25 Years of Liebherr RTG cranes

Since the introduction of its first RTG, Liebherr has consistently led the way in RTG development. Today, Liebherr marks 25 years of RTG innovation with a next-gen range offering five base models, incorporating electric, hybrid and variable speed genset options. Designed for efficiency, sustainability and performance, the RTGs are backed by advanced modelling software, helping terminals choose the right solution to optimise operations and cut emissions.

LiSIM move at the beach

Training, anywhere. Anytime. LiSIM move.

LiSIM move is your new go-to for flexible, high-quality crane training. It’s a fully portable simulator that delivers immersive VR experiences wherever you are. With realistic visuals, authentic controls, and a compact design, it’s perfect for showcasing, training, or evaluating operators on the spot. No fixed setup required – just unpack, power up, and start training. It’s ideal for events, job fairs, or internal programs where mobility and speed matter. With LiSIM move, Liebherr brings the future of training to your doorstep.

Fitness programme for Board Offshore Cranes

Crane installation on OBANA completed

The successful overload test of the MTC 78000-2000 marked the completion of the installation, commissioning and testing on the OBANA, which also included two BOS 4200 cranes. The final handover to our customer Petrodec, a specialist in decommissioning services, took place in June after a two-phase installation campaign from November 2024 to June 2025.

The OBANA is a self-elevating heavy-lift jack-up vessel, engineered by merging two repurposed jack-ups. It offers solutions for decommissioning complex offshore platforms in the UK North Sea.

Maritime stories: A job with a view

Martin Gerullis was the first crane operator for the gigantic TCC 78000 heavy lift crane at our site in Rostock, Germany before he was bitten by the wanderlust bug again. As a service technician, he is now travelling the world again to set up maritime cranes for our customers on all continents.

Find out more about his adventures and what curious wallabies in Tasmania have to do with it.

Marcegaglia handover highlights shared legacy

In a ceremonial handover in Ravenna, Liebherr delivered its 2000th mobile harbour crane to long-standing partner Marcegaglia. The LHM 600 marks the sixth crane in their fleet and the largest to date, reinforcing operational strength at Italy’s key steel hub. With Mac Port’s dedicated service, this milestone reflects a triad of excellence in engineering, partnership, and support. A shared success story, built to last.

New LHM landing page unveiled

The updated LHM landing page is now live, offering a seamless journey through Liebherr’s mobile harbour crane portfolio. With clear sections on applications, drive systems, and assistance technologies, it empowers users to make informed decisions. This is digital storytelling with purpose, designed to drive interest and action.

Liebherr supports Baltic wind power

Liebherr is supplying three RL 900 Ram Luffing cranes to support offshore substations for the 50Hertz grid connection projects in the German Baltic Sea. The cranes, known for their robust and weight-optimised design, will be used for maintenance and supply tasks. They are equipped with LiMain, Liebherr Intelligent Maintenance, the company's own remote maintenance system, which reliably supports maintenance operations from onshore. This project marks a key contribution to Germany’s energy transition, supporting offshore wind farms that aim to power hundreds of thousands of households sustainably.

Standout electric LHM 280 to be delivered to Saga Fjordbase

Saga Fjordbase has ordered an electric LHM 280 mobile harbour crane, with delivery expected in early 2026. The crane includes a weather-protected staircase for safer operator access and a reactive power compensation unit to improve energy efficiency. These features are tailored to the port’s year-round offshore logistics requirements. The crane will be part of a broader effort to modernise equipment with electric alternatives.

Optimum equipment for maximum protection

Discover our hydraulic block‑off kit – engineered to provide secure sealing and ultimate protection for hydraulic systems on Liebherr maritime cranes. Built for durability and efficiency, the kit ensures reliable operation even in the harshest marine environments. All components are stored in a waterproof, wheeled flight case, making it easy to transport directly to the job site.

Power on pairs for NCL

Both the NCL Vestland and her sister ship, the NCL Nordland, are equipped with two LS-C 80 cranes for maximum flexibility and performance. With high boom pivot points and midship positioning, the cranes support efficient loading from both sides and stacking up to eight containers below deck.

The result: faster turnaround and smarter use of space. Liebherr is proud to support this green logistics evolution.

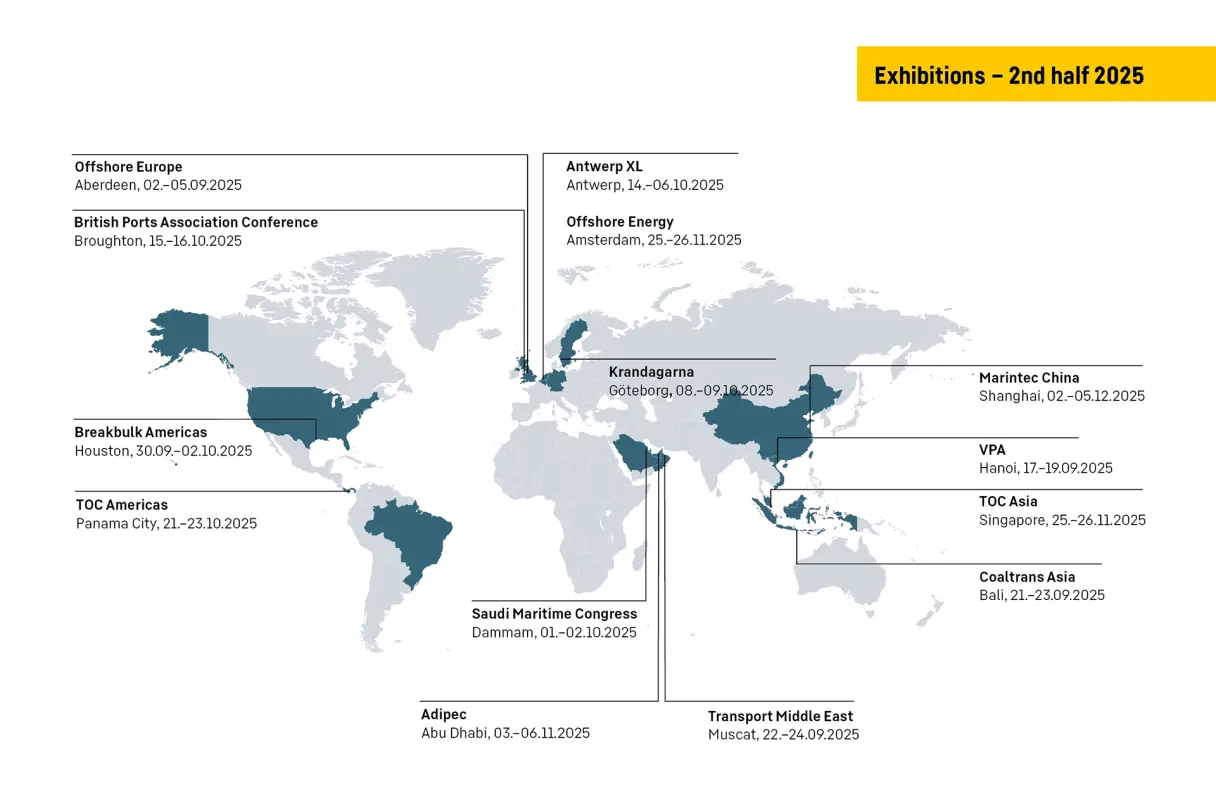

Exhibition highlights – second half of 2025

We are looking forward to 14 international exhibitions during the second half of the year. Visit our Liebherr booths across Asia, America, and Europe to discover the latest in maritime crane technology and solutions.