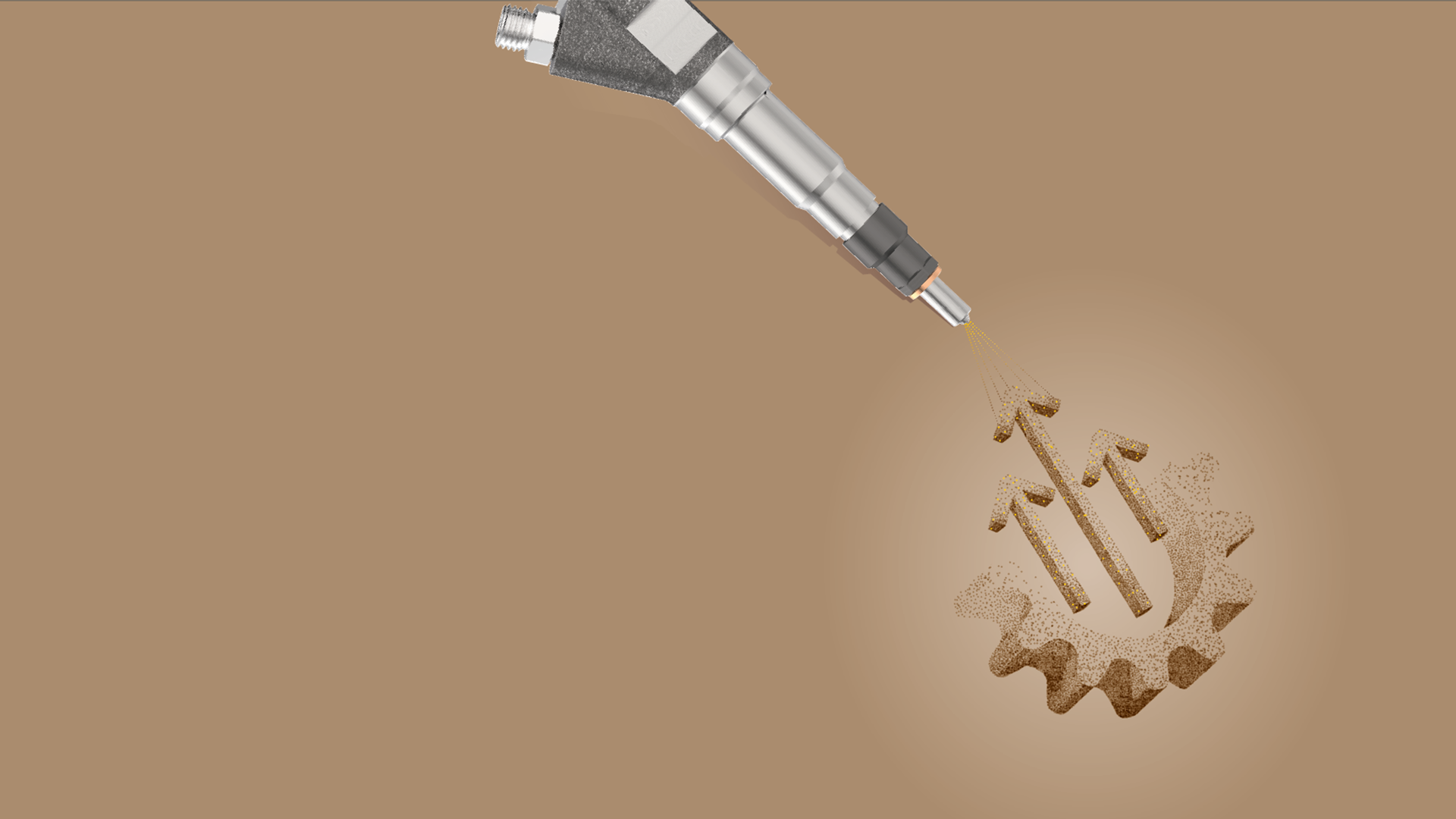

Robust, reliable, flexible - common rail solutions for combustion engines

Benefit from maximum efficiency through robust and powerful Liebherr injection components.

