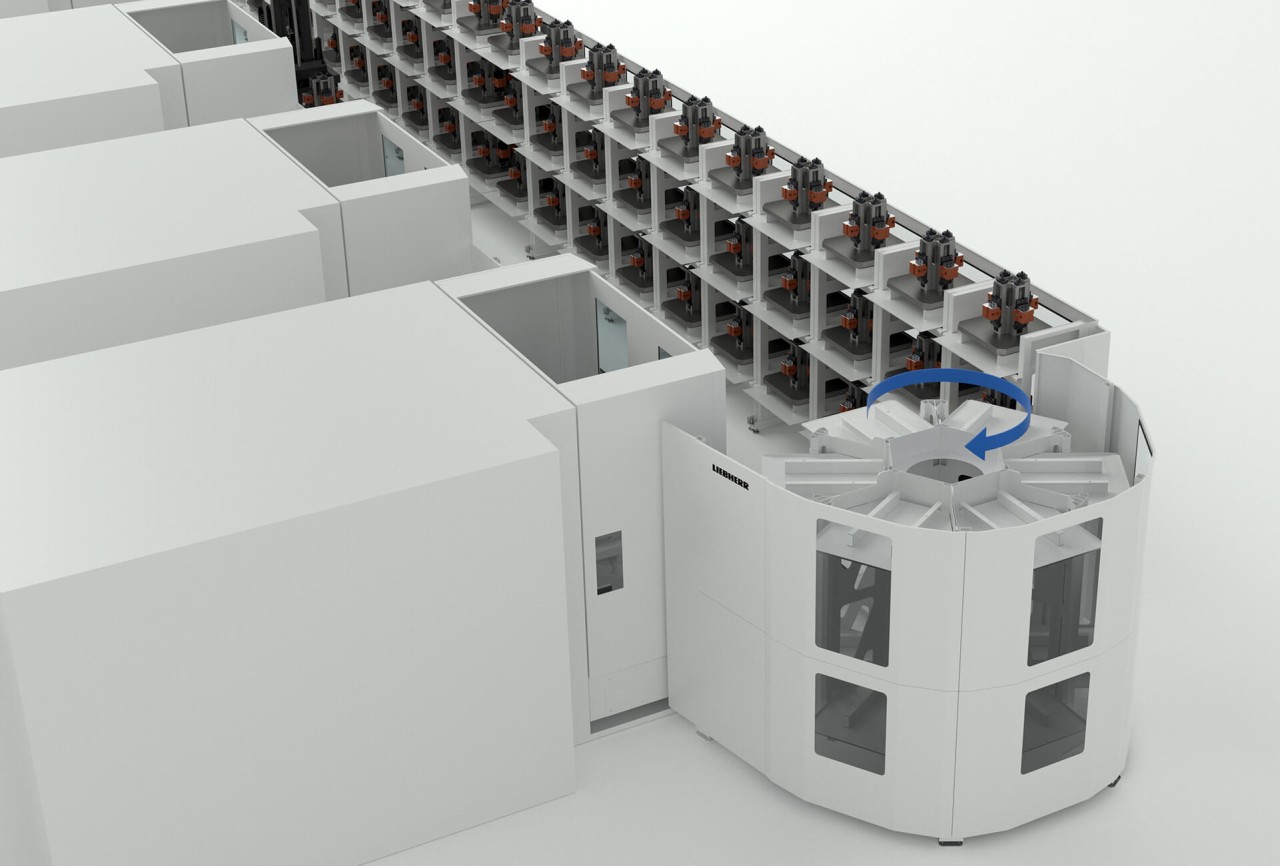

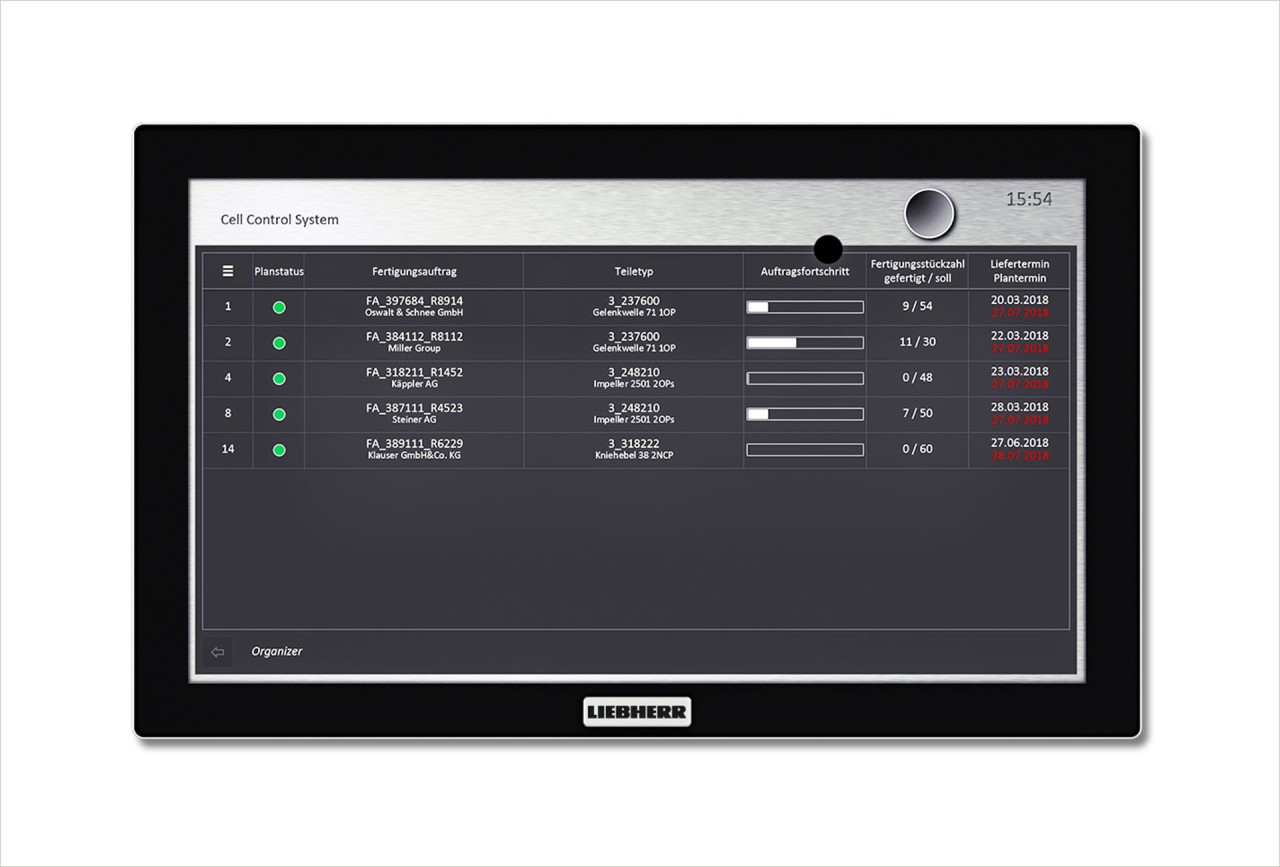

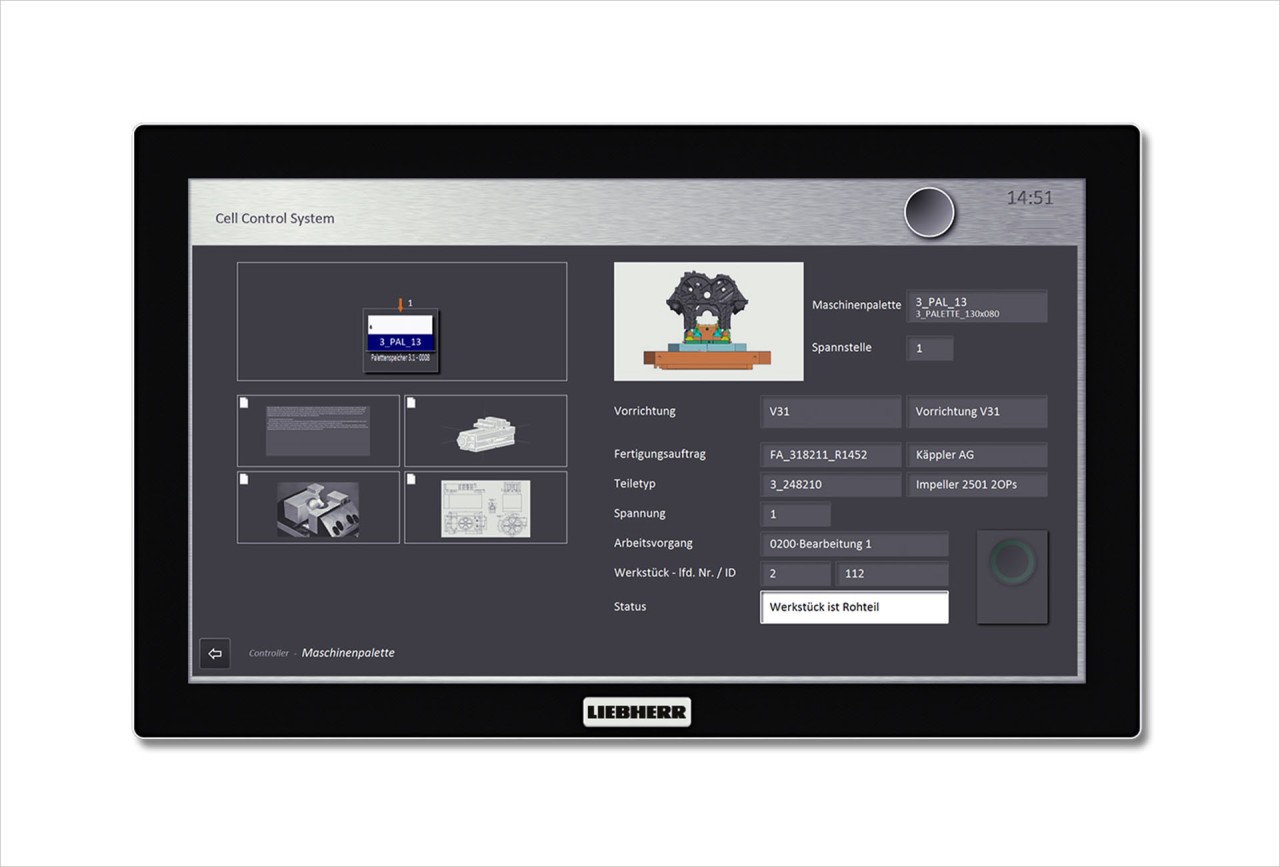

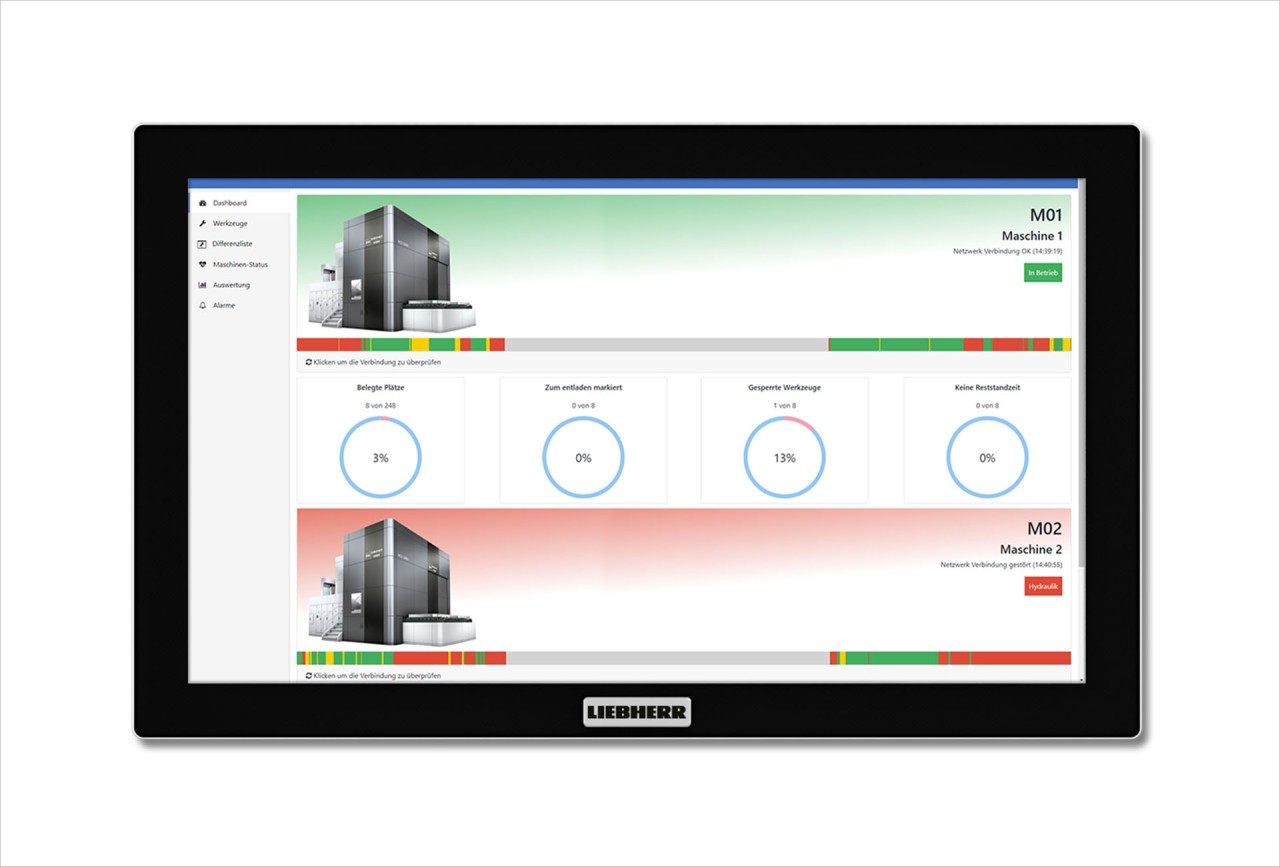

In the PHS Allround, Liebherr offers a space-saving and flexible manufacturing system, even for small batch sizes. It automatically equips machine tools with machine pallets. The pallet handling system increases the machine runtime to up to 90 % and reduces unit costs by up to 40 %. Using the modular system, our customers can configure their system individually while still enjoying the advantages of a standard product: low price, fast delivery time, excellent replacement part availability.

01/04

The product highlights of the PHS Allround:

01/04

01/04

| PHS 800 Allround | PHS 1500 Allround | PHS 3000 Allround | |

| Max. transport weight | 800 kg | 1,500 kg | 3,000 kg |

| Max. transport weight with double loader option | 2 x 600 kg | 2 x 1,200 kg | Not available |

| Max. collision circle diameter* | Ø600 / Ø900 | Ø900 / Ø1,400 | Ø1,400 / Ø1,700 |

| Max. machine pallet size | 400 x 400 / 630 x 630 | 630 x 630 / 800 x 800 | 800 x 800 / 1,000 x 1,000 |

| Shelf levels | 2 to 3 | 2 to 3 | 2 to 3 |

| Max. workpiece height (incl. pallet) | 1,200 mm (2 shelf levels) | 1,200 mm (2 shelf levels) | 1,600 mm (2 shelf levels) |

| *The collision circle diameter designates the maximum permitted deviations of the machine pallet, including workpiece clamping and workpiece. | |||