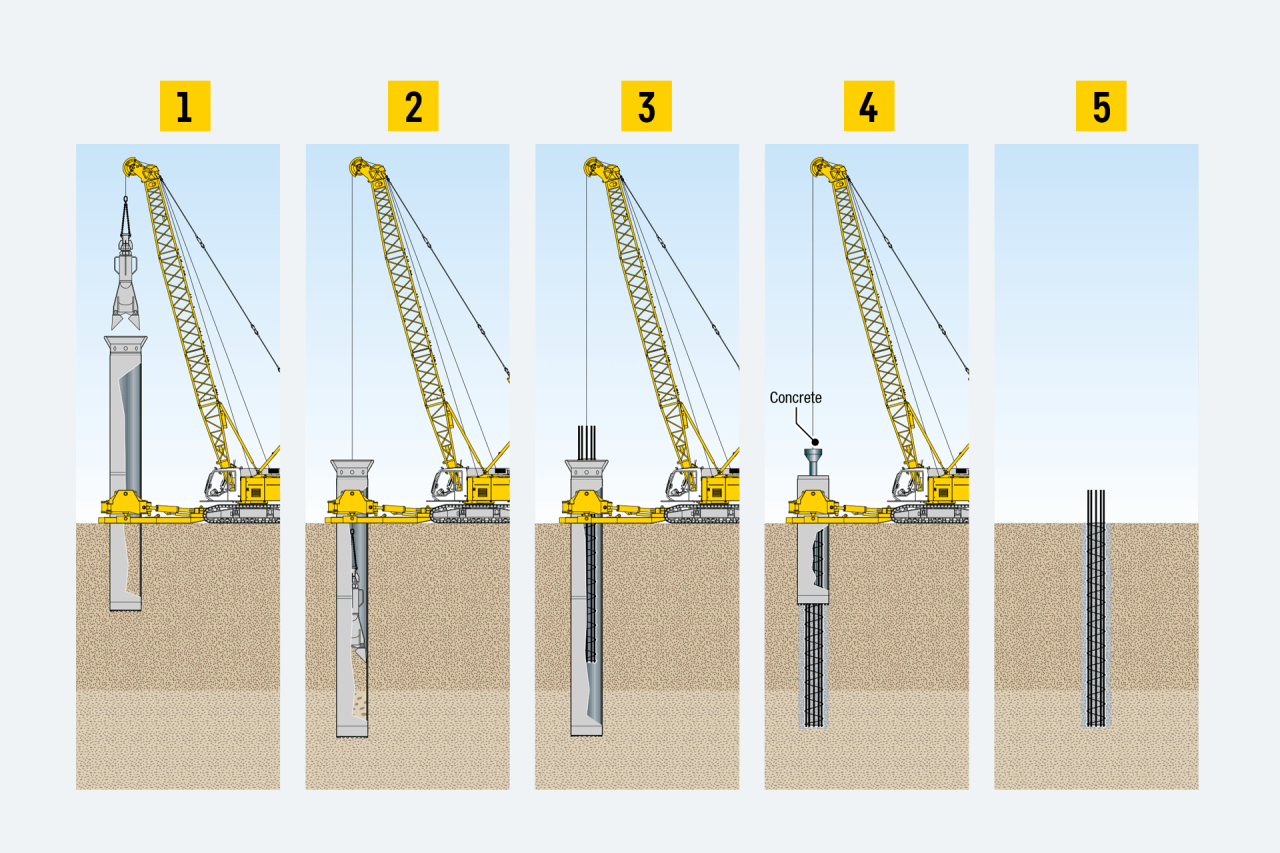

Drilling with bored pile grab is one of the oldest dry drilling methods and is still common today. Depending on the tools used, e.g. bored pile grab, chisel or special tools hanging on a duty cycle crawler crane, the soil is loosened either by cutting or impact driving. This method is applied, for instance, for well drilling with small drilling diameter or for the production of cast-in-place piles with sometimes very large diameters.

Video drilling with hammer grab

The video shows duty cycle crawler cranes from Liebherr in drilling operation with hammer grab at various construction sites.

Examples for drilling with pile grab and casing oscillator

01/10

Machines

Results 1-5 of 5