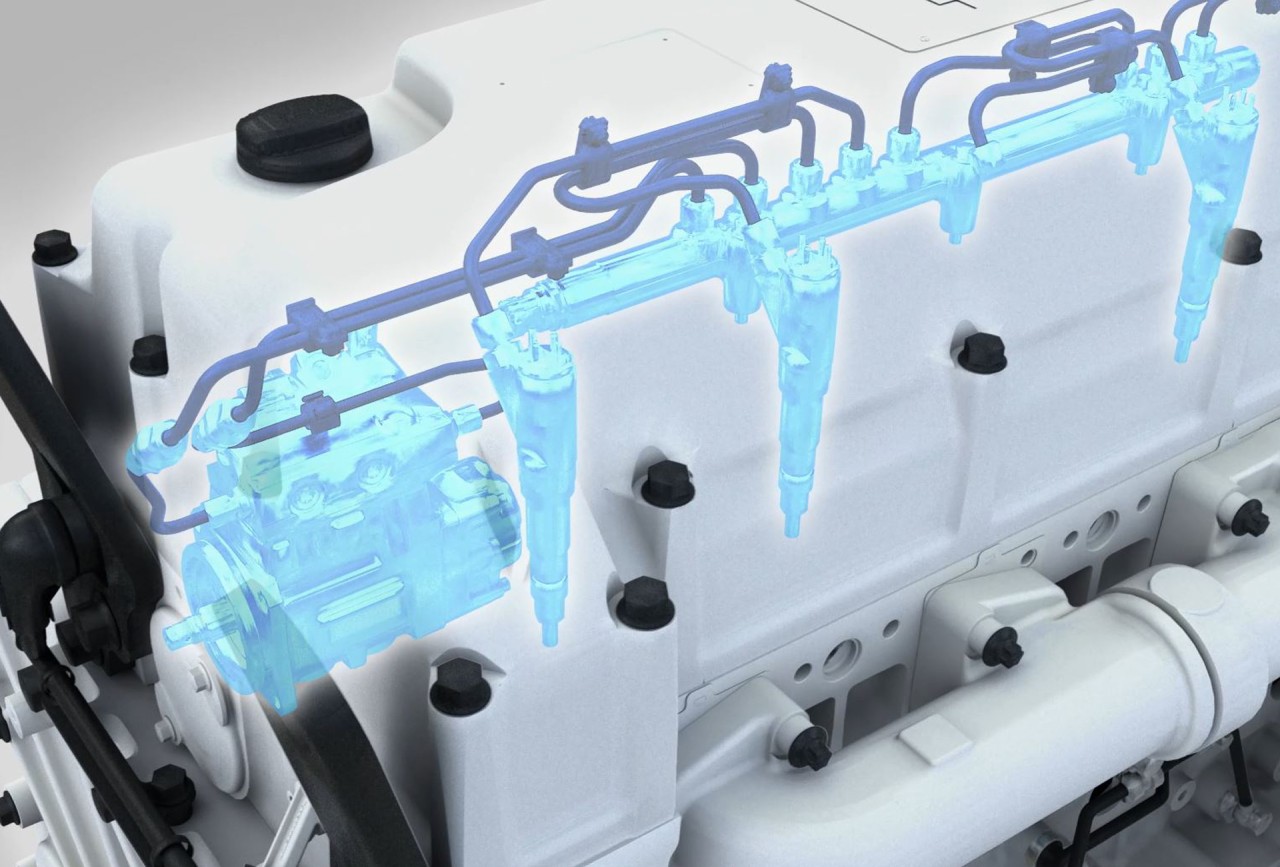

Decades of experience in the development and manufacture of diesel engines result in self-manufactured components and common rail solutions used in heavy-duty trucks, construction, agriculture, mining, rail, genset and marine applications. Learn more

Your benefits

Highly specialized know-how

Individual components and system solutions

Decades of experience

Key technologies as core business

Areas of application and products

Discover the variety and application areas of our products.

Discover the highlights of our products

Powerful and reliable

Our products stand for power and reliability. As your long-term partner, we accompany you from the initial idea to the successful market launch and continuously support your application with performance – for long-term success and growth.

Efficient and robust

Our common rail systems are created with the needs of our customers in mind. They achieve excellent performance in different areas of application and even under extreme conditions. As a trustworthy partner, we drive your application forward efficiently.

Working hard to find an individual customer solution

- Bring it to life

- To the detail

- Powered by digital supply

Improving existing technologies and exploring new possibilities for the powertrain of tomorrow. This passion unites our engineers and development experts. Working under pressure is their profession.

Improving existing technologies and exploring new possibilities for the powertrain of tomorrow. This passion unites our engineers and development experts. Working under pressure is their profession.

Get in touch

Contact our sales team or follow us on our LinkedIn channel.